Abstract

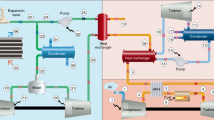

An innovative dual-loop heat recovery and power generation system is proposed here to increase heat recovery from the gas engine (GE) exhaust and jacket cooling water and to augment the system power output and thermal efficiency. As this proposed dual-loop heat recovery system is not studied in existing references, for comparison purpose, 18 existing single- and dual-loop systems in the literature as well as one proposed dual-loop system with six working fluids in topping and six working fluids in bottoming loop (36 cases) are investigated here (54 cases in sum). These systems are modeled in energy, exergy and economic aspects and are optimized by selecting ten design variables and two objective functions (payback period and exergy efficiency) by the use of genetic algorithm. Results show that with water as working fluid for topping loop (Rankine cycle or RC loop) and R141b for bottoming loop (organic Rankine cycle or ORC loop), which are selected in modeling and optimization procedures, the proposed above RC–ORC system has advantages among 53 other studied single- and dual-loop cases. These advantages are higher power output, thermal efficiency, exergy efficiency, annual profit as well as lower investment cost per unit of power output ($ kW−1) and payback period. It is observed that the proposed configuration of RC–ORC (with water–R141b as working fluids), which is integrated with 2 MW gas engine (as an example) generated 617 kW power output with 24% thermal efficiency, 55% exergy efficiency, 1280 $ kW−1 investment cost per unit of power output and about 3-year payback period. Furthermore, the overall thermal efficiency of integrated system (GE–RC–ORC) was about 67%. Finally, RC–ORC power output, exergy efficiency, thermal efficiency and payback period are also obtained for 1, 2 and 3 MW gas engines at various partial loads.

Similar content being viewed by others

Abbreviations

- A:

-

Heat transfer surface area (m2)

- \(\mathrm{AP}\) :

-

Annual profit ($ year−1)

- \(C_{{{\text{CO}}_{2} }}\) :

-

CO2 penalty cost per kg ($ kg−1)

- \(C_{{\text{elec,B}}}\) :

-

Electricity consumption price ($ kWh−1)

- \(C_{{\text{elec,s}}}\) :

-

Electricity selling price ($ kWh−1)

- \(C_{{\text{f}}}\) :

-

Fuel cost (S m−3)

- \(C_{{\text{in,an}}}\) :

-

Annual investment cost ($ year−1)

- \(C_{{{\text{inv}}}}\) :

-

Investment cost ($)

- \(C_{{\text{m}}}\) :

-

CO2 production per (kg kWh−1)

- \(C_{{\text{P}}}\) :

-

Specific heat capacity (kJ kg−1 K−1)

- \(C_{{{\text{Penalty}}}}\) :

-

CO2 penalty cost ($)

- \({\text{CRF}}\) :

-

Capital recovery factor

- \(d\) :

-

Tube diameter (m)

- \(\dot{E}\) :

-

Exergy rate (kW)

- \(F\) :

-

Logarithmic mean temperature difference correction factor

- \(f_{{\text{g}}}\) :

-

Friction factor

- \(G\) :

-

Mass velocity (kg s−1 m−2)

- \(H\) :

-

Annual working time (h)

- \(h\) :

-

Specific enthalpy (kJ kg−1)

- \(I_{{{\text{e}},{\text{s}}}}\) :

-

Income from electricity selling ($)

- \(i\) :

-

Interest rate (%)

- \(K_{{\text{m}}}\) :

-

Pipe material thermal conductivity (W m−1 K−1)

- \({\text{LHV}}\) :

-

Lower heating value (Kcal m−3)

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- \({\text{Nu}}\) :

-

Nusselt number

- \(n\) :

-

System lifetime (year)

- \(P\) :

-

Pressure (bar)

- \({\text{PBP}}\) :

-

Payback period (year)

- \({\text{PL}}\) :

-

Partial load (%)

- \({\text{Pr}}\) :

-

Prandtl number

- \(Q\) :

-

Volumetric flow rate (m3 s−1)

- \(\dot{Q}\) :

-

Heat transfer rate (kW)

- \({\text{Re}}\) :

-

Reynolds number

- \(s\) :

-

Specific entropy (kJ kg−1)

- \(T\) :

-

Temperature (°C)

- \(U\) :

-

Overall heat transfer coefficient (Wm−2 K−1)

