Abstract

Blending polylactide (PLA) with poly(d-lactide) (PDLA) and cellulose nanocrystals (CNC)-based stereocomplex (SC) nanohybrids presents practical approach to produce fully biobased blends and nanocomposites with enhanced properties. This paper investigated the nucleation effect of PLA/PDLA and PLA/PDLA-g-MAH/CNC nanohybrids at low loading levels on the non-isothermal crystallization, morphology, as well as thermal and thermo-mechanical properties of PLA-based samples. Neat PLA, blends and nanocomposites were produced by conventional and microcellular injection molding. Nitrogen (N2) in a supercritical state was used as the physical blowing agent for preparation of microcellular samples. CNC-based SC showed superior nucleating efficiency compared to SC nucleating agents. However, low mold temperature resulted in relatively low degree of crystallinity (~ 15%). In addition, decrease in cell size and increase in cell density of microcellular samples have been observed after introduction of both nucleating agents. Slight increase in mechanical properties of nucleated samples compared to neat PLA has been ascribed to the higher degree of crystallinity. Despite these, decrease in all mechanical properties of microcellular samples has been noticed when compared to solid counterparts. Furthermore, dynamic mechanical analysis (DMA) reveals subsequent foaming and dramatic decrease in dimensional stability of microcellular samples above glass transition temperature (Tg). The storage modulus in a glassy region has been improved in both solid blends and nanocomposites. In addition, shift of Tg due to restricted chain mobility of PLA due to retarded relaxation of amorphous regions due to SC interactions has been observed.

Similar content being viewed by others

References

Nagalakshmaiah M, et al. Biocomposites: present trends and challenges for the future. In: Koronis G, Silva A, editors. Green composites for automotive applications, Elsevier; 2019, pp. 197–215.

European Commission. Europe 2020: a strategy for smart, sustainable and inclusive growth—communication from the commission. Brussels: Publications Office of the European Union; 2010.

Martens W. Europe 2020 and beyond. Eur View. 2010;9(1):1–3.

La Mantia FP, Morreale M. Green composites: a brief review. Compos A Appl Sci Manuf. 2011;42(6):579–88.

Thompson RC, Moore CJ, vom Saal FS, Swan SH. Plastics, the environment and human health: current consensus and future trends. Philos Trans R Soc Lond B Biol Sci. 2009;364(1526):2153–66.

da Silva D, et al. Biocompatibility, biodegradation and excretion of polylactic acid (PLA) in medical implants and theranostic systems. Chem Eng J. 2018;340:9–14.

Auras R, Harte B, Selke S. An overview of polylactides as packaging materials. Macromol Biosci. 2004;4(9):835–64.

Gupta B, Revagade N, Hilborn J. Poly (lactic acid) fiber: an overview. Prog Polym Sci. 2007;32(4):455–82.

Lim L-T, Auras R, Rubino M. Processing technologies for poly (lactic acid). Prog Polym Sci. 2008;33(8):820–52.

Reddy MM, Vivekanandhan S, Misra M, Bhatia SK, Mohanty AK. Biobased plastics and bionanocomposites: current status and future opportunities. Prog Polym Sci. 2013;38(10–11):1653–89.

Tan BH, Muiruri JK, Li Z, He C. Recent progress in using stereocomplexation for enhancement of thermal and mechanical property of polylactide. ACS Sustain Chem Eng. 2016;4(10):5370–91.

Saeidlou S, Huneault MA, Li H, Park CB. Poly(lactic acid) crystallization. Prog Polym Sci. 2012;37(12):1657–77.

Nofar M, Zhu W, Park CB, Randall J. Crystallization kinetics of linear and long-chain-branched polylactide. Ind Eng Chem Res. 2011;50(24):13789–98.

Jacobsen S, Fritz H-G. Plasticizing polylactide—the effect of different plasticizers on the mechanical properties. Polym Eng Sci. 1999;39(7):1303–10.

Kfoury G, et al. Recent advances in high performance poly (lactide): from “green” plasticization to super-tough materials via (reactive) compounding. Front Chem. 2013;1:32.

Gupta A, Simmons W, Schueneman GT, Mintz EA. Lignin-coated cellulose nanocrystals as promising nucleating agent for poly(lactic acid). J Therm Anal Calorim. 2016;126(3):1243–51.

Vidović E, Faraguna F, Jukić A. Influence of inorganic fillers on PLA crystallinity and thermal properties. J Therm Anal Calorim. 2017;127(1):371–80.

