Abstract

Pool boiling is a well-known heat transfer mechanism which is accomplished by submerging a heating surface in a pool of stationary liquid. The role and share of different energy transfer mechanisms in pool boiling can be determined through entropy generation analysis. In this paper, entropy generation due to energy transfer through circular surfaces is analyzed and the optimized thermodynamic system is achieved. Furthermore, two models of total heat flux (linear and nonlinear) are developed for pool boiling heat transfer in which the effect of different parameters such as nucleation site density, contact angle, Prandtl number (Pr) as well as surface diameter are considered. The obtained results reveal the enhanced heat flux and entropy generation as the consequences of increased wall superheat temperature, contact angle, Prandtl number and surface diameter. The developed model is validated by comparing the obtained results with respective experimental data and semi-analytical results. In addition, results exhibit that the maximum entropy generation is observed at \(\Delta T = 15 \,{\text{K}}\) and \(Pr = 3.5\) which was equal to 4.06 W m−1 K−1 and 3.78 W m−1 K−1 for Model 1 and Model 2, respectively.

Graphical abstract

Similar content being viewed by others

Abbreviations

- A :

-

Surface area \(\left( {{\text{m}}^{2}} \right)\)

- Ar :

-

Archimedes number

- B :

-

Specific liquid constant

- \(C_{{\text{P}}}\) :

-

Specific heat capacity \(\left( {{{\text{J}}}\,{{{\text{kg}}^{-1}\,{\text{K}}^{-1}}}} \right)\)

- D :

-

Diameter (m)

- f :

-

Bubble departure frequency \(\left( {{{\text{s}}^{-1}}} \right)\)

- F :

-

Force \(\left( {\text{N}} \right)\)

- g :

-

Gravity acceleration \(\left( {{{\text{m}}}\,{{{\text{s}}^{-2}}}} \right)\)

- h :

-

Specific enthalpy \(\left( {{{\text{J}}}\,{{{\text{kg}}^{-1}}}} \right)\)

- H :

-

Heat transfer coefficient \( \left( {{{\text{W}}}\,{{{\text{m}}^{-2} \,{\text{K}}^{-1}}}} \right) \)

- Ja :

-

Jacob number

- k :

-

Thermal conductivity \( \left( {{{\text{W}}}\,{{{\text{m}}^{-1} \,{\text{K}}^{-1}}}} \right) \)

- \(\dot{m}\) :

-

Mass flow rate

- \(N_{{\text{a}}}\) :

-

Active nucleation site density \(\left( {\frac{{{\text{site}}}}{{{\text{m}}^{{\text{2}}}}}} \right)\)

- P :

-

Pressure \(\left( {{\text{Pa}}} \right)\)

- Pr :

-

Prandtl number

- q :

-

Heat flux \(\left( {{{\text{W}}}\,{{{\text{m}}^{{\text{-2}}}}}} \right)\)

- \(\dot{Q}\) :

-

Heat transfer rate \(\left( {\text{W}} \right)\)

- \(R_{{\text{a}}}\) :

-

Roughness \(\left( {\text{m}} \right)\)

- s :

-

Entropy \(\left( {{{\text{J}}}\,{{\text{K}}^{-1}}} \right)\)

- \(\dot{S}\) :

-

Rate of entropy per unit length \( \left( {{{\text{W}}}\,{{{\text{m}}^{-1} \,{\text{K}}^{-1}}}} \right) \)

- T :

-

Temperature \(\left( {\text{K}} \right)\)

- \(T_{{\text{w}}}\) :

-

Wall temperature \(\left( {\text{K}} \right)\)

- t :

-

Time (s)

- x :

-

Vapor quality

- α :

-

Thermal diffusivity \(\left( {\frac{{{\text{m}}^{2}}}{{\text{s}}}} \right)\)

- γ :

-

Influence of heating surface material

- δ :

-

Thickness of micro layer (m)

- \(\theta\) :

-

Contact angle

- μ :

