Abstract

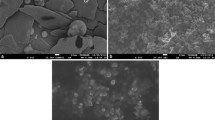

Silica plays an important role in aluminium-based materials. However, role of silica in aluminium matrix composite is not clear so far. In the present study, pure silica was successfully extracted from rice husk by thermal and chemical treatments. The extracted silica had undergone FESEM, FTIR, and XRD for characterizing the purity of silica particles. The results showed that the obtained silica particles were highly pure. The rice husk-extracted pure silica was used as reinforcement in graphite/aluminium matrix hybrid composites. Composites were made using powder metallurgy process followed by sintering. Reinforcements of silica and graphite in aluminium matrix composites were done at different compositions to control the hardness in order to improve machinability. The aluminium matrix hybrid composites had shown excellent physical, mechanical, and thermal properties in terms of surface strength along with light mass as well as controlled thermal conductivity. The hardness of the hybrid composites had increased significantly compared to the single phase aluminium and also was controlled by the combined effect of added silica nanoparticle and graphite flake as reinforcements. Beside mechanical properties, these hybrid composites showed significantly desired thermal properties, particularly lower thermal expansion than that of pristine aluminium. Hence, the newly developed rice husk-extracted pure silica reinforced graphite/aluminium matrix hybrid composites can be used as potential materials for various advanced applications including microelectronic devices, engine piston, and automobile components.

Similar content being viewed by others

Data availability

Not applicable.

References

Croissant JG, Fatieiev Y, Almalik A, Khashab NM. Mesoporous silica and organosilica nanoparticles: physical chemistry, biosafety, delivery strategies, and biomedical applications. Adv Healthc Mater. 2018;7(4):1700831.

Croissant JG, Brinker CJ. Biodegradable silica-based nanoparticles: dissolution kinetics and selective bond cleavage. In: Tamanoi F, editor. The enzymes, vol. 43. New York: Academic Press; 2018. p. 181–214.

Nakamura M. Organosilica nanoparticles and medical imaging. In: Tamanoi F, editor. Enzymes, vol. 44. New York: Academic Press; 2018. p. 137–73.

Cholkar K, Hirani ND, Natarajan C. Nanotechnology-based medical and biomedical imaging for diagnostics. In: Mitra AK, Cholkar K, Mandal A, editors. Emerging nanotechnologies for diagnostics, drug delivery and medical devices 2017. pp. 355–374.

Athinarayanan J, Periasamy VS, Alhazmi M, Alatiah KA, Alshatwi AA. Synthesis of biogenic silica nanoparticles from rice husks for biomedical applications. Ceram Int. 2015;41(1):275–81.

Ryan JG, Theis TN. Interconnects. In: Buschow KJ, Cahn RW, Flemings MC, Ilschner B, Kramer EJ, Mahajan S, editors. Encyclopedia of materials: science and technology. Oxford: Elsevier; 2001. p. 4128.

Dadabhai F, Gaspari F, Zukotynski S, Bland C. Reduction of silicon dioxide by aluminum in metal–oxide–semiconductor structures. J Appl Phys. 1996;80(11):6505–9.

Sangha SP, Jacobson DM, Ogilvy AJ, Azema M, Junai AA, Botter E. Novel aluminium-silicon alloys for electronics packaging. Eng Sci Educ J. 1997;6(5):195–201.

Mamaeva V, Sahlgren C, Lindén M. Mesoporous silica nanoparticles in medicine—recent advances. Adv Drug Deliv Rev. 2013;65(5):689–702.

Wang Y, Zhao Q, Han N, Bai L, Li J, Liu J, Che E, Hu L, Zhang Q, Jiang T, Wang S. Mesoporous silica nanoparticles in drug delivery and biomedical applications. NanomedNanotechnol Biol Med. 2015;11(2):313–27.

Heinz A, Haszler A, Keidel C, Moldenhauer S, Benedictus R, Miller WS. Recent development in aluminium alloys for aerospace applications. Mater Sci Eng, A. 2000;280(1):102–7.

Dursun T, Soutis C. Recent developments in advanced aircraft aluminium alloys. Mater Design (1980–2015). 2014;56:862–71.

Miller WS, Zhuang L, Bottema J, Wittebrood A, De Smet P, Haszler A, Vieregge A. Recent development in aluminium alloys for the automotive industry. Mater Sci Eng, A. 2000;280(1):37–49.

Yang HS, Kim DJ, Kim HJ. Rice straw–wood particle composite for sound absorbing wooden construction materials. Biores Technol. 2003;86(2):117–21.

Tham LM, Gupta M, Cheng L. Effect of limited matrix–reinforcement interfacial reaction on enhancing the mechanical properties of aluminium–silicon carbide composites. Acta Mater. 2001;49(16):3243–53.

