Abstract

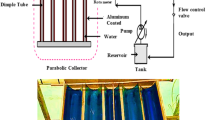

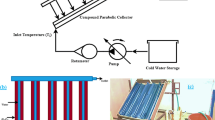

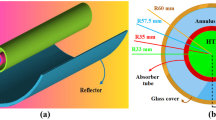

The solar water heating system efficiently converts available solar energy into useful thermal energy. The collector is the predominant unit of the solar water heating system. Using a heat transfer enhancer in the tube is pondered as one of the effective methods to improve the thermal efficiency of the system. Dimples are used as heat transfer enhancer and created using a punching machine. The primary objective of the research is to endow a numerical investigation on the influence of dimples and its various parameters on the thermal efficiency and friction factor of the solar collector. Simulation is performed by varying pitch-to-dimple diameter ratio (P/Dd), number of dimples and mass flow rate. For the result to be independent of mesh, the optimum number of control volumes is identified as 2.2 million. Numerical modeling is done in such a way that the experimental and CFD results are in good agreement with each other and the error percentage is below 10%. Dimples on the tube disturb the fluid flow and reduce the hydraulic diameter, thus enhancing the heat transfer rate and efficiency of the collector. A maximum of 2.5 times increment in the Nusselt number was observed for the dimpled tube with P/Dd ratio 3 and six dimples between two pitches than plain tube at a mass flow rate of 2.5 kg min−1. The friction factor due to the presence of dimples increased by 11.1% compared to that of the normal tube. The relative better enhancement in thermal efficiency with less friction factor makes dimples a superior heat transfer enhancer.

Similar content being viewed by others

Abbreviations

- P :

-

Pitch (mm)

- D d :

-

Diameter of the dimple (mm)

- D i :

-

Inner diameter of the tube (mm)

- D o :

-

Outer diameter of the tube (mm)

- Q :

-

Heat transfer rate (W)

- A c :

-

Area of the collector (m2)

- m :

-

Mass flow rate (kg min−1)

- D h :

-

Hydraulic diameter (mm)

- V :

-

Velocity (ms−1)

- K t :

-

Thermal conductivity (W m−1 K−1)

- ΔP :

-

Change in pressure (Pa)

- K :

-

Kinetic energy (J)

- C p :

-

Specific heat capacity (J K−1)

- W :

-

Width of the collector (mm)

- H :

-

Height of the collector (mm)

- F :

-

Focus distance (mm)

- h :

-

Convective heat transfer coefficient (W m−2 K−1)

- η :

-

Thermal efficiency (%)

- ρ :

-

Density (kg m3)

- µ :

-

Dynamic viscosity (Ns m−2)

- ɛ :

-

Dissipation rate (m2s−3)

References

Akram N, Sadri R, Kazi SN, Ahmed SM, Zubir MNM, Ridha M, Soudagar M, Ahmed W, Arzpeyma M, Tong GB. An experimental investigation on the performance of a flat-plate solar collector using eco-friendly treated graphene nanoplatelets–water nanofluids. J Therm Anal Calorim. 2019;138(2):609–21.

Balaji K, Idrish Khan A, Ganesh Kumar P, Iniyan S, Goic R. Experimental analysis on free convection effect using two different thermal performance enhancers in absorber tube of a forced circulation flat plate solar water heater. Sol Energy. 2019;185:445–54.

Sheikhani H, Barzegarian R, Heydari A, Kianifar A, Kasaeian A, Gróf G, et al. A review of solar absorption cooling systems combined with various auxiliary energy devices. J Therm Anal Calorim. 2018;134(1):2197–212.

Bellos E, Tzivanidis C. A review of concentrating solar thermal collectors with and without nanofluids. J Therm Anal Calorim. 2019;135(2):763–86.

Rajendran DR, Ganapathy Sundaram E, Jawahar P, Sivakumar V, Mahian O, Bellos E. Review on influencing parameters in the performance of concentrated solar power collector based on materials, heat transfer fluids and design. J Therm Anal Calorim. 2019;140(1):33–51.