- \({\text{V}}\) :

-

Water velocity (m s−1)

- \(\dot{W}\) :

-

Work produced/consumed rate (kW)

- \(x\) :

-

Steam quality

- α :

-

Heat transfer coefficient (Wm−2 K−1)

- \(\eta_{{{\text{thermal}}}}\) :

-

Thermal efficiency (%)

- \(\eta_{{{\text{ex}}}}\) :

-

Exergy efficiency (%)

- \(\gamma\) :

-

Isobaric to isometric specific heat capacity ratio

- \(\gamma \left( {i,n} \right)\) :

-

Sinking fund factor

- \(\Delta p_{{\text{g}}}\) :

-

Gas side pressure drop (kPa)

- \(\rho\) :

-

Density (kg m−3)

- μ :

-

Dynamic viscosity (Pa s)

- \({\text{APTD}}\) :

-

Approach point temperature difference

- \({\text{amb}}\) :

-

Ambient

- \({\text{atm}}\) :

-

Atmosphere

- \({\text{Cond}}\) :

-

Condenser

- \({\text{CHP}}\) :

-

Combined heat and power

- \({\text{Des}}\) :

-

Exergy destruction

- \({\text{DOS}}\) :

-

Degree of superheat

- \({\text{Eva}}\) :

-

Evaporator

- \({\text{exp}}\) :

-

Expander

- f:

-

Fuel

- \({\text{GE}}\) :

-

Gas engine

- \({\text{GWP}}\) :

-

Global warming potential

- g:

-

Gas

- HRSG:

-

Heat recovery steam generator

- i :

-

Internal

- \({\text{JCW}}\) :

-

Jacket cooling water

- \({\text{ma}}\) :

-

Maintenance

- \({\text{NTU}}\) :

-

Number of transfer units

- \({\text{ODP}}\) :

-

Ozone depletion potential

- \({\text{OP}}\) :

-

Operational

- \({\text{ORC}}\) :

-

Organic Rankine cycle

- \(o\) :

-

Outer

- \({\text{PPTD}}\) :

-

Pinch point temperature difference

- \({\text{RC}}\) :

-

Rankine cycle

- \({\text{ST}}\) :

-

Steam turbine

- \({\text{SV}}\) :

-

Salvage value

- \({\text{Sat}}\) :

-

Saturation state

- s:

-

Isentropic process

- \({\text{st}}\) :

-

Steam

- t:

-

Turbine

- \({\text{Wa}}\) :

-

Water

- \({\text{Wf}}\) :

-

Working fluid

References

Catalog of CHP technologies. U.S. Environmental Protection Agency, Combined Heat and Power Agency partnership, Washington, DC, United States; 2014.

Song J, Gu CW. Performance analysis of a dual-loop organic Rankine cycle (ORC) system with wet steam expansion for engine waste heat recovery. Appl Energy. 2015;156:280–9.

Yang F, Cho H, Zhang H, Zhang J. Thermo-economic multi-objective optimization of a dual loop organic Rankine cycle (ORC) for CNG engine waste heat recovery. Appl Energy. 2017;205:1100–18.

Yang FB, Zhang HG, Yu ZB, Wang EH, Meng FX, Liu HD, Wang JF. Parametric optimization and heat transfer analysis of a dual loop ORC (organic Rankine cycle) system for CNG engine waste heat recovery. Energy. 2017;118:753–75.

Panesar AS. An innovative organic Rankine cycle system for integrated cooling and heat recovery. Appl Energy. 2016;186:396–407.

Peris B, Esbrí JN, Molés F. Bottoming organic Rankine cycle configurations to increase internal combustion engines power output from cooling water waste heat recovery. Appl Therm Eng. 2013;61:364–71.

Shu G, Wang X, Tian H. Theoretical analysis and comparison of Rankine cycle and different organic Rankine cycles as waste heat recovery system for a large gaseous fuel internal combustion engine. Appl Therm Eng. 2016;108:525–37.

Mehrdad S, Dadsetani R, Amiriyoon A, Leon AS, Safaei MR, Goodarzi M. Exergo-economic optimization of organic Rankine cycle for saving of thermal energy in a sample power plant by using of strength Pareto evolutionary algorithm II. Processes. 2020. https://doi.org/10.3390/pr8030264.

