Abstract

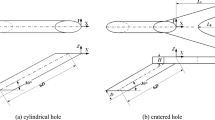

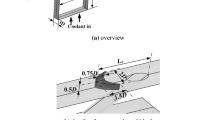

In the present work, experimental and numerical study has been performed to investigate the effects of a novel film-cooling design with shaped multi-holes on the film-cooling effectiveness over a flat plate. A single cylindrical hole with 11.1 mm diameter has been replaced by multi-holes (14 holes with 2.97 mm diameter) with elliptical and fan-shaped configurations. The exit area, length to diameter ratio (L/D = 4.0) and injection angle (35°) of multi-holes are selected identical to the single cylindrical hole. The multi-holes were machined with a fixed spacing pitch (33.3 mm) between the centers of two adjacent holes. The surface temperature of the test plate was measured by an infrared camera. The experimental studies were performed at blowing ratios of 0.5 and 2. The numerical results based on the steady RANS with realizable k–ε turbulence model and enhanced wall treatment were capable to predict the influence of the shape of multi-hole configurations on overall adiabatic film-cooling effectiveness. The experimental and numerical results showed that replacing a single hole with a shaped multi-hole leads to a considerable increase in film-cooling effectiveness in both axial and lateral directions. According to the results at blowing ratio of 2.0, the elliptical and fan-shaped configurations provide a higher area-averaged film-cooling effectiveness by 75% and 248.2% in comparison with the single hole, respectively.

Similar content being viewed by others

Abbreviations

- M :

-

Blowing ratio = \({\left(\rho U\right)}_{{\rm c}}/{\left(\rho U\right)}_{\infty }\)

- T :

-

Temperature (K)

- Tu:

-

Turbulent intensity (%)

- x/D :

-

Non-dimensional streamwise distance

- DR:

-

Coolant to free-stream density ratio = \({\rho }_{{\rm c}}/{\rho }_{\infty }\)

- D :

-

Diameter of the hole (mm)

- k :

-

Turbulent kinetic energy (m2 s−2)

- L :

-

Length of the hole (mm)

- Re:

-

Reynolds number

- β :

-

Streamwise injection angle (°)

- Θ:

-

Internal energy (J)

- θ :

-

Heat flux (W m−2)

- ε :

-

Dissipation rate of turbulent kinetic energy (m2 s−3)

- η (eta):

-

Adiabatic film-cooling effectiveness; \(\eta =\frac{{T}_{{\rm aw}}-{T}_{\infty }}{{T}_{{\rm j}}-{T}_{\infty }}\)

- ρ :

-

Density of the fluid (kg m−3)

- τ w :

-

Wall shear stress (kg m−1 s−2)

- μ :

-

Dynamic viscosity (kg m−1 s−1)

- μ t :

-

Turbulent dynamic viscosity (kg m−1 s−1)

- j:

-

Jet

- ∞:

-

Free stream

- aw:

-

Adiabatic wall

References

Hale CA, Plesniak MW, Ramadhyani S. Film cooling effectiveness for short film cooling holes fed by a narrow plenum. J Turbomach. 2000;122:553–7.

Lutum E, Johnson BV. Influence of the hole length-to-diameter ratio on film cooling with cylindrical holes. J Turbomach. 1999;121:209–16.

Yuen CHN, Martinez-Botas RF. Film cooling characteristics of a single round hole at various streamwise angles in a crossflow: part 1 effectiveness. Int J Heat Mass Transf. 2003;46:221–35.

Nasir H, Ekkad SV, Acharya S. Effect of compound angle injection on flat surface film cooling with large streamwise injection angle. Exp Therm Fluid Sci. 2001;25:23–9.

Shine SR, Sunil Kumar S, Suresh BN. Internal wall-jet film cooling with compound angle cylindrical holes. Energy Convers Manag. 2013;68:54–62.

Miao JM, Wu CY. Numerical approach to hole shape effect on film cooling effectiveness over flat plate including internal impingement cooling chamber. Int J Heat Mass Transf. 2006;49:919–38.

Leedom DH, Acharya S. Large Eddy simulation of film cooling flow field from cylindrical and shaped holes. In: ASME Turbo Expo 2008, Paper No. GT2008–51009, June 9–13, Berlin, Germany.

Gandhi N, Suresh S. Effect of mist concentration on the cooling effectiveness of a diffused hole mist cooling system. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-020-09680-1.

Saumweber C, Schulz A. Effect of geometry variations on the cooling performance of fan-shaped cooling holes. In: Proceedings of ASME Turbo Expo 2008, GT2008–51038.

Gritsch M, Colban W, Schär H, Döbbeling K. Effect of hole geometry on the thermal performance of fan-shaped film cooling holes. J Turbomach. 2005;127:718–25.

Peng W, Jiang PX. Experimental and numerical study of film cooling with internal coolant cross-flow effects. Exp Heat Transf. 2012;25:282–300.

Fua W-S, Chaoa W-S, Tsubokura M, Lic C-G, Wangd W-H. Investigation of boundary layer thickness and turbulence intensity on film cooling with a fan-shaped hole by direct numerical simulation. Int Commun Heat Mass Transf. 2018;96:12–9.

