Abstract

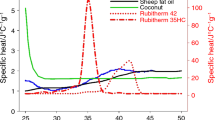

The thermal behavior of materials based on the renewable raw resource, beeswax, was studied to evaluate their potential as phase-change materials, PCMs, for latent heat thermal energy storage, LHTES. Beeswax, transesterified beeswax methyl esters and mixtures of beeswax with paraffin were studied. Additionally, waste vegetable cooking oil, a widely available and underused renewable raw material, was fully hydrogenated and the product, and its mixtures with beeswax, were investigated as candidates to PCMs. Transesterified beeswax shows an increase of about 15% in melting/crystallization enthalpies relative to the already suitable beeswax. In addition, the phase transitions take place at a 10 °C higher temperature range. These characteristics, and the minimal undercooling for crystallization, make both samples good PCM candidates. The addition of beeswax to hydrogenated waste cooking oil was found to be efficient in promoting the formation of the most stable triacylglycerides polymorph, making mixtures of these two renewable raw materials promising candidates for LHTES. Beeswax + paraffin mixtures, with 40% beeswax content, show near ideal thermal behavior for a PCM, while decreasing the amount of the crude derivative. Additionally, the volume change upon melting, one of the major problems of paraffins as PCMs, is considerably less for this mixture (about 50%).

Similar content being viewed by others

References

Assembly UG. Transforming our world: the 2030 agenda for sustainable development: UN General Assembly 2015 21 October 2015 contract no.: A/RES/70/1.

Salunkhe PB, Krishna DJ. Investigations on latent heat storage materials for solar water and space heating applications. J Energy Storage. 2017;12:243–60. https://doi.org/10.1016/j.est.2017.05.008.

Pethurajan V, Sivan S, Konatt AJ, Reddy AS. Facile approach to improve solar thermal energy storage efficiency using encapsulated sugar alcohol based phase change material. Sol Energy Mater Sol Cells. 2018;185:524–35. https://doi.org/10.1016/j.solmat.2018.06.007.

Settino J, Sant T, Micallef C, Farrugia M, Spiteri Staines C, Licari J, et al. Overview of solar technologies for electricity, heating and cooling production. Renew Sustain Energy Rev. 2018;90:892–909. https://doi.org/10.1016/j.rser.2018.03.112.

Dinker A, Agarwal M, Agarwal GD. Heat storage materials, geometry and applications: a review. J Energy Inst. 2017;90(1):1–11. https://doi.org/10.1016/j.joei.2015.10.002.

Bruno F, Belusko M, Liu M, Tay NHS. Using solid–liquid phase change materials (PCMs) in thermal energy storage systems. In: Cabeza LF, editor. Advances in thermal energy storage systems. Cambridge: Woodhead Publishing; 2015. p. 201–46.

O’Neil GW, Yen TQ, Leitch MA, Wilson GR, Brown EA, Rider DA, et al. Alkenones as renewable phase change materials. Renew Energy. 2019;134:89–94. https://doi.org/10.1016/j.renene.2018.11.001.

Abhat A. Low temperature latent heat thermal energy storage: heat storage materials. Sol Energy. 1983;30(4):313–32. https://doi.org/10.1016/0038-092X(83)90186-X.

Sharma A, Tyagi VV, Chen CR, Buddhi D. Review on thermal energy storage with phase change materials and applications. Renew Sustain Energy Rev. 2009;13(2):318–45. https://doi.org/10.1016/j.rser.2007.10.005.

Saydam V, Duan X. Dispersing different nanoparticles in paraffin wax as enhanced phase change materials. J Therm Anal Calorim. 2019;135(2):1135–44. https://doi.org/10.1007/s10973-018-7484-4.

Jering A. Use of renewable raw materials: presented to the ETC/SCP 2010. Report: European Environment Agency 2010 March 2010. report no.: ETC/SCP report 1/2010.

Barros A, Nunes F, Costa M. Manual de Boas Prácticas na Produção de Cera de Abelha: FNAP2009.