Hinojosa JF, Cabanillas RE, Alvarez G, Estrada CE. Nusselt number for the natural convection and surface thermal radiation in a square tilted open cavity. Int Commun Heat Mass Transf. 2005;32:1184–92.

Reichl C, Hengstberger F, Zauner C. Heat transfer mechanisms in a compound parabolic concentrator: comparison of computational fluid dynamics simulations to particle image velocimetry and local temperature measurements. Sol Energy. 2013;97:436–46.

Gudekar AS, Jadhav AS, Panse SV, Joshi JB, Pandit AB. Cost effective design of compound parabolic collector for steam generation. Sol Energy. 2013;90:43–50.

Chamsa-Ard W, Sukchai S, Sonsaree S, Sirisamphanwong C. Thermal performance testing of heat pipe evacuated tube with compound parabolic concentrating Solar collector BY ISO 9806-1. Energy Procedia. 2014;56:237–46.

Waghmare SA, Gulhane NP. Design and ray tracing of a compound parabolic collector with tubular receiver. Sol Energy. 2016;137:165–72.

Xu RJ, Zhang XH, Wang RX, Xu SH, Wang HS. Experimental investigation of a solar collector integrated with a pulsating heat pipe and a compound parabolic concentrator. Energy Convers Manag. 2017;148:68–77.

Francesconi M, Antonelli M. A CFD analysis to investigate thermal losses in a panel composed of several CPC concentrators. Therm Sci Eng Prog. 2018;5:278–88.

Bhattacharyya S. The effects of short length and full length swirl generators on heat transfer and flow fields in a solar air heater tube. J Therm Anal Calorim 2019;0123456789.

Jaisankar S, Radhakrishnan TK, Sheeba KN. Experimental studies on heat transfer and thermal performance characteristics of thermosyphon solar water heating system with helical and Left-Right twisted tapes. Energy Convers Manag. 2011;52:2048–55.

Ananth J, Jaisankar S. Experimental studies on heat transfer and friction factor characteristics of thermosyphon solar water heating system fitted with regularly spaced twisted tape with rod and spacer. Energy Convers Manag. 2013;73:207–13.

Patil AG. Laminar flow heat transfer and pressure drop characteristics of power-law fluids inside tubes with varying width twisted tape inserts. J Heat Transfer. 2000;122:143–9.

Eiamsa-ard S, Thianpong C, Eiamsa-ard P, Promvonge P. Convective heat transfer in a circular tube with short-length twisted tape insert. Int Commun Heat Mass Transf. 2009;36:365–71.

Jaisankar S, Radhakrishnan TK, Sheeba KN. Experimental studies on heat transfer and friction factor characteristics of forced circulation solar water heater system fitted with helical twisted tapes. Sol Energy. 2009;83:1943–52.

Zhang X, Liu Z, Liu W. Numerical studies on heat transfer and flow characteristics for laminar flow in a tube with multiple regularly spaced twisted tapes. Int J Therm Sci. 2012;58:157–67.

Anvari AR, Lotfi R, Rashidi AM, Sattari S. Experimental research on heat transfer of water in tubes with conical ring inserts in transient regime. Int Commun Heat Mass Transf. 2011;38:668–71.

Eiamsa-Ard S, Somkleang P, Nuntadusit C, Thianpong C. Heat transfer enhancement in tube by inserting uniform/non-uniform twisted-tapes with alternate axes: effect of rotated-axis length. Appl Therm Eng. 2013;54:289–309.

Wongcharee K, Eiamsa-ard S. Friction and heat transfer characteristics of laminar swirl flow through the round tubes inserted with alternate clockwise and counter-clockwise twisted-tapes. Int Commun Heat Mass Transf. 2011;38:348–52.

Eiamsa-ard S, Thianpong C, Eiamsa-ard P. Turbulent heat transfer enhancement by counter/co-swirling flow in a tube fitted with twin twisted tapes. Exp Therm Fluid Sci. 2010;34:53–62.

Murugesan P, Mayilsamy K, Suresh S. Heat transfer and friction factor studies in a circular tube fitted with twisted tape consisting of wire-nails. Chinese J Chem Eng. 2010;18:1038–42.