-

Dynamic viscosity \(\left( {{\text{Pa}}\,{\text{s}}} \right)\)

- \(\nu\) :

-

Momentum diffusivity \(\left( {{{{\text{m}}^{2}}}\,{{\text{s}}^{-1}}} \right)\)

- ρ :

-

Density \(\left( {{{{\text{kg}}}}\,{{{\text{m}}^{-3}}}} \right)\)

- σ :

-

Surface tension \(\left( {{{\text{N}}}\,{{\text{m}}^{-1}}} \right)\)

- \(\Gamma\) :

-

Perimeter (m)

- \({\text{bub}}\) :

-

Bubble

- \({\text{d}}\) :

-

Dry

- \({\text{g}}\) :

-

Growth

- \({\text{gen}}\) :

-

Generation

- \({\text{l}}\) :

-

Liquid

- \({\text{me}}\) :

-

Micro-layer evaporation

- \({\text{nc}}\) :

-

Natural convection

- \({\text{r}}\) :

-

Reformation

- \({\text{tot}}\) :

-

Total

- \({\text{v}}\) :

-

Vapor

- \({\text{w}}\) :

-

Waiting

- CHF:

-

Critical heat flux

- HTC:

-

Heat transfer coefficient

- MHF:

-

Minimum heat flux

- NSD:

-

Nucleation site density

- ONB:

-

Onset of nucleate boiling

References

Kim DE, Yu DI, Jerng DW, Kim MH, Ahn HS. Review of boiling heat transfer enhancement on micro/nanostructured surfaces. Exp Thermal Fluid Sci. 2015;66:173–96.

Yu B, Cheng P. A fractal model for nucleate pool boiling heat transfer. Heat Transf. 2002;124(6):1117–24.

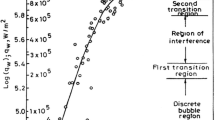

Nukiyama S. The maximum and minimum values of the heat Q transmitted from metal to boiling water under atmospheric pressure. Int J Heat Mass Transf. 1966;9(12):1419–33.

Liang G, Mudawar I. Review of spray cooling—part 2: high temperature boiling regimes and quenching applications. Int J Heat Mass Transf. 2017;115:1206–22.

Liang G, Mudawar I. Review of spray cooling—part 1: single-phase and nucleate boiling regimes, and critical heat flux. Int J Heat Mass Transf. 2017;115:1174–205.

Saffari H, Moghadasi H, Malekian N, Hosseinalipour SM (2019) Modeling heat transfer in nucleate pool boiling: influence of nucleation sites density, contact angle and Prandtl number. In: The third international conference on innovation and research in engineering sciences. Tbilisi, Georgia

Saffari H, Fathalizadeh H, Moghadasi H, Alipour S, Hosseinalipour SM. Experimental study of pool boiling enhancement for surface structuring with inclined intersected mesochannels using WEDM method on copper surfaces. Therm Anal Calorim. 2020;139:1849–61.

Liang G, Mudawar I. Review of pool boiling enhancement by surface modification. Int J Heat Mass Transf. 2019;128:892–933.

Deng D, Wan W, Feng J, Huang Q, Qin Y, Xie Y. Comparative experimental study on pool boiling performance of porous coating and solid structures with reentrant channels. Appl Therm Eng. 2016;107:420–30.

Moghadasi H, Saffari H, Malekian N. Experimental and semi-analytical investigation of heat transfer in nucleate pool boiling by considering surface structuring methods. Exp Heat Transf 2020;1–21. https://doi.org/10.1080/08916152.2020.1743385.

Moghadasi H, Saffari H. Experimental study of nucleate pool boiling heat transfer improvement utilizing micro/nanoparticles porous coating on copper surfaces. Int J Mech Sci. 2021;196:106270.

Moghadasi H, Malekian N, Saffari H, Mirza Gheitaghy A, Zhang GQ. Recent advances in the critical heat flux amelioration of pool boiling surfaces using metal oxide nanoparticle deposition. Energies. 2020;13(15):4026.

