Abstract

This work presents the feasibility study of utilizing neat plastic oil TiO\(_2\) nanoparticle is added as additive in the proportion of 100, 150, and 200 ppm fuelled in a stationary single cylinder diesel engine to asses the performance, emission and combustion characteristics. From the local municipality, the waste plastic bottles are collected and it it fed into the pyrolysis reactor to convert into pyrolysis oil. The results from performance analysis revealed that the enrichment of neat plastic with TiO\(_2\) nanoparticle enhanced the brake thermal efficiency than without any additives in the raw oil (plastic oil). Similarly, the results of emission revealed that smoke, and hydrocarbon are considerably reduced with increased proportion of nano additive. Results also revealed that the formation of NOx is higher with POAL200 than plastic oil and other concentration of TiO\(_2\) nanoparticle and diesel fuel. This is due to the higher availability of oxygen content in the fuel, higher quality of fuel and reduced ignition delay.

Similar content being viewed by others

References

Sundararajan NK, Ammal ARB. Improvement studies on emission and combustion characteristics of DICI engine fuelled with colloidal emulsion of diesel distillate of plastic oil, TiO\(_2\) nanoparticles and water. Environ Sci Pollut Res. 2018;25(12):11595–613.

Sekhar SC, Karuppasamy K, Vedaraman N, Kabeel A, Sathyamurthy R, Elkelawy M, et al. Biodiesel production process optimization from Pithecellobium dulce seed oil: performance, combustion, and emission analysis on compression ignition engine fuelled with diesel/biodiesel blends. Energy Convers Manage. 2018;161:141–54.

Sekhar SC, Karuppasamy K, Sathyamurthy R, Elkelawy M, Bastawissi HAED, Paramasivan P, et al. Emission analysis on compression ignition engine fueled with lower concentrations of Pithecellobium dulce biodiesel–diesel blends. Heat Transfer Asian Res. 2019;48(1):254–69.

Kalargaris I, Tian G, Gu S. Combustion, performance and emission analysis of a DI diesel engine using plastic pyrolysis oil. Fuel Process Technol. 2017;157:108–15.

Rakopoulos C, Antonopoulos K, Rakopoulos D, Hountalas D, Giakoumis E. Comparative performance and emissions study of a direct injection diesel engine using blends of diesel fuel with vegetable oils or bio-diesels of various origins. Energy Convers Manage. 2006;47(18–19):3272–87.

Mangesh V, Padmanabhan S, Tamizhdurai P, Ramesh A. Experimental investigation to identify the type of waste plastic pyrolysis oil suitable for conversion to diesel engine fuel. J Clean Prod. 2020;246:119066.

Nagaraju P, Ravichandra M, Lahari MC, Sai PST. Experimental investigation on the performance of tyre pyrolysis oil blended with palm stearin methyl ester as a fuel for single-cylinder CI engine. In: Advances in industrial automation and smart manufacturing. Springer; 2021. p. 945–952.

Ravichandra M, Nagaraju P, Moulali P, Nagaraju K. Effect of exhaust gas recirculation and cerium oxide on tire pyrolysis oil blends. In: Advances in industrial automation and smart manufacturing. Springer; 2021. p. 969–985.

Lam SS, Russell AD, Lee CL, Chase HA. Microwave-heated pyrolysis of waste automotive engine oil: influence of operation parameters on the yield, composition, and fuel properties of pyrolysis oil. Fuel. 2012;92(1):327–39.

Panneerselvam N, Murugesan A, Vijayakumar C, Kumaravel A, Subramaniam D, Avinash A. Effects of injection timing on bio-diesel fuelled engine characteristics. An overview. Renew Sustain Energy Rev. 2015;50:17–31.

Sathiyamoorthi R, Sankaranarayanan G, Pitchandi K. Combined effect of nanoemulsion and EGR on combustion and emission characteristics of neat lemongrass oil (LGO)-DEE-diesel blend fuelled diesel engine. Appl Therm Eng. 2017;112:1421–32.

Subramaniam M, Solomon JM, Nadanakumar V, Anaimuthu S, Sathyamurthy R. Experimental investigation on performance, combustion and emission characteristics of DI diesel engine using algae as a biodiesel. Energy Rep. 2020;6:1382–92.

Sundar PS, Vijayabalan P, Balachandar M, Sathyamurthy R, Chamkha AJ. Influence of oxygen enrichment on performance, combustion, and emission characteristics of a stationary diesel engine fuelled with Calophyllum inophyllum biodiesel blend. Asia-Pac J Chem Eng. 2020;15:e2472.

Balasubramanian K, Purushothaman K. Effect of acetylene addition on performance, emission and combustion characteristics of neem biodiesel and corn biodiesel-fueled CI engine. J Therm Anal Calorim. 2019;138(2):1405–14.

Saxena V, Kumar N, Saxena VK. Combustion, performance and emissions of Acacia concinna biodiesel blends in a diesel engine with variable specific heat ratio. J Therm Anal Calorim. 2021. https://doi.org/10.1007/s10973-020-10483-7.

Kodate SV, Yadav AK, Kumar G. Combustion, performance and emission analysis of preheated KOME biodiesel as an alternate fuel for a diesel engine. J Therm Anal Calorim. 2020;141:2335–45.

Tamilvanan A, Balamurugan K, Vijayakumar M. Effects of nano-copper additive on performance, combustion and emission characteristics of Calophyllum inophyllum biodiesel in CI engine. J Therm Anal Calorim. 2019;136(1):317–30.

