Abstract

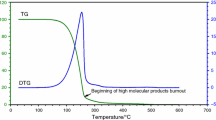

Biodiesel has been widely used as an alternative fuel in diesel engines. However, although its physicochemical properties make it a substitute for traditional diesel fuel, biodiesel is more susceptible to oxidation and degradation during storage than diesel. The high content of unsaturated fatty acid methyl (or ethyl) esters in biodiesel causes its fast oxidative degradation when in contact with precursor agents as oxygen. These reaction products are highly unstable, resulting in a mixture of different species, some of them of high molecular weight, producing sediments and undesirable polymeric compounds. In this study, a sample of commercial soybean biodiesel (BS100) was aged at 50 °C, 110 °C, 150 °C and 200 °C in a Rancimat apparatus. This was performed bubbling air into the sample at 10 L h−1 flow rate for 5 h. The original biodiesel and the aged samples were analyzed by thermogravimetry (TG/DTG), in dynamic mode, under nitrogen atmosphere. Data were compared with those obtained from the analyses performed by size-exclusion chromatography (SEC). Fourier transform infrared spectroscopy (FTIR) analyses were also performed. The objective of this work was to evaluate the effect of the aging temperature on the oxidation of biodiesel and on the degraded product composition, as well as to quantify the formed gums and sediments. The thermogravimetric analysis shows that biodiesel samples aged at 150 °C and 200 °C have a higher content of heavier products (gum), 33.4% and 44.9%, respectively, than the non-aged biodiesel (2.8%). The SEC analysis indicates molecular weight value of 283, 1241 and 1380 g mol−1 for samples aged at 150 °C, 200 °C and for the non-aged sample, respectively, which confirms the results of the TG/DTG analysis. The widening of ester carbonyl stretching band (C=O, 1740 cm−1) in the FTIR spectra, as the aging temperature rises, confirms the degradation of biodiesel into acids, ketones and other compounds containing this functional group. The decrease in percentage transmittance in the region corresponding to the fingerprint (1500–500 cm−1) indicates that heavy products (gums and sediments) are produced. These results indicate that the degradation product content in the aged biodiesel is strongly dependent on the temperature of the aging process.

Similar content being viewed by others

Abbreviations

- BS100:

-

100% Soybean biodiesel

- FTIR:

-

Fourier transform infrared spectroscopy

- DTG:

-

Derivative thermogravimetry (ic)

- TG:

-

Thermogravimetry (ic)

- SEC:

-

Size-exclusion chromatography

- NMR:

-

Nuclear magnetic resonance

- GC-MS:

-

Gas chromatography and mass spectrometry

- HPLC:

-

High-performance liquid chromatography

- ASTM:

-

American Society for Testing and Materials

- ANP:

-

Brazilian National Agency of Petroleum, Natural Gas and Biofuels

- Mn:

-

Number-averaged molar weight

- MW:

-

Molecular mass

- T R :

-

Retention time

- DTGS:

-

Deuterated triglycine sulfate detector

- T endset :

-

Endset temperature

- T onset :

-

Onset temperature

- T max :

-

Maximum mass loss rate temperature

References

Ravindranath NH, Sita Lakshmi C, Manuvie R, Balachandra P. Biofuel production and implications for land use, food production and environment in India. Energy Policy. 2011;39:5737–45.

Padula AD, Santos MS, Ferreira L, Borenstein D. The emergence of the biodiesel industry in Brazil: current figures and future prospects. Energy Policy. 2012;44:395–405.

Hamamci C, Saydut A, Tonbul Y, Kaya C, Kafadar AB. Biodiesel production via transesterification from safflower (Carthamus tinctorius L.) seed oil. Energy Sources Part A Recovery Util Environ Effects. 2011;33:512–20.

Singh D, Sharma D, Soni SL, Sharma S, Kumari D. Chemical compositions, properties, and standards for different generation biodiesels: a review. Fuel. 2019;253:60–71.

Yesilyurt MK, Cesur C. Biodiesel synthesis from Styrax officinalis L. seed oil as a novel and potential non-edible feedstock: a parametric optimization study through the Taguchi technique. Fuel. 2020;265:117025.

