Abstract

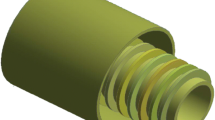

The aim of this paper is to achieve a smaller and cheaper heat exchanger with similar performance. To fulfill this demand, ANSYS-Fluent software and Aspen-HYSYS software are employed. The second goal is to study the effects of using oil-based nanofluids in a refinery heat exchanger. To fulfill this demand, two different nanofluids (MgO-SAE10 and ZnO-SAE10) are studied using two-phase approaches. And the third objective of this paper is to compare the results which are obtained from the singe- and multi-phase approaches. The governing equations have been solved according to the Eulerian–Eulerian single-fluid Two-Phase Model, with presumptuous that the coupling between phases is strong, and nanoparticles carefully follow the suspension flow. The FVM, SIMPLEC algorithm and k–ε turbulence model are applied. The thermal–hydraulic performance evaluation criteria, THPEC, and q″ have major roles. In the second step, the authors try to achieve an efficient model which not only has the THPEC > 1, but also has the maximum value of q″. According to the results, usage of nanofluid and turbulators can enhance thermal–hydraulic performances of heat exchanger significantly (between 84.78 and 105.31% for heat exchanger 1 and between 86.84% and 107.68% for heat exchanger 2). Furthermore, it is concluded that by employing nanofluid and turbulators the costs of manufacturing the refinery heat exchangers are sharply reduced.

Similar content being viewed by others

Abbreviations

- A :

-

Surface area (m2)

- \(c_{\text{P}}\) :

-

Specific heat capacity (J kg−1 K−1)

- D :

-

Diffusion

- D h :

-

Hydraulic diameter (m)

- d :

-

Diameter of nanoparticles (nm)

- f :

-

Mean predicted friction factor

- k :

-

Thermal conductivity (W m−1 K−1)

- L 1 :

-

Upstream length (m)

- L 2 :

-

Test section length (m)

- L 3 :

-

Exit section length (m)

- M :

-

Molar mass

- N :

-

Avogadro number

- Pr:

-

Prandtl number

- PEC or THPEC:

-

Thermal–hydraulic performance evaluation criteria

- p :

-

Pressure (Pa)

- Q :

-

Heat flux (W)

- q″:

-

Specific heat flux (W m−2)

- Re:

-

Reynolds number

- T :

-

Temperature (K)

- u :

-

Velocity

- V m :

-

Velocity

- α :

-

Thermal diffusion

- μ :

-

Dynamic viscosity (Ns m−2)

- ρ :

-

Density (kg m−3)

- φ :

-

Nanoparticles volume fraction

- ∅:

-

Geometrical diameter (m)

- B:

-

Brownian

- bf:

-

Base fluid

- cro:

-

Crude oil

- nf:

-

Nanofluid

- np:

-

Nanoparticle

- BLA:

-

Blade-corrugated

- CYL:

-

Cylindrical-corrugated

- ROD:

-

Rod-corrugated

- SOL:

-

Solar-corrugated

References

Oyakawa K, Shinzato T, Mabuchi I. The effects of the channel width on heat-transfer augmentation in a sinusoidal wave channel. JSME Int J. 1989;32:403–10.

Wang GV, Vanka S. Convective heat transfer in periodic wavy passages. Int J Heat Mass Transf. 1995;38(17):3219–30.

Rush TA, Newell TA, Jacobi AM. An experimental study of flow and heat transfer in sinusoidal wavy passages. Int J Heat Mass Transf. 1999;42(9):1541–53.

Ničeno B, Nobile E. Numerical analysis of fluid flow and heat transfer in periodic wavy channels. Int J Heat Fluid Flow. 2001;2:15–167.

Wang CC, Chen CK. Forced convection in a wavy-wall channel. Int J Heat Mass Transf. 2002;45(12):2587–95.

Comini G, Nonino C, Savino S. Effect of aspect ratio on convection enhancement in wavy channels. Numer Heat Transf Part A Appl. 2003;44(1):21–37.

Naphon P, Kornkumjayrit K. Numerical analysis on the fluid flow and heat transfer in the channel with V-shaped wavy lower plate. Int Commun Heat Mass Transfer. 2008;35(7):839–43.