Mehdikhani A, Moghadasi H, Saffari H. An experimental investigation of pool boiling augmentation using four-step electrodeposited micro/nanostructured porous surface in distilled water. Int J Mech Sci. 2020;187:105924.

Mukherjee S, Mishra PC, Chaudhuri P. Pool boiling performance of aqueous Al2O3 and TiO2 nanofluids on a horizontally placed flat polished surface: an experimental investigation. J Therm Anal Calorim 2020;1–19. https://doi.org/10.1007/s10973-020-09995-z.

Kamel MS, Al-agha MS, Lezsovits F, Mahian O. Simulation of pool boiling of nanofluids by using Eulerian multiphase model. J Therm Anal Calorim.2019;142:1–13.

Gajghate SS, Barathula S, Das S, Saha BB, Bhaumik S. Experimental investigation and optimization of pool boiling heat transfer enhancement over graphene-coated copper surface. J Therm Anal Calorim. 2019;140:1393–411.

Safaei MR, Tlili I, Gholamalizadeh E, Abbas T, Alkanhal TA, Goodarzi M, Dahari M. Thermal analysis of a binary base fluid in pool boiling system of glycol–water alumina nano-suspension. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09911-5.

Chi-Yeh H, Griffith P. The mechanism of heat transfer in nucleate pool boiling—part I: bubble initiaton, growth and departure. Int J Heat Mass Transf. 1965;8(6):887–904.

Judd R, Hwang K. A comprehensive model for nucleate pool boiling heat transfer including microlayer evaporation. Heat Transf. 1976;98(4):623–9.

Paul D, Abdel-Khalik S. A statistical analysis of saturated nucleate boiling along a heated wire. Int J Heat Mass Transf. 1983;26(4):509–19.

Li Y-Y, Liu Z-H, Wang G-S. A predictive model of nucleate pool boiling on heated hydrophilic surfaces. Int J Heat Mass Transf. 2013;65:789–97.

Benjamin R, Balakrishnan A. Nucleate pool boiling heat transfer of pure liquids at low to moderate heat fluxes. Int J Heat Mass Transf. 1996;39(12):2495–504.

Hibiki T, Ishii M. Active nucleation site density in boiling systems. Int J Heat Mass Transf. 2003;46(14):2587–601.

Serret D, Guignard S, Tadrist L. Nucleate boiling on a single site: contact angle analysis for a quasi-2D growing vapour bubble. Microgr Sci Technol. 2009;21(1–2):101–5.

Chung HJ, No HC. A nucleate boiling limitation model for the prediction of pool boiling CHF. Int J Heat Mass Transf. 2007;50(15–16):2944–51.

Chen L, Meng F, Sun F. Thermodynamic analyses and optimization for thermoelectric devices: The state of the arts. Sci China Technol Sci. 2016;59(3):442–55.

Chen L, Wu C, Sun F. Finite time thermodynamic optimization or entropy generation minimization of energy systems. J Non Equilib Thermodyn. 1999;24(4):327–59.

Ghanbarpour M, Khodabandeh R. Entropy generation analysis of cylindrical heat pipe using nanofluid. Thermochim Acta. 2015;610:37–46.

Orhan MF, Erek A, Dincer I. Entropy generation during a phase-change process in a parallel plate channel. Thermochim Acta. 2009;489(1–2):70–4.

Popovic M. Comparative study of entropy and information change in closed and open thermodynamic systems. Thermochim Acta. 2014;598:77–81.

Abdous MA, Saffari H, Avval HB, Khoshzat M. The study of entropy generation during flow boiling in a micro-fin tube. Int J Refrig. 2016;68:76–93.

Holagh SG, Abdous MA, Shamsaiee M, Saffari H. Assessment of heat transfer enhancement technique in flow boiling conditions based on entropy generation analysis: twisted-tape tube. Heat Mass Transf. 2020;56(2):429–43.

Awad MM. A review of entropy generation in microchannels. Adv Mech Eng. 2015;7(12):1687814015590297.