Song J, Gu CW. Parametric analysis of a dual loop Organic Rankine Cycle (ORC) system for engine waste heat recovery. Energy Convers Manage. 2015;105:995–1005.

Apostol V, Pop H, Dobrovicescu A, Prisecaru T, Alexandru A, Prisecaru M. Thermodynamic analysis of ORC configurations used for WHR from a turbocharged diesel engine. Proc Eng. 2015;100:549–58.

Xia XX, Wang ZQ, Zhou NJ, Hu YH, Zhang JP, Chen Y. Working fluid selection of dual-loop organic Rankine cycle using multi-objective optimization and improved grey relational analysis. Appl Therm Eng. 2020. https://doi.org/10.1016/j.applthermaleng.2020.115028.

Zhou Y, Li Sh, Sun L, Zhao Sh, AshrafTalesh SS. Optimization and thermodynamic performance analysis of a power generation system based on geothermal flash and dual-pressure evaporation organic Rankine cycles using zeotropic mixtures. Energy. 2019. https://doi.org/10.1016/j.energy.2019.116785.

Sanaye S, Khakpay N. Thermo-economic multi-objective optimization of an innovative cascaded organic Rankine cycle heat recovery and power generation system integrated with gas engine and ice thermal energy storage. J Energy Storage. 2020. https://doi.org/10.1016/j.est.2020.101697.

Shu G, Li X, Tian H, Liang X, Wei H, Wang X. Alkanes as working fluids for high-temperature exhaust heat recovery of diesel engine using organic Rankine cycle. Appl Energy. 2014;119:204–17.

Toffolo A, Lazzaretto A, Manente G, Paci M. A multi-criteria approach for the optimal selection of working fluid and design parameters in organic Rankine cycle systems. Appl Energy. 2014;121:219–32.

Gimelli A, Luongo A, Muccillo M. Efficiency and cost optimization of a regenerative organic Rankine cycle power plant through the multi-objective approach. Appl Therm Eng. 2016. https://doi.org/10.1016/j.applthermaleng.2016.12.009.

Wang YZ, Zhao J, Wang Y, An QS. Multi-objective optimization and grey relational analysis on configurations of organic Rankine cycle. Appl Thermal Eng. 2016. https://doi.org/10.1016/j.applthermaleng.2016.10.075.

Ameri M, Jorjani M. Performance assessment and multi-objective optimization of an integrated organic Rankine cycle and multi-effect desalination system. Desalination. 2016;392:34–45.

Wang J, Yan Z, Wang M, Li M, Dai Y. Multi-objective optimization of an organic Rankine cycle (ORC) for low grade waste heat recovery using evolutionary algorithm. Energy Convers Manage. 2013;71:146–58.

Imran M, Park BS, Kim HJ, Lee DH, Usman M, Heo M. Thermo-economic optimization of regenerative organic Rankine cycle for waste heat recovery applications. Energy Convers Manage. 2014;87:107–18.

Feng Y, Zhang Y, Li B, Yang J, Shi Y. Comparison between regenerative organic Rankine cycle (RORC) and basic organic Rankine cycle (BORC) based on thermo-economic multi-objective optimization considering exergy efficiency and levelized energy cost (LEC). Energy Convers Manage. 2015;96:58–71.

Fergani Z, Touil D, Morosuk T. Multi-criteria exergy based optimization of an Organic Rankine Cycle for waste heat recovery in the cement industry. Energy Convers Manage. 2016;112:81–90.

Astolfi M, Romano MC, Bombarda P, Macchi E. Binary ORC (organic Rankine cycles) power plants for the exploitation of medium-low temperature geothermal sources Part B: techno-economic optimization. Energy. 2014;66:435–46.

Wang XR, Dai YP. Exergo-economic analysis of utilizing the transcritical CO2 cycle and the ORC for a recompression supercritical CO2 cycle waste heat recovery: a comparative study. Appl Energy. 2016;170:193–207.

Imran M, Usman M, Park BS, Yang YM. Comparative assessment of Organic Rankine Cycle integration for low temperature geothermal heat source applications. Energy. 2016;102:473–90.

Kazemi N, Samadi F. Thermodynamic, economic and thermo-economic optimization of a new proposed organic Rankine cycle for energy production from geothermal resources. Energy Convers Manage. 2016;121:391–401.