Kousksou T, Jamil A, Rhafiki TE, Zeraouli Y. Paraffin wax mixtures as phase change materials. Sol Energy Mater Sol Cells. 2010;94(12):2158–65. https://doi.org/10.1016/j.solmat.2010.07.005.

Agyenim F, Hewitt N, Eames P, Smyth M. A review of materials, heat transfer and phase change problem formulation for latent heat thermal energy storage systems (LHTESS). Renew Sustain Energy Rev. 2010;14(2):615–28. https://doi.org/10.1016/j.rser.2009.10.015.

He B, Setterwall F. Technical grade paraffin waxes as phase change materials for cool thermal storage and cool storage systems capital cost estimation. Energy Convers Manag. 2002;43(13):1709–23. https://doi.org/10.1016/S0196-8904(01)00005-X.

Hadiya JP, Shukla AKN. Experimental thermal behavior response of paraffin wax as storage unit. J Therm Anal Calorim. 2016;124(3):1511–8. https://doi.org/10.1007/s10973-016-5276-2.

Hasanabadi S, Sadrameli SM, Soheili H, Moharrami H, Heyhat MM. A cost-effective form-stable PCM composite with modified paraffin and expanded perlite for thermal energy storage in concrete. J Therm Anal Calorim. 2019;136(3):1201–16. https://doi.org/10.1007/s10973-018-7731-8.

Ma L, Guo C, Ou R, Wang Q, Li L. Synthesis and characterization of the n-butyl palmitate as an organic phase change material. J Therm Anal Calorim. 2019;136(5):2033–9. https://doi.org/10.1007/s10973-018-7846-y.

Zeng J-L, Shu L, Jiang L-M, Chen Y-H, Zhang Y-X, Xie T, et al. Thermodynamic and thermal energy storage properties of a new medium-temperature phase change material. J Therm Anal Calorim. 2019;135(6):3171–9. https://doi.org/10.1007/s10973-018-7530-2.

Buhler M, Popa AM, Scherer LJ, Lehmeier FKS, Rossi RM. Heat protection by different phase change materials. Appl Therm Eng. 2013;54(2):359–64. https://doi.org/10.1016/j.applthermaleng.2013.02.025.

Abhat A, Heine D, Heinisch M, Malatidis NA, Neuer G. Development of a modular heat exchanger with integrated latent heat energy store. Stuttgart: Institut fuer Kemtechnik und Energiewandlung; 1979.

Grompone MA. Sunflower oil. Veg Oils Food Technol. 2011. https://doi.org/10.1002/9781444339925.ch5.

Hamilton RJ. Fatty acids: structure, occurrence, nomenclature, biosynthesis and properties. Trans Fatty Acids. 2008. https://doi.org/10.1002/9780470697658.ch1.

Dell’Anna MM, Gagliardi M, Mastrorilli P, Suranna GP, Nobile CF. Hydrogenation reactions catalysed by a supported palladium complex. J Mol Catal A: Chem. 2000;158(2):515–20. https://doi.org/10.1016/S1381-1169(99)00445-8.

Philippaerts A, Jacobs P, Sels B. Catalytic hydrogenation of vegetable oils. In: Rinaldi R, editor. Catalytic hydrogenation for biomass valorization, Energy and environment series, book 13. Cambridge: Royal Society of Chemistry; 2015. p. 223–41.

King AO, Larsen RD, Negishi E-I. Palladium-catalyzed heterogeneous hydrogenation. In: Handbook of organopalladium chemistry for organic synthesis; 2002, p. 2719–52. https://doi.org/10.1002/0471212466.ch124.

Stankovic M, Krstic J, Gabrovska M, Radonjic V, Nikolova D, Loncarevic D et al. Supported nickel-based catalysts for partial hydrogenation of edible oils. In: Ravanchi MT, editor. New advances in hydrogenation processes-fundamentals and applications. Rjeka: Intech, 2017. p. 131–180.