Kok M. Production and mechanical properties of Al2O3 particle-reinforced 2024 aluminium alloy composites. J Mater Process Technol. 2005;161(3):381–7.

Zuhailawati H, Samayamutthirian P. Fabrication of low cost of aluminium, matrix composite reinforced with silica sand. J Phys Sci. 2007;18(1):47–55.

Saravanan S, Inokawa H, Tomoshige R, Raghukandan K. Effect of silicon carbide particles in microstructure and mechanical properties of dissimilar aluminium explosive cladding. J Manuf Process. 2019;47:32–40.

Sulaiman S, Marjom Z, Ismail MI, Ariffin MK, Ashrafi N. Effect of modifier on mechanical properties of aluminium silicon carbide (Al-SiC) composites. Proc Eng. 2017;184:773–7.

Suresha S, Sridhara BK. Effect of silicon carbide particulates on wear resistance of graphitic aluminium matrix composites. Mater Des. 2010;31(9):4470–7.

Tiwari S, Pradhan MK. Effect of rice husk ash on properties of aluminium alloys: a review. Mater Today Proc. 2017;4(2):486–95.

Stephenson T, Le Petitcorps Y, Quenisset JM. Silica-aluminium alloy composites: a kinetic study. Mater Sci Eng, A. 1991;135:101–4.

Mishra P, Mishra P, Rana RS. Effect of rice husk ash reinforcements on mechanical properties of aluminium alloy (lm6) matrix composites. Mater Today Proc. 2018;5(2):6018–22.

Kordatos K, Gavela S, Ntziouni A, Pistiolas KN, Kyritsi A, Kasselouri-Rigopoulou V. Synthesis of highly siliceous ZSM-5 zeolite using silica from rice husk ash. Microporous Mesoporous Mater. 2008;115(1–2):189–96.

Yuvakkumar R, Elango V, Rajendran V, Kannan N. High-purity nano silica powder from rice husk using a simple chemical method. J Exp Nanosci. 2014;9(3):272–81.

Sidharta I, Haryono JA, Devara AA. Properties of aluminum graphite composite prepared by stir casting. InAIP Conf Proc. 2018;1983(1):050019.

Suresha S, Sridhara BK. Friction characteristics of aluminium silicon carbide graphite hybrid composites. Mater Des. 2012;34:576–83.

Maruyama B, Ohuchi FS, Rabenberg L. Catalytic carbide formation at aluminium-carbon interfaces. J Mater Sci Lett. 1990;9(7):864–6.

Novak B, Tschöpe K, Ratvik AP, Grande T. Fundamentals of aluminium carbide formation. Light Met. 2012;2012:1343–8.

Emadi D, Whiting LV, Nafisi S, Ghomashchi R. Applications of thermal analysis in quality control of solidification processes. J Therm Anal Calorim. 2005;81:235–42.

Jerina L, Medved J, Godec M, Vončina M. Influence of the specific surface area of secondary material on the solidification process and microstructure of aluminium alloy AA7075. J Therm Anal Calorim. 2018;134(1):455–62.

Chakraverty A, Kaleemullah S. Conversion of rice husk into amorphous silica and combustible gas. Energy Convers Manag. 1991;32(6):565–70.

Karthikeyan P, Pramanik S. Effect of vibration of moulding on the gravity casted specimen during pouring of molten aluminium in metallic mould. IOP Conf Ser: Mater Sci Eng. 2018;402(1):012037.

Pramanik S, Agarwala P, Vasudevan K, Sarkar K. Human-lymphocyte cell friendly starch–hydroxyapatite biodegradable composites: Hydrophilic mechanism, mechanical, and structural impact. J Appl Polym Sci. 2020;137(30):48913.

Karthikeyan P, Pramanik S. Thermal fatigue cycle shock effects on physical and structural properties of H13 tool steels before and after heat treatments. IOP Conf Ser: Mater Sci Eng. 2020;912(5):052014.

Moradi A, Pramanik S, Ataollahi F, Kamarul T, Pingguan-Murphy B. Archimedes revisited: computer assisted micro-volumetric modification of the liquid displacement method for porosity measurement of highly porous light materials. Anal Methods. 2014;6(12):4396–401.

Moradi A, Ataollahi F, Sayar K, Pramanik S, Chong PP, Khalil AA, Kamarul T, Pingguan-Murphy B. Chondrogenic potential of physically treated bovine cartilage matrix derived porous scaffolds on human dermal fibroblast cells. J Biomed Mater Res, Part A. 2016;104(1):245–56.

Pramanik S, Ataollahi F, Pingguan-Murphy B, Oshkour AA, Osman NA. In vitro study of surface modified poly (ethylene glycol)-impregnated sintered bovine bone scaffolds on human fibroblast cells. Sci Rep. 2015;5:9806.

