Abstract

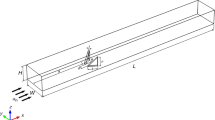

The purpose of this study is to numerically investigate flow field and turbulent heat transfer of hybrid nanofluid, water–DWCNT–TiO2 in a two-dimensional rectangular channel with triangular and semicircular vortex generators with three different heights of 1, 2 and 3 mm. For numerically modeling this study, SIMPLEC algorithm was used. Therefore, initially, the geometry of channel and the grid points were generated, and then for solving the mathematical equations via finite volume method, ANSYS Fluent was used. The results indicate that with an increase in Reynolds number and volume fraction (φ) of nanoparticles, the average Nusselt number increases. Also, with an increase in the φ, the pressure loss in the channel increases. About the geometrical shape of the vortex generators, results indicate that with using the semicircular vortex generator, average Nusselt number is higher compared to that of triangular vortex generator. Also, by investigating the performance evaluation criteria of thermal–hydraulic, which is a criterion for comparing the positive effect of the Nusselt number increase with the negative effect of pressure drop, results indicate that this criterion is higher for the semicircular vortex generator.

Similar content being viewed by others

Abbreviations

- c P :

-

Specific heat capacity (J kg−1 °C)

- h :

-

Heat transfer coefficient (W m−2 °C)

- D :

-

The tube diameter (mm)

- K :

-

Thermal conductivity coefficient (W m−1 °C)

- β :

-

Height of VG (mm)

- Nu:

-

Nusselt number (–)

- Δp :

-

Pressure reduction penalty (Pa)

- Re:

-

Reynolds number (–)

- T :

-

Temperature (°C or K)

- U :

-

Component of flow velocity (m s−1)

- ′:

-

Fluctuated of variable (m s−1)

- α :

-

Wavy-wall amplitude (mm)

- ε :

-

Rate of turbulent dissipation (m2 s−3)

- ρ :

-

Density (kg m−3)

- \(\mu\) :

-

Dynamic viscosity (N s m−2)

- Av:

-

Average or mean

- bf:

-

Base fluid

- M:

-

Average or mean

- np:

-

Nanoparticle

- nf:

-

Nanofluid

References

Yari M, Kalbasi R, Talebizadehsardari P. Energetic-exergetic analysis of an air handling unit to reduce energy consumption by a novel creative idea. Int J Numer Methods Heat Fluid Flow. 2019;29:3959–75.

Kalbasi R, Shahsavar A, Afrand M. Incorporating novel heat recovery units into an AHU for energy demand reduction-exergy analysis. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-0906.

Kalbasi R, Shahsavar A, Afrand M. Reducing AHU energy consumption by a new layout of using heat recovery units. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-09070-2.

Li Z, Shahsavar A, Al-Rashed AA, Kalbasi R, Afrand M, Talebizadehsardari P. Multi-objective energy and exergy optimization of different configurations of hybrid earth-air heat exchanger and building integrated photovoltaic/thermal system. Energy Convers Manag. 2019;195:1098–110.

Li Z, Al-Rashed AA, Rostamzadeh M, Kalbasi R, Shahsavar A, Afrand M. Heat transfer reduction in buildings by embedding phase change material in multi-layer walls: effects of repositioning, thermophysical properties and thickness of PCM. Energy Convers Manag. 2019;195:43–56.

Kalbasi R, Ruhani B, Rostami S. Energetic analysis of an air handling unit combined with enthalpy air-to-air heat exchanger. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-09158-9.

Kalbasi R, Afrand M, Alsarraf J, Tran M-D. Studies on optimum fins number in PCM-based heat sinks. Energy. 2019;171:1088–99.

Salimpour MR, Kalbasi R, Lorenzini G. Constructal multi-scale structure of PCM-based heat sinks. Contin Mech Thermodyn. 2017;29(2):477–91.

Kalbasi R, Alemrajabi AA, Afrand M. Thermal modeling and analysis of single and double effect solar stills: an experimental validation. Appl Therm Eng. 2018;129:1455–65.

Afrand M, Kalbasi R, Karimipour A, Wongwises S. Experimental investigation on a thermal model for a basin solar still with an external reflector. Energies. 2017;10(1):18.

Shanazari E, Kalbasi R. Improving performance of an inverted absorber multi-effect solar still by applying exergy analysis. Appl Therm Eng. 2018;143:1–10.

Kalbasi R, Alaeddin SM, Akbari M, Afrand M. Analytical solution of heat conduction in a symmetrical cylinder using the solution structure theorem and superposition technique. Symmetry. 2019;11(12):1522.

Nadooshan AA, Kalbasi R, Afrand M. Perforated fins effect on the heat transfer rate from a circular tube by using wind tunnel: an experimental view. Heat Mass Transf. 2018;54(10):3047–57.

