Abstract

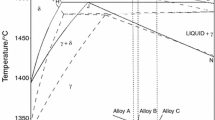

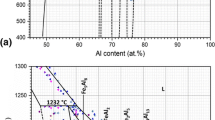

Three Fe–C–Cr and three Fe–C–Cr–Ni-based alloys containing carbon between 0.318 and 0.410 mass%, chromium and nickel between of 0.001 and 4.990 mass% were studied. Original temperatures of solidus, liquidus and peritectic transformation were determined and clarified for all six specific alloys. Phase transition temperatures were experimentally obtained using differential thermal analysis (DTA), and the start of melting of alloys was investigated using the high-temperature laser scanning confocal microscopy. Additionally, experimental data were compared and discussed with calculation results using SW IDS and Thermo-Calc operating with commercially available thermodynamic database TCFE8. The combination of both experimental methods contributed substantially to investigate more clearly the start of melting. Determination of solidus temperatures/incipient melting point temperatures on DTA curves is often challenging, and there are significant differences when compared with the determination of liquidus and peritectic transformation temperatures. HT-LSCM method brings an improvement in that regard because it can reveal thermal events which are hardly identified on DTA curves. The relation between homogeneity/inhomogeneity of investigated alloys and the initiation of their melting was observed depending mainly on the state of alloys.

Similar content being viewed by others

References

Argandona G, Biezma MV, Berrueta JM, Berlanga C, Ruiz A. Detection of secondary phases in UNS S32760 superduplex stainless steel by destructive and non-destructive techniques. J Mater Eng Perform. 2016;25:5269–79.

Thomas Paul V, Sudha C, Saroja S. Influence of alloy content and prior microstructure on evolution of secondary phases in weldments of 9Cr-reduced activation ferritic-martensitic steel. Metall Mater Trans A. 2015;46:3378–92.

Vázquez-Gómez O, Gallegos-Pérez AI, López-Martínez E, Vergara-Hernández HJ, Barrera-Godínez JA. Criteria for the dilatometric analysis to determine the transformations kinetics during continuous heating. J Therm Anal Calorim. 2019;135:2985–93.

Kolesnikov VI, Migal’ YF, Kolesnikov IV, Novikov ES. Compatibility of chemical elements at grain boundaries in steel. Doklady Phys Chem. 2015;464:194–7.

Chaliampalias D, Vourlias G, Pavlidou E, Chrissafis K. Examination of the oxidation resistance of Cr–Mo–V tool steel by thermal analysis. J Therm Anal Calorim. 2012;108:677–84.

Steiner Petrovič D, Pirnat M, Klančnik G, Mrvar P, Medved J. The effect of cooling rate on the solidification and microstructure evolution in duplex stainless steel: a DSC study. J Therm Anal Calorim. 2012;109:1185–91.

Kargul T, Wielgosz E, Falkus J. Application of thermal analysis tests results in the numerical simulations of continuous casting process. Arch Metall Mater. 2015;60:221–5.

Žaludová M, Smetana B, Zlá S, et al. Experimental study of Fe–C–O based system above 1,000 °C. J Therm Anal Calorim. 2013;112:465–71.

Žaludová M, Smetana B, Zlá S, et al. Experimental study of Fe–C–O based system below 1000 °C. J Therm Anal Calorim. 2013;111:1203–10.

Drozdová Ľ, Smetana B, Zlá S, et al. Study of phase transformation temperatures of alloys based on Fe–C–Cr in high-temperature area. J Therm Anal Calorim. 2018;133:41–8.

Yamaguchi K, Ueda S. High temperature enthalpy measurement of SUS340 stainless steel. High Temp. Mater. Process. 2012;30:569–72.

Luo BC, Wang HP, Wei B. Specific heat, enthalpy, and density of undercooled liquid Fe–Si–Sn alloy. Philos Mag Lett. 2009;89:527–33.

Fremunt P, Podrábský T. Structural steels. Brno: Akademické nakladatelství CERM; 1996.

Schaffnit P, Stallybrass C, Konrad J, Stein F, Weinberg M. A Scheil–Gulliver model dedicated to the solidification of steel. Calphad. 2015;48:184–8.

Matsumiya T. Steelmaking technology for a sustainable society. Calphad. 2011;35:627–35.

Wielgosz E, Kargul T. Differential scanning calorimetry study of peritectic steel grades. J Therm Anal Calorim. 2015;119:1547–53.

