Abstract

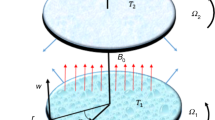

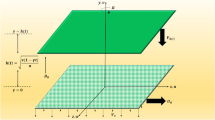

This paper studies an unsteady magnetohydrodynamic (MHD) Maxwell fluid flow on a rotating as well as a vertically moving disk in the presence of homogeneous–heterogeneous reactions. An improved heat conduction theory, namely Cattaneo–Christov heat flux, is implemented instead of classical Fourier’s law to analyze the thermal features. The problem is basically an extension of the well-known von Karman viscous pump problem to the situation where a disk is rotating. The leading equations of motion are converted into a set of nonlinear differential equations by using von Karman transformations. A Matlab-based scheme, namely bvp4c, which uses finite difference method, is employed for numerical integration. It is noted that the wall motion of the rotating disk performs a similar effect to that of suction/injection. Further, it is observed that by elevating thermal relaxation time parameter, the temperature field diminishes. Moreover, stronger rates of homogeneous and heterogeneous reactions cause to reduce the concentration profile.

Similar content being viewed by others

Abbreviations

- \(r,\varphi ,z\) :

-

Cylindrical coordinates

- u, v, w :

-

Velocity components \(({\hbox {m s}}^{-1})\)

- a(t):

-

Vertical distance \(\left( {\hbox {m}}\right)\)

- \(\overset{\centerdot }{a}(t)\) :

-

Vertical velocity \(({\hbox {m s}}^{-1})\)

- h :

-

Location of vertically moving disk \(\left( {\hbox {m}}\right)\)

- T :

-

Temperature of fluid \(\left( {\hbox {K}}\right)\)

- \(\varOmega (t)\) :

-

Angular velocity \(\left( {\hbox {rad s}}^{-1}\right)\)

- S :

-

Wall motion parameter

- \(\lambda _{1}\) :

-

Fluid relaxation time

- \(\nu\) :

-

Kinematic viscosities \(({\hbox {m}}^{2}\,{\hbox {s}}^{-1})\)

- M :

-

Magnetic field parameter

- \(\alpha _{1}\) :

-

Wall temperature parameter \(\left( {\hbox {K}}\right)\)

- \(\rho c_{p}\) :

-

Specific heat

- G :

-

Dimensionless azimuthal velocity

- \(B_{0}\) :

-

Magnetic field strength \(\left( {\hbox { N s C}}^{-1}\,\mathrm{m}^{-1}\right)\)

- c :

-

Arbitrary constant

- \(A^{*},B^{*}\) :

-

Chemical species

- \(a^{*},b^{*}\) :

-

Concentration of chemical species

- \(D_\mathrm{A},D_\mathrm{B}\) :

-

Diffusion coefficients

- g :

-

Homogeneous concentration

- h :

-

Heterogeneous concentration

- \(k_\mathrm{c},k_{\rm s}\) :

-

Rate constants

- \(\delta\) :

-

Ratio of mass diffusion coefficient

- \(\alpha\) :

-

Thermal diffusivity \(\left( {\hbox {m}}^{2}\ {\hbox {s}}^{-1}\right)\)

- Re:

-

Reynolds number

- \(T_{\infty }\) :

-

Ambient fluid temperature

- \(T_\mathrm{w}(t)\) :

-

Wall temperature \(\left( {\hbox {K}}\right)\)

- \(\rho c_{p}\) :

-

Heat capacity of fluid \(\left( {\hbox {J m}}^{-2}\,\mathrm{K}^{-1}\right)\)

- \(\eta\) :

-

Dimensionless variable

- \(\theta\) :

-

Dimensionless temperature

- \(\omega\) :

-

Rotation parameter

- \(k_\mathrm{1}\) :

-

Strength of homogeneous reaction

- H :

-

Dimensionless axial velocity

- \(\beta _{1}\) :

-

Deborah number

- \(k_{2}\) :

-

Strength of heterogeneous reaction

- \({\mathbf {V}}\) :

-

Velocity field \(\left( {\hbox {m s}}^{-1}\right)\)

- \({\mathbf {q}}\) :

-

Heat flux \(\left( {\hbox {W m}}^{-2}\right)\)

- F :

-

Dimensionless radial velocity

- \(\beta\) :

-

Wall permeability

- \(\rho\) :

-

Fluid density \(\left( {\hbox {kg m}}^{-3}\right)\)

- \(\lambda _{2}\) :

-

Thermal relaxation time parameter

- k :

-

Thermal conductivity

- \(\sigma\) :

-

Electric conductivity \(\left( {\hbox {S m}}^{-1}\right)\)

- \(\beta _{2}\) :

-

Thermal relaxation parameter

- Sc:

-

Schmidt number

- \(\mu\) :

-

Dynamic viscosities \(({\hbox {kg m}}^{-1}\ \hbox{s}^{-1})\)

References

Karman TV. Uber laminare und turbulente reibung. Z Angew Math Mech. 1921;1:233.

