Abstract

The impact of corrugated absorber tubes on the performance of a parabolic trough collector (PTC) is experimentally analyzed. For this purpose, nine different helically corrugated absorber tubes were applied. The impacts of the pitch length and roughness height on the performance of the PTC were examined under the ASHRAE standard 93 (2010). The Reynolds number varied between 5000 and 10,000. The results demonstrate that the thermal performance and heat transfer are considerably increased in the corrugated absorber tubes. The average heat transfer rate increases between 85.7 and 107.2% in corrugated tubes, which is related to the roughness height and pitch ratio. The thermal performance has a maximum value of about 2.29 for the pitch length and roughness height of 3 mm and 1.5 mm. The average friction factor increases between 1.25 and 1.85 times in corrugated tubes. Furthermore, the variations of the Nusselt number and friction factor versus pitch-to-diameter ratio, roughness height-to-diameter ratio, Prandtl number, and Reynolds number are presented as correlations by using the best fit to the series of experimental data.

Similar content being viewed by others

Abbreviations

- A :

-

Area (m2)

- c p :

-

Specific heat (J kg−1 °C)

- D H :

-

Absorber tube hydraulic diameter (m)

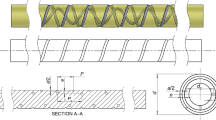

- e :

-

Roughness height (mm)

- f :

-

Friction factor (−)

- F :

-

Focal distance (m)

- G t :

-

The global solar radiation (W m−2)

- h fi :

-

Heat transfer coefficient (W m−2 °C)

- kf :

-

Thermal conductivity of fluid (W m−1 °C)

- L :

-

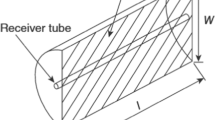

The absorber tube length (m)

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- Nu:

-

Nusselt number (−)

- P :

-

Pitch (mm)

- Pr:

-

Prandtl number (−)

- P cs :

-

Perimeter (m)

- Q u :

-

The useful energy gain (W)

- Re:

-

Reynolds number (−)

- T :

-

Temperature (°C)

- u :

-

Fluid mean velocity (m s−1)

- U L :

-

Heat loss coefficient (W m−2 °C)

- U o :

-

Overall heat loss coefficient (W m−2 °C)

- w :

-

The aperture width (m)

- \(\Delta p\) :

-

Pressure drop (Pa)

- \(\eta\) :

-

Thermal performance factor (−)

- \(\mu\) :

-

Viscosity (kg m s−1)

- \(\rho\) :

-

Density (kg m−3)

- \(\phi\) :

-

Function (−)

- \(\varphi\) :

-

Function (−)

- amb:

-

Ambient

- c:

-

Corrugated

- g:

-

Glass

- i:

-

In

- o:

-

Out

- p:

-

Plain

- r:

-

Receiver

- w:

-

Tube wall

- PTC:

-

Parabolic trough collector

References

Akbarzadeh S, Valipour MS. Heat transfer enhancement in parabolic trough collectors: a comprehensive review. Renew Sustain Energy Rev. 2018;92:198–218. https://doi.org/10.1016/J.RSER.2018.04.093.

Kasaeian A, Daviran S, Azarian RD. Optical and thermal investigation of selective coatings for solar absorber tube. Int J Renew Energy Res. 2016;6:15–20.

Abdel Hamid Z, Abdel Aal A, Schmuki P. Nanostructured black cobalt coatings for solar absorbers. Surf Interface Anal. 2008;40:1493–9. https://doi.org/10.1002/sia.2950.

Kennedy CE. Review of mid- to high-temperature solar selective absorber. Materials. 2002. https://doi.org/10.2172/15000706.

Barriga J, Ruiz-De-Gopegui U, Goikoetxea J, Coto B, Cachafeiro H. Selective coatings for new concepts of parabolic trough collectors. Energy Procedia. 2013;49:30–9. https://doi.org/10.1016/j.egypro.2014.03.004.

Zhang QC, Shen YG. High performance W-AlN cermet solar coatings designed by modelling calculations and deposited by DC magnetron sputtering. Sol Energy Mater Sol Cells. 2004;81:25–37. https://doi.org/10.1016/j.solmat.2003.08.021.

Sakhaei SA, Valipour MS. Investigation on the effect of different coated absorber plates on the thermal efficiency of the flat-plate solar collector. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-09148-x.