Lee KD, Kim KY. Shape optimization of a fan-shaped hole to enhance film cooling effectiveness. Int J Heat Mass Transf. 2010;53:2996–3005.

Fraas M, Glasenapp T, Schulz A, Bauer H-J. Optimized inlet geometry of a laidback fan-shaped film cooling hole—experimental study of film cooling performance. Int J Heat Mass Transf. 2019;128:980–90.

Sun X, Zhao G, Jiang P, Peng W, Wang J. Influence of hole geometry on film cooling effectiveness for a constant exit flow area. Appl Therm Eng. 2018;130:1404–15.

Kim J-H, Kim K-Y. Film-cooling performance of converged-inlet hole shapes. Int J Therm Sci. 2018;124:196–21111.

Azzi A, Jubran BA. Numerical modelling of film cooling from converging slot-hole. Heat Mass Transf. 2007;43:381–8.

Sargison JE, Guo SM, Oldfield MLG, Lock GD, Rawlinson AJ. A converging slot-hole film cooling geometry—part 1: low-speed flat-plate heat transfer and loss. J Turbomach. 2002;124:453–60.

Chi Z, Ren J, Jiang H, Zang S. Geometrical optimization and experimental validation of a tripod film cooling hole with asymmetric side holes. J Heat Transf. 2016;138:061701.

Abdala AMM, Elwekeel FNM. An influence of novel upstream steps on film cooling performance. Int J Heat Mass Transf. 2016;93:86–96.

Ye L, Liu C-L, Liu H-Y, Zhu H-R, Luo J-X. Experimental and numerical study on the effects of rib orientation angle on film cooling performance of compound angle holes. Int J Heat Mass Transf. 2018;126:1099–112.

Zhang F, Wang X, Li J. The effects of upstream steps with unevenly spanwise distributed height on rectangular hole film cooling performance. Int J Heat Mass Transf. 2016;102:1209–21.

Ely MJ, Jubran BA. A numerical study on increasing film cooling effectiveness through the use of sister holes. ASME Paper. 2008; GT-50366.

Heidmann JD. A numerical study of anti-vortex film cooling designs at high blowing ratio. ASME Paper. 2008; GT-50845.

Dhungel A, Lu Y, Philips A, Ekkad S, Heidmann J. Film cooling from a row of holes supplemented with anti vortex holes. ASME Paper. 2007; GT2007–27419.

Leblanc C, Narzary D, Ekkad SV. Film cooling performance of an anti-vortex hole on a flat plate. AJTEC2011–44161, 2011 AJTEC, Hawaii, 2011.

Singh K, Premachandran B, Ravi MR. Experimental and numerical studies on film cooling with reverse/backward coolant injection. Int J Therm Sci. 2017;111:390–408.

Kline SJ, McClintock FA. Describing uncertainties in single-sample experiments. Mech Eng. 1953;75:3–8.

ANSYS Inc. ANSYS FLUENT 16.0.0, Cononsburg, PA, USA; 2014.

Shih T-H, Liou WW, Shabbir A, Yang Z, Zhu J. A new k−ε Eddy-viscosity model for high Reynolds number turbulent flows—model development and validation. Comput Fluids. 1995;24:227–38.

ANSYS Inc. ANSYS FLUENT theory guide, ANSYS FLUENT 16.0.0, Cononsburg, PA, USA; 2014.

Schmidt DL, Sen B, Bogard DG. Film cooling with compound angle holes: adiabatic effectiveness. J Turbomach. 1996;118(4):807–13.

Liu JH, Liu YB, Liu L. Film cooling modeling of a turbine vane with multiple configurations of holes. Case Stud Therm Eng. 2018;11:71–80.

Wang J, Gu C, Sundén B. Investigations of film cooling and its nonuniform distribution for the conjugate heat transfer passage with a compound inclined angle jet. Numer Heat Trans Part A. 2015;69:14–30.

Saumweber C, Schulz A. Effect of geometry variations on the cooling performance of fan-shaped cooling holes. In: Proceedings of ASME Turbo Expo. 2008; GT2008–51038.

Leylek JH, Zerkle RD. Discrete-jet film cooling: a comparison of computational results with experiments. ASME J Turbomach. 1994;113:358–68.

Moeini A, Zargarabadi MR. Genetic algorithm optimization of film cooling effectiveness over a rotating blade. Int J Therm Sci. 2018;125:248–55.

Haven BA, Kurosaka M. Kidney and anti-kidney vortices in crossflow jets. J Fluid Mech. 1997;352:27–64.

Walters DK, Leylek JH. A detailed analysis of film-cooling physics: part I—streamwise injection with cylindrical holes. ASME J Turbomach. 2000;122:102–12.

Hyams DG, Leylek JH. A detailed analysis of film cooling physics: part 3—streamwise injection with shaped holes. ASME J Turbomach. 2000;122:122–32.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Taheri, Y., Rajabi Zargarabadi, M. & Jahromi, M. Experimental and numerical study on the effects of shaped multi-holes on the effectiveness of film cooling. J Therm Anal Calorim 146, 1723–1733 (2021). https://doi.org/10.1007/s10973-020-10157-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10157-4