Anderssen IH, Webber C. Localised production and supply of biodiesel from used cooking oils. State of the art in Europe: European commission intelligent energy Europe 2007 December 2007 contract no.: 12/07.

Jiménez JJ, Bernal JL, Aumente S, del Nozal MJ, Martı́n MT, Bernal J. Quality assurance of commercial beeswax: part I. Gas chromatography–electron impact ionization mass spectrometry of hydrocarbons and monoesters. J Chromatogr A. 2004;1024(1):147–54. https://doi.org/10.1016/j.chroma.2003.10.063.

Jimenez JJ, Bernal JL, Aumente S, Toribio L, Bernal J. Quality assurance of commercial beeswax: II. Gas chromatography–electron impact ionization mass spectrometry of alcohols and acids. J Chromatogr A. 2003;1007(1):101–16. https://doi.org/10.1016/S0021-9673(03)00962-2.

Della Gatta G, Richardson Michael J, Sarge Stefan M, Stølen S. Standards, calibration, and guidelines in microcalorimetry. Part 2. Calibration standards for differential scanning calorimetry* (IUPAC technical report). Pure and Applied Chemistry; 2006. p. 1455.

Sabbah R, An XW, Chickos JS, Leitao MLP, Roux MV, Torres LA. Reference materials for calorimetry and differential thermal analysis. Thermochim Acta. 1999;331(2):93–204. https://doi.org/10.1016/s0040-6031(99)00009-x.

Timbers GE, Robertson GD, Gochnauer TA. Thermal properties of beeswax and Beeswax–Paraffin mixtures. J Apic Res. 1977;16(1):49–55. https://doi.org/10.1080/00218839.1977.11099860.

Gaillard Y, Mija A, Burr A, Darque-Ceretti E, Felder E, Sbirrazzuoli N. Green material composites from renewable resources: polymorphic transitions and phase diagram of beeswax/rosin resin. Thermochim Acta. 2011;521(1):90–7. https://doi.org/10.1016/j.tca.2011.04.010.

Riemenschneider W, Bolt HM. Esters, organic. Ullmann’s Encyclopedia of Industrial Chemistry. Major Reference Works; 2005.

Hernqvist L. Polymorphism of triglycerides—a crystallographic review. Food Struct. 1990;9(1):39–44.

Hale JE, Schroeder F. Phase-behavior of triolein and tripalmitin detected by differential scanning calorimetry. Lipids. 1981;16(11):805–9. https://doi.org/10.1007/Bf02535033.

Small DM. The physical chemistry of lipids : from Alkanes to phospholipids. Handbook of lipid research. New York: Plenum Press; 1986.

Yoshikawa S, Kida H, Sato K. Fat crystallization with talc particles is influenced by particle size, concentration, and cooling rate. Eur J Lipid Sci Technol. 2014;117(6):858–68. https://doi.org/10.1002/ejlt.201400420.

Yoshikawa S, Kida H, Sato K. Promotional effects of new types of additives on fat crystallization. J Oleo Sci. 2014;63(4):333–45. https://doi.org/10.5650/jos.ess13155.

Chazhengina SY, Kotelnikova EN, Filippova IV, Filatov SK. Phase transitions of n-alkanes as rotator crystals. J Mol Struct. 2003;647(1):243–57. https://doi.org/10.1016/S0022-2860(02)00531-8.

Acknowledgements

The authors are grateful to José Vicente for supplying the beeswax used in this project. This work is supported by Coimbra Chemistry Center, CQC, through the Fundação para a Ciência e a Tecnologia, FCT, project UID/QUI/00313/2019 and by Project MATIS—Materiais e Tecnologias Industriais Sustentáveis (CENTRO-01-0145-FEDER-000014).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Baptista, J.A., Eusébio, M.E.S. & Pereira, M.M. New renewable raw materials for thermal energy storage. J Therm Anal Calorim 145, 27–37 (2021). https://doi.org/10.1007/s10973-020-09685-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09685-w