Singh G, Mohapatra SK, Ragit S, Kundu K. Optimization of biodiesel production from grape seed oil using Taguchi’s orthogonal array. Energy Sources Part A Recovery Util Environ Effects. 2018;40:2144–53.

Manaf ISA, Embong NH, Khazaai SNM, Rahim MHA, Yusoff MM, Lee KT, et al. A review for key challenges of the development of biodiesel industry. Energy Convers Manag. 2019;185:508–17.

Sitepu EK, Heimann K, Raston CL, Zhang W. Critical evaluation of process parameters for direct biodiesel production from diverse feedstock. Renew Sustain Energy Rev. 2020;123:109762.

Gülüm M, Yesilyurt MK, Bilgin A. The modeling and analysis of transesterification reaction conditions in the selection of optimal biodiesel yield and viscosity. Environ Sci Pollut Res. 2020;27:10351–66.

Hoekman SK, Broch A, Robbins C, Ceniceros E, Natarajan M. Review of biodiesel composition, properties, and specifications. Renew Sustain Energy Rev. 2012;16:143–69.

Kassem Y, Çamur H. Effects of storage under different conditions on the fuel properties of biodiesel admixtures derived from waste frying and canola oils. Biomass Convers Biorefinery. 2018;8:825–45.

MacAmo AJ, Lucas C, Boene KM, Biquiza L, Kobashi Y, Kato S. Effect of storage conditions on the quality of Jatropha curcas oils. ACS Appl Mater Interfaces. 2020;34:3239–43.

Santos MN, De Souza EF, Fiorucci AR, Da Silva MS. Assessment of antioxidant action of curcumin during storage of commercial biodiesel produced from soybean oil and beef tallow. Periodico Tche Quimica. 2019;16:491–502.

Byrne G, Shaughnessy SMO, Byrne G, Shaughnessy SMO. Performance characteristics and exhaust gas analysis of a diesel engine using biodiesel fuel blends biodiesel fuel blends. Biofuels. 2020;11:297–308.

Yesilyurt MK, Arslan M. Analysis of the fuel injection pressure effects on energy and exergy efficiencies of a diesel engine operating with biodiesel. Biofuels. 2019;10:643–55.

Mccarthy P, Rasul MG, Moazzem S. Comparison of the performance and emissions of different biodiesel blends against petroleum diesel. Int J Low-Carbon Technol. 2011;6:255–60.

Alves-Fortunato M, Ayoub E, Bacha K, Mouret A, Dalmazzone C. Fatty acids methyl esters (FAME) autoxidation: new insights on insoluble deposit formation process in biofuels. Fuel. 2020;268:117074.

Mayer FD, Brondani M, VasquezCarrillo MC, Hoffmann R, SilvaLora EE. Revisiting energy efficiency, renewability, and sustainability indicators in biofuels life cycle: analysis and standardization proposal. J Clean Prod. 2020;252:119850.

Rand SJ, Verstuyft AW. Manual Significance of test for petroleum products, 9th edition. ASTM Stock Number: MNL1-9TH. 2018.

Urzędowska W, Stępień Z. Prediction of threats caused by high FAME diesel fuel blend stability for engine injector operation. Fuel Process Technol. 2016;142:403–10.

Rizwanul Fattah IM, Masjuki HH, Kalam MA, Hazrat MA, Masum BM, Imtenan S, et al. Effect of antioxidants on oxidation stability of biodiesel derived from vegetable and animal based feedstocks. Renew Sustain Energy Rev. 2014;30:356–70.

Kumar N. Oxidative stability of biodiesel: causes, effects and prevention. Fuel. 2017;190:328–50.

Silva WC, Castro MPP, Perez VH, Machado FA, Mota L, Sthel MS. Thermal degradation of ethanolic biodiesel: physicochemical and thermal properties evaluation. Energy. 2016;114:1093–9.

Christensen ED, Alleman T, McCormick RL. Re-additization of commercial biodiesel blends during long-term storage. Fuel Process Technol. 2018;177:56–65.

Baena LM, Zuleta EC, Calderón JA. Evaluation of the stability of polymeric materials exposed to palm biodiesel and biodiesel-organic acid blends. Polymers. 2018;10:511.