Khosravi H, Salehi GR, TorabiAzad M. Design of structure and optimization of organic Rankine cycle for heat recovery from gas turbine: the use of 4E, advanced exergy and advanced exergoeconomic analysis. Appl Thermal Eng. 2018. https://doi.org/10.1016/j.applthermaleng.2018.09.128.

Emadi MA, Chitgar N, Oyewunmi OA, Markides CN. Working-fluid selection and thermo-economic optimisation of a combined cycle cogeneration dual-loop organic Rankine cycle (ORC) system for solid oxide fuel cell (SOFC) waste-heat recovery. Appl Energy. 2020;261:1–20.

Sun Q, Wang Y, Cheng Z, Wang J, Zhao P, Dai Y. Thermodynamic and economic optimization of a double-pressure organic Rankine cycle driven by low-temperature heat source. Renew Energy. 2018. https://doi.org/10.1016/j.renene.2018.11.093.

Keshavarzzadeh AH, Ahmadi P, Safaei MR. Assessment and optimization of an integrated energy system with electrolysis and fuel cells for electricity, cooling and hydrogen production using various optimization techniques. Int J Hydrogen Energy. 2019. https://doi.org/10.1016/j.ijhydene.2019.06.127.

Sanaye S, Ghaffari A. Modeling, multi-objective optimization and comparison of fire and water tube heat recovery steam generators for gas engine cogeneration plants. J Therm Anal Calorim. 2021. https://doi.org/10.1007/s10973-020-10522-3.

Ghaffari A, Ahmadi R, Eyvazkhani M. Modeling and optimization of finless and finned tube heat recovery steam generators for cogeneration plants. Eng Rep. 2020. https://doi.org/10.1002/eng2.12262.

Wang JF, Yan ZQ, Wang M, Ma SL, Dai YP. Thermodynamic analysis and optimization of an (organic Rankine cycle) ORC using low grade heat source. Energy. 2013;49:356–65.

Ayachi F, Ksayer EB, Zoughaib A. ORC optimization for medium grade heat recovery. Energy. 2014;68:47–56.

Sadeghi M, Nemati A, Ghavimi A, Yari M. Thermodynamic analysis and multi-objective optimization of various ORC (organic Rankine cycle) configurations using zeotropic mixtures. Energy. 2016;109:791–802.

Imran M, Haglind F, Lemort V, Meroni A. Optimization of organic Rankine cycle power systems for waste heat recovery on heavy-duty vehicles considering the performance, cost, mass and volume of the system. Energy. 2019;180:229–41.

Van Kleef LMT, Oyewunmi OA, Markides CN. Multi-objective thermo-economic optimization of organic Rankine cycle (ORC) power systems in waste-heat recovery applications using computer aided molecular design techniques. Appl Energy. 2019;251:1–21.

Fang Y, Yang F, Zhang H. Comparative analysis and multi-objective optimization of organic Rankine cycle (ORC) using pure working fluids and their zeotropic mixtures for diesel engine waste heat recovery. Appl Therm Eng. 2019;157:1–15.

Li J, Mohammadi A, Maleki A. Techno-economic analysis of new integrated system of humid air turbine, organic Rankine cycle, and parabolic trough collector. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08855-9.

Bademlioglu AH, Canbolat AS, Kaynakli O. Multi-objective optimization of parameters affecting Organic Rankine Cycle performance characteristics with Taguchi-Grey Relational Analysis. Renew Sustain Energy Rev. 2020;117:1–13.

Abam FI, Ekwe EB, Effiom SO, Ndukwu MC, Briggs TA, Kadurumba CH. Optimum exergetic performance parameters and thermo-sustainability indicators of low-temperature modified organic Rankine cycles (ORCs). Sustainable Energy Technol Assess. 2018;30:91–104.

Amiri Rad E, Mohammadi S, Tayyeban E. Simultaneous optimization of working fluid and boiler pressure in an organic Rankine cycle for different heat source temperatures. Energy. 2019. https://doi.org/10.1016/j.energy.2019.116856.

Sadeghi S, Maghsoudi P, Shabani B, Haghshenas Gorgani H, Shabani N. Performance analysis and multi-objective optimization of an organic Rankine cycle with binary zeotropic working fluid employing modified artificial bee colony algorithm. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7801-y.