Naphon P. Effect of wavy plate geometry configurations on the temperature and flow distributions. Int Commun Heat Mass Transf. 2009;36(9):942–6.

Assato M, de Lemos MJ. Turbulent flow in wavy channels simulated with nonlinear models and a new implicit formulation. Numer Heat Transf Part A Appl. 2009;56(4):301–24.

Sui Y, Teo CJ, Lee PS, Chew YT, Shu C. Fluid flow and heat transfer in wavy microchannels. Int J Heat Mass Transf. 2010;53(13–14):2760–72.

Duan Z, Muzychka YS. Effects of axial corrugated roughness on low Reynolds number slip flow and continuum flow in microtubes. J Heat Transfer. 2010;132(4):1–8.

Zhang L, Che D. Influence of corrugation profile on the thermal hydraulic performance of cross-corrugated plates. Numer Heat Transf Part A Appl. 2011;59(4):267–96.

Zhang L, Che D. Turbulence models for fluid flow and heat transfer between cross-corrugated plates. Numer Heat Transf Part A Appl. 2011;60(5):410–40.

Santra AK, Sen S, Charaborty N. Study of heat transfer due to laminar flow of copper–water nanofluid through two isothermally heated parallel plates. Int J Therm Sci. 2009;48(2):391–400.

Abu-Nada E. Application of nanofluids for heat transfer enhancement of separated flows encountered in a backward facing step. Int J Heat Fluid Flow. 2008;29(1):242–9.

Mohammed HA, Gunnasegaran P, Shuaib NH. Numerical simulation of heat transfer enhancement in wavy microchannel heat sink. Int Commun Heat Mass Transf. 2011;38(1):63–8.

Yin J, Yang G, Li Y. The effects of wavy plate phase shift on flow and heat transfer characteristics in corrugated channel. Energy Procedia. 2012;14:1566–73.

Manca O, Nardini S, Ricci D. A numerical study of nanofluid forced convection in ribbed channels. Appl Therm Eng. 2012;37:280–92.

Mohammed HA, Al-Shamani AN, Sheriff JM. Thermal and hydraulic characteristics of turbulent nanofluids flow in a rib-groove channel. Int Commun Heat Mass Transf. 2012;39(10):1584–94.

Heidary H, Kermani MJ. Effect of nano-particles on forced convection in sinusoidal-wall channel. Int Commun Heat Mass Transf. 2010;37(10):1520–7.

Ahmed MA, Shuaib NH, Yusoff MZ, Al-Falahi AH. Numerical investigations of flow and heat transfer enhancement in a corrugated channel using nanofluid. Int Commun Heat Mass Transf. 2011;38(10):1368–75.

Ahmed MA, Shuaib NH, Yusoff MZ. Numerical investigations on the heat transfer enhancement in a wavy channel using nanofluid. Int J Heat Fluid Flow. 2012;55(21–22):5891–8.

Ahmed MA, Shuaib NH, Yusoff MZ. Effects of geometrical parameters on the flow and heat transfer characteristics in trapezoidal-corrugated channel using nanofluid. Int Commun Heat Mass Transf. 2013;42:69–74.

Abbasian Arani AA, Sadripour S, Kermani S. Nanoparticle shape effects on thermal-hydraulic performance of boehmite alumina nanofluids in a sinusoidal–wavy mini-channel with phase shift and variable wavelength. Int J Mech Sci. 2017;128–129:550–63.

Sadripour S, Ghorashi SA, Estajloo M. Numerical investigation of a cavity equipped with corrugated heat source: a full convection-conduction-radiation coupling. Am J Aerosp Eng. 2017;4(3):27–37.

Heris SZ, Esfahany MN, Etemad G. Numerical investigation of nanofluid laminar convective heat transfer through a circular tube. Numer Heat Transf Part A Appl. 2017;52(11):1043–58.

Heris SZ, Etemad SG, Esfahany MN. Convective heat transfer of a Cu/water nanofluid flowing through a circular tube. Exp Heat Transf. 2019;22(4):217–27.

Keshavarz Moraveji M, Haddad SMH, Darabi M. Modeling of forced convective heat transfer of a non-Newtonian nanofluid in the horizontal tube under constant heat flux with computational fluid dynamics. Int Commun Heat Mass Transf. 2012;39:995–9.