Shahsavani E, Afrand M, Kalbasi R. Experimental study on rheological behavior of water–ethylene glycol mixture in the presence of functionalized multi-walled carbon nanotubes. J Therm Anal Calorim. 2018;131(2):1177–85.

Shahsavani E, Afrand M, Kalbasi R. Using experimental data to estimate the heat transfer and pressure drop of non-Newtonian nanofluid flow through a circular tube: applicable for use in heat exchangers. Appl Therm Eng. 2018;129:1573–81.

Izadi F, Ranjbarzadeh R, Kalbasi R, Afrand M. A new experimental correlation for non-Newtonian behavior of COOH-DWCNTs/antifreeze nanofluid. Phys E. 2018;98:83–9.

Abedini E, Zarei T, Rajabnia H, Kalbasi R, Afrand M. Numerical investigation of vapor volume fraction in subcooled flow boiling of a nanofluid. J Mol Liq. 2017;238:281–9.

Khodadadi H, Aghakhani S, Majd H, Kalbasi R, Wongwises S, Afrand M. A comprehensive review on rheological behavior of mono and hybrid nanofluids: effective parameters and predictive correlations. Int J Heat Mass Transf. 2018;127:997–1012.

Mei S, Qi C, Liu M, Fan F, Liang L. Effects of paralleled magnetic field on thermo-hydraulic performances of Fe3O4–water nanofluids in a circular tube. Int J Heat Mass Transf. 2019;134:707–21.

Mei S, Qi C, Luo T, Zhai X, Yan Y. Effects of magnetic field on thermo-hydraulic performance of Fe3O4–water nanofluids in a corrugated tube. Int J Heat Mass Transf. 2019;128:24–45.

Qi C, Liu M, Luo T, Pan Y, Rao Z. Effects of twisted tape structures on thermo-hydraulic performances of nanofluids in a triangular tube. Int J Heat Mass Transf. 2018;127:146–59.

Qi C, Liu M, Tang J. Influence of triangle tube structure with twisted tape on the thermo-hydraulic performance of nanofluids in heat-exchange system based on thermal and exergy efficiency. Energy Convers Manag. 2019;192:243–68.

Qi C, Luo T, Liu M, Fan F, Yan Y. Experimental study on the flow and heat transfer characteristics of nanofluids in double-tube heat exchangers based on thermal efficiency assessment. Energy Convers Manag. 2019;197:111877.

Zhai X, Qi C, Pan Y, Luo T, Liang L. Effects of screw pitches and rotation angles on flow and heat transfer characteristics of nanofluids in spiral tubes. Int J Heat Mass Transf. 2019;130:989–1003.

Yang L, Du K. A comprehensive review on the natural, forced, and mixed convection of non-Newtonian fluids (nanofluids) inside different cavities. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08987-y.

Yang L, Du K, Zhang Z. Heat transfer and flow optimization of a novel sinusoidal minitube filled with non-Newtonian SiC/EG-water nanofluids. Int J Mech Sci. 2019 (in press). https://doi.org/10.1016/j.ces.2019.06.045.

Yang L, Huang J, Ji W, Mao M. Investigations of a new combined application of nanofluids in heat recovery and air purification. Powder Technol. 2019;347:21–34.

Yang L, Huang J, Mao M, Ji W. Numerical assessment of Ag–water nano-fluid flow in two new microchannel heatsinks: thermal performance and thermodynamic considerations. Int Commun Heat Mass Transf. 2020;110:104415.

Yang L, Ji W, Huang J, Xu G. An updated review on the influential parameters on thermal conductivity of nano-fluids. J Mol Liquids. 2019; 111780.

Yang L, Ji W, Zhang Z, Jin X. Thermal conductivity enhancement of water by adding graphene nano-sheets: consideration of particle loading and temperature effects. Int Commun Heat Mass Transf. 2019;109:104353.

Yang L, Mao M, Huang J-N, Ji W. Enhancing the thermal conductivity of SAE 50 engine oil by adding zinc oxide nano-powder: an experimental study. Powder Technol. 2019;356:335–41.

Yang L, Xu J, Du K, Zhang X. Recent developments on viscosity and thermal conductivity of nanofluids. Powder Technol. 2017;317:348–69.

Yang L, Du K. Numerical simulation of nanofluid flow and heat transfer in a microchannel: the effect of changing the injection layout arrangement. Int J Mech Sci. 2019;172:105415.

Hong Y, Du J, Li Q, Xu T, Li W. Thermal-hydraulic performances in multiple twisted tapes inserted sinusoidal rib tube heat exchangers for exhaust gas heat recovery applications. Energy Convers Manag. 2019;185:271–90.

Ghanbari S, Javaherdeh K. Thermal performance enhancement in perforated baffled annuli by nanoporous graphene non-Newtonian nanofluid. Appl Therm Eng. 2019;167:114719.

