Abstract

The mechanism and kinetics of nickel oxide reduction by Mg + C combined reducer at non-isothermal conditions in a wide range of high heating rates (100–1200 °C min−1) were studied by high-speed temperature scanner technique. It was shown that both the magnesiothermal and magnesiocarbothermal reduction processes, unlike low heating rates (5–20 °C min−1, DTA/DTG method), start beyond the melting point of magnesium and proceed via solid + liquid scheme. It was found out that the utilization of Mg + C combined reducer allows to significantly lower the reduction temperature (by about 200–400 °C) of nickel oxide as compared with exclusively magnesium or carbon reducers evidencing on the synergetic effect of combined reducers in the ternary mixture. The effective values of activation energy (Ea) for the NiO + Mg and 2NiO + Mg + C reactions were determined to be 185 ± 15 kJ mol−1 and 195 ± 15 kJ mol−1, respectively.

Graphic abstract

Similar content being viewed by others

References

Jaleel MA, Gurji EZ. The tribological and chemical properties of Ni–W alloy electrodeposition. JAARU. 2019;26(1):145–9.

Al-Sahli A, Ghanbari E, Macdonald DD. Effect of tungsten alloying on passivity breakdown of nickel. Mater Corros. 2019;70:216–33.

Sheng J, Yi X, Li F, Fang W. Effects of tungsten on the catalytic activity of Ni–W catalysts for the hydrogenation of aromatic hydrocarbons. React Kinet Mech Catal. 2010;99:371–9.

Sadat T, Faurie D, Tingaud D, Mocuta C, Thiaudiere D, Dirras G. Fracture behavior of Ni–W alloy probed by in situ synchrotron X-ray diffraction. Mater Lett. 2018;239:116–9.

Hamidi AG, Arabi H, Khakic JV. Sintering of a nano-crystalline tungsten heavy alloy powder. Int J Refract Met Hard Mater. 2019;80:204–9.

Mangnus PJ, Bos A, Moulijn JA. Temperature-programmed reduction of oxidic and sulfidic alumina-supported NiO, WO3, and NiO–WO3 catalysts. J Catal. 1994;146:437–48.

Navarro-Flores E, Chong Z, Omanovic S. Characterization of Ni, NiMo, NiW and NeFe electroactive coatings as electrocatalysts for hydrogen evolution in an acidic medium. J Mol Catal A Chem. 2005;226:179–97.

Mentus S, Majstorovic DM, Tomic BS, Dimitrijevic RZ. Reduction of NiO–WO3 oxide mixtures synthesized by gel-combustion technique: a route to Ni–W alloys. Mater Sci Forum. 2005;494:345–50.

Tingaud D, Sadat T, Dirras G. Nickel–tungsten composite-like microstructures processed by spark plasma sintering for structural applications. In: Cavaliere P, editor. Spark plasma sintering of materials: advances in processing and applications. Basel: Springer; 2019. p. 605–34.

Ahmed HM, Seetharaman S. Reduction–carburization of NiO–WO3 under isothermal conditions using H2–CH4 gas mixture. Metall Mater Trans B. 2010;41:173–81.

Quintana-Melgoza JM, Gomez-Cortes A, Avalos-Borja M. Reduction of NO by CO over NiWO4, NiO, and WO3 catalysts. React Kinet Catal Lett. 2002;76:131–40.

Zhang H, Chen G, Bai L, Chang N, Wang Y. Selective hydrogenation of aromatics in coal-derived liquids over novel NiW and NiMo carbide catalysts. Fuel. 2019;244:359–65.

Ivekovića A, Montero-Sistiaga ML, Vanmeensel K, Kruth JP, Vleugels J. Effect of processing parameters on microstructure and properties of tungsten heavy alloys fabricated by SLM. Int J Refract Met Hard Mater. 2019;82:23–30.

Zakaryan M, Aydinyan S, Kharatyan S. Combustion synthesis and consolidation of Ni–W nanocomposite material. Ceram Mod Tech. 2019;1:67–74.

Chanadee T, Singsarothai S. Effect of high-energy milling on magnesiothermic self-propagating high-temperature synthesis in a mixture of SiO2, C, and Mg reactant powders. Combust Explos Shock Waves. 2019;55(1):97–106.

Hobosyan MA, Kirakosyan KG, Kharatyan SL, Martirosyan KS. PTFE–Al2O3 reactive interaction at high heating rates. J Therm Anal Calorim. 2015;119:245–51.

Nepapushev AA, Kirakosyan KG, Moskovskikh DO, Kharatyan SL, Rogachev AS, Mukasyan AS. Influence of high-energy ball milling on reaction kinetics in the Ni–Al system: an electrothermographic study. Int J SHS. 2015;24(1):21–8.

Aydinyan SV, Nazaretyan KT, Zargaryan AG, Tumanyan ME, Kharatyan SL. Reduction mechanism of WO3 + CuO mixture by combined Mg/C reducer. Non isothermal conditions—high heating rates. J Therm Anal Calorim. 2018;133(7):261–9.

Kissinger HE. Reaction kinetics in differential thermal analysis. Anal Chem. 1957;29:1702–6.