Decker EA, Alamed J, Castro IA. Interaction between polar components and the degree of unsaturation of fatty acids on the oxidative stability of emulsions. JAOCS J Am Oil Chem Soc. 2010;87:771–80.

Chaiyasit W, Elias RJ, Mcclements DJ, Decker EA. Role of physical structures in bulk oils on lipid oxidation. Crit Rev CRC Crit Rev Food Sci Nutr. 2007;47:299–317.

Waynick JA. Characterization of biodiesel oxidation and oxidation products (CRC Project No. AVFL-2b) SwRI® Project No. 08-10721. NREL-National Renewable Energy Laboratory. 2005;1–51.

Pullen J, Saeed K. Factors affecting biodiesel engine performance and exhaust emissions—part I: review. Energy. 2014;72:1–16.

Singer P, Rühe J. On the mechanism of deposit formation during thermal oxidation of mineral diesel and diesel/biodiesel blends under accelerated conditions. Fuel. 2014;133:245–52.

Fan L, Bai Y, Ma X, Song E. Analysis upon fuel injection quantity variation of common rail system for diesel engines. J Mech Sci Technol. 2016;30:3365–77.

Todaka M, Kowhakul W, Masamoto H, Shigematsu M, Onwona-Agyeman S. Thermal decomposition of biodiesel fuels produced from rapeseed, jatropha, and coffee oils with different alcohols. J Therm Anal Calorim. 2013;113:1355–61.

Jeyalakshmi P. Characterization of Simarouba glauca seed oil biodiesel: a comprehensive study. J Therm Anal Calorim. 2019;136:267–80.

Santos AGD, Caldeira VPS, Farias MF, Araújo AS, Souza LD, Barros AK. Characterization and kinetic study of sunflower oil and biodiesel. J Therm Anal Calorim. 2011;106:747–51.

Wako FM, Reshad AS, Goud VV. Thermal degradation kinetics study and thermal cracking of waste cooking oil for biofuel production. J Therm Anal Calorim. 2018;131:2157–65.

de Miranda MIG, Samios D, de Oliveira Piñeiro T, Vaghetti JCP, Piatnicki CMS. Kinetics of oxidation and decomposition of soybean biodiesel evaluated by the TTT superposition theory and the Freeman–Carroll method. J Mol Liq. 2017;245:121–8.

Fang HL, McCormick RL. Spectroscopic study of biodiesel degradation pathways. SAE Technical Papers. 2006;776–90.

Velvarská R, Vráblík A, Fiedlerová M, Černý R. Near-infrared spectroscopy for determining the oxidation stability of diesel, biodiesel and their mixtures. Chem Papers. 2019;73:2987–93.

Hariram V, John JG, Seralathan S. Spectrometric analysis of algal biodiesel as a fuel derived through base-catalysed transesterification. Int J Ambient Energy. 2019;40:195–202.

Popovicheva OB, Irimiea C, Carpentier Y, Ortega IK, Kireeva ED, Shonija NK, et al. Chemical composition of diesel/biodiesel particulate exhaust by FTIR spectroscopy and mass spectrometry: impact of fuel and driving cycle. Aerosol Air Qual Res. 2017;17:1717–34.

Kim JK, Jeon CH, Lee HW, Park YK, Min K, Hwang I, et al. Effect of accelerated high temperature on oxidation and polymerization of biodiesel from vegetable oils. Energies. 2018;11:1–11.

Knothe G, Kenar JA. Determination of the fatty acid profile by 1H-NMR spectroscopy. Eur J Lipid Sci Technol. 2004;106:88–96.

Chand P, Reddy CV, Venkat JG, Wang T, Grewell D. Thermogravimetric quantification of biodiesel produced via alkali catalyzed transesterification of soybean oil. Energy Fuels. 2009;23:989–92.

Flitsch S, Neu PM, Schober S, Kienzl N, Ullmann J, Mittelbach M. Quantitation of aging products formed in biodiesel during the Rancimat accelerated oxidation test. Energy Fuels. 2014;28:5849–56.

Besser C, Pisarova L, Frauscher M, Hunger H, Litzow U, Orfaniotis A, et al. Oxidation products of biodiesel in diesel fuel generated by artificial alteration and identified by mass spectrometry. Fuel. 2017;206:524–33.

