Abstract

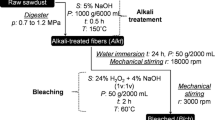

The effects of chemical treatment sequences on the chemical, physical, and mainly the thermal properties of Imperata Brasiliensis grass in the process used to obtain cellulose fibers were analyzed. The thermal properties were extensively investigated by a thermogravimetric analysis, and a thermal behavior prediction was carried out using kinetic parameters and simulation. Thermal simulations using statistical tools enable thermal predictions for any material under different conditions. However, they are currently not widely reported in the literature for untreated and treated natural fibers. We used an alkaline treatment and alkaline treatment followed by one, two, or three bleaching steps with hydrogen peroxide (H2O2) (24% v/v). After each chemical treatment, changes in chemical composition due to the removal of amorphous constituents were observed and confirmed by the analysis of properties such as coloration, density, porosity, crystallinity, and thermal decomposition. The alkaline treatment followed by one step of bleaching was the most effective and viable chemical treatment sequence to obtain cellulose. The changes in coloration from dark brown to light yellow were accompanied by increases in real density (65%), crystallinity (69%), and thermal stability (27.4%) upon one step of bleaching. In general, the subsequent bleaching steps provided similar values. The predicted thermal degradation profiles were compared with experimental data in order to validate the proposed degradation mechanisms and models. The obtained kinetic parameters adequately described the mass loss histories of the studied natural fibers, even when extremely simplified kinetic schemes were used. The degradation mechanisms consisted of diffusion followed by autocatalytic reactions for all studied fibers.

Similar content being viewed by others

References

Vadivel V, Moncalvo A, Dordoni R, Spigno G. Effects of on acid/alkaline treatment on the release of antioxidants and cellulose from different agro food wastes. Waste Manag. 2017;64:305–14.

Csiszár E, Nagy SA. Comparative study on cellulose nanocrystals extracted from bleached cotton and flax and used for casting films with glycerol and sorbitol plasticizers. Carbohyd Polym. 2017;174:740–9.

Oliveira FBO, Bras J, Pimenta MTB, Curvelo AAS, Belgacem MN. Production of cellulose nanocrystals from sugarcane bagasse fibers and pith. Ind Crop Prod. 2016;93:48–57.

Pereira PHF, Waldron KK, Wilson DR, Cunha AP, Brito ES, Rodrigues THS, Rosa MF, Azeredo HMC. Wheat straw hemicelluloses added with cellulose nanocrystals and citric acid. Effect on film physical properties. Carbohydr Polym. 2017;164:317–24.

Balakrishnan P, Sreekala MS, Kunaver M, Huskic M, Thomas S. Morphology, transport characteristics and viscoelastic polymer chain confinement in nanocomposites based on thermoplastic potato starch and cellulose nanofibers from pineapple leaf. Carbohydr Polym. 2017;169:176–88.

Pereira PHF, Oliveira TIS, Rosa MF, Cavalcante FL, Moates GK, Wellner N, Waldron KK, Wilson DR, Azeredo HMC. Pectin extraction from pomegranate peels with citric acid. Int J Biol Macromol. 2016;88:373–9.

Mujtaba M, Slaberria AM, Andres MA, Kaya M, Gunyakti A, Labidi J. Utilization of flax (L. Usitatissimum) cellulose nanocomposite as reinforcing material for chitosan films. Int J Biol Macromol. 2017;104:944–52.

Rathore A, Pradhn MK. Hybrid nanocomposite bionanocomposites from banana and jute fibre: a Review of preparation, properties and applications. Mater today Proc. 2017;4:3942–51.

Zhan Z, Li Y, Chen C. Synergic effects of cellulose nanocrystals and alkali on the mechanical properties of sisal fibers and their bonding properties with epoxy. Compos Part A Appl S. 2017;101:480–9.

Siró I, Plackett D. Microfibrillated cellulose and new nanocomposites materials: a review. Cellulose. 2010;17:459–94.

Sghaier AEO, Chaabouni Y, Msahli S, Sakli F. Morphological and crystalline characterization of NaOH and NaOCl treated Agave nanocomposite L. fiber. Ind Crop Prod. 2012;36:257–66.

Kalia S, Kaith BS, Kaur I. Pretreatments of natural fibers and their application as reinforcing material in polymer composites—a review. Polym Eng Sci. 2009;49:1253–72.

Campos A, Teodoro KBR, Marconcini JM, Mattoso LHC. Efeito do Tratamento das Fibras nas Propriedades do Biocompósito de Amido Termoplástico/Policaprolactona/Sisal. Polímeros. 2011;21:217–22.

