Abstract

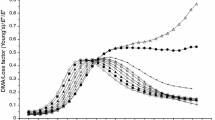

In this work, the acoustic absorption performance of polyurethane (PU) elastomer consisted of different molecular masses of polypropylene glycol (PPG), and a PU composite sample was made by adding multi-wall carbon nanotubes (MWCNT) was studied. Using the acoustic pulse tube device and spectrum of dynamic mechanical thermal analysis, modulus, glass transition temperature (Tg), damping, and acoustic absorption properties of PU with different components were analyzed. The sound absorption results in the frequency range of 2–18 kHz showed that the PU_2 (PPG 2000, TDI) had good acoustic absorption properties. The average acoustic absorption coefficient of PU_2 was 0.8, and the maximum acoustic absorption coefficient was 0.95. The PU_3 (PPG 1000, TDI + 0.1 mass% MWCNT) had lower acoustic absorption properties than PU_2, while the sample had a lower acoustic reflection coefficient compared to the samples PU_1 (PPG 1000, TDI) and PU_3. The damping properties showed that, with an increase in polyether molecular mass and also with the addition of MWCNT, the maximum value of tan(δ) was increased, while the glass transition temperature Tg decreased and increased compared to PU_1, respectively. The PU samples' hardness showed that the increase in molecular mass increases the soft segment and decreases the hardness, while the PU_3 hardness is superior to PU_2.

Similar content being viewed by others

Abbreviations

- DMTA:

-

Dynamic mechanical thermal analysis

- FRFM:

-

Frequency response function method

- MWCNT:

-

Multi-wall carbon nanotubes

- PPG:

-

Polypropylene glycol

- PU:

-

Polyurethane

- SEM:

-

Scanning electron microscope

- α :

-

Absorption coefficient

- c :

-

Speed of acoustic waves in water, m s−1

- Eʹ:

-

Storage modulus, MPa

- Eʹʹ:

-

Loss modulus, MPa

- H :

-

Transfer function between the sound pressure (P1 & P2)

- k :

-

Wavenumber in water

- i :

-

Distance from the farthest microphone to the sample surface

- PU_1:

-

PPG 1000

- PU_2:

-

PPG 2000

- PU_3:

-

PPG 1000 + 0.1 w% MWCNT

- R :

-

Reflection coefficient

- s :

-

Distance between two microphones

- T g :

-

Glass transition temperature, °C

- tan(δ):

-

Loss factor

References

Jarzynski J, Balizer E, Fedderly JJ, Lee G. Acoustic properties. Encyclopedia of Polymer Science and Technology. 2002.

Yang M, Chen S, Fu C, Sheng P. Optimal sound-absorbing structures. Mater Horiz. 2017;4(4):673–80.

Zhang X, Ying W, Yang B. Parameter estimation for class a modeled ocean ambient noise. J Eng Technol Sci. 2018;50(3):330–45.

Sharma GS, Skvortsov A, MacGillivray I, Kessissoglou N. Sound transmission through a periodically voided soft elastic medium submerged in water. Wave Motion. 2017;70:101–12.

Gao N, Zhang Y. A low frequency underwater metastructure composed by helix metal and viscoelastic damping rubber. J Vib Control. 2019;25(3):538–48.

Huang S-L, Lai J-Y. Structure-tensile properties of polyurethanes. Eur Polym J. 1997;33(10–12):1563–7.

Huang Y, Hou H, Oterkus S, Wei Z, Zhang S. Mechanical and acoustic performance prediction model for elastomers in different environmental conditions. J Acoust Soc Am. 2018;144(4):2269–80.

Jayakumari V, Shamsudeen RK, Ramesh R, Mukundan T. Modeling and validation of polyurethane based passive underwater acoustic absorber. J Acoust Soc Am. 2011;130(2):724–30.

Sperling LH. Sound and vibration damping with polymers: Basic viscoelastic definitions and concepts. Washington, DC: ACS Publications; 1990.

Sun W, Yan X, Zhu X. Dynamic mechanical and underwater acoustic properties of the polyurethane/epoxy resin blend elastomers filled with macroporous poly (vinyl acetate-co-triallyl isocyanurate) resin beads. J Appl Polym Sci. 2011;122(4):2359–67.

Liu Z, Sheng M. Study on characteristics of sound absorption of underwater visco-elastic coated compound structures. Mod Appl Sci. 2009;3(1):32–41.

Shi M, Zheng J, Huang Z, Qin Y. Synthesis of polyurethane prepolymers and damping property of polyurethane/epoxy composites. Adv Sci Lett. 2011;4(3):740–4.

Sun W, Yan X, Zhu X. The synthetic kinetics and underwater acoustic absorption properties of novel epoxyurethanes and their blends with epoxy resin. Polym Bull. 2012;69(5):621–33.

Verdejo R, Stämpfli R, Alvarez-Lainez M, Mourad S, Rodriguez-Perez M, Brühwiler P, et al. Enhanced acoustic damping in flexible polyurethane foams filled with carbon nanotubes. Compos Sci Technol. 2009;69(10):1564–9.

Wen Q-Z, Zhu J-H, Yao S-R. Study on the relationship between underwater acoustic attenuation and dynamic mechanical property of polymer materials. Gaofenzi Cailiao Kexue yu Gongcheng/Polym Mater Sci Eng. 2006;22(5):121–4.

Guo C, Zhu Q, Zheng Z, Wang X. Tetrapod-shaped ZnO whiskers reinforced polyurethane. J Polym Eng. 2007;27(5):357–70.

Lapčík L, Vašina M, Lapčíková B, Otyepková E, Waters KE. Investigation of advanced mica powder nanocomposite filler materials: Surface energy analysis, powder rheology and sound absorption performance. Compos B Eng. 2015;77:304–10.

Panigrahi S, Jog C, Munjal M. Multi-focus design of underwater noise control linings based on finite element analysis. Appl Acoust. 2008;69(12):1141–53.

Tay G-S, Nanbo T, Hatakeyama H, Hatakeyama T. Polyurethane composites derived from glycerol and molasses polyols filled with oil palm empty fruit bunches studied by TG and DMA. Thermochim Acta. 2011;525(1–2):190–6.

Doyle E. The development and use of polyurethane products. McGraw-Hill; 1971.

Zhao H, Wen J, Yang H, Lv L, Wen X. Backing effects on the underwater acoustic absorption of a viscoelastic slab with locally resonant scatterers. Appl Acoust. 2014;76:48–51.

Acknowledgements

The authors gratefully acknowledge financial support from the Vice-Chancellor of Research and Technology of Arak University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sharifi, M.J., Ghalehkhondabi, V. & Fazlali, A. Investigation of the underwater sound absorption and damping properties of polyurethane elastomer. J Therm Anal Calorim 147, 4113–4118 (2022). https://doi.org/10.1007/s10973-021-10754-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10754-x