Abstract

The water ingress phenomenon in sandwich-structured composites used in the aerospace/aeronautical sector is a current issue. This type of defect can cause in the course of time several other defects at the boundary, such as corrosions, deformations, detachments. In fact, water may change its state of physical matter going towards the freeze–thaw cycle caused by the atmosphere re-entry of, e.g. space probes. In this work, the alveoli of a composite laminate have been filled with water, which was initially transformed into ice. By taking into account, the known quantity of water, the freeze–thaw cycle was simulated by Comsol Multiphysics® software, reproducing exactly the shape of the sandwich as well as the real conditions in which it was subsequently subjected in a climatic chamber. The experimental part consisted of monitoring the front side of the specimen by means of a thermal camera operating into the long-wave infrared spectrum, and by setting both the temperature and the relative humidity of the test chamber according to the values imposed during the numerical simulation step. It was found that the numerical and experimental temperature trends are in good agreement with each other since the model was built by following a physico-chemical point-of-view. It was also seen that the application of the independent component thermography (ICT) technique was able both to retrieve the positions of the defects (i.e. the water inclusions) and to characterize the defects in which a detachment (fabricated between the fibres and the resin) is present; the latter was realized above an inclusion caused by the water ingress. To the best of our knowledge, this is the first time that ICT is applied to satisfy this purpose.

Similar content being viewed by others

References

https://pdfs.semanticscholar.org/bc00/402f3f47bbf9cab4dbb7d7f613d8c473f36e.pdf. Accessed 01 Dec 2019.

https://apps.dtic.mil/dtic/tr/fulltext/u2/a402011.pdf. Accessed 01 Dec 2019.

Geyer B. Drying method for composite honeycomb structures. In: Proceedings of the 28th international SAMPE technical conference, USA, November 1996, p. 1183–1192.

Anon. Airbus adopts infrared thermography for in-service inspection. Insight. 1994;23:774–5.

Vavilov VP, Nesteruk DA. Detecting water in aviation honeycomb structures: the quantitative approach. Quant Infr Therm J. 2004;1:173–84.

Vavilov V, Nesteruk D. Evaluating water content in aviation honeycomb panels by transient IR thermography. In: Proceedings of SPIE—The International Society for Optical Engineering—Thermosense XXVII, USA, March 2005, article number 55, p. 411–17.

Crawley NM. Non-destructive testing & the link between environmental degradation & mechanical properties of composite honeycomb panels. In: Annual forum proceedings—AHS international 62nd annual forum, USA, May 2006, p. 1219–31.

Tang BPY, Bennet LGI, Lewis WJ, Sweetapple CP, Francescone O. POD assessment of the RMC neutron radiology system for water detection in CF188 hornet flight control surfaces. In: 8th World conference on neutron radiography (WCNR-8), USA, October 2006, p. 274–84.

Lai WL, Kou SC, Poon CS, Tsang WF, Lai CC. Effects of elevated water temperatures on interfacial delaminations, failure modes and shear strength in externally-bonded CFRP-concrete beams using infrared thermography, gray-scale images and direct shear test. Constr Build Mater. 2009;23:3152–60.

Sfarra S, Ibarra-Castanedo C, Avdelidis NP, Genest M, Bouchagier L, Kourousis D, Tsimogiannis A, Anastassopoulous A, Bendada A, Maldague X, Ambrosini D, Paoletti D. A comparative investigation for the non-destructive testing of honeycomb structures by holographic interferometry and infrared thermography. J Phys: Conf Ser. 2010;214:012071.

Válek J, Kruschwitz S, Wőstmann J, Kind T, Valach J, Kőpp C, Lesák J. Nondestructive investigation of wet building material: multimethodical approach. J Perform Constr Fac. 2010;24:462–72.

Zeng Z, Tao N, Feng L, Li Y, Zhang C. The effect of flash power on the measurement of thermal effusivity using thermal wave imaging. In: Proceedings of SPIE—the international society for optical engineering—international symposium on photoelectronic detection and imaging 2011: advances in infrared imaging and applications, China, May 2011, article number 81930Y.

Zeng Z, Tao N, Feng L, Li Y, Zhang C. Hidden heterogeneous materials recognition in pulsed thermography. AIP Conf Proc. 2012;1430:705–12.

Guo X, Zhang F, Liu Y. Study on pulsed thermography for water ingress detection in composite honeycomb panels. Hangkong Xuebao/Acta Aeronautica et Astronautica Sinica. 2012;33:1134–46.

Ibarra-Castanedo C, Brault L, Marcotte F, Genest M, Farley V, Maldague X. Water ingress detection in honeycomb sandwich panels by passive infrared thermography using a high-resolution thermal imaging camera. In: Proceedings of SPIE—The International Society for Optical Engineering—Thermosense: Thermal Infrared Applications XXXIV, USA, April 2012, vol. 8354, article number 835405.

Chen D, Zeng Z, Tao N, Zhang C, Zhang Z. Liquid ingress recognition in honeycomb structure by pulsed thermography. EPJ Appl Phys. 2013;62:120539.

