Abstract

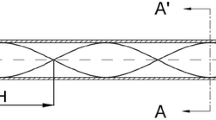

A numerical analysis is performed to investigate the thermal performance of turbulent fluid flow and heat transfer through a circular tube equipped with curved twisted tapes. The considered geometrical parameters are the pitch ratio, height and curvature of the curved twisted tape. Three-dimensional simulations are validated by experimental data available in the literature. The governing equations of turbulent flow are solved by using k − ε model for range of Reynolds number between 2500 and 20,000. Due to swirl flow, the effect of two regions, including near wall region and core region, on heat transfer and pressure drop are discussed. The presence of curved profile twisted tape leads to better heat transfer rate. The results show that case with height of curved twisted tape equal to 7 mm has around 35% higher thermal performance than the base case. Also, case with height of curved twisted tape equal to 5 mm has 30% higher thermal performance than the base case. Cases with pitch ratio between 5 and 15 have better thermal performance than normal pipe, but generally case with pitch ratio equal to unity has lower average thermal performance than the normal pipe. The maximum and minimum thermal performance improvement belongs to pitch ratio equal to 5 at Re = 10,000 (around 26%) and pitch ratio equal to unity at Re = 2500 (− 14%). The maximum and minimum thermal performance belongs to curve of curved twisted tape equal to 5 mm and 1.5 mm with 28% (at Re = 20,000) and − 4% (at Re = 2500), respectively.

Similar content being viewed by others

Abbreviations

- d :

-

Diameter (mm)

- u :

-

Velocity (m s−1)

- P :

-

Pressure (bar)

- T :

-

Temperature (K)

- C p :

-

Specific heat capacity (J kg−1 K−1)

- V :

-

Volume (m3)

- k :

-

Turbulent kinetic energy (W)

- G k :

-

Generation of turbulent kinetic energy (W)

- g :

-

Gravity acceleration, (m s−2)

- L :

-

Length (m)

- \(\dot{Q}\) :

-

Heat flux (W m−2)

- f :

-

Friction factor

- Pr:

-

Prandtl number

- Nu:

-

Nusselt number

- Re:

-

Reynolds number

- h :

-

Heat transfer coefficient (W m−2 K−1)

- \(\mu_{\text{t}}\) :

-

Eddy viscosity

- PR:

-

Pitch ratio

- \(\lambda\) :

-

Thermal conductivity (W m−1 K−1)

- \(\mu\) :

-

Dynamic viscosity (kg m−1 s)

- ρ :

-

Density, kg m−3

- η :

-

Thermal performance

- α :

-

Inverse effective Prandtl number

- ε :

-

Dissipation ratio

- τ :

-

Stress tensor

- Φ:

-

Dissipation

- w:

-

Wall

- t:

-

Turbulent

- h:

-

Hydraulic

- 0:

-

Reference

- eff:

-

Effective

- b:

-

Bulk

- m:

-

Average

References

Sun F, et al. Flow simulation of the mixture system of supercritical CO2 & superheated steam in toe-point injection horizontal wellbores. J Pet Sci Eng. 2018;163:199–210.

Belan M, Tordella D, De Ponte S. A system of fast acceleration of a mass of gas for the laboratory simulation of stellar jets. In: 19th international congress on ICIASF 2001 instrumentation in aerospace simulation facilities. IEEE, 2001.

Bergles A. Heat transfer enhancement—the encouragement and accommodation of high heat fluxes. J Heat Transf. 1997;119(1):8–19.

Williams W, Buongiorno J, Hu L-W. Experimental investigation of turbulent convective heat transfer and pressure loss of alumina/water and zirconia/water nanoparticle colloids (nanofluids) in horizontal tubes. J Heat Transf. 2008;130(4):042412.

Rea U, et al. Laminar convective heat transfer and viscous pressure loss of alumina–water and zirconia–water nanofluids. Int J Heat Transf. 2009;52(7–8):2042–8.

Godson L, et al. Heat transfer characteristics of silver/water nanofluids in a shell and tube heat exchanger. Arch Civ Mech Eng. 2014;14(3):489–96.

Mohammed H, et al. Heat transfer enhancement of nanofluids in a double pipe heat exchanger with louvered strip inserts. Int Commun Heat Mass Transf. 2013;40:36–46.