Ahmadi B, Golneshan AA, Arasteh H, Karimipour A, Vu BQ. Energy and exergy analysis and optimization of a gas turbine cycle coupled by a bottoming organic Rankine cycle. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-09088-6.

Maleki A, Thao Thi Ngo P, Irandoost Shahrestani M. Energy and exergy analysis of a PV module cooled by an active cooling approach. J Thermal Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09916-0.

Toghyani S, Afshari E, Baniasadi E, Shadloo MS. Energy and exergy analyses of a nanofluid based solar cooling and hydrogen production combined system. Renewable Energy. 2019. https://doi.org/10.1016/j.renene.2019.04.073.

Rostami S, Sepehrirad M, Dezfulizadeh A, Kadhim Hussein A, Shahsavar Goldanlou A, Shadloo MS. Exergy optimization of a solar collector in flat plate shape equipped with elliptical pipes filled with turbulent nanofluid flow: a study for thermal management. Water. 2020. https://doi.org/10.3390/w12082294.

Masum BM, Masjuki HH, Kalam MA, Palash SM, Habibullah M. Effect of alcohol–gasoline blends optimization on fuel properties, performance and emissions of a SI engine. J Clean Prod. 2014. https://doi.org/10.1016/j.jclepro.2014.08.032.

Pierobon L, Benato A, Scolari E, Haglind F, Stoppato A. Waste heat recovery technologies for offshore platforms. Appl Energy. 2014;136:228–41.

Feng YQ, Zhang YN, Li BX, Yang JF, Yang S. Sensitivity analysis and thermo-economic comparison of ORCs (organic Rankine cycles) for low temperature waste heat recovery. Energy. 2015;82:664–7.

Maleki A, Nazari MA, Pourfayaz F. Harmony search optimization for optimum sizing of hybrid solar schemes based on battery storage unit. Energy Rep. 2020. https://doi.org/10.1016/j.egyr.2020.03.014.

Cai W, Li X, Maleki A, Pourfayaz F, Rosen MA, Nazari MA, Bui DT. Optimal sizing and location based on economic parameters for an off-grid application of a hybrid system with photovoltaic, battery and diesel technology. Energy. 2020. https://doi.org/10.1016/j.energy.2020.117480.

Zhang G, Shi Y, Maleki A, Rosen MA. Optimal location and size of a grid-independent solar/hydrogen system for rural areas using an efficient heuristic approach. Renew Energy. 2020. https://doi.org/10.1016/j.renene.2020.04.010.

Li Z, Sarafraz MM, Mazinani A, Moria H, Tlili I, Alkanhal TA, Goodarzi M, Safaei MR. Operation analysis, response and performance evaluation of a pulsating heat pipe for low temperature heat recovery. Energy Convers Manage. 2020. https://doi.org/10.1016/j.enconman.2020.113230.

Toghyani S, Fakhradini S, Afshar E, Baniasadi E, Abdollahzadeh Jamalabadi MY, Safdari SM. Optimization of operating parameters of a polymer exchange membrane electrolyzer. Int J Hydrogen Energy. 2019. https://doi.org/10.1016/j.ijhydene.2019.01.186.

Bejan A, Tsatsaronis G, Moran M. Thermal design and optimization. New York: Wiley; 1996.

Roshenow W, Hartnett JP. Handbook of heat transfer. New York: McGraw-Hill; 1972. p. 13–56.

Kakac S, Liu H, Pramuanjaroenkij A. Heat exchangers selection, rating and thermal design. 3rd ed. Boca Raton, Florida: CRC Press; 2012.

Bahmani MH, Akbari OA, Alrashed AAAA, Sheikhzadeh G, Zarringhalam M, Ahmadi Sheikh Shabani G, Goodarzi M. Investigation of turbulent heat transfer and nanofluid flow in a double pipe heat exchanger. Adv Powder Technol. 2017. https://doi.org/10.1016/j.apt.2017.11.013.

Ganapathy V. Industrial boilers and heat recovery steam generators: Design, applications and calculations. 3rd ed. New York, Basel: Marcel Dekker Inc; 2003.

Shahsavar A, Bakhshizadeh MA, Arici M, Afrand M, Rostami S. Numerical study of the possibility of improving the hydrothermal performance of an elliptical double-pipe heat exchanger through the simultaneous use of twisted tubes and non-Newtonian nanofluid. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-10201-3.

