Abstract

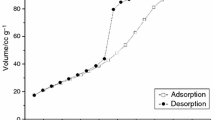

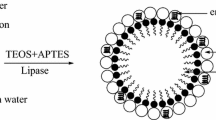

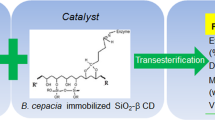

The present work aims to evaluate the synergistic effect of imidazolium-based ionic liquids (IL) in the preparation and immobilization of Burkholderia cepacia lipase in a new hybrid support of poly(hydroxybutyrate-co-hydroxyvalerate) (PHBV) and silica. In addition, these biocatalysts were applied in transesterification reactions of crude coconut oil for the production of ethyl esters. Lipase immobilized on hybrid support with [C4min][NTf2] or [C6min][NTf2] ionic liquid exhibited nearly ≈ 1.6-fold immobilization yield greater than IB-Control. The use of IL during the preparation of the hybrid support promoted changes in its morphological structure as presented by B.E.T. and FTIR. Thermogravimetric analyzes were used to characterize the prepared derivatives and support the results of immobilization yields and the synergic effect of IL used. Transesterification reactions applying biocatalysts showed that the conversion maximum in esters (59%) was found under conditions of molar ratio 1:7 (oil:ethanol) in 72 h of reaction. These results were obtained using [C4min][NTf2] during the preparation of the hybrid support for the immobilization of Burkholderia cepacia lipase, thus showing the potential of these new biocatalysts.

Similar content being viewed by others

References

Ben Bacha A, Moubayed NMS, Al-Assaf A. An organic solvent-stable lipase from a newly isolated Staphylococcus aureus ALA1 strain with potential for use as an industrial biocatalyst. Biotechnol Appl Biochem. 2016;63(3):378–90. https://doi.org/10.1002/bab.1381.

Badgujar VC, Badgujar KC, Yeole PM, Bhanage BM. Immobilization of Rhizomucor miehei lipase on a polymeric film for synthesis of important fatty acid esters: kinetics and application studies. Bioprocess Biosyst Eng. 2017;40(10):1463–78. https://doi.org/10.1007/s00449-017-1804-0.

Barbosa MS, Freire CCC, Almeida LC, Freitas LS, Souza RL, Pereira EB et al. Optimization of the enzymatic hydrolysis of Moringa oleifera Lam oil using molecular docking analysis for fatty acid specificity. Biotechnol Appl Biochem. 2019. https://doi.org/10.1002/bab.1793.

Brady D, Jordaan J, Simpson C, Chetty A, Arumugam C, Moolman FS. Spherezymes: A novel structured self-immobilisation enzyme technology. BMC Biotechnol. 2008;8(1):8. https://doi.org/10.1186/1472-6750-8-8.

Ma L, Zhou L, Jiang Y, He Y, Wang L, Gao J. Lipase based static emulsions as efficient biocatalysts for biodiesel production. J Chem Technol Biotechnol. 2017;92(6):1248–55. https://doi.org/10.1002/jctb.5118.

Barsé LQ, Graebin NG, Cipolatti EP, Robert JM, Pinto MCC, Pinto JCCS, et al. Production and optimization of isopropyl palmitate via biocatalytic route using home-made enzymatic catalysts. J Chem Technol Biotechnol. 2019;94(2):389–97. https://doi.org/10.1002/jctb.5782.

Balcão VM, Paiva AL, Xavier MF. Bioreactors with immobilized lipases: State of the art. Enzyme Microb Technol. 1996;18(6):392–416. https://doi.org/10.1016/0141-0229(95)00125-5.

Kennedy JF, Cabral JMS. Enzyme Technology. In: Rehm HJ, Reed G, editors. Biotechnology—a comprehensive treatise. Weinheim: VCH Verlagsgesellscbaft; 1987. p. 347–404.

Kumar GS, Rather GM, Gurramkonda C, Reddy BR. Thermostable α-amylase immobilization: Enhanced stability and performance for starch biocatalysis. Biotechnol Appl Biochem. 2016;63(1):57–66. https://doi.org/10.1002/bab.1350.

Alves NR, Pereira MM, Giordano RLC, Tardioli PW, Lima ÁS, Soares CMF, et al. Design for preparation of more active cross-linked enzyme aggregates of Burkholderia cepacia lipase using palm fiber residue. Bioprocess Biosyst Eng. 2020. https://doi.org/10.1007/s00449-020-02419-0.

Padilha GS, Tambourgi EB, Alegre RM. Evaluation of lipase from Burkholderia cepacia immobilized in alginate beads and application in the synthesis of banana flavor (isoamyl acetate). Chem Eng Commun. 2018;205(1):23–33. https://doi.org/10.1080/00986445.2017.1370707.