Cochran WG. The flow due to a rotating disc. Math Proc Camb Philos Soc. 1934;30(3):365–75.

Sparrow EM, Gregg JL. Mass transfer flow and heat transfer about a rotating disk. J Heat Transf. 1960;82(4):294–302.

Rashidi MM, Pour SM, Hayat T, Obaidat S. Analytic approximate solutions for steady flow over a rotating disk in porous medium with heat transfer by homotopy analysis method. Comput Fluids. 2012;54:1–9.

Sheikholeslami M, Ganji DD. Three dimensional heat and mass transfer in a rotating system using nanofluid. Powder Technol. 2014;253:789–96.

Turkyilmazoglu M. MHD fluid flow and heat transfer due to a shrinking rotating disk. Comput Fluids. 2014;90:51–6.

Xun S, Zhao J, Zheng L, Chen X, Zhang X. Flow and heat transfer of Ostwald-de waele fluid over a variable thickness rotating disk with index decreasing. Int J Heat Mass Transf. 2016;103:1214–24.

Mustafa M. MHD nanofluid flow over a rotating disk with partial slip effects Buongiorno’s model. Int J Heat Mass Transf. 2017;108:1910–6.

Hayat T, Rashid M, Imtiaz M, Alsaedi A. Nanofluid flow due to rotating disk with variable thickness and homogeneous–heterogeneous reactions. Int J Heat Mass Transf. 2017;113:96–105.

Turkyilmazoglu M. Fluid flow and heat transfer over a rotating and vertically moving disk. Phys Fluids. 2018;30(6):063605.

Akar S, Rashidi S, Esfahani JA. Second law of thermodynamic analysis for nanofluid turbulent flow around a rotating cylinder. J Therm Anal Calorim. 2018;132(2):1189–200.

Khan M, Ahmed J, Ahmad L. Chemically reactive and radiative von Kármán swirling flow due to a rotating disk. Appl Math Mech Engl Ed. 2018;39(9):1295–310.

Ahmed J, Khan M, Ahmad L. Stagnation point flow of Maxwell nanofluid over a permeable rotating disk with heat source/sink. J Mol Liq. 2019;287:110853.

Fourier B, Joseph JB. Théorie analytique de la chaleur F. Didot. 1822

Cattaneo C. Sulla conduzione del calore. Atti Sem Mat Fis Univ Modena. 1948;3:83–101.

Christov CI. On frame indifferent formulation of the Maxwell–Cattaneo model of finite-speed heat conduction. Mech Res Commun. 2009;36:481–6.

Ciarletta M, Straughan B. Uniqueness and structural stability for the Cattaneo–Christov equations. Mech Res Commun. 2010;37:445–7.

Khan JA, Mustafa M, Hayat T, Alsaedi A. Numerical study of Cattaneo–Christov heat flux model for viscoelastic flow due to an exponentially stretching surface. PLOS ONE. 2015;10(9):e0137363.

Hayat T, Aziz A, Muhammad T, Alsaedi A. Model and comparative study for the flow of viscoelastic nanofluids with Cattaneo–Christov double diffusion. PLOS ONE. 2017;12(1):0168824.

Khan SU, Ali N, Sajid M, Hayat T. Heat transfer characteristics in oscillatory hydromagnetic channel flow of Maxwell fluid using Cattaneo–Christov model. Proc Natl Acad Sci. 2019;89(2):377–85.

Rashidi S, Eskandarian M, Mahian O, Poncet S. Combination of nanofluid and inserts for heat transfer enhancement. J Therm Anal Calorim. 2019;135(1):437–60.

Asadollahi A, Esfahani JA, Ellahi R. Evacuating liquid coatings from a diffusive oblique fin in micro-/mini-channels. J Therm Anal Calorim. 2019;138:1–9.

Alamri SZ, Khan AA, Azeez M, Ellahi R. Effects of mass transfer on MHD second grade fluid towards stretching cylinder: a novel perspective of Cattaneo–Christov heat flux model. Phys Lett A. 2019;383(2–3):276–81.

