Abstract

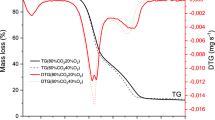

In this paper, it was suggested the use of green corn husk, which is a biomass from agro-industry, as an alternative source of energy through its pyrolysis. Green corn husk characterization was done through immediate and elemental analysis of its components: cellulose, hemicelluloses, and lignin. It was also measured its higher calorific value. The pyrolysis study of green corn husk was done by the isoconversion and the Master plots method. Thermogravimetric plots were obtained at heating rates of 5, 10, 15, and 20 °C min−1. The pyrolysis kinetics parameters were studied through the Flynn–Wall–Ozawa (FWO), Kissinger, and Friedman models. The Master plots method was used to determine the pyrolysis reaction order. The results of the reaction energy activation were found to be in the range 105.21–157.46 kJ mol−1 by the FWO method, 150.50 kJ mol−1 by the Kissinger method, and ranged 120.66–163.81 kJ mol−1 by the Friedman method. The Master plots method showed a three-way-transport diffusional kinetics for the biomass de-volatilization process. The higher calorific value found for green corn husk was 16.14 MJ kg−1. The simulation showed correlation between the experimental data and the proposed model for conversion values up to 0.8.

Similar content being viewed by others

References

Manić N, Janković B, Pijović M, et al. Apricot kernel shells pyrolysis controlled by non-isothermal simultaneous thermal analysis (STA). J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09307-5.

Bhattacharjee N, Biswas AB. Pyrolysis of Ageratum conyzoides (goat weed). J Therm Anal Calorim. 2020;139:1515–36. https://doi.org/10.1007/s10973-019-08437-9.

Zanatta ER, Reinehr TO, Awadallak JA, et al. Kinetic studies of thermal decomposition of sugarcane bagasse and cassava bagasse. J Therm Anal Calorim. 2016;125:437–45. https://doi.org/10.1007/s10973-016-5378-x.

Nigam PS, Pandey A. Biotechnology for agro-industrial residues utilisation: utilisation of agro-residues. Berlin: Springer; 2009.

Gokcol C, Dursun B, Alboyaci B, Sunan E. Importance of biomass energy as alternative to other sources in Turkey. Energy Policy. 2009;37:424–31. https://doi.org/10.1016/j.enpol.2008.09.057.

Sharma A, Pareek V, Zhang D. Biomass pyrolysis—a review of modelling, process parameters and catalytic studies. Renew Sustain Energy Rev. 2015;50:1081–96. https://doi.org/10.1016/j.rser.2015.04.193.

Jia C, Chen J, Liang J, et al. Pyrolysis characteristics and kinetic analysis of rice husk. J Therm Anal Calorim. 2020;139:577–87. https://doi.org/10.1007/s10973-019-08366-7.

Conesa JA, Urueña A, Díez D. Corn stover thermal decomposition in pyrolytic and oxidant atmosphere. J Anal Appl Pyrolysis. 2014;106:132–7. https://doi.org/10.1016/j.jaap.2014.01.010.

Honorato AC, Machado JM, Celante G, et al. Biossorção de azul de metileno utilizando resíduos agroindustriais. Rev Bras Eng Agrícola e Ambient. 2015;19:705–10. https://doi.org/10.1590/1807-1929/agriambi.v19n7p705-710.

Zambrzycki GC, Vale AT, Dantas VFS. Potencial energético dos resíduos da cultura do milho (Zea mays). Evidência. 2013;13:153–64.

Basu P. Biomass gasification, pyrolysis and torrefaction: practical design and theory. Amsterdam: Elsevier Inc; 2013.

Riegel I, Moura ABD, Morisso FDP, De Souza Mello F. Análise termogravimétrica da pirólise da acácia-negra (acacia mearnsii de wild.) cultivada no Rio Grande do Sul, Brasil. Rev Arvore. 2008;32:533–43. https://doi.org/10.1590/s0100-67622008000300014.

Chong CT, Mong GR, Ng J-H, et al. Pyrolysis characteristics and kinetic studies of horse manure using thermogravimetric analysis. Energy Convers Manag. 2019;180:1260–7. https://doi.org/10.1016/j.enconman.2018.11.071.

Ozawa T. A new method of analyzing thermogravimetric data. Bull Chem Soc Jpn. 1965;38:1881–6. https://doi.org/10.1246/bcsj.38.1881.

Flynn JH, Wall LA. A quick, direct method for the determination of activation energy from thermogravimetric data. J Polym Sci Part B Polym Lett. 1966;4:323–8. https://doi.org/10.1002/pol.1966.110040504.

Kissinger HE. Reaction kinetics in differential thermal analysis. Anal Chem. 1957;29:1702–6. https://doi.org/10.1021/ac60131a045.

Friedman HL. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J Polym Sci Part C Polym Symp. 2007;6:183–95. https://doi.org/10.1002/polc.5070060121.

Han J, Sun Y, Guo W, et al. Non-isothermal thermogravimetric analysis of pyrolysis kinetics of four oil shales using Sestak–Berggren method. J Therm Anal Calorim. 2019;135:2287–96. https://doi.org/10.1007/s10973-018-7392-7.

Qiao Y, Wang B, Zong P, et al. Thermal behavior, kinetics and fast pyrolysis characteristics of palm oil: analytical TG-FTIR and Py-GC/MS study. Energy Convers Manag. 2019;199:111964. https://doi.org/10.1016/j.enconman.2019.111964.

Vuppaladadiyam AK, Liu H, Zhao M, et al. Thermogravimetric and kinetic analysis to discern synergy during the co-pyrolysis of microalgae and swine manure digestate. Biotechnol Biofuels. 2019;12:170. https://doi.org/10.1186/s13068-019-1488-6.