Shuai W, Das RK, Naghdi M, Brar SK, Verma M. A review on the important aspects of lipase immobilization on nanomaterials. Biotechnol Appl Biochem. 2017;64(4):496–508. https://doi.org/10.1002/bab.1515.

Simões AS, Mori RY, Faria R, Castro HF, Mendes AA. Desempenho da matriz híbrida SiO2-quitosana na imobilização da lipase microbiana de Candida rugosa. Quím Nova. 2011;34:33–8. https://doi.org/10.1590/S0100-40422011000100007.

Zdarta J, Meyer SA, Jesionowski T, Pinelo M. A General overview of support materials for enzyme immobilization: Characteristics, properties, practical utility. Catalysts. 2018;8(2). doi:https://doi.org/10.3390/catal8020092.

Kołodziejczak-Radzimska A, Zdarta J, Ciesielczyk F, Jesionowski T. An organofunctionalized MgO·SiO2 hybrid support and its performance in the immobilization of lipase from Candida rugosa. Korean J Chem Eng. 2018;35(11):2220–31. https://doi.org/10.1007/s11814-018-0146-1.

Llerena Suster CR, Toledo MV, Fittipaldi AS, Morcelle SR, Briand LE. Lipase B of Candida antarctica co-adsorbed with polyols onto TiO2 nanoparticles for improved biocatalytic performance. J Chem Technol Biotechnol. 2017;92(11):2870–80. https://doi.org/10.1002/jctb.5305.

Gascón V, Castro-Miguel E, Díaz-García M, Blanco RM, Sanchez-Sanchez M. In situ and post-synthesis immobilization of enzymes on nanocrystalline MOF platforms to yield active biocatalysts. J Chem Technol Biotechnol. 2017;92(10):2583–93. https://doi.org/10.1002/jctb.5274.

Benvenutti EV, Moro CC, Costa TMH, Gallas MR. Silica based hybrid materials obtained by the sol-gel method. Quím Nova. 2009;32:1926–33. https://doi.org/10.1590/S0100-40422009000700039.

Nowacka M, Klapiszewski Ł, Norman M, Jesionowski T. Dispersive evaluation and surface chemistry of advanced, multifunctional silica/lignin hybrid biomaterials. Cent Eur J Chem. 2013;11(11):1860–73. https://doi.org/10.2478/s11532-013-0322-4.

Naushad M, Alothman ZA, Khan AB, Ali M. Effect of ionic liquid on activity, stability, and structure of enzymes: A review. Int J Biol Macromol. 2012;51(4):555–60. https://doi.org/10.1016/j.ijbiomac.2012.06.020.

Zhao H. Methods for stabilizing and activating enzymes in ionic liquids—a review. J Chem Technol Biotechnol. 2010;85(7):891–907. https://doi.org/10.1002/jctb.2375.

Gao J, Ndong RS, Shiflett MB, Wagner NJ. Creating nanoparticle stability in ionic liquid [C4mim][BF4] by inducing solvation layering. ACS Nano. 2015;9(3):3243–53. https://doi.org/10.1021/acsnano.5b00354.

Putz A-M, Len A, Ianăşi C, Savii C, Almásy L. Ultrasonic preparation of mesoporous silica using pyridinium ionic liquid. Korean J Chem Eng. 2016;33(3):749–54. https://doi.org/10.1007/s11814-016-0021-x.

Greaves TL, Drummond CJ. Protic ionic liquids: properties and applications. Chem Rev. 2008;108(1):206–37. https://doi.org/10.1021/cr068040u.

Karimi B, Tavakolian M, Akbari M, Mansouri F. Ionic liquids in asymmetric synthesis: an overall view from reaction media to supported ionic liquid catalysis. ChemCatChem. 2018;10(15):3173–205. https://doi.org/10.1002/cctc.201701919.

Martins SRS, dos Santos A, Fricks AT, Lima ÁS, Mattedi S, Silva DP, et al. Protic ionic liquids influence on immobilization of Lipase Burkholderia cepacia on hybrid supports. J Chem Technol Biotechnol. 2017;92(3):633–41. https://doi.org/10.1002/jctb.5044.

Paula AV, Moreira ABR, Braga LP, Castro HFd, Bruno LM. Comparative performance of Candida rugosa lipase immobilized on polysiloxane polyvinyl alcohol hybrid support using different methodologies. Quím Nova. 2008;31:35–40. https://doi.org/10.1590/S0100-40422008000100007

Soares CMF, De Castro HF, De Moraes FF, Zanin GM. Characterization and utilization of Candida rugosa lipase immobilized on controlled pore silica. Appl Biochem Biotechnol. 1999;79(1):745–57. https://doi.org/10.1385/ABAB:79:1-3:745.