Chaudhary MA, Merkin JH. A simple isothermal model for homogeneous–heterogeneous reactions in boundary layer flow equal diffusivities. Fluid Dyn Res. 1995;16:311–33.

Merkin JH. A model for isothermal homogeneous–heterogeneous reactions in boundary-layer flow. Math Comput Mod. 1996;24(8):125–36.

Khan WA, Pop IM. Effects of homogeneous–heterogeneous reactions on the viscoelastic fluid toward a stretching sheet. J Heat Transf. 2012;134(6):064506.

Kameswaran PK, Shaw S, Sibanda P, Murthy PVSN. Homogeneous–heterogeneous reactions in a nanofluid flow due to a porous stretching sheet. Int J Heat Mass Transf. 2013;57(2):465–72.

Khan MI, Waqas M, Hayat T, Alsaedi A. A comparative study of Casson fluid with homogeneous–heterogeneous reactions. J Colloid Interface Sci. 2017;498:85–90.

Hayat T, Muhammad K, Alsaedi A, Asghar S. Numerical study for melting heat transfer and homogeneous–heterogeneous reactions in flow involving carbon nanotubes. Res Phys. 2018;8:415–21.

Almutairi F, Khaled SM, Ebaid A. MHD flow of nanofluid with homogeneous–heterogeneous reactions in a porous medium under the influence of second-order velocity slip. MDPI Math. 2019;7(3):220.

Hsiao KL. Stagnation electrical MHD nanofluid mixed convection with slip boundary on a stretching sheet. Appl Therm Eng. 2016;98:850–61.

Hsiao KL. To promote radiation electrical MHD activation energy thermal extrusion manufacturing system efficiency by using Carreau-Nanofluid with parameters control method. Energy. 2017;130:486–99.

Hsiao KL. Combined electrical MHD heat transfer thermal extrusion system using Maxwell fluid with radiative and viscous dissipation effects. Appl Therm Eng. 2017;112:1281–8.

Hsiao KL. Micropolar nanofluid flow with MHD and viscous dissipation effects towards a stretching sheet with multimedia feature. Int J Heat Mass Transf. 2017;112:983–90.

Khan LA, Raza M, Mir NA, Ellahi R. Effects of different shapes of nanoparticles on peristaltic flow of MHD nanofluids filled in an asymmetric channel. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08348-9.

Hassan M, Ellahi R, Bhatti MM, Zeeshan A. A comparative study on magnetic and non-magnetic particles in nanofluid propagating over a wedge. Can J Phys. 2018;97(3):277–85.

Zeeshan A, Shehzad N, Abbas T, Ellahi R. Effects of radiative electro-magnetohydrodynamics diminishing internal energy of pressure-driven flow of titanium dioxide-water nanofluid due to entropy generation. Entropy. 2019;21(3):236.

Yousif MA, Ismael HF, Abbas T, Ellahi R. Numerical study of momentum and heat transfer of MHD Carreau nanofluid over an exponentially stretched plate with internal heat source/sink and radiation. Heat Transf Res. 2019;50(7):649–58.

Ellahi R, Sait SM, Shehzad N, Mobin N. Numerical simulation and mathematical modeling of electro-osmotic Couette–Poiseuille flow of MHD power-law nanofluid with entropy generation. Symmetry. 2019;11(8):1038.

Sarafraz MM, Pourmehran O, Yang B, Arjomandi M, Ellahi R. Pool boiling heat transfer characteristics of iron oxide nano-suspension under constant magnetic field. Int J Therm Sci. 2020;147:106131.

Ahmed J, Khan M, Ahmad L. Transient thin-film spin-coating flow of chemically reactive and radiative Maxwell nanofluid over a rotating disk. Appl Phys A. 2019;125(3):161.

Ahmed J, Khan M, Ahmad L, Alzahrani AK. Thermally radiative flow of Maxwell nanofluid over a permeable rotating disk. Phys Scr. 2019. https://doi.org/10.1088/1402-4896/ab3b9a.

Acknowledgements

This work has the financial supports from Higher Education Commission (HEC) of Pakistan under the project number: 6210.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Khan, M., Ahmed, J. & Ali, W. An improved heat conduction analysis in swirling viscoelastic fluid with homogeneous–heterogeneous reactions. J Therm Anal Calorim 143, 4095–4106 (2021). https://doi.org/10.1007/s10973-020-09342-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09342-2