Abstract

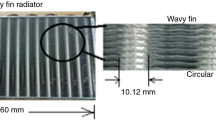

Energetic and exergetic performance for an automotive radiator with wavy fin configuration has been investigated and compared for water-based 1% vol. fraction of hybrid nanofluids of different shapes of nanoparticles, i.e., spherical (Al2O3) and cylindrical (CNT), spherical (Al2O3) and platelet (graphene) shapes at 15l pm flow rate. Effects of effectiveness, heat transfer rate and pressure drop, as well as exergy loss, entropy generation, second law efficiency with steady-state coolant flow rate, hybrid nanofluid vol. fractions and air velocity are discussed well. Results show that energetic–exergetic performances are enhanced by using the hybrid nanofluid of different shapes of nanoparticles. Nanoparticles of spherical (Al2O3) and cylindrical (CNT)-based hybrid nanofluid show the decrement in performance within the study. Nanoparticles of different shapes have been delivered a promising effect on both parameters (irreversibility and second law efficiency) and are increases with coolant flow rate. Spherical and platelet-shaped nanoparticle-based hybrid nanofluid has 2.94% 1.73% and 1.62% of higher effectiveness, entropy change in the air and coolants, respectively, compared to hybrid nanofluid of spherical and cylindrical shape nanoparticles. This inspection divulges on the particle shape, which has a critical consequence on the accomplishment of hybrid nanofluids in automotive radiators and the application of spherical and graphene shape nanoparticle-based hybrid nanofluid is more effective to enhance the radiator performance.

Similar content being viewed by others

Abbreviations

- CFR:

-

Coolant flow rate

- C :

-

Heat capacity rate (W K−1)

- C*:

-

Heat capacity ratio

- c p :

-

Specific heat (J kg K−1)

- D a :

-

Hydraulic diameter (m)

- G :

-

Mass velocity (kg m−2 s−1)

- J :

-

Colburn factor

- F l :

-

Longitudinal fin pitch

- F t :

-

Transverse fin pitch

- θ :

-

Wavy angle

- r :

-

Radius of curvature for wavy fin

- NTU:

-

Number of heat transfer units

- h :

-

Heat transfer coefficient (W/m2K)

- I :

-

Irreversibility (W)

- Q :

-

Heat transfer rate (W)

- Re:

-

Reynolds number

- k :

-

Thermal conductivity (W mK−1)

- Pr:

-

Prandtl number

- m :

-

Mass flow rate (kg s−1)

- Nu:

-

Nusselt number

- P F :

-

Fan power (W)

- p :

-

Pressure (kPa)

- P P :

-

Pumping power (W)

- PI:

-

Performance index

- S :

-

Entropy generation rate (W K−1)

- T 0 :

-

Dead state temperature (K)

- T :

-

Temperature (K)

- I * :

-

Dimensionless exergy loss

- ∆p :

-

Pressure drop (Pa)

- u :

-

Air velocity (m s−1)

- V :

-

Volume flow rate (m3 s−1)

- U :

-

Overall heat transfer coefficient (W m−2 K−1)

- ∆Ex:

-

Exergy gain or loss rate (W)

- η o :

-

Total heat transfer surface effectiveness

- η 2 :

-

Second law efficiency

- ρ :

-

Fluid density (kg m−3)

- ε :

-

Radiator effectiveness

- a:

-

Air

- nf:

-

Nanofluid (coolant)

- i:

-

Inlet

- e:

-

Exit

- hnf:

-

Hybrid Nanofluid

References

Peyghambarzadeh SM, Hashemabadi SH, Naraki M, Vermahmaudi Y. Experimental study of overall heat transfer coefficient in the application of dilute nanofluids in the car radiator. Appl Therm Eng. 2013;52:8–16.

Choi S. Enhancing thermal conductivity of fluids with nanoparticles. In: Siginer DA, Wang HP, editors. Developments applications of non-newtonian flows, vol. 66. New York: ASME; 1995. p. 99–105.

Esfahani JA, Akbarzadeh M, Rashidi S, Rosen MA, Ellahi R. Influences of wavy wall and nanoparticles on entropy generation over heat exchanger plate. Int J Heat Mass Transf. 2017;109:1162–71.

Elias MM, Shahrul IM, Mahbubul IM, Saidur R, Rahim NA. Effect of different nanoparticle shapes on shell and tube heat exchanger using different baffle angles and operated with nanofluid. Int J Heat Mass Transf. 2014;70:289–97.