Xia J, Wang J, Lou J, Zhao P, Dai Y. Thermo-economic analysis and optimization of a combined cooling and power (CCP) system for engine waste heat recovery. Energy Convers Manage. 2016;128:303–16.

Shu G, Yu G, Tian H, Wei H, Liang X. A multi-approach evaluation system (MA-ES) of Organic Rankine Cycles (ORC) used in waste heat utilization. Appl Energy. 2014;132:325–38.

Ma J, Liu L, Zhu T, Zhang T. Cascade utilization of exhaust gas and jacket water waste heat from an internal combustion engine by a single loop organic Rankine cycle system. Appl Therm Eng. 2016;107:218–26.

Mehdizadeh-Fard M, Pourfayaz F, Maleki A. Exergy analysis of multiple heat exchanger networks: an approach based on the irreversibility distribution ratio. Energy Rep. 2021. https://doi.org/10.1016/j.egyr.2020.11.166.

Nazari N, Heidarnejad P, Porkhial S. Multi-objective optimization of a combined steam-organic Rankine cycle based on exergy and exergo-economic analysis for waste heat recovery application. Energy Convers Manage. 2016;127:366–79.

Neto R, Sotomonte C, Coronado CJR, Nascimento MAR. Technical and economic analyses of waste heat energy recovery from internal combustion engines by the Organic Rankine Cycle. Energy Convers Manag. 2016;129:168–79.

Humpherys KK, Kattell S. Basic cost engineering. New York: MarcelDekker; 1981.

Macchi E, Astolfi M. Organic Rankine cycle power systems, technologies and applications. Woodhead Publishing Series in Energy; 2017.

Liu X, Wei M, Yang L, Wang X. Thermo-economic analysis and optimization selection of ORC system configurations for low temperature binary-cycle geothermal plant. Appl Therm Eng. 2017;125:153–64.

https://www.cat.com/en_US/products/new/power-systems/industrial/gas-engines.html

Vaja I, Gambarotta A. Internal combustion engine (ICE) bottoming with organic Rankine cycles (ORCs). Energy. 2010;35:1084–93.

Deb K, Agrawal S, Pratap A, Meyarivan TA. fast elitist non-dominated sorting genetic algorithm for multi-objective optimization: NSGA-II. Lect Notes Comput Sci. 2000;19:849–58.

Sanaye S, Shirazi A. Four E analysis and multi-objective optimization of an ice thermal energy storage for air-conditioning applications. Int J Refrig. 2013;36:828841.

Wang X, Shu G, Tian H, Feng W, Liu P, Li X. Effect factors of part-load performance for various Organic Rankine cycles using in engine waste heat recovery. Energy Convers Manage. 2018;174:504–15.

https://www.mwm.net/mwm-kwk-bhkw/gasmotoren-stromaggregate/gasmotor-tcg-2032/

Nami H, Mahmoudi SMS, Nemati A. Exergy, economic and environmental impact assessment and optimization of a novel cogeneration system including a gas turbine, a supercritical CO2 and an organic Rankine cycle (GT-HRSG/SCO2). Appl Thermal Eng. 2016. https://doi.org/10.1016/j.applthermaleng.2016.08.197.

Franco A, Giannini N. A general method for the optimum design of heat recovery steam generators. Energy. 2006;31:3342–61.

Amicabile S, Lee JI, Kum D. A comprehensive design methodology of organic Rankine cycles for the waste heat recovery of automotive heavy duty diesel engines. Appl Therm Eng. 2015;87:574–85.

Macián V, Serrano JR, Dolz V, Sánchez J. Methodology to design a bottoming Rankine cycle, as a waste energy recovering system in vehicles. Appl Energy. 2013;104:758–71.

Pili R, Romagnoli A, Kamossa K, Schuster A, Spliethoff H, Wieland C. Organic Rankine Cycles (ORC) for mobile applications—economic feasibility in different transportation sectors. Appl Energy. 2017. https://doi.org/10.1016/j.apenergy.2017.04.056.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sanaye, S., Ghaffari, A. Thermo-economic multi-objective optimization of an innovative Rankine–organic Rankine dual-loop system integrated with a gas engine for higher energy/exergy efficiency and lower payback period. J Therm Anal Calorim 144, 1883–1905 (2021). https://doi.org/10.1007/s10973-021-10753-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10753-y