Qu W, Wang R, Hong H, Sun J, Jin H. Test of a solar parabolic trough collector with rotatable axis tracking. Appl Energy. 2017;207:7–17. https://doi.org/10.1016/j.apenergy.2017.05.114.

Qu W, Wang R, Hong H, Sun J, Jin H. Prototype testing of a 300 kW th solar parabolic-trough collector using rotatable axis tracking. Energy Procedia. 2017;105:780–6. https://doi.org/10.1016/j.egypro.2017.03.389.

Yao Y, Hu Y, Gao S, Yang G, Du J. A multipurpose dual-axis solar tracker with two tracking strategies. Renew Energy. 2014;72:88–98. https://doi.org/10.1016/j.renene.2014.07.002.

Alsaady M, Fu R, Li B, Boukhanouf R, Yan Y, Fu R, Li B, Boukhanouf R, Yan Y. Thermo-physical properties and thermo-magnetic convection of ferrofluid. Appl Therm Eng. 2015. https://doi.org/10.1016/j.applthermaleng.2014.09.087.

Sakhaei SA, Valipour MS. Performance enhancement analysis of the flat plate collectors: a comprehensive review. Renew Sustain Energy Rev. 2019;102:186–204. https://doi.org/10.1016/J.RSER.2018.11.014.

Ghadirijafarbeigloo S, Zamzamian AH, Yaghoubi M. 3-D numerical simulation of heat transfer and turbulent flow in a receiver tube of solar parabolic trough concentrator with louvered twisted-tape inserts. Energy Procedia. 2013;49:373–80. https://doi.org/10.1016/j.egypro.2014.03.040.

Bellos E, Tzivanidis C, Tsimpoukis D. Optimum number of internal fins in parabolic trough collectors. Appl Therm Eng. 2018;137:669–77. https://doi.org/10.1016/j.applthermaleng.2018.04.037.

Mwesigye A, Bello-Ochende T, Meyer JP. Heat transfer and entropy generation in a parabolic trough receiver with wall-detached twisted tape inserts. Int J Therm Sci. 2016;99:238–57. https://doi.org/10.1016/j.ijthermalsci.2015.08.015.

Bellos E, Tzivanidis C, Tsimpoukis D. Optimum number of internal fins in parabolic trough collectors. Appl Therm Eng. 2018;137:669–77. https://doi.org/10.1016/j.applthermaleng.2018.04.037.

Amani K, Ebrahimpour M, Akbarzadeh S, Valipour MS. The utilization of conical strip inserts in a parabolic trough collector. J. Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-019-09233-1.

Jamal-Abad MT, Saedodin S, Aminy M. Experimental investigation on a solar parabolic trough collector for absorber tube filled with porous media. Renew Energy. 2017;107:156–63. https://doi.org/10.1016/j.renene.2017.02.004.

Reddy KS, Ravi Kumar K, Ajay CS. Experimental investigation of porous disc enhanced receiver for solar parabolic trough collector. Renew Energy. 2015;77:308–19. https://doi.org/10.1016/j.renene.2014.12.016.

Tayebi R, Akbarzadeh S, Valipour MS. Numerical investigation of efficiency enhancement in a direct absorption parabolic trough collector occupied by a porous medium and saturated by a nanofluid. Environ Prog Sustain Energy. 2018. https://doi.org/10.1002/ep.13010.

Huang Z, Li ZY, Yu GL, Tao WQ. Numerical investigations on fully-developed mixed turbulent convection in dimpled parabolic trough receiver tubes. Appl Therm Eng. 2017;114:1287–99. https://doi.org/10.1016/j.applthermaleng.2016.10.012.

Kasaeian A, Daneshazarian R, Rezaei R, Pourfayaz F, Kasaeian G. Experimental investigation on the thermal behavior of nanofluid direct absorption in a trough collector. J Clean Prod. 2017;158:276–84. https://doi.org/10.1016/j.jclepro.2017.04.131.

Qin C, Kim JB, Lee BJ. Performance analysis of a direct-absorption parabolic-trough solar collector using plasmonic nanofluids. Renew Energy. 2019;143:24–33. https://doi.org/10.1016/j.renene.2019.04.146.