Souza RL, Faria ELP, Figueiredo RT, Mettedi S, Santos OAA, Lima AS, et al. Protic ionic liquid applied to enhance the immobilization of lipase in sol–gel matrices. J Therm Anal Calorim. 2017;128(2):833–40. https://doi.org/10.1007/s10973-016-5950-4.

Cabrera-Padilla RY, Lisboa MC, Pereira MM, Figueiredo RT, Franceschi E, Fricks AT, et al. Immobilization of Candida rugosa lipase onto an eco-friendly support in the presence of ionic liquid. Bioprocess Biosyst Eng. 2015;38(5):805–14. https://doi.org/10.1007/s00449-014-1322-2.

Cabrera-Padilla RY, Lisboa MC, Fricks AT, Franceschi E, Lima AS, Silva DP, et al. Immobilization of Candida rugosa lipase on poly(3-hydroxybutyrate-co-hydroxyvalerate): a new eco-friendly support. J Ind Microbiol Biot. 2012;39(2):289–98. https://doi.org/10.1007/s10295-011-1027-3.

Freitas L, Da Rós PCM, Santos JC, de Castro HF. An integrated approach to produce biodiesel and monoglycerides by enzymatic interestification of babassu oil (Orbinya sp). Process Biochem. 2009;44(10):1068–74. https://doi.org/10.1016/j.procbio.2009.05.011.

Fan Y, Wu G, Su F, Li K, Xu L, Han X, et al. Lipase oriented-immobilized on dendrimer-coated magnetic multi-walled carbon nanotubes toward catalyzing biodiesel production from waste vegetable oil. Fuel. 2016;178:172–8. https://doi.org/10.1016/j.fuel.2016.03.071.

Cabrera-Padilla RY, Melo EB, Pereira MM, Figueiredo RT, Fricks AT, Franceschi E, et al. Use of ionic liquids as additives for the immobilization of lipase from Bacillus sp. J Chem Technol Biotechnol. 2015;90(7):1308–16. https://doi.org/10.1002/jctb.4438.

Almeida RM, Marques AC. Characterization of Sol-Gel materials by infrared spectroscopy. In: Klein L, Aparicio M, Jitianu A, editors. Handbook of Sol-Gel Science and Technology: Processing, Characterization and Applications. Cham: Springer International Publishing; 2018. p. 1121–51.

Chemspider. The free chemical database. http://www.chemspider.com. 03 January 2020.

Sánchez DA, Tonetto GM, Ferreira ML. Burkholderia cepacia lipase: A versatile catalyst in synthesis reactions. Biotechnol Bioeng. 2018;115(1):6–24. https://doi.org/10.1002/bit.26458.

Qin J, Zou X, Lv S, Jin Q, Wang X. Influence of ionic liquids on lipase activity and stability in alcoholysis reactions. RSC Adv. 2016;6(90):87703–9. https://doi.org/10.1039/C6RA19181A.

Pan S, Liu X, Xie Y, Yi Y, Li C, Yan Y, et al. Esterification activity and conformation studies of Burkholderia cepacia lipase in conventional organic solvents, ionic liquids and their co-solvent mixture media. Bioresource Technol. 2010;101(24):9822–4. https://doi.org/10.1016/j.biortech.2010.07.107.

Barbosa MS, Santos AJ, Carvalho NB, Figueiredo RT, Pereira MM, Lima ÁS, et al. Enhanced activity of immobilized lipase by phosphonium-based ionic liquids used in the support preparation and immobilization process. ACS Sustain Chem Eng. 2019;7(18):15648–59. https://doi.org/10.1021/acssuschemeng.9b03741.

Meera KMS, Sankar RM, Jaisankar SN, Mandal AB. Mesoporous and biocompatible surface active silica aerogel synthesis using choline formate ionic liquid. Colloid Surface B. 2011;86(2):292–7. https://doi.org/10.1016/j.colsurfb.2011.04.011.

Guisan JM. Immobilization of Enzymes and Cells. 2nd ed. Totowa-New Jersey: Humana Press; 2006.

Souza RL, Faria ELP, Figueiredo RT, Freitas LdS, Iglesias M, Mattedi S et al. Protic ionic liquid as additive on lipase immobilization using silica sol–gel. Enzyme Microb Technol. 2013;52(3):141–50. https://doi.org/10.1016/j.enzmictec.2012.12.007.

