Abstract

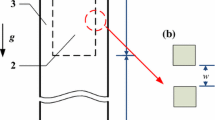

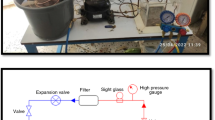

Based on innovative design, a liquid–vapor separation plate condenser with excellent heat transfer performance is invented. It takes less time to discharge condensate from the refrigerant channel and get a thinner liquid film in condensing channel with the new-type condenser than with the conventional one. The evaluation of the heat transfer performance of the liquid–vapor separation plate condenser and the optimization of its structure design is realized with a validated mathematical model. In this numerical simulation, the performance evaluation criterion and penalty factor are used to assess the refrigerant side performance, while the exergy efficiency is used to evaluate the overall performance, which includes the water-side performance. According to the simulation results, the optimal structure of the liquid–vapor separation plate condenser is achieved when altitude ratio is equal to 0.6 and length ratio is equal to 0.5. In this structure, when the condensation temperature of refrigerant R410A is 20 °C, the heat flux is kW m−2, the mass flux is 50 kg m−2 s−1, the performance evaluation criterion is at 1.13, the penalty factor is at 0.89, and the exergy efficiency is at 0.34. All these values outperform those of conventional plate condenser. Compared with conventional one, the heat transfer coefficients of refrigerant of liquid–vapor separation plate condenser increase by 15.98%, and its the pressure drop increases by 16.45% under the setting conditions.

Similar content being viewed by others

Abbreviations

- A :

-

Effective heat transfer area [m2]

- b :

-

Corrugation altitude [m]

- D h :

-

Hydraulic diameter [m]

- Ė :

-

Exergy flow [kJ s−1]

- f :

-

Friction factor

- e :

-

Specific exergy flow [kJ kg−1]

- G :

-

Mass flux [kg m−2 s−1]

- g :

-

Gravitational acceleration [m s−2]

- h :

-

Specific enthalpy [J kg−1]

- HTCr:

-

Heat transfer coefficient of refrigerant [W m−2 K−1]

- L :

-

Plate height [m]

- ṁ :

-

Mass flow rate [kg s−1]

- P r :

-

Prandtl number

- q :

-

Heat flux [W m-2]

- Re :

-

Reynolds number

- s :

-

Specific entropy [kJ kg−1 K−1]

- T :

-

Temperature [°C]

- u :

-

Flow velocity[m s−1]

- v :

-

Specific volume [m3 kg−1]

- x :

-

Vapor quality

- ρ :

-

Density [kg m−3]

- μ :

-

Dynamic viscosity [Pa s]

- λ :

-

Thermal conductivity [W m−1 K−1)]

- ν :

-

Kinematic viscosity [m2 s−1]

- γ :

-

Latent heat of vaporization [J kg−1]

- β :

-

Corrugation angle [rad]

- φ :

-

Enlargement factor

- Δp :

-

Pressure drop [Pa]

- ave:

-

Average value

- eq:

-

Equivalent

- CPC:

-

Conventional plate condenser

- fr:

-

Friction

- in:

-

Inlet

- k :

-

No. k path, k = 1,2

- l:

-

Liquid

- LVSPC:

-

Liquid–vapor separation plate condenser

- out:

-

Outlet

- po:

-

Port

- g :

-

Gas

- r :

-

Refrigerant

- total:

-

Total

- w :

-

Water

- wall:

-

Liquid against plate wall

- 1:

-

LVSPC-part1

- 2:

-

LVSPC-part2

References

Han X, Chen N, Yan J, et al. Thermodynamic analysis and life cycle assessment of supercritical pulverized coal-fired power plant integrated with No.0 feedwater pre-heater under partial loads. J Clean Prod. 2019;233:1106–22. https://doi.org/10.1016/j.jclepro.2019.06.159.

Wang G, Yao Y, Chen Z, et al. Thermodynamic and optical analyses of a hybrid solar CPV/T system with high solar concentrating uniformity based on spectral beam splitting technology. Energy. 2019;166:256–66. https://doi.org/10.1016/j.energy.2018.10.089.