Torii K, et al. Heat transfer enhancement accompanying pressure-loss reduction with winglet-type vortex generators for fin-tube heat exchangers. Int Commun Heat Mass Transf. 2002;45(18):3795–801.

Webb R, Eckert ER. Application of rough surfaces to heat exchanger design. Int J Heat Mass Transf. 1972;15(9):1647–58.

Eiamsa-Ard S, Promvonge P. Performance assessment in a heat exchanger tube with alternate clockwise and counter-clockwise twisted-tape inserts. Int J Heat Mass Transf. 2010;53(7–8):1364–72.

Eiamsa-Ard S, et al. Thermal characteristics in a heat exchanger tube fitted with dual twisted tape elements in tandem. Int Commun Heat Mass Transf. 2010;37(1):39–46.

Hong S, Bergles AE. Augmentation of laminar flow heat transfer in tubes by means of twisted-tape inserts. J. Heat Transfer. 1976;98(2):251–256

Promvonge P, Eiamsa-ard S. Heat transfer behaviors in a tube with combined conical-ring and twisted-tape insert. Int Commun Heat Mass Transf. 2007;34(7):849–59.

Promvonge P, Eiamsa-Ard SJET, Science F. Heat transfer augmentation in a circular tube using V-nozzle turbulator inserts and snail entry. Exp Therm Fluid Sci. 2007;32(1):332–40.

Promvonge P, et al. Thermal performance enhancement in a heat exchanger tube fitted with inclined vortex rings. Appl Therm Eng. 2014;62(1):285–92.

Gunes S, et al. Heat transfer enhancement in a tube with equilateral triangle cross sectioned coiled wire inserts. Exp Therm Fluid Sci. 2010;34(6):684–91.

Liu S, Sakr MJR. A comprehensive review on passive heat transfer enhancements in pipe exchangers. Renew Sustain Energy Rev. 2013;19:64–81.

Sheikholeslami M, et al. Review of heat transfer enhancement methods: focus on passive methods using swirl flow devices. Renew Sustain Energy Rev. 2015;49:444–69.

Dewan A, et al. Review of passive heat transfer augmentation techniques. Proc Inst Mech Eng Part A: J Power Energy. 2004;218(7):509–27.

Badescu VJ. Simple and accurate model for the ground heat exchanger of a passive house. Renew Energy. 2007;32(5):845–55.

Yildiz C, et al. Effect of twisted strips on heat transfer and pressure drop in heat exchangers. Energy Conserv Manag. 1998;39(3–4):331–6.

Nakhchi ME, Esfahani JA. Numerical investigation of rectangular-cut twisted tape insert on performance improvement of heat exchangers. Int J Therm Sci. 2019;138:75–83.

Sarada N, et al. Enhancement of heat transfer using varying width twisted tape inserts. Int J Eng Sci Technol. 2010;2:107–18.

Eiamsa-ard S, et al. Thermohydraulic investigation of turbulent flow through a round tube equipped with twisted tapes consisting of centre wings and alternate-axes. Exp Therm Fluid Sci. 2010;34(8):1151–61.

Thianpong C, et al. Effect of perforated twisted-tapes with parallel wings on heat tansfer enhancement in a heat exchanger tube. Energy Procedia. 2012;14:1117–23.

Eiamsa-ard S, et al. Heat transfer enhancement in a tube using delta-winglet twisted tape inserts. Appl Therm Eng. 2010;30(4):310–8.

Murugesan P, Mayilsamy K, Suresh S. Heat transfer and friction factor studies in a circular tube fitted with twisted tape consisting of wire-nails. Chin J Chem Eng. 2010;18(6):1038–42.

Sheikholeslami M, Arabkoohsar A, Jafaryar M. Impact of a helical-twisting device on the thermal–hydraulic performance of a nanofluid flow through a tube. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08683-x.

Wang W, Zhang Y, Li B, Li Y. Numerical investigation of tube-side fully developed turbulent flow and heat transfer in outward corrugated tubes. Int J Heat Mass Transf. 2018;116:115–26.

Wang W, Zhang Y, Liu J, Li B, Sundén B. Numerical investigation of entropy generation of turbulent flow in a novel outward corrugated tube. Int J Heat Mass Transf. 2018;126:836–47.