Akbari OA, Toghraie D, Karimipour A, Marzban A, Ahmadi GR. The effect of velocity and dimension of solid nanoparticles on heat transfer in non-Newtonian nanofluid. Physica E. 2017;86:68–75.

Minea AA. Uncertainties in modeling thermal conductivity of laminar forced convection heat transfer with water alumina nanofluids. Heat Mass Transf. 2014;68:78–84.

Zeinali Heris S, Etemad SGh, Nasr Esfahany M. Numerical investigation of nanofluid laminar convective heat transfer through a circular tube. Numer Heat Transf Part A Appl. 2007;52(11):1043–58.

Mohammed HA, Abuobeidab IAMA, Vuthaluru HB, Liua S. Two-phase forced convection of nanofluids flow in circular tubes using convergent and divergent conical rings inserts. Int Commun Heat Mass Transf. 2019;101:10–20.

Karimi A, Alrashed Abdullah AAA, Afrand M, Mahian O, Wong wises S, Shahsavar A. The effects of tape insert material on the flow and heat transfer in a nanofluid-based double tube heat exchanger: two-phase mixture model. Int J Mech Sci. 2019;156:397–409.

Sheikholeslami M, Rokni HB. Influence of melting surface on MHD nanofluid flow by means of two phase model. Chin J Phys. 2018;55:1352–60.

Sheikholeslami M, Rokni HB. Nanofluid two phase model analysis in existence of induced magnetic field. Int J Heat Mass Transf. 2017;107:288–99.

Alsarraf J, Moradikazerouni A, Shahsavar A, Afrand M, Salehipour H, Tran MD. Hydrothermal analysis of turbulent boehmite alumina nanofluid flow with different nanoparticle shapes in a minichannel heat exchanger using two-phase mixture model. Phys A. 2019;520:275–88.

Borah A, Boruah MP, Pati S. Conjugate heat transfer in a duct using nanofluid by two-phase Eulerian-Lagrangian method: effect of non-uniform heating. Powder Technol. 2019;346:180–92.

Barnoon P, Toghraie D, Eslami F, Mehmandoust B. Entropy generation analysis of different nanofluid flows in the space between two concentric horizontal pipes in the presence of magnetic field: single-phase and two-phase approaches. Comput Math Appl. 2019;77:662–92.

Rashidi I, Kolsi L, Ahmadi G, Mahian O, Wongwises S, Abu-Nada E. Three-dimensional modelling of natural convection and entropy generation in a vertical cylinder under heterogeneous heat flux using nanofluids. Int J Numer Meth Heat Fluid Flow. 2019;30(1):119–42. https://doi.org/10.1108/HFF-12-2018-0731.

Mahian Omid, Kolsi Lioua, Amani Mohammad, Estellé Patrice, Ahmadi Goodarz, Kleinstreuer Clement, Marshall Jeffrey S, Siavashi Majid, Taylor Robert A, Niazmand Hamid, Wongwises Somchai, Hayat Tasawar, Kolanjiyil Arun, Kasaeian Alibakhsh, Pop Ioan. Recent advances in modeling and simulation of nanofluid flows-Part I: fundamentals and theory. Phys Rep. 2019;790:1–48.

Mahian O, Kolsi L, Amani M, Estellé P, Ahmadi G, Kleinstreuer C, Marshall JS, Taylor RA, Abu-Nada E, Rashidi S, Niazmand H, Wongwises S, Hayat T, Kasaeian A, Pop I. Recent advances in modeling and simulation of nanofluid flows. Phys Rep. 2019;791:1–59.

Al-Rashed AA, Aich W, Kolsi L, Mahian O, Hussein AK, Borjini MN. Effects of movable-baffle on heat transfer and entropy generation in a cavity saturated by CNT suspensions: three-dimensional modeling. Entropy. 2017;19(5):200. https://doi.org/10.3390/e19050200.

Kolsi L, Mahian O, Öztop HF, Aich W, Borjini MN, Abu-Hamdeh N, Aissia HB. 3D buoyancy-induced flow and entropy generation of nanofluid-filled open cavities having adiabatic diamond shaped obstacles. Entropy. 2016;18:232.