Dartora PC, da Rosa Loureiro M, de Camargo Forte MM. Crystallization kinetics and morphology of poly (lactic acid) with polysaccharide as nucleating agent. J Therm Anal Calorim. 2018;134(3):1705–13.

Anderson KS, Hillmyer MA. Melt preparation and nucleation efficiency of polylactide stereocomplex crystallites. Polymer. 2006;47(6):2030–5.

Wei X-F, Bao R-Y, Cao Z-Q, Yang W, Xie B-H, Yang M-B. Stereocomplex crystallite network in asymmetric PLLA/PDLA blends: formation, structure, and confining effect on the crystallization rate of homocrystallites. Macromolecules. 2014;47(4):1439–48.

Ikada Y, Jamshidi K, Tsuji H, Hyon SH. Stereocomplex formation between enantiomeric poly (lactides). Macromolecules. 1987;20(4):904–6.

Tsuji H. Poly (lactide) stereocomplexes: formation, structure, properties, degradation, and applications. Macromol Biosci. 2005;5(7):569–97.

Xue S, Jia P, Ren Q, Liu X, Lee RE, Zhai W. Improved expansion ratio and heat resistance of microcellular poly (l-lactide) foam via in situ formation of stereocomplex crystallites. J Cell Plast. 2018;54(1):103–19.

Bai J, et al. Stereocomplex crystallite-assisted shear-induced crystallization kinetics at a high temperature for asymmetric biodegradable PLLA/PDLA blends. ACS Sustain Chem Eng. 2015;4(1):273–83.

Wei X-F, et al. Synergistic effect of stereocomplex crystals and shear flow on the crystallization rate of poly (l-lactic acid): a rheological study. RSC Adv. 2014;4(6):2733–42.

Pantani R, Volpe V, Titomanlio G. Foam injection molding of poly (lactic acid) with environmentally friendly physical blowing agents. J Mater Process Technol. 2014;214(12):3098–107.

Speranza V, De Meo A, Pantani R. Thermal and hydrolytic degradation kinetics of PLA in the molten state. Polym Degrad Stab. 2014;100:37–41.

Kothapalli CR, Shaw MT, Wei M. Biodegradable HA-PLA 3-D porous scaffolds: effect of nano-sized filler content on scaffold properties. Acta Biomater. 2005;1(6):653–62.

Borkotoky SS, Dhar P, Katiyar V. Biodegradable poly (lactic acid)/cellulose nanocrystals (CNCs) composite microcellular foam: effect of nanofillers on foam cellular morphology, thermal and wettability behavior. Int J Biol Macromol. 2018;106:433–46.

Šturcová A, Davies GR, Eichhorn SJ. Elastic modulus and stress-transfer properties of tunicate cellulose whiskers. Biomacromol. 2005;6(2):1055–61.

Nelson K, et al. American process: production of low cost nanocellulose for renewable, advanced materials applications. In: Madsen LD, Svedberg EB, editors. Materials research for manufacturing. Berlin: Springer; 2016. p. 267–302.

Yuan M, Winardi A, Gong S, Turng L. Effects of nano-and micro-fillers and processing parameters on injection-molded microcellular composites. Polym Eng Sci. 2005;45(6):773–88.

Matuana LM, Diaz CA. Study of cell nucleation in microcellular poly (lactic acid) foamed with supercritical CO2 through a continuous-extrusion process. Ind Eng Chem Res. 2010;49(5):2186–93.

Boruvka M, Behalek L, Lenfeld P, Ngaowthong C, Pechociakova M. Structure-related properties of bionanocomposites based on poly (lactic acid), cellulose nanocrystals and organic impact modifier. Mater Technol. 2019;34(3):143–56.

Mohanty AK, Misra M, Drzal LT. Natural fibers, biopolymers, and biocomposites. Boca Raton: CRC Press; 2005.

Sarasua J, Arraiza AL, Balerdi P, Maiza I. Crystallization and thermal behaviour of optically pure polylactides and their blends. J Mater Sci. 2005;40(8):1855–62.

Hayashi H, Mori T, Okamoto M, Yamasaki S, Hayami H. Polyethylene ionomer-based nano-composite foams prepared by a batch process and MuCell® injection molding. Mater Sci Eng C. 2010;30(1):62–70.

Du J, Wang Y, Xie X, Xu M, Song Y. Styrene-assisted maleic anhydride grafted poly (lactic acid) as an effective compatibilizer for wood flour/poly (lactic acid) bio-composites. Polymers. 2017;9(11):623.