Razmmand F, Mehdipour R, Mousavi SM. A numerical investigation on the effect of nanofluids on heat transfer of the solar parabolic trough collectors. Appl Therm Eng. 2019;152:624–33. https://doi.org/10.1016/J.APPLTHERMALENG.2019.02.118.

Bretado de los Rios MS, Rivera-Solorio CI, García-Cuéllar AJ. Thermal performance of a parabolic trough linear collector using Al2O3/H2O nanofluids. Renew Energy. 2018;122:665–73. https://doi.org/10.1016/j.renene.2018.01.094.

Natividade PSG, de Moraes Moura G, Avallone E, Bandarra Filho EP, Gelamo RV, Gonçalves JCDSI. Experimental analysis applied to an evacuated tube solar collector equipped with parabolic concentrator using multilayer graphene-based nanofluids. Renew Energy. 2019;152:160. https://doi.org/10.1016/j.renene.2019.01.091.

Sheikholeslami M, Jafaryar M, Shafee A, Li Z. Nanofluid heat transfer and entropy generation through a heat exchanger considering a new turbulator and CuO nanoparticles. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7866-7.

Bellos E. Thermal efficiency enhancement of nanofluid-based parabolic trough collectors. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7056-7.

Bozorg MV, Hossein Doranehgard M, Hong K, Xiong Q. CFD study of heat transfer and fluid flow in a parabolic trough solar receiver with internal annular porous structure and synthetic oil–Al2O3 nanofluid. Renew Energy. 2020;145:2598–614. https://doi.org/10.1016/j.renene.2019.08.042.

Xiong Q, Bozorg MV, Doranehgard MH, Hong K, Lorenzini G. A CFD investigation of the effect of non-Newtonian behavior of Cu–water nanofluids on their heat transfer and flow friction characteristics. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08757-w.

Jouybari HJ, Nimvari ME, Saedodin S. Thermal performance evaluation of a nanofluid-based flat-plate solar collector: an experimental study and analytical modeling. J Therm Anal Calorim. 2019;137:1757–74. https://doi.org/10.1007/s10973-019-08077-z.

Jouybari HJ, Saedodin S, Zamzamian A, Nimvari ME, Wongwises S. Effects of porous material and nanoparticles on the thermal performance of a flat plate solar collector: an experimental study. Renew Energy. 2017;114:1407–18. https://doi.org/10.1016/J.RENENE.2017.07.008.

Bellos E, Daniil I, Tzivanidis C. Multiple cylindrical inserts for parabolic trough solar collector. Appl Therm Eng. 2018. https://doi.org/10.1016/j.applthermaleng.2018.07.086.

Jaramillo OA, Borunda M, Velazquez-Lucho KM, Robles M. Parabolic trough solar collector for low enthalpy processes: an analysis of the efficiency enhancement by using twisted tape inserts. Renew Energy. 2016;93:125–41. https://doi.org/10.1016/j.renene.2016.02.046.

Jafar KS, Sivaraman B. Performance characteristics of parabolic solar collector water heater system fitted with nail twisted tapes absorber. J Eng Sci Technol. 2017;12:608–21.

Mwesigye A, Bello-Ochende T, Meyer JP. Multi-objective and thermodynamic optimisation of a parabolic trough receiver with perforated plate inserts. Appl Therm Eng. 2015;77:42–56. https://doi.org/10.1016/j.applthermaleng.2014.12.018.

Bellos E, Tzivanidis C, Tsimpoukis D. Enhancing the performance of parabolic trough collectors using nanofluids and turbulators. Renew Sustain Energy Rev. 2018;91:358–75. https://doi.org/10.1016/j.rser.2018.03.091.

Sun M, Zeng M. Investigation on turbulent flow and heat transfer characteristics and technical economy of corrugated tube. Appl Therm Eng. 2018;129:1–11. https://doi.org/10.1016/j.applthermaleng.2017.09.136.

Vicente PG, Garc A, Viedma A. Experimental investigation on heat transfer and frictional characteristics of spirally corrugated tubes in turbulent flow at different Prandtl numbers. 2004;47:671–81. https://doi.org/10.1016/j.ijheatmasstransfer.2003.08.005.

Naphon P, Nuchjapo M, Kurujareon J. Tube side heat transfer coefficient and friction factor characteristics of horizontal tubes with helical rib. Energy Convers Manag. 2006;47:3031–44. https://doi.org/10.1016/j.enconman.2006.03.023.