Zhao H, Li Y, Song Q, et al. Investigation on the physicochemical structure and gasification reactivity of nascent pyrolysis and gasification char prepared in the entrained flow reactor. Fuel. 2019;240:126–37. https://doi.org/10.1016/j.fuel.2018.11.145.

Luo XL, Yi ZT, Zhang BJ, et al. Mathematical modelling and optimization of the liquid separation condenser used in organic rankine cycle. Appl Energy. 2017;185(2):1309–23. https://doi.org/10.1016/j.apenergy.2015.12.073.

Luo XL, Xu JJ, Chen Y, et al. Mathematical optimization of the liquid separation condenser used in the organic rankine cycle. Energy Proc. 2015;75:3127–32. https://doi.org/10.1016/j.egypro.2015.07.645.

Zhong TM, Chen Y, Zheng WX, et al. Experimental investigation on micro-channel condensers with and without liquid–vapor separation headers. Appl Therm Eng. 2014;73:1510–8. https://doi.org/10.1016/j.applthermaleng.2014.08.047.

Zhong TM, Chen Y, Yang QC, et al. Experimental investigation on the thermodynamic performance of double-row liquid–vapor separation microchannel condenser. Int J Refrig. 2016;67:373–82. https://doi.org/10.1016/j.ijrefrig.2016.02.020.

Chen JY, Ding R, Li YH, et al. Application of a vapor-liquid separation heat exchanger to the air conditioning system at cooling and heating modes. Int J Refrig. 2018;100:27–36. https://doi.org/10.1016/j.ijrefrig.2018.10.030.

Luo XL, Liang ZH, Guo GQ, et al. Thermo-economic analysis and optimization of a zoetropic fluid organic Rankine cycle with liquid–vapor separation during condensation. Energy Convers Manag. 2017;148:517–32. https://doi.org/10.1016/j.enconman.2017.06.002.

Yao Y, Chen Y, Chen JY, et al. Comparative study of heat transfer enhancement on liquid–vapor separation plate condenser. Open Phys. 2020;18:48–57. https://doi.org/10.1515/phys-2020-0006.

Kuo WS, Lie YM, Hsieh YY, et al. Condensation heat transfer and pressure drop of refrigerant R-410A flow in a vertical plate heat exchanger. Int J Heat Mass Transf. 2005;48:5205–20. https://doi.org/10.1115/1.2825923.

Kim YS, Master. thesis, Yonsei University ,Seoul, Korea,1999

Muley A, Manglik RM, et al. Experimental study of turbulent flow heat transfer and pressure drop in a plate heat exchanger with chevron plates. J Heat Transf. 1999;121:110–7. https://doi.org/10.1115/1.2825923.

Xie J, Xu JJ, Cheng Y, et al. Condensation heat transfer of R245fa in tubes with and without lyophilic porous-membrane-tube insert. Int J Heat Mass Transf. 2015;88:261–75. https://doi.org/10.1016/j.ijheatmasstransfer.2015.04.081.

Cavallini A, Brown JS, Col DD, et al. In-tube condensation performance of refrigerants considering penalization terms (exergy losses) for heat transfer and pressure drop. Int J Heat Mass Transf. 2010;5:2885–96. https://doi.org/10.1016/j.ijheatmasstransfer.2010.02.007.

Chen JY, Hans H, Bjorn P, et al. Conventional and advanced exergy analysis of an ejector refrigeration system. Appl Energy. 2015;144:139–51. https://doi.org/10.1016/j.apenergy.2015.01.139.

Chen JY, Zhu KD, Luo XL, et al. Application of liquid-separation condensation to plate heat exchanger: Comparative studies. Appl Therm Eng. 2019;157:113739. https://doi.org/10.1016/j.applthermaleng.2019.113739.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yao, Y., Chen, Y., Chen, J. et al. Numerical simulation and structure optimization of a liquid–vapor separation plate condenser. J Therm Anal Calorim 144, 2357–2367 (2021). https://doi.org/10.1007/s10973-021-10549-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-021-10549-0