Karagoz M, Uysal C, Agbulut U, Saridemir S. Energy, exergy, economic and sustainability assessments of a compression ignition diesel engine fueled with tire pyrolytic oil–diesel blends. J Clean Prod. 2020;264:121724.

Karagöz M, Ağbulut Ü, Sarıdemir S. Waste to energy: Production of waste tire pyrolysis oil and comprehensive analysis of its usability in diesel engines. Fuel. 2020;275:117844.

Zhang G, Chen F, Zhang Y, Zhao L, Chen J, Cao L, et al. Properties and utilization of waste tire pyrolysis oil: a mini review. Fuel Process Technol. 2021;211:106582.

Wongkhorsub C, Chindaprasert N, et al. A comparison of the use of pyrolysis oils in diesel engine. Energy Power Eng. 2013;5(04):350.

Van de Beld B, Holle E, Florijn J. The use of pyrolysis oil and pyrolysis oil derived fuels in diesel engines for CHP applications. Appl Energy. 2013;102:190–7.

Hariharan S, Murugan S, Nagarajan G. Effect of diethyl ether on tyre pyrolysis oil fueled diesel engine. Fuel. 2013;104:109–15.

Kaimal VK, Vijayabalan P. A study on synthesis of energy fuel from waste plastic and assessment of its potential as an alternative fuel for diesel engines. Waste Manage (Oxford). 2016;51:91–6.

Kaimal VK, Vijayabalan P. An investigation on the effects of using DEE additive in a DI diesel engine fuelled with waste plastic oil. Fuel. 2016;180:90–6.

Mani M, Nagarajan G, Sampath S. An experimental investigation on a DI diesel engine using waste plastic oil with exhaust gas recirculation. Fuel. 2010;89(8):1826–32.

Murugan S, Ramaswamy M, Nagarajan G. The use of tyre pyrolysis oil in diesel engines. Waste Manage (Oxford). 2008;28(12):2743–9.

Murugan S, Ramaswamy M, Nagarajan G. Performance, emission and combustion studies of a DI diesel engine using distilled tyre pyrolysis oil–diesel blends. Fuel Process Technol. 2008;89(2):152–9.

Frigo S, Seggiani M, Puccini M, Vitolo S. Liquid fuel production from waste tyre pyrolysis and its utilisation in a diesel engine. Fuel. 2014;116:399–408.

Ayodhya AS, Lamani VT, Thirumoorthy M, Kumar G. NOx reduction studies on a diesel engine operating on waste plastic oil blend using selective catalytic reduction technique. J Energy Inst. 2019;92(2):341–50.

Churkunti PR, Mattson J, Depcik C, Devlin G. Combustion analysis of pyrolysis end of life plastic fuel blended with ultra low sulfur diesel. Fuel Process Technol. 2016;142:212–8.

Paul Daniel M, Kumar KV, Durga Prasad B, Puli RK. Performance and emission characteristics of diesel engine operated on plastic pyrolysis oil with exhaust gas recirculation. Int J Ambient Energy. 2017;38(3):295–9.

Mani M, Subash C, Nagarajan G. Performance, emission and combustion characteristics of a DI diesel engine using waste plastic oil. Appl Therm Eng. 2009;29(13):2738–44.

Mani M, Nagarajan G. Influence of injection timing on performance, emission and combustion characteristics of a DI diesel engine running on waste plastic oil. Energy. 2009;34(10):1617–23.

Devaraj J, Robinson Y, Ganapathi P. Experimental investigation of performance, emission and combustion characteristics of waste plastic pyrolysis oil blended with diethyl ether used as fuel for diesel engine. Energy. 2015;85:304–9.

Rinaldini CA, Mattarelli E, Savioli T, Cantore G, Garbero M, Bologna A. Performance, emission and combustion characteristics of a IDI engine running on waste plastic oil. Fuel. 2016;183:292–303.

Damodharan D, Sathiyagnanam A, Rana D, Kumar BR, Saravanan S. Combined influence of injection timing and EGR on combustion, performance and emissions of DI diesel engine fueled with neat waste plastic oil. Energy Convers Manage. 2018;161:294–305.

Ananthakumar S, Jayabal S, Thirumal P. Investigation on performance, emission and combustion characteristics of variable compression engine fuelled with diesel, waste plastics oil blends. J Brazil Soc Mech Sci Eng. 2017;39(1):19–28.

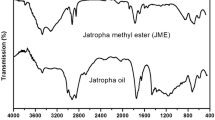

Senthilkumar P, Sankaranarayanan G. Effect of Jatropha methyl ester on waste plastic oil fueled DI diesel engine. J Energy Inst. 2016;89(4):504–12.

Kumar R, Mishra M, Singh S, Kumar A. Experimental evaluation of waste plastic oil and its blends on a single cylinder diesel engine. J Mech Sci Technol. 2016;30(10):4781–9.

Bharathy S, Gnanasikamani B, Lawrence KR. Investigation on the use of plastic pyrolysis oil as alternate fuel in a direct injection diesel engine with titanium oxide nanoadditive. Environ Sci Pollut Res. 2019;26(10):10319–32.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sundar, S.P., Palanimuthu, V., Sathyamurthy, R. et al. Feasibility study of neat plastic oil with TiO2 nanoadditive as an alternative fuel in internal combustion engine. J Therm Anal Calorim 147, 2567–2578 (2022). https://doi.org/10.1007/s10973-021-10657-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10657-x