Abstract

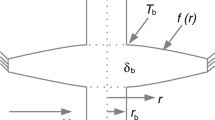

The porous fin of radial profile is considered in the current analysis along with the radiation and thermal-dependent internal heat generation condition. In addition, two different cases have been examined based on the linear dependency and exponential dependency of thermal conductivity on temperature. The Darcy’s law is used to study the porous nature of fin. The modeled governing equation is a second-order nonlinear ordinary differential equation and is solved via Runge–Kutta–Fehlberg fourth–fifth-order method. The important terms are grouped as dimensionless parameters and discussed their influence on the heat transfer rate and thermal stresses of the fin. The thermal stresses like radial stress and tangential stress are addressed comprehensively and interpreted graphically. Also, the fin efficiency is defined and discussed graphically. It is found that the tangential stress shows higher compression near fin base region and larger tensile stress near tip radius.

Similar content being viewed by others

Abbreviations

- A:

-

Thermal conductivity parameter

- Cp :

-

Specific heat at constant pressure (J kg-1 K-1)

- CT :

-

Temperature ratio

- Da :

-

Darcy number

- E :

-

Young’s modulus

- G :

-

Generation number

- K :

-

Permeability (m2)

- Nr :

-

Radiation–conduction parameter

- R :

-

Dimensionless radius

- R* :

-

Ratio of tip radius to base radius

- Ra :

-

Rayleigh number

- T :

-

Local fin temperature (K)

- T ∞ :

-

Ambient temperature (K)

- T b :

-

Base temperature (K)

- b2 :

-

Variable parameter (K-1)

- g:

-

Acceleration due to gravity (m s-2)

- h :

-

Heat transfer coefficient (W m-2 K-1)

- k 0 :

-

Thermal conductivity of the material (W m-1 K-1)

- q :

-

Heat transfer rate (W)

- r :

-

Fin radius (m)

- r b :

-

Base radius (m)

- r t :

-

Tip radius (m)

- t :

-

Fin thickness (m)

- ρ f :

-

Density of the ambient fluid (kg m-3)

- νf :

-

Kinematic viscosity (m2 s-1)

- ν:

-

Poisson’s ratio

- θ :

-

Non-dimensional temperature

- ϕ :

-

Porosity

- σ :

-

Stefan-Boltzmann constant (W m-2 K-4)

- σ r ,σ ϕ :

-

Radial and tangential stress

- ε :

-

Surface emissivity of fin

- ε r ,ε ϕ :

-

Radial and tangential strain

- α :

-

Linear coefficient of thermal expansion

- β f :

-

Volumetric thermal expansion coefficient

References

Kiwan S, Al-Nimr MA. Using porous fins for heat transfer enhancement. J Heat Transf. 2001;123(4):790–5.

Kiwan S. Thermal analysis of natural convection porous fins. Transp Porous Media. 2007;67(1):17.

Gorla RS, Bakier AY. Thermal analysis of natural convection and radiation in porous fins. Int Commun Heat Mass Transf. 2011;38(5):638–45.

Hatami M, Ganji DD. Thermal performance of circular convective–radiative porous fins with different section shapes and materials. Energy Convers Manage. 2013;76:185–93.

Torabi M, Yaghoobi H. Series solution for convective-radiative porous fin using differential transformation method. J Porous Media. 2013;16(4):341–9.

Aziz A, Torabi M, Zhang K. Convective–radiative radial fins with convective base heating and convective–radiative tip cooling: homogeneous and functionally graded materials. Energy Convers Manage. 2013;74:366–76.

Darvishi MT, Khani F, Gorla RS. Natural convection and radiation in a radial porous fin with variable thermal conductivity. Int J Appl Mech Eng. 2014;19(1):27–37.

Gireesha BJ, Sowmya G, Macha M. Temperature distribution analysis in a fully wet moving radial porous fin by finite element method. Int J Numer Meth Heat Fluid Flow. 2019. https://doi.org/10.1108/HFF-12-2018-0744.

Vo DD, Hedayat M, Ambreen T, Shehzad SA, Sheikholeslami M, Shafee A, Nguyen TK. Effectiveness of various shapes of Al2O3 nanoparticles on the MHD convective heat transportation in porous medium. J Therm Anal Calorim. 2020;139(2):1345–53.

Abbas Z, Rauf A, Shehzad SA. Aspects of heterogenous and homogenous reactions on hydromagnetic oscillatory rotating flow in porous medium. J Porous Media. 2020;23(9):837–50.

Aziz A, Bouaziz MN. A least squares method for a longitudinal fin with temperature dependent internal heat generation and thermal conductivity. Energy Convers Manage. 2011;52(8–9):2876–82.

