Abstract

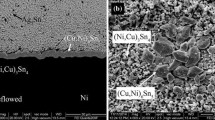

The use of Al for replacing high-cost alloying metals, like Ag, Bi, and Cu, as the second major element in Sn-based alloys, arises as a promising alternative for the development of low-cost Pb-free solder alloys. To date, however, the interfacial characteristics of Sn–Al solder joints in electronic substrates remain barely explored. Thus, the present study focuses on an understanding of the mechanisms affecting the heat transfer efficiency between a Sn–Al eutectic alloy and two types of substrates, establishing correlations with the microstructure evolution. Results of solidification experiments coupled with mathematical modeling demonstrate an interfacial thermal conductance between the Ni substrate and the Sn-0.5mass%Al alloy higher than that observed for the Sn–Al/Cu couple. Furthermore, Al-rich intermetallics are shown to occur at the interfacial reaction layers for both tested conditions. While dendritic and dendritic/cellular morphologies predominate in the solidification of the Sn–Al eutectic alloy in a Cu substrate, the better heat extraction through the Ni substrate induces the growth of refined high-cooling rate cells. Then, growth laws relating the length scale of the Sn-matrix, represented by cellular or primary dendritic spacings, to solidification thermal parameters such as cooling rate and growth rate are proposed.

adapted from Saito [23] with emphasis on the eutectic composition (Sn-0.5mass%Al)

Similar content being viewed by others

References

Şahin M, Çadırlı E, Bayram Ü, Esener PA. Investigation of the thermoelectrical properties of the Sn 91.2−x–Zn 8.8–Ag x alloys. J Therm Anal Calorim. 2018;132:317–25.

Suganuma K. Advances in lead-free electronics soldering. Curr Opin Solid State Mater Sci. 2001;5:55–64.

Parliament E. Directive 2011/65/EU of the European Parliament and of the Council of 8 June 2011 on the restriction of the use of certain hazardous substances in electrical and electronic equipment. Off J Eur Union. 2011;174:88–110.

Kotadia HR, Howes PD, Mannan SH. A review: On the development of low melting temperature Pb-free solders. Microelectron Reliab. 2014;54:1253–73.

Silva LS, Souza JS, Silva RAG. Effects of Ag addition on phase transitions, microstructures and solder/copper interfaces of Sn 99.1−x Cu 0.9 Ag x alloys. J Therm Anal Calorim. 2019;136:2205–10.

Santos WLR, Silva BL, Bertelli F, Spinelli JE, Cheung N, Garcia A. An alternative thermal approach to evaluate the wettability of solder alloys. Appl Therm Eng. 2016;107:431–40.

Prabhu KN, Kumar ST, Venkataraman N. Heat transfer at the metal/substrate interface during solidification of Pb-Sn solder alloys. J Mater Eng Perform. 2002;11:265–73.

Silva BL, Cheung N, Garcia A, Spinelli JE. Evaluation of solder/substrate thermal conductance and wetting angle of Sn-0.7 wt%Cu-(0–0.1 wt%Ni) solder alloys. Mater Lett. 2015;142:163–7.

Curtulo JP, Dias M, Bertelli F, Silva BL, Spinelli JE, Garcia A, et al. The application of an analytical model to solve an inverse heat conduction problem: Transient solidification of a Sn-Sb peritectic solder alloy on distinct substrates. J Manuf Process. 2019;48:164–73.

Silva BL, Cheung N, Garcia A, Spinelli JE. Sn-0.7 wt%Cu-(xNi) alloys: Microstructure-mechanical properties correlations with solder/substrate interfacial heat transfer coefficient. J Alloys Compd. 2015;632:274–85.

Leong Y, Haseeb ASMA. Soldering characteristics and mechanical properties of Sn-1.0Ag-0.5Cu solder with minor aluminum addition. Materials. 2016;9:522.

Kotadia HR, Mokhtari O, Bottrill M, Clode MP, Green MA, Mannan SH. Reactions of Sn-3.5Ag-based solders containing Zn and Al additions on Cu and Ni(P) substrates. J Electron Mater. 2010;39:2720–31.

Alam ME, Gupta M. Development of extremely ductile lead-free Sn–Al solders for futuristic electronic packaging applications. Electron Mater Lett. 2014;10:515–24.

Lin KL, Liu TP. High-temperature oxidation of a Sn-Zn-Al solder. Oxid Met. 1998;50:255–67.

Tezel FM, Saatçi B, Arı M, Durmuş Acer S, Altuner E. Structural and thermo-electrical properties of Sn–Al alloys. Appl Phys A Mater Sci Process. 2016;122:1–12.

Goumiri L, Joud JC, Desre P, Hicter JM. Tensions superficielles d’alliages liquides binaires présentant un caractère dimmiscibilité: Al-Pb, Al-Bi. Al-Sn et Zn-Bi Surf Sci. 1979;83:471–86.