Wu C-S. Renewable resource-based composites of recycled natural fibers and maleated polylactide bioplastic: characterization and biodegradability. Polym Degrad Stab. 2009;94(7):1076–84.

De Roover B, Sclavons M, Carlier V, Devaux J, Legras R, Momtaz A. Molecular characterization of maleic anhydride-functionalized polypropylene. J Polym Sci A Polym Chem. 1995;33(5):829–42.

Qiu W, Endo T, Hirotsu T. A novel technique for preparing of maleic anhydride grafted polyolefins. Eur Polym J. 2005;41(9):1979–84.

Hwang SW, et al. Grafting of maleic anhydride on poly (l-lactic acid). Effects on physical and mechanical properties. Polym Test. 2012;31(2):333–44.

Detyothin S, Selke SE, Narayan R, Rubino M, Auras R. Reactive functionalization of poly (lactic acid), PLA: effects of the reactive modifier, initiator and processing conditions on the final grafted maleic anhydride content and molecular weight of PLA. Polym Degrad Stab. 2013;98(12):2697–708.

Murariu M, Dechief A-L, Ramy-Ratiarison R, Paint Y, Raquez J-M, Dubois P. Recent advances in production of poly(lactic acid) (PLA) nanocomposites: a versatile method to tune crystallization properties of PLA. Nanocomposites. 2015;1(2):71–82.

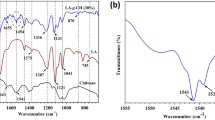

Pan P, et al. Temperature-variable FTIR and solid-state 13C NMR investigations on crystalline structure and molecular dynamics of polymorphic poly (l-lactide) and poly (l-lactide)/poly (d-lactide) stereocomplex. Macromolecules. 2011;45(1):189–97.

Sarasua J-R, Rodríguez NL, Arraiza AL, Meaurio E. Stereoselective crystallization and specific interactions in polylactides. Macromolecules. 2005;38(20):8362–71.

Pilla S, Kramschuster A, Gong S, Chandra A, Turng L-S. Solid and microcellular polylactide-carbon nanotube nanocomposites. Int Polym Proc. 2007;22(5):418–28.

Zhao H, Cui Z, Sun X, Turng L-S, Peng X. Morphology and properties of injection molded solid and microcellular polylactic acid/polyhydroxybutyrate-valerate (PLA/PHBV) blends. Ind Eng Chem Res. 2013;52(7):2569–81.

Wu H, Nagarajan S, Zhou L, Duan Y, Zhang J. Synthesis and characterization of cellulose nanocrystal-graft-poly (d-lactide) and its nanocomposite with poly (l-lactide). Polymer. 2016;103:365–75.

Sasaki S, Asakura T. Helix distortion and crystal structure of the α-form of poly (l-lactide). Macromolecules. 2003;36(22):8385–90.

Androsch R, Schick C, Di Lorenzo ML, Kinetics of nucleation and growth of crystals of poly (l-lactic acid). In: Di Lorenzo ML, Androsch R, editors. Synthesis, structure and properties of poly (lactic acid), Springer; 2017, pp. 235–272.

Wang Y, Funari SS, Mano JF. Influence of semicrystalline morphology on the glass transition of poly (l-lactic acid). Macromol Chem Phys. 2006;207(14):1262–71.

Androsch R, Schick C, Di Lorenzo ML. Melting of conformationally disordered crystals (α′-Phase) of poly (l-lactic acid). Macromol Chem Phys. 2014;215(11):1134–9.

Wang L, Lee RE, Wang G, Chu RK, Zhao J, Park CB. Use of stereocomplex crystallites for fully-biobased microcellular low-density poly (lactic acid) foams for green packaging. Chem Eng J. 2017;327:1151–62.

Nofar M, Park CB. Poly (lactic acid) foaming. Prog Polym Sci. 2014;39(10):1721–41.

Purnama P, Kim SH. Biodegradable blends of stereocomplex polylactide and lignin by supercritical carbon dioxide-solvent system. Macromol Res. 2014;22(1):74–8.

Chen J, He H, Yu P, Jia Y, Meng S, Wang J. Preparation and properties of poly (lactic acid)/cellulose nanocrystals nanocomposites compatibilized with maleated poly (lactic acid). Polym Compos. 2018;39(9):3092–101.

Park SD, Todo M, Arakawa K, Koganemaru M. Effect of crystallinity and loading-rate on mode I fracture behavior of poly (lactic acid). Polymer. 2006;47(4):1357–63.