Hatami M, Hasanpour A, Ganji DD. Heat transfer study through porous fins (Si3N4 and AL) with temperature-dependent heat generation. Energy Convers Manage. 2013;74:9–16.

Ghasemi SE, Hatami M, Ganji DD. Thermal analysis of convective fin with temperature-dependent thermal conductivity and heat generation. Case Stud Thermal Eng. 2014;4:1–8.

Hoshyar H, Ganji DD, Abbasi M. Determination of temperature distribution for porous fin with temperature-dependent heat generation by homotopy analysis method. J Appl Mech Eng. 2015;4:153.

Sowmya G, Gireesha BJ, Sindhu S. Thermal exploration of radial porous fin fully wetted with SWCNTs and MWCNTs along with temperature-dependent internal heat generation. Proceedings of the Institution of Mechanical Engineers, Part C J Mech Eng Sci. 2020:0954406220931555.

Wu SS. Analysis on transient thermal stresses in an annular fin. J Therm Stress. 1997;20(6):591–615.

Chiu CH, Chen CO. Thermal stresses in annular fins with temperature-dependent conductivity under periodic boundary condition. J Therm Stress. 2002;25(5):475–92.

Chiu CH, Chen CK. Application of the decomposition method to thermal stresses in isotropic circular fins with temperature-dependent thermal conductivity. Acta Mech. 2002;157(1–4):147–58.

Wang CC, Liao WJ, Yang CY. Hybrid spline difference method for heat transfer and thermal stresses in annular fins. Numer Heat Transf Part B Fundament. 2013;64(1):71–88.

Mallick A, Ghosal S, Sarkar PK, Ranjan R. Homotopy perturbation method for thermal stresses in an annular fin with variable thermal conductivity. J Therm Stress. 2015;38(1):110–32.

Yıldırım A, Yarımpabuç D, Celebi K. Thermal stress analysis of functionally graded annular fin. J Therm Stresses. 2019;42(4):440–51.

Yıldırım A, Celebi K, Yarımpabuç D. A practical approach for thermal stress of functionally graded annular fin. J Eng Thermophys. 2019;28(4):556–68.

Yildirim A, Yarimpabuç D, Celebi K. Transient thermal stress analysis of functionally graded annular fin with free base. J. Thermal Stress. 2020:1–2.

Aziz A, Makinde OD. Entropy generation minimization design of a two-dimensional orthotropic convection pin fin. Int J Exergy. 2010;7:579–92.

Mhlongo MD, Moitsheki RJ, Makinde OD. Transient response of longitudinal rectangular fins to step change in base temperature and in base heat flow conditions. Int J Heat Mass Transf. 2013;57(1):117–25.

Hatami M, Ganji DD, Gorji-Bandpy M. Numerical study of finned type heat exchangers for ICEs exhaust waste heat recovery. Case Stud Thermal Eng. 2014;4:53–64.

Hatami M, Jafaryar M, Ganji DD, Gorji-Bandpy M. Optimization of finned-tube heat exchangers for diesel exhaust waste heat recovery using CFD and CCD techniques. Int Commun Heat Mass Transf. 2014;57:254–63.

Hatami M, Ganji DD, Gorji-Bandpy M. Experimental and numerical analysis of the optimized finned-tube heat exchanger for OM314 diesel exhaust exergy recovery. Energy Convers Manage. 2015;97:26–41.

Moitsheki RJ, Makinde OD. Analysis of nonlinear heat transfer in solids of various geometries with variable thermal conductivity and heat source. Defect Diffus Forum. 2017;377:1–16.

Fallo N, Moitsheki RJ, Makinde OD. Analysis of heat transfer in a cylindrical spine fin with variable thermal properties. Defect Diffus Forum. 2018;387:10–22.

Sowmya G, Gireesha BJ, Makinde OD. Thermal performance of fully wet longitudinal porous fin with temperature-dependent thermal conductivity, surface emissivity and heat transfer coefficient. Multidiscip Model Mater Struct. 2020;16(4):749–64.

Gireesha BJ, Sowmya G. Heat transfer analysis of an inclined porous fin using Differential Transform Method. Int. J. Ambient Energy. 2020:1–7.

Acknowledgement

The authors thank the Department of Science and Technology, Government of India for their support under DST-FIST programme for HEIs. (Grant No. SR/FST/MS-I/2018/23(C)).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sowmya, G., Gireesha, B.J. Thermal stresses and efficiency analysis of a radial porous fin with radiation and variable thermal conductivity and internal heat generation. J Therm Anal Calorim 147, 4751–4762 (2022). https://doi.org/10.1007/s10973-021-10801-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10801-7