Chen D, Zeng Z, Zhang C, Jin X, Zhang Z. Quantitative study of water ingress in pulsed thermography. Insight. 2013;55:257–63.

Avdelidis NP, Ibarra-Castanedo C, Maldague XPV. Infrared thermography inspection of glass reinforced plastic (GRP) wind turbine blades and the concept of an automated scanning device. In: Proceedings of SPIE—The International Society for Optical Engineering—Thermosense: Thermal Infrared Applications XXXV, USA, April 2013, vol. 8705, article number 87050G.

Martínez-Garrido MI, Gómez-Heras M, Fort R, Varas-Muriel MJ. Monitoring moisture distribution on stone and masonry walls. In: Rogerio-Candeleda MA, editor. Science, technology and cultural heritage for the conservation of cultural heritage. Balkema: CRC Press; 2014. p. 35–40.

Barreira E, Almeida RMSF, Delgado JMPQ. Infrared thermography for assessing moisture related phenomena in building components. Constr Build Mater. 2016;110:251–69.

Adams J, Salvador M, Lucera L, Langner S, Spyropoulos GD, Fecher FW, Voigt MM, Dowland SA, Osvet A, Egelhaaf H-J, Brabec CJ. Water ingress in encapsulated inverted organic solar cells: correlating infrared imaging and photovoltaic performance. Adv Energy Mater. 2015;5:1501065.

Saarimäki E, Laatikainen Y. Novel thermographic inspection method to detect the moisture in early stage of the water ingress and a procedure to remove the moisture from the composite structure. In: 34th ICAF conference and 28th symposium of the international committee on aeronautical fatigue and structural integrity (ICAF 2015), Finland, June 2015, vol. 2, p. 797–800.

Isakov DV. Infrared detection of water ingress in a composite laminate crevice based on room temperature evaporation. Int J Heat Mass Tran. 2015;86:39–42.

Vavilov V, Marinetti S, Pan Y, Chulkov A. Detecting water ingress in aviation honeycomb panels: qualitative and quantitative aspects. Polym Test. 2016;54:270–80.

Chulkov AO, Vavilov VP, Moskovchenko AI, Pan Y-Y. Quantitative evaluation of water content in composite honeycomb structures by using one-sided IR thermography: is there any promise? In: Proceedings of SPIE—The International Society for Optical Engineering—Thermosense: Thermal Infrared Applications XXXIX, USA, April 2017, vol. 10214, article number 102140U.

Vavilov VP, Pan Y, Moskovchenko AI, Čapka A. Modelling detecting and evaluating water ingress in aviation honeycomb panels. Quant Infr Therm J. 2017;14:206–17.

Bora M, Lordi V, Varley JB. Water ingress mapping in photovoltaic module packaging materials. In: IEEE 7th World conference on photovoltaic energy conversion (WCPEC 2018)—a joint conference of 45th IEEE PVSC, 28th PVSEC and 34th EU PVSEC, USA, June 2018, code 143042.

Duan Y, Liu S, Hu C, Hu J, Zhang H, Yan Y, Tao N, Zhang C, Maldague X, Fang Q, Ibarra-Castanedo C, Chen D, Li X, Meng J. Automated defect detection in infrared thermography based on a neural network. NDT&E Int. 2019;107:102147.

Hu C, Duan Y, Liu S, Yan Y, Tao N, Osman A, Ibarra-Castanedo C, Sfarra S, Chen D, Zhang C. LSTM-RNN-based defect classification in honeycomb structures using infrared thermography. Infrared Phys Techn. 2019;102:103032.

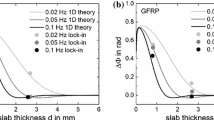

Shrestha R, Choi M, Kim W. Thermographic inspection of water ingress in composite honeycomb sandwich structure: a quantitative comparison among lock-in thermography algorithms. Quant Infr Therm J. 2019. https://doi.org/10.1080/17686733.2019.1697848.

Yao Y, Sfarra S, Lagüela S, Ibarra-Castanedo C, Wu J-Y, Maldague XPV, Ambrosini D. Active thermography testing and data analysis for the state of conservation of panel paintings. Int J Therm Sci. 2018;126:143–51.

Liu Y, Wu J-Y, Liu K, Wen H-L, Yao Y, Sfarra S, Zhao C. Independent component thermography for non-destructive testing of defects in polymer composites. Meas Sci Technol. 2019;30:044006.

Zhang H, Sfarra S, Osman A, Szielasko K, Stumm C, Genest M, Maldague XPV. An infrared-induced terahertz imaging modality for foreign object detection in a lightweight honeycomb composite structure. IEEE Trans Ind Inform. 2018;14:5629–36.

Zhang H, Sfarra S, Genest M, Ibarra-Castanedo C, Duan Y, Fernandes H, Avdelidis NP, Maldague XPV. A comparative study of enhanced infrared image processing for foreign object detection in lightweight composite honeycomb structures. Int J Thermophys. 2018;39:1–10.