Starink MJ. The determination of activation energy from linear heating rate experiments: a comparison of the accuracy of isoconversion methods. Thermochim Acta. 2003;404:163–76.

Akahira T, Sunose T. Method of determining activation deterioration constant of electrical insulating materials. Res Rep Chiba Inst Technol. 1971;16:22–31.

Kongkaew N, Pruksakit W, Patumsawad S. Thermogravimetric kinetic analysis of the pyrolysis of rice straw. Energy Proc. 2015;79:663–70.

Ahmed HM, El-Geassy AHA, Viswanathan NN, Seetharaman S. Kinetics and mathematical modeling of hydrogen reduction of NiO–WO3 precursors in fluidized bed reactor. ISIJ Int. 2011;51(9):1383–91.

Valendar HM, Rezaie H, Samim H, Barati M, Razavizadeh H. Reduction and carburization behavior of NiO–WO3 mixtures by carbon monoxide. Thermocim Acta. 2014;590:210–8.

Mohammadzadeh H, Rezaie HR, Barati M, Yu D, Samim HR. Kinetics of nonisothermal reduction and carburization of WO3–NiO nano-composite powders by CO–CO2. Int J Chem Kinet. 2019;51:463–75.

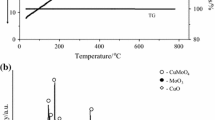

Zakaryan MK, Niazyan OM, Aydinyan SV, Kharatyan SL. DTA/TG study of NiO reduction by Mg + C combined reducer. Chem J Arm. 2018;71(4):473–85.

Syed-Hassan SSA, Li CZ. Effects of crystallite size on the kinetics and mechanism of NiO reduction with H2. Int J Chem Kinet. 2011;43(12):667–76.

Jankovic B, Adnadevic B, Mentus S. The kinetic analysis of non-isothermal nickel oxide reduction in hydrogen atmosphere using the invariant kinetic parameters method. Thermochim Acta. 2007;456:48–55.

Richardson JT, Scates R, Twigg MV. X-ray diffraction study of nickel oxide reduction by hydrogen. Appl Catal A Gen. 2003;246(1):137–50.

Krasuk JH, Smith JM. Kinetics of reduction of nickel oxide with CO. AIChE J. 1972;18(3):506–12.

Sharma SK, Vastola FJ, Walker PL. Reduction of nickel oxide by carbon: III. Kinetic studies of the interaction between nickel oxide and natural graphite. Carbon. 1997;35(4):535–41.

Bakhshandeh S, Setoudeh N, Zamani M, Mohassel A. Carbothermic reduction of mechanically activated NiO–carbon mixture: non-isothermal kinetics. J Min Metall. 2018;54(3):313–22.

Zheng J, Jin Y, Chi Y, Wen J, Jiang X, Ni M. Pyrolysis characteristics of organic components of municipal solid waste at high heating rates. Waste Manag. 2009;29:1089–94.

Yin Q, Lai C, Chena S, Peng J, Li H, Zhou W, Hu P, Wang J. Investigations of the nickel promotional effect on the reduction and sintering of tungsten compounds. Int J Refract Met Hard Mater. 2019;78:296–302.

Zakaryan MK, Niazyan OM, Aydinyan SV, Kharatyan SL. Reaction pathway in the WO3–NiO–Mg–C system. DTA/TG study. Chem J Arm. 2019;72(3):223–32.

Qiao D, Wang Y, Li F, Wang D, Yan B. Kinetic study on preparation of substoichiometric tungsten oxide WO2.72 via hydrogen reduction process. J Therm Anal Calorim. 2019;137:389–97.

Gaglieri C, Alarcon RT, de Moura A, Cairez FJ. Nickel selenate: a deep and efficient characterization. J Therm Anal Calorim. 2019;139:1707–15.

Aydinyan SV, Kirakosyan HV, Kharatyan SL. Cu–Mo composite powders obtained by combustion–coreduction process. Int J Refract Met Hard Mater. 2016;54:455–63.

Zakaryan M, Kirakosyan H, Aydinyan S, Kharatyan S. Combustion synthesis of W–Cu composite powders from oxide precursors with various proportions of metals. Int J Refract Met Hard Mater. 2017;64:176–83.

Baghdasaryan AM, Niazyan OM, Khachatryan HL, Kharatyan SL. DTA/TGA study of molybdenum oxide reduction by Mg/Zn & Mg/C combined reducers at non-isothermal conditions. Int J Refract Met Hard Mater. 2015;51:315–23.

Baghdasaryan AM, Niazyan OM, Khachatryan HL, Kharatyan SL. DTA/TG study of tungsten oxide and ammonium tungstate reduction by (Mg + C) combined reducers at non-isothermal conditions. Int J Refract Met Hard Mater. 2014;43:216–21.

Acknowledgements

The work was performed with financial support from the Committee of Science MES of Republic of Armenia (Research Grant 18T-1D051) and the Estonian Research Council Grant PSG220 (S. Aydinyan).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zakaryan, M.K., Nazaretyan, K.T., Aydinyan, S.V. et al. NiO reduction by Mg + C combined reducer at high heating rates. J Therm Anal Calorim 146, 1811–1817 (2021). https://doi.org/10.1007/s10973-020-10148-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10148-5