Abstract

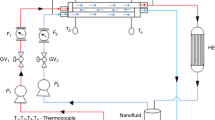

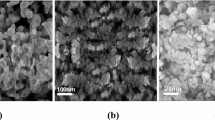

In recent times, the mini heat sink is suggested for cooling the miniature components employed in several engineering applications. In the present work, the thermal performance of the mini hexagonal tube heat sink (MHTHS) was investigated experimentally. Nanofluids and deionized water (DIW) were made to flow through the hexagonal tube side and mini-passage side, respectively. For the preparation of different nanofluids of 0.01 volume fraction, DIW was considered to be a base fluid; Al2O3, CuO, and SiO2 nanoparticles were reckoned to be the supporting materials. Experiments were run under two different conditions in order to ascertain the enhanced thermal performance of the MHTHS. They are as follows: (1) keeping the flow rate of hot DIW constant at 30 L h−1 in the mini-passage side, the flow rates of nanofluids in the hexagonal tube were varied such as 15, 20, 25, 30, 35, 40, 45, and 50 L h−1; (2) keeping the flow rate of nanofluids constant at 30 L h−1 in the hexagonal tube side, the flow rates of hot DIW in the mini-passage side were varied such as 15, 20, 25, 30, 35, 40, 45, and 50 L h−1. From the experimental results, it divulges that the heat transfer coefficient and effectiveness were found to be higher for Al2O3–DIW nanofluid, while comparing other nanofluids. A further improvement in the thermal performance of MHTHS could be achieved at higher volume flow rates of nanofluids in the hexagonal tube side and constant volume flow rate of hot DIW in the mini-passage side.

Similar content being viewed by others

References

Choi SUS, Siginer DA, Wang HP. Enhancing thermal conductivity of fluids with nanoparticles in developments applications of non-Newtonian flows. ASME. 1995;66:99–105.

Murshed SMS, Leong KC, Yang C. Enhanced thermal conductivity of TiO2–water based nanofluids. Int J Therm Sci. 2005;44:367–73.

Yiamsawasd T, Dalkilic AS, Wongwises S. Measurement of the thermal conductivity of titania and alumina nanofluids. Thermochim Acta. 2012;545:48–56.

Lee SW, Park SD, Kang S, Bang IC. Kim JH Investigation of viscosity and thermal conductivity of SiC nanofluids for heat transfer applications. Int J Heat Mass Transf. 2011;54:433–8.

Harikrishnan S, Magesh S, Kalaiselvam S. Preparation and thermal energy storage behaviour of stearic acid–TiO2 nanofluids as a phase change material for solar heating systems. Thermochim Acta. 2013;565:137–45.

Harikrishnan S, Roseline AA, Kalaiselvam S. Preparation and thermo physical properties of water-glycerol mixture-based CuO nanofluids as PCM for cooling applications. IEEE Trans Nanotechnol. 2013;12(4):629–35.

Keblinski P, Eastman JA, Cahill DG. Nanofluids for thermal transport. Mater Today. 2005;8:36–44.

Mahbubul IM, Fadhilah SA, Saidur R, Leong KY, Amalina MA. Thermo physical properties and heat transfer performance of Al2O3/R134 a nano refrigerants. Int J Heat Mass Transf. 2013;57:100–8.

Choi J, Zhang Y. Numerical simulation of laminar forced convection heat transfer of Al2O3–water nanofluid in a pipe with return bend. Int J Therm Sci. 2012;55:90–102.

Chein R, Huang G. Analysis of micro channel heat sink performance using nanofluids. Appl Therm Eng. 2005;25:3104–14.

Xuan Y, Li Q. Heat transfer enhancement of nanofluids. Int J Heat Fluid Flow. 2000;21:58–64.

Li Q, Xuan Y. Experimental investigation on convective heat transfer of nanofluids. J Eng Thermophys. 2002;23:721–3.

Liu Fang, Cai Yang, Wang Liqiu, Zhao Jun. Effects of nanoparticles shape on laminar forced convective heat transfer in curved ducts using two-phase model. Int J Heat Mass Transf. 2018;116:292–305.

Tuckerman DB, Pease RFW. High performance heat sinking for VLSI. IEEE Electron Device Lett. 1981;2:126–9.

Hetsroni G, Mosyak A, Pogrebnyak E, Yarin LP. Fluid flow in micro channels. Int J Heat Mass Transf. 2005;48:1982–98.

Harms TM, Kazmierczak MJ, Cerner FM, Holke A, Henderson HT, Pilchowski J, Baker K. Experimental investigation of heat transfer and pressure drop through deep micro channels in a (1 0 0) silicon substrate. Proc ASME Heat Transf Div. 1997;351:347–57.

Garg H, Negi VS, Garg N, Lall A. Numerical and experimental analysis of micro channel heat transfer for nanoliquid coolant using different shapes and geometries. Proc Inst Mech Eng Part C J Mech Eng Sci. 2014;229:2056–65.

Rudyak VY, Minakov AV. Thermo physical properties of nanofluids. Eur Phys J E. 2018;41:15.

Chein R, Chuang J. Experimental micro channel heat sink performance studies using nanofluids. Int J Therm Sci. 2007;46:57–66.

Husain A, Kim KY. Thermal optimization of a micro channel heat sink with trapezoidal cross section. J Electron Packag. 2009;131:021-005.

Salimpour MR, Sharifhasan M, Shirani E. Constructal optimization of micro channel heat sinks with noncircular cross sections. Heat Transf Eng. 2013;34:863–74.

Khan AA, Kim KY. Evaluation of various channel shapes of a micro channel heat sink. Int J Air-Cond Refrig. 2016;24:165018.

Garg H, Negi VS, Garg N, Lall A. Numerical and experimental analysis of micro channel heat transfer for nanoliquid coolant using different shapes and geometries. Proc Inst Mech Eng Part C J Mech Eng Sci. 2015;229:2056–65.

Drew DA, Passman SL. Theory of multicomponent fluids, vol. 1351. Berlin: Springer; 1999. p. 308.

Hamilton RL, Crosser OK. Thermal conductivity of heterogeneous two component systems. Ind Eng Chem Fundam. 1962;1:182–91.

Brinkman HC. The viscosity of concentrated suspensions and solutions. J Chem Phys. 1952;20:571–81.

Yang SM, Tao WQ. Heat transfer. 3rd ed. China: Higher Education Press Beijing; 1998.

Harikrishnan S, Deepak K, Kalaiselvam S. Thermal energy storage behavior of composite using hybrid nanomaterials as PCM for solar heating systems. J Therm Anal Calorim. 2013;115:1563–71.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sriharan, G., Harikrishnan, S. & Ali, H.M. Experimental investigation on the effectiveness of MHTHS using different metal oxide-based nanofluids. J Therm Anal Calorim 143, 1251–1260 (2021). https://doi.org/10.1007/s10973-020-09779-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09779-5