Dalakova NV, Elekoeva KM, Kashezhev AZ, Manukyants AR, Prokhorenko AD, Ponezhev MK, et al. Polytherms of angles of aluminum and aluminum-lithium alloy wetting by tin-based melts. J Surf Investig. 2014;8:360–3.

Leinenbach C, Valenza F, Giuranno D, Elsener HR, Jin S, Novakovic R. Wetting and soldering behavior of eutectic Au-Ge alloy on Cu and Ni substrates. J Electron Mater. 2011;40:1533–41.

Xavier MGC, Silva BL, Garcia A, Spinelli JE. High cooling rate, regular and plate like cells in Sn-Ni solder alloys. Adv Eng Mater. 2018;20:1701179.

Soares T, Cruz C, Silva B, Brito C, Garcia A, Spinelli JE, et al. Interplay of wettability, interfacial reaction and interfacial thermal conductance in Sn-0.7Cu solder alloy/substrate couples. J Electron Mater. 2020;49:173–87.

Fima P, Gancarz T, Pstruś J, Sypień A. Wetting of Sn-Zn-xIn (x = 0.5, 1.0, 1.5 wt%) alloys on Cu and Ni substrates. J Mater Eng Perform. 2012;21:595–8.

Kurz W, Fisher D. Fundamentals of Solidification. 4th ed. Switzerland: CRC Press; 1984.

Saito Y, Todoroki H, Kobayashi Y, Shiga N, Tanaka S-I. Hot-cracking mechanism in Al–Sn alloys from a viewpoint of measured residual stress distributions. Mater Trans. 2018;59:908–16.

Spinelli JE, Cheung N, Goulart PR, Quaresma JMV, Garcia A. Design of mechanical properties of Al-alloys chill castings based on the metal/mold interfacial heat transfer coefficient. Int J Therm Sci. 2012;51:45–154.

Kim K, Huh S, Suganuma K. Effects of cooling speed on microstructure and tensile properties of Sn–Ag–Cu alloys. Mater Sci Eng A. 2002;333:106–14.

Septimio RS, Costa TA, Silva CA, Vida TA, Damborenea J, Garcia A, Cheung N. Correlation between unsteady-state solidification thermal parameters and microstructural growth of Zn–8 mass% Al and Zn–8 mass% Al–XBi tribological alloys. J Therm Anal Calorim. 2020;139:1741–61.

Gündüz M, Çadirli E. Directional solidification of aluminium-copper alloys. Mater Sci Eng A. 2002;327:167–85.

Çadırlı E, Büyük U, Engin S, Kaya H. Effect of silicon content on microstructure, mechanical and electrical properties of the directionally solidified Al–based quaternary alloys. J Alloys Compd. 2017;694:471–9.

Brimacombe JK, Samarasekera I V., Lait JE. The continuous-casting mould. In: Continuous Casting – Heat flow, solidification and crack formation. Warrendale: Iron and Steel Society of AIME, 1984. pp. 29–31.

Liu Y, Wang W, Ma F, Zhang H. Study of solidification and heat transfer behavior of mold flux through mold flux heat transfer simulator technique: Part I. Development of the technique. Metall Mater Trans B. 2015;46:1419–30.

Incropera FP, Dewitt DP. Fundamentals of heat and mass transfer. 3rd ed. New York: John Wiley and Sons; 1990.

Silva-Santos CH, Goulart PR, Bertelli F, Garcia A, Cheung N. An artificial immune system algorithm applied to the solution of an inverse problem in unsteady inward solidification. Adv Eng Softw. 2018;121:178–87.

Ruddle RW. The solidification of castings. 2nd ed. London: Institute of Metals; 1957.

Meydaneri F, Saatçi B, Özdemir M. Thermal conductivities of solid and liquid phases for pure Al, pure Sn and their binary alloys. Fluid Phase Equilib. 2010;298:97–105.

MatWeb: Online Materials Information Resource. 2020. http://www.matweb.com/. Accessed 15 May 2020.

Chellaih T, Kumar G, Prabhu KN. Effect of thermal contact heat transfer on solidification of Pb-Sn and Pb-free solders. Mater Des. 2007;28:1006–11.

Noor EEM, Nasir NFM, Idris SRA. A review: Lead free solder and its wettability properties. Solder Surf Mt Technol. 2016;28:125–32.

Laurila T, Vuorinen V, Kivilahti JK. Interfacial reactions between lead-free solders and common base materials. Mater Sci Eng R Reports. 2005;49:1–60.

Ding Z, Hu Q, Lu W, Sun S, Xia M, Li J. In situ observation on the formation of intermetallics compounds at the interface of liquid Al/solid Ni. Scr Mater. 2017;130:214–8.

Laurila T, Vuorinen V, Paulasto-Kröckel M. Impurity and alloying effects on interfacial reaction layers in Pb-free soldering. Mater Sci Eng R Reports. 2010;68:1–38.

Reimer L. Scanning electron microscopy: Physics of image formation and microanalysis. 2nd ed. New York: Springer-Verlag, Berlin Heidelberg; 1998.