Tábi T. The application of the synergistic effect between the crystal structure of poly (lactic acid) (PLA) and the presence of ethylene vinyl acetate copolymer (EVA) to produce highly ductile PLA/EVA blends. J Therm Anal Calorim. 2019;138(2):1–11.

Gao H, Qiang T. Fracture surface morphology and impact strength of cellulose/PLA composites. Materials. 2017;10(6):624.

Ahmed J, Varshney SK, Janvier F. Rheological and thermal properties of stereocomplexed polylactide films. J Therm Anal Calorim. 2014;115(3):2053–61.

Borkotoky SS, Chakraborty G, Katiyar V. Thermal degradation behaviour and crystallization kinetics of poly (lactic acid) and cellulose nanocrystals (CNC) based microcellular composite foams. Int J Biol Macromol. 2018;118:1518–31.

Woo EM, Lugito G. Origins of periodic bands in polymer spherulites. Eur Polym J. 2015;71:27–60.

Maillard D, Prud’homme RE. Differences between crystals obtained in PLLA-rich or PDLA-rich stereocomplex mixtures. Macromolecules. 2010;43(9):4006–10.

Wang X, Prud’homme RE. Dendritic crystallization of poly (l-lactide)/poly (d-lactide) stereocomplexes in ultrathin films. Macromolecules. 2014;47(2):668–76.

Tsuji H. Poly(lactic acid) stereocomplexes: a decade of progress. Adv Drug Deliv Rev. 2016;107:97–135.

Tsuji H, Ikada Y. Stereocomplex formation between enantiomeric poly (lactic acid) s. XI. Mechanical properties and morphology of solution-cast films. Polymer. 1999;40(24):6699–708.

López-Rodríguez N, de Arenaza IM, Meaurio E, Sarasua J. Improvement of toughness by stereocomplex crystal formation in optically pure polylactides of high molecular weight. J Mech Behav Biomed Mater. 2014;37:219–25.

Migliaresi C, Cohn D, De Lollis A, Fambri L. Dynamic mechanical and calorimetric analysis of compression-molded PLLA of different molecular weights: effect of thermal treatments. J Appl Polym Sci. 1991;43(1):83–95.

Sarasua J, Arraiza AL, Balerdi P, Maiza I. Crystallinity and mechanical properties of optically pure polylactides and their blends. Polym Eng Sci. 2005;45(5):745–53.

Krishnan S, Pandey P, Mohanty S, Nayak SK. Toughening of polylactic acid: an overview of research progress. Polym Plast Technol Eng. 2016;55(15):1623–52.

Gámez-Pérez J, Velazquez-Infante JC, Franco-Urquiza E, Carrasco F, Santana O, Maspoch ML. Fracture behavior of quenched poly (lactic acid). Express Polym Lett. 2011;5(1):82–91.

Shimbo M, Higashitani I, Miyano Y. Mechanism of strength improvement of foamed plastics having fine cell. J Cell Plast. 2007;43(2):157–67.

Rachtanapun P, Selke SE, Matuana LM. Relationship between cell morphology and impact strength of microcellular foamed high-density polyethylene/polypropylene blends. Polym Eng Sci. 2004;44(8):1551–60.

Tsuji H, Ikada Y. Properties and morphologies of poly(l-lactide): 1. Annealing condition effects on properties and morphologies of poly(l-lactide). Polymer. 1995;36(14):2709–16.

Nagarajan V, Zhang K, Misra M, Mohanty AK. Overcoming the fundamental challenges in improving the impact strength and crystallinity of PLA biocomposites: influence of nucleating agent and mold temperature. ACS Appl Mater Interfaces. 2015;7(21):11203–14.

Tang Z, Zhang C, Liu X, Zhu J. The crystallization behavior and mechanical properties of polylactic acid in the presence of a crystal nucleating agent. J Appl Polym Sci. 2012;125(2):1108–15.

Acknowledgements

This publication was written as part of the Student Grant Contest “SGS 21284” with the support of the Specific University Research Grant and was supported by the Ministry of Education, Youth and Sports of the Czech Republic through the European Union—European Structural and Investment Funds in the frames of Operational Programme Research, Development and Education—Project Hybrid Materials for Hierarchical Structures (HyHi, Reg. No. CZ.02.1.01/0.0/0.0/16_019/0000843).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Boruvka, M., Behalek, L., Lenfeld, P. et al. Solid and microcellular polylactide nucleated with PLA stereocomplex and cellulose nanocrystals. J Therm Anal Calorim 142, 695–713 (2020). https://doi.org/10.1007/s10973-020-09477-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09477-2