Manjunath K, Kaushik S. Second law efficiency analysis of heat exchangers. Heat Transf Asian Res. 2015;44(2):89–108.

Manjunath K, Kaushik S. Second law thermodynamic study of heat exchangers: a review. Renew Sustain Energy Rev. 2014;40:348–74.

Ahmad S, Nadeem S, Ullah N. Entropy generation and temperature-dependent viscosity in the study of SWCNT–MWCNT hybrid nanofluid. Appl Nanosci. 2020;10:5107–119.

Ahmad S, Nadeem S. Cattaneo–Christov-based study of SWCNT–MWCNT/EG Casson hybrid nanofluid flow past a lubricated surface with entropy generation. Appl Nanosci. 2020;10:5449–458.

Aminian E, Moghadasi H, Saffari H, Gheitaghy AM. Investigation of forced convection enhancement and entropy generation of nanofluid flow through a corrugated minichannel filled with a porous media. Entropy. 2020;22(9):1008.

Pordanjani AH, Aghakhani S, Karimipour A, Afrand M, Goodarzi M. Investigation of free convection heat transfer and entropy generation of nanofluid flow inside a cavity affected by magnetic field and thermal radiation. J Therm Anal Calorim. 2019;137(3):997–1019.

Darbari B, Rashidi S, Keshmiri A. Nanofluid heat transfer and entropy generation inside a triangular duct equipped with delta winglet vortex generators. J Therm Anal Calorim. 2019;140:1045–55.

Shi E, Zang X, Jiang C, Mohammadpourfard M. Entropy generation analysis for thermomagnetic convection of paramagnetic fluid inside a porous enclosure in the presence of magnetic quadrupole field. J Therm Anal Calorim. 2020;139(3):2005–22.

Bibi F, Hayat T, Farooq S, Khan A, Alsaedi A. Entropy generation analysis in peristaltic motion of Sisko material with variable viscosity and thermal conductivity. J Therm Anal Calorim. 2019;143:363–75.

Bejan A, Pfister PA Jr. Evaluation of heat transfer augmentation techniques based on their impact on entropy generation. Lett Heat Mass Transf. 1980;7(2):97–106.

Vargas J, Bejan A. Thermodynamic optimization of the match between two streams with phase change. Energy. 2000;25(1):15–33.

Dağtekin İ, Öztop HF, Şahin AZ. An analysis of entropy generation through a circular duct with different shaped longitudinal fins for laminar flow. Int J Heat Mass Transf. 2005;48(1):171–81.

Sahiti N, Krasniqi F, Fejzullahu X, Bunjaku J, Muriqi A. Entropy generation minimization of a double-pipe pin fin heat exchanger. Appl Therm Eng. 2008;28(17–18):2337–44.

Khairul MA, Saidur R, Rahman MM, Alim MA, Hossain A, Abdin Z. Heat transfer and thermodynamic analyses of a helically coiled heat exchanger using different types of nanofluids. Int J Heat Mass Transf. 2013;67:398–403.

Bianco V, Manca O, Nardini S. Entropy generation analysis of turbulent convection flow of Al2O3–water nanofluid in a circular tube subjected to constant wall heat flux. Energy Convers Manag. 2014;77:306–14.

Zehtabiyan-Rezaie N, Saffar-Avval M, Mirzaei M. Analytical and numerical investigation of heat transfer and entropy generation of stratified two-phase flow in mini-channel. Int J Therm Sci. 2015;90:24–37.

Wang C, Dhir V. Effect of surface wettability on active nucleation site density during pool boiling of water on a vertical surface. Heat Transf. 1993;115(3):659–69.

Xiao B, Yu B. A fractal model for critical heat flux in pool boiling. Int J Therm Sci. 2007;46(5):426–33.

Xiao B. A new analytical model for heat transfer in pool boiling. Mod Phys Lett B. 2010;24(12):1229–36.

Mohanty RL, Das MK. A critical review on bubble dynamics parameters influencing boiling heat transfer. Renew Sustain Energy Rev. 2017;78:466–94.