Wang YW, Lin YW, Kao CR. Kirkendall voids formation in the reaction between Ni-doped SnAg lead-free solders and different Cu substrates. Microelectron Reliab. 2009;49:248–52.

Shen J, Pu Y, Yin H, Luo D, Chen J. Effects of minor Cu and Zn additions on the thermal, microstructure and tensile properties of Sn-Bi-based solder alloys. J Alloys Compd. 2014;614:63–70.

Aravind M, Yu P, Yau MY, Ng DHL. Formation of Al2Cu and AlCu intermetallics in Al(Cu) alloy matrix composites by reaction sintering. Mater Sci Eng A. 2004;380:384–93.

Meetsma A, De Boer JL, Van Smaalen S. Refinement of the crystal structure of tetragonal Al2Cu. J Solid State Chem. 1989;83:370–2.

El-Ashram T. Structure and properties of rapidly solidified pure tin. Radiat Eff Defects Solids. 2006;161:193–7.

Tian CS, Qian D, Wu D, He RH, Wu YZ, Tang WX, et al. Body-centered-cubic Ni and its magnetic properties. Phys Rev Lett. 2005;94:137210.

Ilbagi A, Delshad Khatibi P, Swainson IP, Reinhart G, Henein H. Microstructural analysis of rapidly solidified aluminium–nickel alloys. Can Metall Q. 2011;50:295–302.

Li JF, Agyakwa PA, Johnson CM. Effect of trace Al on growth rates of intermetallic compound layers between Sn-based solders and Cu substrate. J Alloys Compd. 2012;545:70–9.

Moreno GR, Silva BL, Bogno AA, Henein H, Spinelli JE. Microstructure-property relations in as-atomized and as-extruded Sn-Cu (-Ag) solder alloys. J Alloys Compd. 2016;680:259–67.

Trivedi R, Sekhar JA, Seetharaman V. Solidification microstructures near the limit of absolute stability. Metall Trans A. 1989;20:769–77.

Dias M, Costa T, Rocha O, Spinelli JE, Cheung N, Garcia A. Interconnection of thermal parameters, microstructure and mechanical properties in directionally solidified Sn-Sb lead-free solder alloys. Mater Charact. 2015;106:52–61.

Cruz C, Lima T, Kakitani R, Barros A, Garcia A, Cheung N. Plate-like growth in a eutectic Bi–Ni alloy: Effects of morphological microstructure evolution and Bi3Ni intermetallic phase on tensile properties. J Mater Res Technol. 2020;9:4940–50.

Soares T, Cruz C, Barros A, Garcia A, Cheung N. Microstructure Growth Morphologies, Macrosegregation, and Microhardness in Bi–Sb Thermal Interface Alloys. Adv Eng Mater. 2020;22:1901592.

Rodrigues AV, Lima TS, Vida TA, Brito C, Garcia A, Cheung N. Microstructure and tensile/corrosion properties relationships of directionally solidified Al–Cu–Ni alloys. Met Mater Int. 2018;24:1058–76.

Brito C, Reinhart G, Nguyen-Thi H, Mangelinck-Noël N, Cheung N, Spinelli JE, et al. High cooling rate cells, dendrites, microstructural spacings and microhardness in a directionally solidified Al-Mg-Si alloy. J Alloys Compd. 2015;636:145–9.

Acknowledgements

The authors are grateful to: FAPEAM – Fundação de Amparo à Pesquisa do Estado do Amazonas, FAPESP—São Paulo Research Foundation, Brazil (Grant 2017/15158-0), CAPES – Coordenação de Aperfeiçoamento de Pessoal de Nível Superior – Brasil, and CNPq – National Council for Scientific and Technological Development for their financial support, as well as the Brazilian Nanotechnology National Laboratory – LNNano for the use of X-ray diffractometer and scanning electron microscope.

Funding

This study has been financially supported by: FAPEAM – Fundação de Amparo à Pesquisa do Estado do Amazonas, FAPESP – São Paulo Research Foundation, Brazil (Grant 2017/15158-0), and CAPES – Coordenação de Aperfeiçoamento de Pessoal de Nível Superior – Brasil, and CNPq – National Council for Scientific and Technological Development.

Author information

Authors and Affiliations

Contributions

All authors contributed substantially to the conception and design of the study. First, alloys preparation, solidification experiments, data collection and analysis were carried out by RO, CC, and AB. The solidification model development and simulations were performed by Prof. FB and Prof. NC. Prof. JES and Prof. AG critically revised the work for important intellectual content. The first draft of the manuscript was written by RO, CC, AB, Prof. NC and all authors commented on previous versions of the manuscript. Finally, all authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Availability of data and material

The data that support the findings of this work are available from the corresponding author, Prof. Noé Cheung, upon reasonable request.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Oliveira, R., Cruz, C., Barros, A. et al. Thermal conductance at Sn-0.5mass%Al solder alloy/substrate interface as a factor for tailoring cellular/dendritic growth. J Therm Anal Calorim 147, 4945–4958 (2022). https://doi.org/10.1007/s10973-021-10755-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10755-w