Abstract

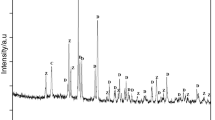

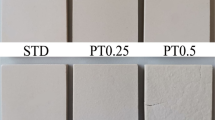

In the production of wall tiles, trends are moving toward larger-format wall tiles. Moisture expansion of larger-format wall tiles is one of the most important technological parameter that determine the quality of their service life. Clay, kaolin, quartz, carbonate and less fluxing materials are generally used in monoporosa tile recipes. In this study, alkali containing raw materials such as perlite, rhyolitic tuff, granite and nepheline syenite, were used instead of quartz and kaolin in the recipes. The investigated bodies are fired under industrial fast firing cycle at 1150 °C—50 min. Firing shrinkage, water absorption and color values (L*, a*, b*) of alkaline raw materials and bodies were measured. Thermal expansion coefficient and moisture expansion values of the bodies were determined by dilatometer and the sintering behavior of the representative formulations was evaluated using a double-beam non-contact optical dilatometer (ODHT). Phase and microstructural analyses were performed by XRD and SEM, respectively. As a result, the analytical data obtained from this study revealed that the alkaline/flux materials which have more or less similar chemical compositions, represent distinctly different physico-mechanical behavior. According to the petrographical examinations, whereas the holocrystalline textured alkaline materials such as nepheline syenite and granite decrease moisture expansion, the use of amorphous-glassy textured raw materials such as perlite and rhyolitic tuff increase moisture expansion in monoporosa tile body manufacturing. Using of the alkali raw materials as a partial replacement of quartz also enables the development of lower thermal expansion bodies.

Similar content being viewed by others

References

Amorós JL, Escardino A, E. Sanchez E, Zaera F. Dimensional stability in single-fired porous tile. In: Qualicer 2nd world congress on ceramic tile quality, Spain; 1992. p. 335–362.

Amoros JL, Orts MJ, Mestre S, Garcia-Ten J, Feliu C. Porous single-fired wall tile bodies: influence of quartz particle size on tile properties. J Eur Ceram Soc. 2010;30:17–28.

Kayacı K, Küçüker AS, Genç SC, Kara A. Utilization of a sandy clay in double—fired wall tiles. Ind Ceram. 2010;30(1):7–15.

Swapan KD, Kausik D, Nar S, Ritwik S. Shrinkage and strength behaviour of quartzitic and kaolinitic clays in wall tile compositions. Appl Clay Sci. 2005;29:137–43.

Escardino A, García-Ten J, Feliu C, Moreno A. Calcium carbonate thermal decomposition in white-body wall tile during firing. I. Kinetic study. J Eur Ceram Soc. 2010;30:1989–2001.

Tarhan M, Tarhan B, Aydın T. The Effect of fine fire clay sanitaryware wastes on ceramic wall tiles. Ceram Int. 2016;42(15):17110–5.

Sagadaes AM, Carvalho MA, Ferreira HC. Using phase diagrams to deal with moisture expansion. Ceram Int. 2003;29:947–54.

Vasic R, Vasic M. Phenomenon of moisture expansion and its influence on mechanical properties of brick clay products. Ceram Mater. 2011;63(1):54–7.

Abdrakhimov VZ, Abdrakhimova ES, Abdrakhimov DM. Moisture expansion of ceramic materials. Glass Ceram. 1998;55:30–8.

Almeida JV, Verreira VM, Corria AMS. Moısture expansion in ceramic building materials. Key Eng Mater. 1997;132:2176–9.

Plesingerova B, Klapac M, Kovalcikova M. Moisture expansion of porous biscuit bodies—reason of glaze cracking. Ceram Silikate. 2002;46(4):159–65.

Zvezdin DF, Kiryanov AV. Moisture expansion of ceramic tiles in double firing. Glass Ceram. 2006;63(1):20–1.

Cengiz Ö, Kara A. Effect of alkaline-earth oxides on firing behaviour of monoporoza wall tile bodies. J Ceram Proc R. 2018;19(3):189–97.

Aydın T, Tarhan M, Tarhan B. Addition of cement kiln dust in ceramic wall tile bodies. J Therm Anal Calorim. 2019;136:527–33.

Tarhan M, Tarhan B. Effect of usage of perlite on technical properties of ceramic wall tile. Int J Eng RD. 2018;10(1):94–100.

Klein G. Application of feldspar raw materials in the silicate ceramics. Interceram. 2001;50(1–2):8–11.

Bozkurt V, Kara A, Ucbas Y, Kayacı K, Ciftci M. Possible use of trachyte as a flux in floor tile production. Ind Ceram. 2006;26(2):87–94.

Espasito L, Salem A, Tucci A, Gualtieri A, Jazayeri SH. The use of nepheline syenite in a body mix for porcelain stoneware tiles. Ceram Int. 2005;31(2):233–40.

Kara A, Kayaci K, Küçüker AS, Bozkurt V, Ucbas Y, Özdamar S. Use of rhyolite as flux in porcelain tile production. Ind Ceram. 2009;29(2):71–81.

Kayacı K, Genç SC. Sintering behaviour of albite and microgranite containing porcelain stoneware bodies. Ind Ceram. 2009;29(2):91–7.

El-Maghraby HF, El-Omla MM, Bondioli F, Naga SM. Granite as flux in stoneware tile manufacturing. J Eur Ceram Soc. 2011;31:2057–63.

Hanuskova M. Feldspar-based sintering aids for the c eramic industry. Int Ceram J. 2003;4:35–9.

Sousa SJG, Holanda JNF. Sintering behaviour of porous wall tile bodies during single firing process. Mater Res. 2005;18(2):197–200.

Kara A, Özer F, Kayacı K, Özer P. Development of a multipurpose tile body: phase and microstructural development. J Eur Ceram Soc. 2006;26:3769–82.

Triboudino M, Angel RJ, Comora F, Nestola P, Pasqual D, Margiolaki I. Thermal expansion of plagioclase feldspars. Contrib Min Petrol. 2010;160:899–908.

Kayacı K. The use of perlite as flux in the production of porcelain stoneware tiles. Bol Soc Esp Ceram. 2020. https://doi.org/10.1016/j.bsecv.2020.03.003.

Montorsi M, Raginelli M, Rovini A, Settembre D, Siligardi C, Lugli C. Reactivities of carbonates with illite and kaolinite in monoporoza bodies. Ceram World Rev. 2006;69:110–20.

Pal M, Das S, Gupta S, Das SK. Thermal analysis and vitrification behavior of slag containing porcelain stoneware body. J Therm Anal Calorim. 2016;124:1169–77.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kayaci, K. Effect of fluxing raw materials on moisture expansion of monoporosa wall tile bodies. J Therm Anal Calorim 146, 1603–1611 (2021). https://doi.org/10.1007/s10973-020-10378-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10378-7