Abstract

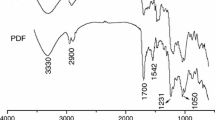

Phenolic foam (PF) has excellent performance in fire resistance, thermal insulation and other fields. It has the advantages of lightweight, flame retardant, no dropping and low level of toxic gas emission during combustion. In order to learn the relationships between density and properties, PF samples with density of 40, 50 and 60 kg · m−3 were obtained by adjusting the amount of blowing agent. Their micro-characteristics were analyzed with Fourier transform infrared spectroscopy (FT-IR) and scanning electron microscope (SEM) experiments. Mechanical properties were measured with universal extending machine. Thermal properties and stability were tested by laser thermal conductivity analyzer and thermogravimetry analysis (TG), respectively. FT-IR spectra of samples demonstrate that chemical structure will not be affected by the ratio of foaming agent. Higher density comes with better sealing property of the cell holes and leads to better compressive strength. Changing PF density with foaming agent dosage could affect insulation effect, and the sample with density of 60 kg · m−3 showed poor performance compared with the other foams. TG–DTG curves of the PF samples are similar. Evaporation of water, volatilization of phenols and aldehydes, and pyrolysis of surfactant and curing agents are the main reason for the mass loss. Residues of samples increased with the increase in density at 900 °C. Results of this study can clarify that changing the density of PF with amount of foaming agent will not affect its chemical properties, but the ratio has impact on its physical properties.

Similar content being viewed by others

Data availability

The raw data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

Code availability

Not applicable.

References

Li Q, Chen L, Li X, Zhang J, Zhang X, Zheng K, et al. Effect of multi-walled carbon nanotubes on mechanical, thermal and electrical properties of phenolic foam via insitu polymerization. Composer Part A Appl S. 2016;82:214–25.

Sui X, Wang Z. Flame-retardant and mechanical properties of phenolic foams toughened with polyethylene glycol phosphates. Polym Adv Technol. 2013;24(6):593–9.

Parameswaran P, Bhuvaneswary M, Thachil E. Control of microvoids in resole phenolic resin using unsaturated polyester. J Appl Polym Sci. 2009;113(2):802–10.

Kim DK, Lee SB. Properties and thermal characteristics of phenol foams for heat insulating materials. J Korean Ind Eng Chem. 2006;17:357–60.

Desai A, Tutt SR. Modeling of fiber reinforced phenolic foam. J Cell Plast. 2008;44:391–413.

Zhou J, Yao Z, Chen Y, et al. Thermomechanical analyses of phenolic foam reinforced with glass fiber mat. Mater Des. 2013;51(oct.):131–5.

Yang J, Li P. Characterization of short glass fiber reinforced polypropylene foam composites with the effect of compatibilizers: a comparison. J Reinf Plast Compos. 2015;34(7):534–46.

Li B, Wang Y, Mahmood N, Yuan Z, Schmidt J, Xu C. Preparation of bio-based phenol formaldehyde foams using depolymerized hydrolysis lignin. Ind Crop Prod. 2016;97:409–16.

Guo Y, Hu L, Zhang N. Characterization of thermal stability and toughness of nanoSiO2-lignin based phenolic foam. Chem Ind Eng Prog. 2017;36:4569–74.

Zhou J, Yao Z, Chen Y, et al. Fabrication and mechanical properties of phenolic foam reinforced with graphene oxide. Polym Compos. 2014;35(3):581–6.

Saz-orozco B, Oliet M, Alonso MV, et al. Formulation optimization of unreinforced and lignin nanoparticle- reinforced phenolic foams using an analysis of variance approach. Compos Sci Technol. 2012;72(6):667–74.

Nemoto T, Takagi J, Ohshima M. Control of bubble size and location in nano-/microscale cellular poly(propylene)/rubber blend foams. Macromol Mater Eng. 2008;293(7):574–80.

Song S, Chung Y, Kim S. The mechanical and thermal characteristic of phenolic foams reinforced with carbon nanoparticles. Compos Sci Technol. 2014;103:85–93.

Li J, Zhang A, Zhang S, et al. Larch tannin-based rigid phenolic foam with high compressive strength, low friability, and low thermal conductivity reinforced by cork powder. Composites. 2019;156:368–77.

Mougel C, Garnier T, Cassagnau P, et al. Phenolic foams: a review of mechanical properties, fire resistance and new trends in phenol substitution. Polymer. 2019;164:86–117.

Gibson L, Ashby M. Cellular Solids: Structure and Properties. Cambridge: Cambridge University Press; 1999.

Wang Y. Heat and mass transfer of surrounding rock and air flow in deep thermal environment. Xuzhou: China University of Mining and Technology; 2010.

Li B, Feng S, Niasar HS, Zhang Y, Yuan Z, Schmidt J, et al. Preparation and characterization of bark-derived phenol formaldehyde foams. RSC Adv. 2016;6(47):40975–81.

Rodrigue D, Souici S, Twite-Kabamba E. Effect of wood powder on polymer foam nucleation. J Vinyl Addit Technol. 2006;12(1):19–24.

Yang H, Wang X, Yuan H, et al. Fire performance and mechanical properties of phenolic foams modified by phosphorus-containing polyethers. J Polym Res. 2012;19(3):9831.

Wei G, Wen H, Deng J, et al. Enhanced coalbed permeability and methane recovery via hydraulic slotting combined with liquid CO2 injection. Process Saf Environ Prot. 2021;147:234–244.

Carvalho G, Frollini E, Santos WND. Thermal conductivity of polymers by hot-wire method. J Appl Polym Sci. 1996;62(13):2281–5.

Hu X, Wang D, Cheng W, Zhou G. Effect of polyethylene glycol on the mechanical property, microstructure, thermal stability, and flame resistance of phenol-urea-formaldehyde foams. J Mater Sci. 2013;49(4):1556–65.

Bo C, Wei S, Hu L, Jia P, Liang B, Zhou J, et al. Synthesis of a cardanol-based phosphorus-containing polyurethane prepolymer and its application in phenolic foams. RSC Adv. 2016;6(67):2999–3005.

Acknowledgements

The authors are grateful to the National Key Research of China (Project 2018YFC0808104) for financial support. We appreciated Changchun Liu for professional guidance in our experiments and data analysis.

Funding

The research was supported by National Key Research of China (Project 2018YFC0808104), which is granted by the author Li Ma.

Author information

Authors and Affiliations

Contributions

Xiaokun Chen and Li Ma directed the design of experiments. Shasha Zhou and Xixi Liu performed the preparation of resole resin and phenolic foams. Wencong Yu carried out the characteristic tests of samples and analyzed the raw data. Zhenping Wang gave professional guidance and comments. All authors read and approved the final manuscript.

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, X., Yu, W., Ma, L. et al. Mechanical properties and thermal characteristics of different-density phenolic foams. J Therm Anal Calorim 144, 393–401 (2021). https://doi.org/10.1007/s10973-020-10361-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10361-2