Venkata RR, Kalyankar VD. Parameters optimization of continuous casting process using teaching-learning-based optimization algorithm. In: Panigrahi BK, Das S, Suganthan PN, Nanda PK, editors. Swarm, evolutionary, and memetic computing. SEMCCO 2012. Lecture notes in computer science. Heidelberg: Springer; 2012. p. 540–7.

Alves CLM, Rezende J, Senk D, Kundin J. Peritectic phase transformation in the Fe–Mn and Fe–C system utilizing simulations with phase-field method. J Mater Res Technol. 2019;8:233–42.

Martiník O, Smetana B, Dobrovská J, Kalup A, Zlá S, Kawuloková M, Gryc K, Dostál P, Drozdová Ľ. Thermal analysis of medium-carbon steels. In: Proceedings paper, METAL 2016: 25th anniversary international conference on metallurgy and materials. p. 148–53. ISBN 978-80-87294-67-3.

Kalup A, Smetana B, Kawuloková M, Zlá S, Francová H, Dostál P, Waloszková K, Waloszková L, Dobrovská J. Liquidus and solidus temperatures and latent heats of melting steels. J Therm Anal Calorim. 2017;127:123–8.

Drozdová Ľ, Smetana B, Machů M, Zlá S, Vontorová J, Váňová P, Řeháčková L, Novák V, Konečná K, Petlák D, Jahodová K. Experimental and theoretical determination of heat capacities of model alloys based on Fe–C–Cr. In: Proceedings paper, METAL 2018: 27th anniversary international conference on metallurgy and materials. p. 63–8. ISBN 978-808729484-0.

Miettinen J, Louhenkilpi S, Kytönen H, Laine J. IDS: thermodynamic-kinetic-empirical tool for modelling of solidification, microstructure and material properties. Math Comput Simulat. 2010;80:1536–50.

Smetana B, Žaludová M, Tkadlečková M, et al. Experimental verification of hematite ingot mould heat capacity and its direct utilisation in simulation of casting process. J Therm Anal Calorim. 2013;112:473–80.

Chen Q, Sundman B. Modeling of thermodynamic properties for Bcc, Fcc, liquid, and amorphous iron. JPE. 2001;22:631–44.

Loder D, Michelic SK, Mayerhofer A, Bernhard C, Dippenaar RJ. In situ observation of acicular ferrite formation using HT-LSCM: possibilities, challenges and influencing factors. In Proceedings paper: materials science and technology conference and exhibition 2014. p. 469–76. ISBN 9781634397230.

Sopoušek J. Phase equilibria and diffusion-controlled processes in selected systems of metals and their alloys (commentary). Brno: MU in Brno, Science Faculty, Chemical Institute; 2002.

Lašček M. Specific heat capacity of austenitic chrome–nickel steel Cr18Ni9. Acta MetallurgicaSlovaca. 2008;1:34–49.

Bhadeshia HKDH. Phasefield modelling. In: Kinetics and microstructure modelling. University of Cambridge; 2010. https://www.phase-trans.msm.cam.ac.uk/mphil/MP6-15.pdf. Accessed 16 Sept 2018.

Chen L-Q. Phase-field models for microstructure evolution. Annu Rev Mater Res. 2002;32:113–40.

Presoly P, Pierer R, Bernhard C. Identification of defect prone peritectic steel grades by analyzing high-temperature phase transformations. Metall and Mat Trans A. 2013;44:5377–88.

Yin H, Emi T, Shibata H. Determination of free energy of δ-ferrite/γ-austenite interphase boundary of low carbon steels by in situ observation. ISIJ Int. 1998;38:794–801.

McDonald NJ, Sridhar S. Observations of the advancing δ-ferrite/γ-austenite/liquid interface during the peritectic reaction. J Mater Sci. 2005;40:2411–6.

Reid M, Phelan M, Dippenaar R. Concentric solidification for high temperature laser scanning confocal microscopy. ISIJ Int. 2004;44:565–72.

Acknowledgements

This paper was created on the Faculty of Materials Science and Technology in GAČR Project No. 17-18668S, the Project No. CZ.1.05/2.1.00/19.0387, faculty student Projects SP2020/89, SP2020/34 and of the Moravian-Silesian Region as part of the project “Support of gifted students of doctoral studies at VŠB-TUO” No.: 04766/2017/RRC.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Drozdová, Ľ., Smetana, B., Presoly, P. et al. Investigation of Fe–C–Cr and Fe–C–Cr–Ni-based systems with the use of DTA and HT-LSCM methods. J Therm Anal Calorim 142, 535–546 (2020). https://doi.org/10.1007/s10973-020-10305-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10305-w