Elias MM, Miqbad M, Mahbubul IM, Saidur R, Kamalisarvestani M, Sohel MR, Hepbasli A, Rahim NA, Amalina MA. Effect of nanoparticle shape on the heat transfer and thermodynamic performance of a shell and tube heat exchanger. Int Commun Heat Mass Transf. 2013;44:93–9.

Ellahi R, Hassan M, Zeeshan A. Shape effects of nanosize particles in Cu–H2O nanofluid on entropy generation. Int J Heat Mass Transf. 2015;81:449–56.

Khairul MA, Alim MA, Mahbubul IM, Saidur R, Hepbasli A, Hossain A. Heat transfer performance and exergy analyses of a corrugated plate heat exchanger using metal oxide nanofluids. Int Commun Heat Mass Transf. 2014;50:8–14.

Sahu M, Sarkar J. Steady-state energetic and exergetic performances of single-phase natural circulation loop with hybrid nanofluids. J Heat Transf. 2019. https://doi.org/10.1115/1.4043819.

Alawi OA, Sidik NA, Wei Xian H, Kean TH, Kazi SN. Thermal conductivity and viscosity models of metallic oxides nanofluids. Int J Heat Mass Transf. 2018;116:1314–25.

Timofeeva EV, Routbort JL, Singh D. Particle shape effects on thermophysical properties of alumina nanofluids. J Appl Phys. 2009;106(014304):1–10.

Arani AAA, Sadripour S, Kermani S. Nanoparticles shape effect on the thermal-hydraulic performance of boehmite alumina nanofluids in a sinusoidal wavy mini-channel with phase shift and variable wavelength. Int J Mech Sci. 2017;129:550–63.

Albadr J, Tayal S, Alasadi M. Heat transfer through a heat exchanger using Al2O3 nanofluid at different concentrations. Case studies in thermal engineering, vol. 1, no. 1. 2013, p. 38–44. https://www.sciencedirect.com/science/article/pii/S2214157X13000075.

Leong KY, Saidur R, Mahlia TMI, Yau YH. Modeling of the shell and tube heat recovery exchanger operated with nanofluid based coolants. Int J Heat Mass Transf. 2012;55:808–16.

Ali HM, Ali H, Liaquat H, Maqsood HTB, Nadir MA. Experimental investigation of convective heat transfer augmentation for car radiator using ZnO-water nanofluids. Energy. 2015;84:317–24.

Sahoo RR, Ghosh P, Sarkar J. Energy, and exergy comparison of water-based optimum brine as coolants for rectangular fin automotive radiator. Int J Heat Mass Transf. 2017;105:690–6.

Sahoo RR, Sarkar J. Heat transfer performance characteristics of hybrid nanofluids as a coolant in louvered fin automotive radiator. Heat Mass Transf. 2017;53:1923–31.

Yilmaz M, Saraa ON, Karsli S. Performance evaluation criteria for heat exchangers based on second law analysis. Exergy Int J. 2001;1:278–94.

Mishra M, Das PK, Sarangi S. Second law based optimization of crossflow plate-fin heat exchanger design using a genetic algorithm. Appl Therm Eng. 2009;29:2983–9.

Ravi P, Bhattacharya P, Phelan PE. Thermal conductivity of nanoscale colloidal solutions (nanofluids). Phys Rev Lett. 2005;94:25901.

Vaisi A, Esmaeilpour M, Taheria H. Experimental investigation of geometry effects on the performance of a compact heat exchanger. Appl Therm Eng. 2011;31:3337–46.

Wang CC, Chi KY. Heat transfer and friction characteristics of plain fin-and- tube heat exchangers. Int J Heat Mass Transf. 2000;43:81–91.

Wais P. Fluid flow consideration in fin-tube heat ex-changer optimization. Arch Thermodyn. 2010;31:87–104.

Tiwari AK, Ghosh P, Sarkar J. Particle concentration levels of various nanofluids in the plate heat exchanger for best performance. Int J Heat Mass Transf. 2015;89:1110–8.

Sundar LS, Sharma KV, Singh MK, Sousa AC. Hybrid nanofluids preparation, thermal properties, heat transfer and friction factor: a review. Renew Sustain Energy Rev. 2017;68:185–98.

Chamkha AJ, Miroshnichenko IV, Sheremet MA. Numerical analysis of unsteady conjugate natural convection of hybrid water-based nanofluid in a semi-circular cavity. ASME J Therm Sci Eng Appl. 2017;9(4):041004.