Liang G, Mudawar I. Review of single-phase and two-phase nanofluid heat transfer in macro-channels and micro-channels. Int J Heat Mass Transf. 2019;136:324–54.

Tang L, Pan J, Sundén B. Parametric study and optimization on heat transfer and flow characteristics in a rectangular channel with longitudinal vortex generators. Numer Heat Transf Part A Appl. 2019;76(11):830–50.

Xie J, Xie Y, Yuan C. Numerical study of heat transfer enhancement using vortex generator for thermal management of lithium ion battery. Int J Heat Mass Transf. 2019;129:1184–93.

Bayareh M, Nourbakhsh A, Khadivar ME. Numerical simulation of heat transfer over a flat plate with a triangular vortex generator. Journal homepage: http://iieta.org/Journals/IJHT. 2018; 36(4):1493–1501.

Bazdar H, Toghraie D, Pourfattah F, Akbari OA, Nguyen HM, Asadi A. Numerical investigation of turbulent flow and heat transfer of nanofluid inside a wavy microchannel with different wavelengths. J Therm Anal Calorim. 2020;139:2365–80. https://doi.org/10.1007/s10973-019-08637-3.

Nakhchi M, Esfahani J. Numerical investigation of different geometrical parameters of perforated conical rings on flow structure and heat transfer in heat exchangers. Appl Therm Eng. 2019;156:494–505.

Hamid KA, Azmi W, Mamat R, Mohamad M, Sharma K. Numerical investigation for turbulent heat transfer of TiO2–SiO2 nanofluids with wire coil inserts. Numer Heat Transf Part A Appl. 2019;75(4):271–89.

Sun Z, Zhang K, Li W, Chen Q, Zheng N. Investigations of the turbulent thermal-hydraulic performance in circular heat exchanger tubes with multiple rectangular winglet vortex generators. Appl Therm Eng. 2019;168:114838.

Sheikholeslami M, Jafaryar M, Shafee A, Li Z, Haq R-U. Heat transfer of nanoparticles employing innovative turbulator considering entropy generation. Int J Heat Mass Transf. 2019;136:1233–40.

Oneissi M, Habchi C, Russeil S, Lemenand T, Bougeard D. Heat transfer enhancement of inclined projected winglet pair vortex generators with protrusions. Int J Therm Sci. 2018;134:541–51.

Solangi K, Sharif S, Ogu Sadiq I, Hisam M. Experimental and numerical investigations on heat transfer and friction loss of functionalized gnp nanofluids. Int J Mech Eng Technol. 2019;10(8):61–77.

Tokgoz N. Experimental and numerical investigation of flow structure in a cylindrical corrugated channel. Int J Mech Sci. 2019;157:787–801.

Dadvand A, Hosseini S, Aghebatandish S, Khoo BC. Enhancement of heat and mass transfer in a microchannel via passive oscillation of a flexible vortex generator. Chem Eng Sci. 2019;207:556–80.

He W, Toghraie D, Lotfipour A, Pourfattah F, Karimipour A, Afrand M. Effect of twisted-tape inserts and nanofluid on flow field and heat transfer characteristics in a tube. Int Commun Heat Mass Transf. 2020;110:104440.

Kashyap U, Das K, Debnath BK. Effect of surface modification of a rectangular vortex generator on heat transfer rate from a surface to fluid. Int J Therm Sci. 2018;127:61–78.

Ranjbarzadeh R, Moradikazerouni A, Bakhtiari R, Asadi A, Afrand M. An experimental study on stability and thermal conductivity of water/silica nanofluid: eco-friendly production of nanoparticles. J Clean Prod. 2019;206:1089–100.

Bahiraei M, Heshmatian S, Goodarzi M, Moayedi H. CFD analysis of employing a novel ecofriendly nanofluid in a miniature pin fin heat sink for cooling of electronic components: effect of different configurations. Adv Powder Technol. 2019;30(11):2503–16.

Bahiraei M, Mazaheri N, Hosseini Y, Moayedi H. A two-phase simulation for analyzing thermohydraulic performance of Cu–water nanofluid within a square channel enhanced with 90° V-shaped ribs. Int J Heat Mass Transf. 2019;145:118612.

Zheng N, Yan F, Zhang K, Zhou T, Sun Z. A review on single-phase convective heat transfer enhancement based on multi-longitudinal vortices in heat exchanger tubes. Appl Therm Eng. 2019;164:114475.

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51979215).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zheng, Y., Yang, H., Mazaheri, H. et al. An investigation on the influence of the shape of the vortex generator on fluid flow and turbulent heat transfer of hybrid nanofluid in a channel. J Therm Anal Calorim 143, 1425–1438 (2021). https://doi.org/10.1007/s10973-020-09415-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09415-2