Khan MR, Pan K, Khan AU, Nadeem S. Dual solutions for mixed convection flow of SiO2–Al2O3/water hybrid nanofluid near the stagnation point over a curved surface. Phys A Stat Mech Appl. 2020;547:123959.

Moghadasi H, Aminian E, Saffari H, Mahjoorghani M, Emamifar A. Numerical analysis on laminar forced convection improvement of hybrid nanofluid within a U-Bend pipe in porous media. Int J Mech Sci. 2020;179.

Aminian E, Moghadasi H, Saffari H. Magnetic field effects on forced convection flow of a hybrid nanofluid in a cylinder filled with porous media: a numerical study. J Therm Anal Calorim. 2020;141:1–13.

Malekian S, Fathi E, Malekian N, Moghadasi H, Moghimi M. Analytical and numerical investigations of unsteady graphene oxide nanofluid flow between two parallel plates. Int J Thermophys. 2018;39(9):100.

Ahmadi AA, Khodabandeh E, Moghadasi H, Malekian N, Akbari OA, Bahiraei M. Numerical study of flow and heat transfer of water–Al2O3 nanofluid inside a channel with an inner cylinder using Eulerian–Lagrangian approach. J Therm Anal Calorim. 2018;132(1):651–65.

Ahmad S, Nadeem S. Analysis of activation energy and its impact on hybrid nanofluid in the presence of hall and ion slip currents. Appl Nanosci. 2020;10:5315–30.

Ahmad S, Nadeem S. Application of CNT-based micropolar hybrid nanofluid flow in the presence of Newtonian heating. Appl Nanosci. 2020;10:5265–277.

Muhammad N, Nadeem S, Issakhov A. Finite volume method for mixed convection flow of Ag–ethylene glycol nanofluid flow in a cavity having thin central heater. Phys A. 2020;537:122738.

Van Stralen S, Sohal M, Cole R, Sluyter W. Bubble growth rates in pure and binary systems: combined effect of relaxation and evaporation microlayers. Int J Heat Mass Transf. 1975;18(3):453–67.

Sernas V, Hooper F. The initial vapor bubble growth on a heated wall during nucleate boiling. Int J Heat Mass Transf. 1969;12(12):1627–39.

Del Valle VH, Kenning D. Subcooled flow boiling at high heat flux. Int J Heat Mass Transf. 1985;28(10):1907–20.

Dhir V. Nucleate and transition boiling heat transfer under pool and external flow conditions. Int J Heat Fluid Flow. 1991;12(4):290–314.

Mikic B, Rohsenow W. A new correlation of pool-boiling data including the effect of heating surface characteristics. Heat Transf. 1969;91(2):245–50.

Arshadi SS, Saffari H, Gheitaghi A. Analytical and experimental investigation of nucleate pool boiling heat transfer on copper hydrophilic surfaces. Iran J Mech Eng. 2015;1240:012093.

Hsu C-C, Chen P-H. Surface wettability effects on critical heat flux of boiling heat transfer using nanoparticle coatings. Int J Heat Mass Transf. 2012;55:3713–719.

Phan HT, Caney N, Marty P, Colasson S, Gavillet J. How does surface wettability influence nucleate boiling? Comptes Rendus Mécanique. 2009;337(5):251–9.

Coulson JM, Richardson JF, Backhurst JR, Harker JH. Chemical engineering: fluid flow, heat transfer and mass transfer, vol. 1. Oxford: Butterworth-Heinemann; 1999.

Cengel YA, Klein S, Beckman W. Heat transfer: a practical approach, vol. 141. New York: McGraw-Hill; 1998.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Moghadasi, H., Malekian, N., Aminian, E. et al. Thermodynamic analysis of entropy generation due to energy transfer through circular surfaces under pool boiling condition. J Therm Anal Calorim 147, 2495–2508 (2022). https://doi.org/10.1007/s10973-021-10561-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10561-4