Kumar V, Sahoo RR. Exergy, and energy analysis of a wavy fin radiator with variously shaped nanofluids as coolants. Heat Transf Asian Res. 2019. https://doi.org/10.1002/htj.21478.

Kumar V, Sahoo RR. Viscosity and thermal conductivity comparative study for hybrid nanofluid in binary base fluids. Heat Transf Asian Res. 2019. https://doi.org/10.1002/htj.21535.

Sheikholeslami M, Shehzad SA. SCVFEM simulation for nanofluid migration in a porous medium using the Darcy model. Int J Heat Mass Transf. 2018;122:1264–71.

Sheikholesami M. New computational approach for exergy and entropy analysis of nanofluid under the impact of Lorentz force through a porous media. Comput Methods Appl Mech Eng. 2019;344:319–33.

Sheikholeslami M, Rezaeianjoubari B, Darzi M, Shafee A, Li Z, Nguyen TK. Application of nano-refrigerant for boiling heat transfer enhancement employing an experimental study. Int J Heat Mass Transf. 2019;141:974–80.

Sheikholeslami M, Haq R, Shafee A, Li Z, Elaraki YG, Tlili I. Heat transfer simulation of a heat storage unit with nanoparticles and fins through a heat exchanger. Int J Heat Mass Transf. 2019;135:470–8.

Sheikholeslami M, Haq R, Shafee A, Li Z. Heat transfer behavior of nanoparticle enhanced PCM solidification through an enclosure with V-shaped fins. Int J Heat Mass Transf. 2019;130:1322–42.

Sheikholeslami M, Jafaryar M, Li Z. Nanofluid turbulent convective flow in a circular duct with helical turbulators considering CuO nanoparticles. Int J Heat Mass Transf. 2018;124:980–9.

Sheikholeslami M, Ghasemi A. Solidification heat transfer of a nanofluid in the existence of thermal radiation by means of FEM. Int J Heat Mass Transf. 2018;123:418–31.

Sheikholeslami M, Seyednezhad M. Simulation of nanofluid flow and natural convection in a porous media under the influence of electric field using CVFEM. Int J Heat Mass Transf. 2018;120:772–81.

Sheikholeslami M, Jafaryar M, Saleem S, Li Z, Shafee A, Jiang Y. Nanofluid heat transfer augmentation and exergy loss inside a pipe equipped with innovative turbulators. Int J Heat Mass Transf. 2018;126:156–63.

Sahoo RR, Kumar V. Development of a new correlation to determine the viscosity of ternary hybrid nanofluid. Int Commun Heat Mass Transf. 2019;111:104451.

Sheikholeslami M. Magnetic field influence on CuO-H2O nanofluid convective flow in a permeable cavity considering various shapes for nanoparticles. Int J Hydrog Energy. 2017;42:19611–21.

Ghazali NM, Estelle P, Halelfadl S, Mare T, Siong TC, Abidin U. Thermal and hydrodynamic performance of a microchannel heat sink with carbon nanotube nanofluids. J Therm Anal Calorim. 2019;138:937.

Khan A, Ali HM, Nazir R, Ali R, Munir A, Ahmad B, Ahmad Z. Experimental investigation of enhanced heat transfer of a car radiator using ZnO nanoparticles in H2O–ethylene glycol mixture. J Therm Anal Calorim. 2019;138:3007.

Palaniappan B, Ramasamy V. Thermodynamic analysis of fly ash nanofluid for automobile (heavy vehicle) radiators. J Therm Anal Calorim. 2019;136:223–33.

Hajabdollahi H, Hajabdollahi Z. Numerical study on impact behaviors of nanoparticle shapes on the performance improvement of shell and tube heat exchanger. Chem Eng Res Des. 2017;125:449–60.

Alsarraf J, Vo DD, Moradikazerouni A, Afrad M, Salehipour H, Qi C. Numerical investigation of ϒ-AlOOH nanofluid convection performance in a wavy channel considering the various shape of nano additives. Powder Technol. 2019;345:649–57.

Holman JP. Experimental methods for engineers. McGraw-Hil: Singapore; 1994.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, V., Sahoo, R.R. Exergy and energy performance for wavy fin radiator with a new coolant of various shape nanoparticle-based hybrid nanofluids. J Therm Anal Calorim 143, 3911–3922 (2021). https://doi.org/10.1007/s10973-020-09361-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09361-z