Liu ZW, Li FS, Wang W, Wang B. Impact of different levels of biodiesel oxidation on its emission characteristics. J Energy Inst. 2019;92:861–70.

Li H, Niu SL, Lu CM, Cheng SQ. Comparative evaluation of thermal degradation for biodiesels derived from various feedstocks through transesterification. Energy Convers Manag. 2015;98:81–8.

de Carvalho GC, de Moura MDV, de Castro HGC, et al. Influence of the atmosphere on the decomposition of vegetable oils: study of the profiles of FTIR spectra and evolution of gaseous products. J Therm Anal Calorim. 2020;140:2247–58.

Ferreira EN, Arruda TBMG, Rodrigues FEA, Arruda DTD, da Silva Júnior JH, Porto DL, et al. Investigation of the thermal degradation of the biolubricant through TG-FTIR and characterization of the biodiesel—Pequi (Caryocar brasiliensis) as energetic raw material. Fuel. 2019;245:398–405.

Tudorachi N, Mustata F. Thermal degradation and evolved gas analysis of some vegetable oils using TG/FT-IR/MS technique. J Therm Anal Calorim. 2015;119:1703–11.

Márquez-Ruiz G, Holgado F, García-Martínez MC, Dobarganes MC. A direct and fast method to monitor lipid oxidation progress in model fatty acid methyl esters by high-performance size-exclusion chromatography. J Chromatogr A. 2007;1165:122–7.

Ball JC, Anderson JE, Wallington TJ. Depolymerization of polyester polymers from the oxidation of soybean biodiesel. Energy Fuels. 2018;32:12587–96.

ASTM D4052- Standard test method for density, relative density, and API gravity of liquids by digital density meter. ASTM committee on petroleum products, liquid fuels, and lubricants. In: ASTM annual book of standards. West Conshohocken: ASTM International; 2018. p. 1–9. https://doi.org/10.1520/D4052-18A.

ASTM D445- Standard test method for kinematic viscosity of transparent and opaque liquids (and calculation of dynamic viscosity). ASTM committee on petroleum products, Liquid Fuels, and Lubricants. In: ASTM annual book of standards. West Conshohocken: ASTM International; 2017. p. 1–16. https://doi.org/10.1520/D0445-17A.

ASTM 6584. Standard test method for determination of total monoglycerides, total diglycerides, total triglycerides, and free and total glycerin in B-100 biodiesel methyl esters by gas chromatography. ASTM committee on petroleum products, liquid fuels, and lubricants. In: ASTM annual book of standards. West Conshohocken: ASTM International; 2017. p. 1–9. https://doi.org/10.1520/D6584-17.

EN 14112. Fat and oil derivatives—Fatty acid methyl esters (FAME). Determination of oxidative stability (accelerated oxidation test), EN 14112:2003. Brussels, Belgium: European Committee for Standardization (CEN); 2003.

EN 14103. Fat and oil derivatives. Fatty acid methyl esters (FAME). Determination of ester and linolenic acid methyl ester contents. Brussels, Belgium: European Committee for Standardization (CEN); 2003.

BIOSTAB. Stability of biodiesel—used as a fuel for diesel engines and heating systems. In: Presentation of the BIOSTAB project results. Proceedings. Graz, July 3rd, 2003. Published by BLT Wieselburg, Austria; 2003.

Ma G, Allen HC. Handbook of spectroscopy, volumes 1 and 2 edited by Günter Gauglitz (University of Tübingen) and Tuan Vo-Dinh (Oak Ridge National Laboratory). Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim. 2003. p. 1168. ISBN: 3-527-29782-0.

Acknowledgements

To the Laboratory of Biodiesel Stability Evaluation of the Chemistry School at Federal University of Rio de Janeiro / Brazil and to the Brazilian National Council of Research (CNPq).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Leonardo, R.S., Dweck, J. & Murta Valle, M.L. Effect of the aging temperature on soybean biodiesel oxidation, quantifying the formed gums and sediments by thermogravimetry. J Therm Anal Calorim 142, 2049–2059 (2020). https://doi.org/10.1007/s10973-020-09900-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09900-8