Bahiraei M, Mazaheri N, Hassanzamani SM. Efficacy of a new graphene–platinum nanofluid in tubes fitted with single and twin twisted tapes regarding counter and co-swirling flows for efficient use of energy. Int J Mech Sci. 2019;150:290–303.

Sheikholeslami M, Jafaryar M, Li Z. Nanofluid turbulent convective flow in a circular duct with helical turbulators considering CuO nanoparticles. Int J Heat Mass Transf. 2018;124:980–9.

Bahiraei M, Mazaheri N, Aliee F. Second law analysis of a hybrid nanofluid in tubes equipped with double twisted tape inserts. Powder Technol. 2019;345:692–703.

Bahiraei M, Mazaheri N, Rizehvandi A. Application of a hybrid nanofluid containing graphene nanoplatelet–platinum composite powder in a triple-tube heat exchanger equipped with inserted ribs. Appl Therm Eng. 2019;149:588–601.

Bahiraei M, Jamshidmofid M, Goodarzi M. Efficacy of a hybrid nanofluid in a new microchannel heat sink equipped with both secondary channels and ribs. J Mol Liq. 2019;273:88–98.

Bahiraei M, Mazaheri N, Mohammadi MS, Moayedi H. Thermal performance of a new nanofluid containing biologically functionalized graphene nanoplatelets inside tubes equipped with rotating coaxial double-twisted tapes. Int Commun Heat Mass Transf. 2019;108:104305.

Fluent AN. 18.2, Theory Guide, ANSYS Inc. Canonsburg, PA. 2017.

Baragh S, Shokouhmand H, Ajarostaghi SS, Nikian M. An experimental investigation on forced convection heat transfer of single-phase flow in a channel with different arrangements of porous media. Int J Therm Sci. 2018;1(134):370–9.

Shirzad M, Ajarostaghi SS, Delavar MA, Sedighi K. Improve the thermal performance of the pillow plate heat exchanger by using nanofluid: numerical simulation. Adv Powder Technol. 2019;30(7):1356–65.

Baragh S, Shokouhmand H, Ajarostaghi SS. Experiments on mist flow and heat transfer in a tube fitted with porous media. Int J Therm Sci. 2019;1(137):388–98.

Shirzad M, Delavar MA, Ajarostaghi SSM, Sedighi K. Evaluation the effects of geometrical parameters on the performance of pillow plate heat exchanger. Chem Eng Res Des. 2019;150:74–83.

Noorbakhsh M, Zaboli M, Ajarostaghi SSM. Numerical evaluation of the effect of using twisted tapes as turbulator with various geometries in both sides of a double-pipe heat exchanger. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08509-w.

Zaboli M, Ajarostaghi SSM, Noorbakhsh M, Delavar MA. Effects of geometrical and operational parameters on heat transfer and fluid flow of three various water based nanofluids in a shell and coil tube heat exchanger. SN Appl Sci. 2019;1(11):1387.

Hamedani FA, Ajarostaghi SSM, Hosseini SA. Numerical evaluation of the effect of geometrical and operational parameters on thermal performance of nanofluid flow in convergent–divergent tube. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08765-w.

Moghadam HK, Ajarostaghi SSM, Poncet S. Extensive numerical analysis of the thermal performance of a corrugated tube with coiled wire. J Therm Anal Calorim. 2020. https://doi.org/10.1007/s10973-019-08876-4.

Kim D, et al. Convective heat transfer characteristics of nanofluids under laminar and turbulent flow conditions. Curr Appl Phys. 2009;9(2, Supplement):e119–23.

Afsharpanah F, Pakzad K, Amirsoleymani M, Delavar MA. Numerical study of heat transfer enhancement using perforated dual twisted tape inserts in converging-diverging tubes. Heat Transf Asian Res. 2018;47:754–67.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Outokesh, M., Ajarostaghi, S.S.M., Bozorgzadeh, A. et al. Numerical evaluation of the effect of utilizing twisted tape with curved profile as a turbulator on heat transfer enhancement in a pipe. J Therm Anal Calorim 140, 1537–1553 (2020). https://doi.org/10.1007/s10973-020-09336-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-020-09336-0