Darzi AR, Farhadi M, Sedighi K. Experimental Investigation of convective heat transfer and friction factor of Al2O3/water nanofluid in helically corrugated tube. Exp Therm Fluid Sci. 2014. https://doi.org/10.1016/j.expthermflusci.2014.04.024.

Rainieri S, Pagliarini G. Convective heat transfer to temperature dependent property fluids in the entry region of corrugated tubes. Int J Heat Mass Transf. 2002;45:4525–36. https://doi.org/10.1016/S0017-9310(02)00156-4.

Saffarian MR, Moravej M, Doranehgard MH. Heat transfer enhancement in a flat plate solar collector with different flow path shapes using nanofluid. Renew Energy. 2020;146:2316–29. https://doi.org/10.1016/j.renene.2019.08.081.

Moravej M, Saffarian MR, Li LKB, Doranehgard MH, Xiong Q. Experimental investigation of circular flat-panel collector performance with spiral pipes. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08879-1.

Wang W, Zhang Y, Li B, Han H, Gao X. Influence of geometrical parameters on turbulent flow and heat transfer characteristics in outward helically corrugated tubes. Energy Convers Manag. 2017;136:294–306. https://doi.org/10.1016/j.enconman.2017.01.029.

Fuqiang W, Qingzhi L, Huaizhi H, Jianyu T. Parabolic trough receiver with corrugated tube for improving heat transfer and thermal deformation characteristics. Appl Energy. 2016;164:411–24. https://doi.org/10.1016/j.apenergy.2015.11.084.

Fuqiang W, Zhexiang T, Xiangtao G, Jianyu T, Huaizhi H, Bingxi L. Heat transfer performance enhancement and thermal strain restrain of tube receiver for parabolic trough solar collector by using asymmetric outward convex corrugated tube. Energy. 2016;114:275–92. https://doi.org/10.1016/j.energy.2016.08.013.

Bellos E, Tzivanidis C, Antonopoulos KA, Gkinis G. Thermal enhancement of solar parabolic trough collectors by using nanofluids and converging-diverging absorber tube. Renew Energy. 2016;94:213–22. https://doi.org/10.1016/j.renene.2016.03.062.

ValanArasu A, Sornakumar T. Design, manufacture and testing of fiberglass reinforced parabola trough for parabolic trough solar collectors. Sol Energy. 2007;81:1273–9. https://doi.org/10.1016/j.solener.2007.01.005.

Duffie JA, Beckman WA. Solar engineering of thermal processes. 4th ed. Wiley; 2013. https://doi.org/10.1002/9781118671603.

Moffat RJ. Describing the uncertainties in experimental results. Exp Therm Fluid Sci. 1988;1:3–17. https://doi.org/10.1016/0894-1777(88)90043-X.

ASHRAE, ASHRAE 93-2010 (RA 2014) Standard 93-2010 (RA 2014)—methods of testing to determine the thermal performance of solar collectors (ANSI approved), 2014.

Bergman TL, Incropera FP, Lavine AS, DeWitt DP. Introduction to heat transfer. 6th ed. Hoboken: Wiley; 2006.

Munson BR, Young DF, Okiishi TH, Huebsch WW. Fundamentals of fluid mechanics 6th—Munson, Young, Okiishi, Huebsch.pdf, Sixth, Don Fowley Editorial; 2009.

Wang W, Zhang Y, Li B, Li Y. Numerical investigation of tube-side fully developed turbulent flow and heat transfer in outward corrugated tubes. Int J Heat Mass Transf. 2018;116:115–26. https://doi.org/10.1016/j.ijheatmasstransfer.2017.09.003.

Pethkool S, Eiamsa-ard S, Kwankaomeng S, Promvonge P. Turbulent heat transfer enhancement in a heat exchanger using helically corrugated tube. Int Commun Heat Mass Transf. 2011;38:340–7. https://doi.org/10.1016/j.icheatmasstransfer.2010.11.014.

Acknowledgements

The authors are grateful for the financial support received from Semnan University Science and Technology Park.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Akbarzadeh, S., Valipour, M.S. Experimental study on the heat transfer enhancement in helically corrugated tubes under the non-uniform heat flux. J Therm Anal Calorim 140, 1611–1623 (2020). https://doi.org/10.1007/s10973-020-09385-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09385-5