Mukherjee I, Mylonakis A, Guo Y, Samuel SP, Li S, Wei RY, et al. Effect of nonsurfactant template content on the particle size and surface area of monodisperse mesoporous silica nanospheres. Micropor Mesopor Mat. 2009;122(1):168–74. https://doi.org/10.1016/j.micromeso.2009.02.030.

Zou B, Song C, Xu X, Xia J, Huo S, Cui F. Enhancing stabilities of lipase by enzyme aggregate coating immobilized onto ionic liquid modified mesoporous materials. Appl Surf Sci. 2014;311:62–7. https://doi.org/10.1016/j.apsusc.2014.04.210.

Wan D, Tian L, Li X, Li B, Zhang Q. A versatile strategy for enzyme immobilization: Fabricating lipase/inorganic hybrid nanostructures on macroporous resins with enhanced catalytic properties. Biochem Eng J. 2018;139:101–8. https://doi.org/10.1016/j.bej.2018.08.010.

Nádia Ligianara Dewes N, Alessandro Rogério P, Clarice S, Marcelo M, Jamile Z, Rogério Marcos D. Optimization of olive oil hydrolysis process using immobilized lipase from Burkholderia cepacia sp. in Polyurethane. Acta Sci-Technol. 2017;39(4). doi:https://doi.org/10.4025/actascitechnol.v39i4.30770.

Carvalho BN, Vidal TB, Barbosa SA, Pereira MM, Mattedi S, Freitas DSL et al. Lipase immobilization on silica xerogel treated with protic ionic liquid and its application in biodiesel production from different oils. Int J Mol Sci. 2018;19(7). doi:https://doi.org/10.3390/ijms19071829.

Izrael Živković LT, Živković LS, Babić BM, Kokunešoski MJ, Jokić BM, Karadžić IM. Immobilization of Candida rugosa lipase by adsorption onto biosafe meso/macroporous silica and zirconia. Biochem Eng J. 2015;93:73–83. https://doi.org/10.1016/j.bej.2014.09.012.

Abdulla R, Ravindra P. Characterization of cross linked Burkholderia cepacia lipase in alginate and κ-carrageenan hybrid matrix. J Taiwan Inst Chem Eng. 2013;44(4):545–51. https://doi.org/10.1016/j.jtice.2013.01.003.

Barbosa AS, Lisboa JA, Silva MAO, Carvalho NB, Pereira MM, Fricks AT, et al. The novel mesoporous silica aerogel modified with protic ionic liquid for lipase immobilization. Quím Nova. 2016;39:415–22. https://doi.org/10.5935/0100-4042.20160042.

Pizarro C, Brañes MC, Markovits A, Fernández-Lorente G, Guisán JM, Chamy R, et al. Influence of different immobilization techniques for Candida Cylindracea lipase on its stability and fish oil hydrolysis. J Mol Catal B Enzym. 2012;78:111–8. https://doi.org/10.1016/j.molcatb.2012.03.012.

Martínez-Aragón M, Burghoff S, Goetheer ELV, de Haan AB. Guidelines for solvent selection for carrier mediated extraction of proteins. Sep Purif Technol. 2009;65(1):65–72. https://doi.org/10.1016/j.seppur.2008.01.028.

Cui JD, Jia SR. Optimization protocols and improved strategies of cross-linked enzyme aggregates technology: current development and future challenges. Crit Rev Biotechnol. 2015;35(1):15–28. https://doi.org/10.3109/07388551.2013.795516.

Tupufia SC, Jeon YJ, Marquis C, Adesina AA, Rogers PL. Enzymatic conversion of coconut oil for biodiesel production. Fuel Process Technol. 2013;106:721–6. https://doi.org/10.1016/j.fuproc.2012.10.007.

Ribeiro BD, Coelho MAZ, Barreto DW. Production of concentrated natural beta-carotene from buriti (Mauritia vinifera) oil by enzymatic hydrolysis. Food Bioprod Process. 2012;90(2):141–7. https://doi.org/10.1016/j.fbp.2011.02.003.

Michelin S, Penha FM, Sychoski MM, Scherer RP, Treichel H, Valério A, et al. Kinetics of ultrasound-assisted enzymatic biodiesel production from Macauba coconut oil. Renew Energy. 2015;76:388–93. https://doi.org/10.1016/j.renene.2014.11.067.

Acknowledgements

This study ws financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001; and Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors have no conflicts of interest to declare that are relevant to the content of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Martins, S.R.S., Andrade, S.M.S., Fricks, A.T. et al. Ionic liquid synergistic effect between preparation of hybrid supports and immobilization of lipase applied to esters production. J Therm Anal Calorim 147, 1143–1156 (2022). https://doi.org/10.1007/s10973-020-10408-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10408-4