Rashidi S, Eskandarian M, Mahian O, et al. Combination of nanofluid and inserts for heat transfer enhancement. J Therm Anal Calorim. 2019;135:437–60. https://doi.org/10.1007/s10973-018-7070-9.

He B, Lin X, Zhang Y. Effect of a novel compound nucleating agent calcium sulfate whisker/β-nucleating agent dicyclohexyl-terephthalamide on crystallization and melting behavior of isotactic polypropylene. J Therm Anal Calorim. 2018;132:1145–52. https://doi.org/10.1007/s10973-018-7043-z.

Rashidi S, Mahian O, Languri EM. Applications of nanofluids in condensing and evaporating systems. J Therm Anal Calorim. 2018;131:2027–39. https://doi.org/10.1007/s10973-017-6773-7.

Moghaddaszadeh N, Rashidi S, Abolfazli Esfahani J. Potential of gear-ring turbulator in three-dimensional heat exchanger tube from second law of thermodynamic viewpoint. Int J Numer Meth Heat Fluid Flow. 2019;29(4):1526–43. https://doi.org/10.1108/HFF-05-2018-0250.

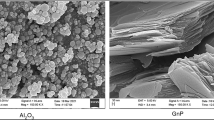

Asadi Amin, Pourfattah Farzad. Heat transfer performance of two oil-based nanofluids containing ZnO and MgO nanoparticles; a comparative experimental investigation. Powder Technol. 2019;343:296–308.

Patankar SV. Numerical heat transfer and fluid flow. Abingdon: Taylor & Francis Group; 1980.

Sadripour S. 3D numerical analysis of atmospheric-aerosol/carbon-black nanofluid flow within a solar air heater located in Shiraz, Iran. Int J Numer Methods Heat Fluid Flow. 2019;29(4):1378–402.

Sadripour S, Chamkha AJ. The effect of nanoparticle morphology on heat transfer and entropy generation of supported nanofluids in a heat sink solar collector. Therm Sci Eng Prog. 2019;9:266–80.

Sadripour S. Investigation of flow characteristics and heat transfer enhancement of a corrugated duct using nanofluid. J Appl Mech Tech Phys. 2018;59(6):1049–57.

Sadripour S. First and second laws analysis and optimization of a solar absorber; using insulator mixers and MWCNTs nanoparticles. Global J Res Eng A Mech Mech. 2017;17(5):37–48.

Sadripour S, Adibi M, Sheikhzadeh GA. Two different viewpoints about using aerosol-carbon nanofluid in corrugated solar collectors: thermal-hydraulic performance and heating performance. Global J Res Eng A Mech Mech. 2017;17(5):19–36.

Corcione M. Empirical correlating equations for predicting the effective thermal conductivity and dynamic viscosity of nanofluids. Energy Convers Manag. 2011;52:789–93.

Keblinski P, Phillpot SR, Choi SUS, Eastman JA. Mechanisms of heat flow in suspensions of nano-sized particles (nanofluids). Int J Heat Mass Transf. 2002;45:855–63.

Launder BE, Spalding DB. Mathematical models of turbulence. New York: Academic Press; 1972.

Anderson JD. Computational fluid dynamics. New York: McGraw-Hill; 1995.

Kim Doohyun, Kwon Younghwan, Cho Yonghyeon, Li Chengguo, Cheong Seongir, Hwang Yujin, Lee Jaekeun, Hong Daeseung, Moon Seongyong. Convective heat transfer characteristics of nanofluids under laminar and turbulent flow conditions. Curr Appl Phys. 2009;9(2):119–23.

Anvari AR, Javaherdeh K, Emami-Meibodi M, Rashidi AM. Numerical and experimental investigation of heat transfer behavior in a round tube with the special conical ring inserts. Energy Convers Manag. 2014;88:214–7.

Promvonge P, Eiamsaard S. Heat transfer behaviors in a tube with combined conical-ring and twisted-tape insert. Int Commun Heat Mass Transfer. 2007;34:849–59.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Vahedi, M., Mollaei Barzi, Y. & Firouzi, M. Two-phase simulation of nanofluid flow in a heat exchanger with grooved wall. J Therm Anal Calorim 146, 1297–1321 (2021). https://doi.org/10.1007/s10973-020-10066-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-10066-6