Guo J, Fan A, Zhang X, Liu W. A numerical study on heat transfer and friction factor characteristics of laminar flow in a circular tube fitted with center-cleared twisted tape. Int J Therm Sci. 2011;50:1263–70.

Murugesan P, Mayilsamy K, Suresh S. Turbulent heat transfer and pressure drop in tube fitted with square-cut twisted tape. Chin J Chem Eng. 2010;18:609–17.

Murugesan P, Mayilsamy K, Suresh S, Srinivasan PSS. Heat transfer and pressure drop characteristics in a circular tube fi tted with and without V-cut twisted tape insert. Int Commun Heat Mass Transf. 2011;38:329–34.

Murugesan P, Mayilsamy K, Suresh S, Srinivasan PSS. Heat transfer and pressure drop characteristics of turbulent flow in a tube fitted with conical ring and twisted tape inserts. Int J Acad Res. 2009;1:123–8.

Bas H, Ozceyhan V. Heat transfer enhancement in a tube with twisted tape inserts placed separately from the tube wall. Exp Therm Fluid Sci. 2012;41:51–8.

Rahimi M, Shabanian SR, Alsairafi AA. Experimental and CFD studies on heat transfer and friction factor characteristics of a tube equipped with modified twisted tape inserts. Chem Eng Process Process Intensif. 2009;48:762–70.

Obot NT, Esen EB, Rabas TJ. The role of transition in determining friction and heat transfer in smooth and rough passages. Int J Heat Mass Transf. 1990;33:2133–43.

Ravigururajan TS, Bergles AE. Visualization of flow phenomena near enhanced surfaces. J Heat Transf. 1994;116:54–7.

Barba A, Rainieri S, Spiga M. Heat transfer enhancement in a corrugated tube. Int Commun Heat Mass Transf. 2002;29:313–22.

Chen J, Müller-Steinhagen H, Duffy GG. Heat transfer enhancement in dimpled tubes. Appl Therm Eng. 2001;21:535–47.

El-Sayed SA, El-Sayed SA, Abdel-Hamid ME, Sadoun MM. Experimental study of turbulent flow inside a circular tube with longitudinal interrupted fins in the streamwise direction. Exp Therm Fluid Sci. 1997;15:1–15.

Eiamsa-Ard S, Wongcharee K. Heat transfer characteristics in micro-fin tube equipped with double twisted tapes: effect of twisted tape and micro-fin tube arrangements. J Hydrodyn. 2013;25:205–14.

Balaji K, Iniyan S, Muthusamyswami V. Experimental investigation on heat transfer and pumping power of forced circulation flat plate solar collector using heat transfer enhancer in absorber tube. Appl Therm Eng. 2017;112:237–47.

Balaji K, Iniyan S, Swami MV. Exergy, economic and environmental analysis of forced circulation flat plate solar collector using heat transfer enhancer in riser tube. J Clean Prod. 2018;171:1118–27.

Aktaş M, Sözen A, Amini A, Khanlari A. Experimental analysis and CFD simulation of infrared apricot dryer with heat recovery. Dry Technol. 2017;35:766–83.

Farshad SA, Sheikholeslami M. Nanofluid flow inside a solar collector utilizing twisted tape considering exergy and entropy analysis. Renew Energy. 2019;141:246–58.

Farshad SA, Sheikholeslami M. FVM modeling of nanofluid forced convection through a solar unit involving MCTT. Int J Mech Sci. 2019;159:126–39.

Jafaryar M, Sheikholeslami M, Li Z. CuO-water nanofluid flow and heat transfer in a heat exchanger tube with twisted tape turbulator. Powder Technol. 2018;336:131–43.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Manoram, R.B., Moorthy, R.S. & Ragunathan, R. Investigation on influence of dimpled surfaces on heat transfer enhancement and friction factor in solar water heater. J Therm Anal Calorim 145, 541–558 (2021). https://doi.org/10.1007/s10973-020-09746-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09746-0