Chen XQ, Niu H, Li D, Li Y. Modeling hardness of polycrystalline materials and bulk metallic glasses. Intermetallics. 2011;19(9):1275–81.

Oshkour AA, Pramanik S, Mehrali M, Yau YH, Tarlochan F, Osman NA. Mechanical and physical behavior of newly developed functionally graded materials and composites of stainless steel 316L with calcium silicate and hydroxyapatite. J Mech Behav Biomed Mater. 2015;49:321–31.

Carruthers P. Theory of thermal conductivity of solids at low temperatures. Rev Mod Phys. 1961;33(1):92.

Childs BG. The thermal expansion of anisotropic metals. Rev Mod Phys. 1953;25(3):665.

Matyunin VM, Abusaif N, Marchenkov AY. Influence of grains and grain boundaries on hardness values. J Phys: Conf Ser. 2019;1399(4):044002.

Tahari MNA, Yarmo MA. Adsorption of CO2 on silica dioxide catalyst impregnated with various alkylamine. AIP Conf Proc. 2014;1614(1):334–41.

Galhotra P. Carbon dioxide adsorption on nanomaterials, Ph.D. thesis, University of Iowa. 2010. https://doi.org/10.17077/etd.detbvuv9.

Han X, Zhao J, Liu S, Yuan Y. Flame retardancy mechanism of poly (butylene terephthalate)/aluminum diethylphosphinate composites with an epoxy-functional polysiloxane. RSC Adv. 2014;4(32):16551–60.

Shen Y-L, Chawla N. On the correlation between hardness and tensile strength in particle reinforced metal matrix composites. Mater Sci Eng, A. 2001;297(1–2):44–7.

Khan M, Ud-Din R, Wadood A, Husain SW, Akhtar S, Aune RE. Physical and mechanical properties of graphene nanoplatelet-reinforced Al6061-T6 composites processed by spark plasma sintering. JOM. 2020;72:1–10.

Al-Fadhalah K, Asi F. Aging behavior of aluminum alloy 6082 subjected to friction stir processing. Crystals. 2018;8(9):337.

Chamroune N, Mereib D, Delange F, Caillault N, Lu Y, Grosseau-Poussard JL, Silvain JF. Effect of flake powder metallurgy on thermal conductivity of graphite flakes reinforced aluminum matrix composites. J Mater Sci. 2018;53(11):8180–92.

Kaschnitz E, Funk W, Pabel T. Electrical resistivity measured by millisecond pulse-heating in comparison to thermal conductivity of the aluminium alloy Al–7Si–0.3 Mg at elevated temperature. High Temp Press. 2014;43:175–91.

Solórzano E, Reglero JA, Rodríguez-Pérez MA, Lehmhus D, Wichmann M, De Saja JA. An experimental study on the thermal conductivity of aluminium foams by using the transient plane source method. Int J Heat Mass Transf. 2008;51(25–26):6259–67.

Woodcraft AL. Predicting the thermal conductivity of aluminium alloys in the cryogenic to room temperature range. Cryogenics. 2005;45(6):421–31.

Rodríguez-Pérez MA, Reglero JA, Lehmhus D, Wichmann M, De Saja JA, Fernández A. The transient plane source technique (TPS) to measure thermal conductivity and its potential as a tool to detect in-homogeneities in metal foams. In: Smolenice C, S, editors. International Conference on Advanced Metallic Materials. 2003;Nov 5. pp 253–257.

Kang S-H, Han JJ, Hwang W-T, Lee S-M, Kim H-K. Failure analysis of die casting pins for an aluminum engine block. Eng Fail Anal. 2019;104:690–703.

Acknowledgements

Authors acknowledge Metalography and Foundry Laboratories, Department of Mechanical Engineering and Nanotechnology Research Centre, SRM Institute of Science and Technology for accessing their research facilities such as syntheses and XRD as well as FTIR, respectively.

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

Authors S.S., A.G., and A.J.M. performed the experiments having equal contribution. S.P. planed and supervised the project, and provided all the facilities. S.S., A.G. and S.P. wrote the manuscript. All authors interpreted the data and reviewed the entire manuscript.

Corresponding author

Ethics declarations

Conflict of interest

Authors do not have any conflict of interests.

Ethics approval and consent to participate

Not applicable.

Consent for publication

Not applicable.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Saini, S., Gupta, A., Mehta, A.J. et al. Rice husk-extracted silica reinforced graphite/aluminium matrix hybrid composite. J Therm Anal Calorim 147, 1157–1166 (2022). https://doi.org/10.1007/s10973-020-10404-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10404-8