Zhao B, Xu X, Li H, et al. Kinetics evaluation and thermal decomposition characteristics of co-pyrolysis of municipal sewage sludge and hazelnut shell. Bioresour Technol. 2018;247:21–9. https://doi.org/10.1016/j.biortech.2017.09.008.

Vyazovkin S. Isoconversional kinetics of thermally stimulated processes. Cham: Springer; 2015.

Chen T, Ku X, Lin J, Ström H. Pyrolysis simulation of thermally thick biomass particles based on a multistep kinetic scheme. Energy Fuels. 2020;34:1940–57. https://doi.org/10.1021/acs.energyfuels.9b04174.

Perry RH, Green DW, Maloney JO. Perry’s chemical engineers’ handbook. New York: Mc Graw-Hills; 1997.

Li S, Xu S, Liu S, et al. Fast pyrolysis of biomass in free-fall reactor for hydrogen-rich gas. Fuel Process Technol. 2004;85:1201–11. https://doi.org/10.1016/j.fuproc.2003.11.043.

Opfermann J, Kaisersberger E. An advantageous variant of the Ozawa–Flynn–Wall analysis. Thermochim Acta. 1992;203:167–75. https://doi.org/10.1016/0040-6031(92)85193-Y.

Apaydin-Varol E, Polat S, Putun A. Pyrolysis kinetics and thermal decomposition behavior of polycarbonate—a TGA-FTIR study. Therm Sci. 2014;18:833–42. https://doi.org/10.2298/TSCI1403833A.

White JE, Catallo WJ, Legendre BL. Biomass pyrolysis kinetics: a comparative critical review with relevant agricultural residue case studies. J Anal Appl Pyrolysis. 2011;91:1–33. https://doi.org/10.1016/j.jaap.2011.01.004.

Doyle CD. Kinetic analysis of thermogravimetric data. J Appl Polym Sci. 1961;5:285–92. https://doi.org/10.1002/app.1961.070051506.

Ceylan S. Kinetic analysis on the non-isothermal degradation of plum stone waste by thermogravimetric analysis and integral master-plots method. Waste Manag Res. 2015;33:345–52. https://doi.org/10.1177/0734242X15574590.

Doyle CD. Estimating isothermal life from thermogravimetric data. J Appl Polym Sci. 1962;6:639–42. https://doi.org/10.1002/app.1962.070062406.

Ali I, Naqvi SR, Bahadar A. Kinetic analysis of Botryococcus braunii pyrolysis using model-free and model fitting methods. Fuel. 2018;214:369–80. https://doi.org/10.1016/j.fuel.2017.11.046.

Poletto M, Zattera AJ, Santana RMC. Thermal decomposition of wood: kinetics and degradation mechanisms. Bioresour Technol. 2012;126:7–12. https://doi.org/10.1016/j.biortech.2012.08.133.

da Silva Miranda MR, Veras CAG, Ghesti GF. Charcoal production from waste pequi seeds for heat and power generation. Waste Manag. 2020;103:177–86. https://doi.org/10.1016/j.wasman.2019.12.025.

Kitani O, Hall CW. Biomass handbook. New York: Gordon and Breach Science Publishers; 1989.

Demirbaş A. Calculation of higher heating values of biomass fuels. Fuel. 1997;76:431–4. https://doi.org/10.1016/S0016-2361(97)85520-2.

Kumar JV, Pratt BC. Compositional analysis of some renewable biofuels. Am Lab. 1996;28(8):15–20.

Quirino WF, Teixeira Do Vale A, Ana, et al Poder Calorífico da Madeira E de Materiais Ligno-Celulósicos Publicado na Revista da Madeira no 89 abril 2005 pag 100–106.

Turmanova SC, Genieva SD, Dimitrova AS, Vlaev LT. Non-isothermal degradation kinetics of filled with rise husk ash polypropene composites. Express Polym Lett. 2008;2:133–46. https://doi.org/10.3144/expresspolymlett.2008.18.

Bartocci P, Tschentscher R, Stensrød RE, et al. Kinetic analysis of digestate slow pyrolysis with the application of the master-plots method and independent parallel reactions scheme. Molecules. 2019;24:1657. https://doi.org/10.3390/molecules24091657.

Cai J, Wu W, Liu R, Huber GW. A distributed activation energy model for the pyrolysis of lignocellulosic biomass. Green Chem. 2013;15:1331. https://doi.org/10.1039/c3gc36958g.

Trninić M, Wang L, Várhegyi G, et al. Kinetics of corncob pyrolysis. Energy Fuels. 2012;26:2005–13. https://doi.org/10.1021/ef3002668.

Dhyani V, Bhaskar T. Kinetic analysis of biomass pyrolysis. In: Waste biorefinery. Elsevier; 2018. p. 39–83. https://doi.org/10.1016/B978-0-444-63992-9.00002-1

Liu R, Yuan H. Kinetics of the low-temperature pyrolysis of walnut shell. Int J Glob Energy Issues. 2008;29:248. https://doi.org/10.1504/IJGEI.2008.018006.

Wu Y, Dollimore D. Kinetic studies of thermal degradation of natural cellulosic materials. Thermochim Acta. 1998;324:49–57. https://doi.org/10.1016/S0040-6031(98)00522-X.

Wang S, Dai G, Yang H, Luo Z. Lignocellulosic biomass pyrolysis mechanism: a state-of-the-art review. Prog Energy Combust Sci. 2017;62:33–86.

Acknowledgements

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior - Brasil (CAPES) - Finance Code 001.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Reinehr, T.O., Ohara, M.A., de Oliveira Santos, M.P. et al. Study of pyrolysis kinetic of green corn husk. J Therm Anal Calorim 143, 3181–3192 (2021). https://doi.org/10.1007/s10973-020-10345-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10345-2