Ibarra-Castanedo C, Sfarra S, Ambrosini D, Paoletti D, Bendada A, Maldague X. Diagnostics of panel paintings using holographic interferometry and pulsed thermography. Quant Infr Therm J. 2010;7:85–114.

Sfarra S, Theodorakeas P, Ibarra-Castanedo C, Avdelidis NP, Paoletti A, Paoletti D, Hrissagis K, Bendada A, Koui M, Maldague X. Evaluation of defects in panel paintings using infrared, optical and ultrasonic techniques. Insight. 2012;54:21–7.

http://www.tc.faa.gov/its/worldpac/techrpt/tc12-14.pdf. Accessed 01 Dec 2019.

Sfarra S, Ibarra-Castanedo C, Theodorakeas P, Avdelidis NP, Perilli S, Zhang H, Nardi I, Koui M, Maldague XPV. Evaluation of the state of conservation of mosaics: simulations and thermographic signal processing. Int J Therm Sci. 2017;117:287–315.

https://www.hexcel.com/user_area/content_media/raw/HexWeb_CRIII_DataSheet.pdf. Accessed 01 Nov 2019.

http://www.matweb.com/search/datasheet_print.aspx?matguid=96d768abc51e4157a1b8f95856c49028. Accessed 01 Nov 2019.

https://www.engineeringtoolbox.com/radiation-heat-emissivity-aluminum-d_433.html. Accessed 01 Nov 2019.

https://www.azom.com/properties.aspx?ArticleID=764. Accessed 01 Nov 2019.

https://www.thermoworks.com/emissivity-table. Accessed 01 Nov 2019.

https://system.eu2.netsuite.com/core/media/media.nl?id=63786&c=3937524&h=a09b4bc563ba50c76da0&_xt=.pdf. Accessed 01 Nov 2019.

Lin F, Bhatia GS, Ford JD. Thermal conductivities of powder-filled epoxy resins. J Appl Polym Sci. 1993;49:1901–8.

Webster JG, Eren H. Measurement, Instrumentation, and Sensors Handbook: Two-Volume Set. 2nd ed. Boca Raton: CRC Press; 2014.

http://usa.dupontteijinfilms.com/wp-content/uploads/2017/01/Mylar_Physical_Properties.pdf. Accessed 01 Nov 2019.

https://www.engineeringtoolbox.com/water-html. Accessed 01 November 2019.

https://www.engineeringtoolbox.com/ice-thermal-properties-d_576.html. Accessed 01 Nov 2019.

Perilli S, Regi M, Sfarra S, Nardi I. Comparative analysis of heat transfer for an advanced composite material used as insulation in the building field by means of Comsol Multiphysics® and Matlab® computer programs. Rom J Mater. 2016;46:185–95.

Lever J, Krzywinski M, Altman N. Principal component analysis. Nat Methods. 2017;14:641–2.

Sfarra S, Ibarra-Castanedo C, Santulli C, Paoletti D, Maldague X. Monitoring of jute/hemp fiber hybrid laminates by non-destructive testing techniques. Sci Eng Compos Mater. 2016;23:283–300.

Garrido I, Lagüela S, Sfarra S, Madruga FJ, Arias P. Automatic detection of moistures in different construction materials from thermographic images. J Therm Anal Calorim. 2019;138:1649–68.

Sfarra S, Yao Y, Zhang H, Perilli S, Scozzafava M, Avdelidis NP, Maldague XPV. Precious walls built in indoor environments inspected numerically and experimentally within log-wave infrared (LWIR) and radio regions. J Therm Anal Calorim. 2019;137:1083–111.

Yousefi B, Sfarra S, Ibarra-Castanedo C, Avdelidis NP, Maldague XPV. Thermography data fusion and nonnegative matrix factorization for the evaluation of cultural heritage objects and buildings. J Therm Anal Calorim. 2019;136:943–55.

Yao Y, Sfarra S, Ibarra-Castanedo C, You R, Maldague XPV. The multi-dimensional ensemble empirical mode decomposition (MEEMD)—an advanced tool for thermographic diagnosis of mosaics. J Therm Anal Calorim. 2017;128:1841–58.

Zhang X, Chen M, Huang Y. Isothermal drying kinetics of municipal sewage sludge coupled with additives and freeze-thaw preatreament. J Therm Anal Calorim. 2017;128:1195–205.

Acknowledgements

Authors would like to thank Eng. E. Valentini from Mecaer Aviation Group (MAG), Monteprandone—Ascoli Piceno (AP), Italy, for providing the sandwich panel sample. This work was financially supported by: UID/ECI/04708/2019—CONSTRUCT—Instituto de I&D em Estruturas e Construções funded by national funds through the FCT/MCTES (PIDDAC).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sfarra, S., Tejedor, B., Perilli, S. et al. Evaluating the freeze–thaw phenomenon in sandwich-structured composites via numerical simulations and infrared thermography. J Therm Anal Calorim 145, 3105–3123 (2021). https://doi.org/10.1007/s10973-020-09985-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09985-1