Vestena M, Gross IP, Muller CMO, Pires ATN. Isolation of whiskers from natural sources and their dispersed in a non-aqueous medium. Polímeros. 2016. https://doi.org/10.1590/0104-1428.2367.

Pereira ALS, Nascimento DM, Filho MMS, Morais JPS, Vasconcelos NF, Feitosa JPA, Brígida AIS, Rosa MF. Improvement of polyvinyl alcohol properties by adding nanocrystalline cellulose isolated from banana pseudostems. Carbohydr Polym. 2014;112:165–72.

Rosa SML, Rehman N, Mirand MIG, Nachtigall SMB, Bica CID. Chlorine-free extraction of cellulose from rice husk and whisker isolation. Carbohydr Polym. 2012;87:1131–8.

Rout J, Misra M, Tripathy SS, Nayak SK, Mohanty AK. The influence of fibre treatment on the performance of coir-polyester composites. Compos Sci Technol. 2000;61:1303–10.

Carvalho KCC, Mulinari DR, Voorwald HJC, Cioffi MOH. Chemical Modification Effect on the mechanical properties of HIPS/coconut fiber composites. BioResources. 2010;5:1143–55.

Pakzad A, Yassar RS. Mechanics of cellulose nanocrystals and their polymer composites. In: Ochsner A, Shokuhfar A, editors. New frontiers of nanoparticles and nanocomposite materials. Advanced structured materials, vol. 4. Berlin: Springer; 2010.

Corrêa AC, Teixeira EM, Pessan LA, Mattoso LHC. Cellulose nanofibers from curaua fibers. Cellulose. 2010;17:1183–92.

Julkapli NM, Bagheri S. Progress on nanocrystalline cellulose biocomposites. React Funct Polym. 2017;112:9–21.

Borsoi C, Ornaghi HL Jr, Scienza LC, Zattera AJ, Ferreira CA. Isolation and characterization of cellulose nanowhiskers from microcrystalline cellulose using mechanical processing. Polym Polym Compos. 2017;25:563–70.

Rao KM, Han AKS. Polysaccharide based bionanocomposite hydrogels reinforced with cellulose nanocrystals: drug release and biocompatibility analyses. Int J Biol Macromol. 2017;101:165–71.

Ornaghi HL Jr, Zattera AJ, Amico SC. Thermal behavior and the compensation effect of vegetal fibers. Cellulose. 2014;21:189–201.

Ornaghi HL Jr, Zattera AJ, Amico SC. Dynamic mechanical properties and correlation with dynamic fragility of sisal reinforced composites. Polym Compos. 2015;36:161–6.

Ku H, Wang H, Pattarachaiyakoop N, Trada M. A review on the tensile properties of natural fiber reinforced polymer. Composites. 2011;42:856–73.

Xu C, Hinks C, Sun C, Wei Q. Establishment of an activated peroxide system for low-temperature cotton bleaching using N-[4-(triethylammoniomethyl) benzoyl] butyrolactam chloride. Carbohydr Polym. 2015;119:71–7.

Vyazovkin S, Burnham AK, Criado JM, Pérez-Maqueda LA, Popescu C, Sbirrazzuoli N. ICTAC kinetics committee recommendations for performing kinetic computations on thermal analysis data. Thermochim Acta. 2011;520:1–19.

Poletto M, Ornaghi HL Jr, Zattera AJ. Thermal decomposition of natural fibers: kinetics and degradation mechanisms. New York: Wiley; 2015. p. 515–45.

Sánchez-Jiménez PE, Pérez-Maqueda LA, Perejón A, Pascúal-Cosp J, Benítez-Guerrero M. An improved model for the kinetic description of the thermal degradation of cellulose. Cellulose. 2011;18:1487–98.

Erceg M, Krešić I, Vrandečić NS, Jakić M. Different approaches to the kinetic analysis of thermal degradation of poly(ethylene oxide). J Therm Anal Calorim. 2018;131:315–34.

Ourique PA, Ornaghi FG, Ornaghi HL Jr, Wanke CH, Bianchi O. Thermo-oxidative degradation kinetics of renewable hybrid polyurethane-urea obtained from air-oxidized soybean oil. J Therm Anal Calorim. 2019;137:1–11.

Zanchet A, Demori R, de Souza FDB, Ornaghi HL Jr, Schiavo LSA, Scuracchio CH. Sugar cane as na alternative green activator to conventional vulcanization additives in natural rubber compounds: termal degradation study. J Clean Prod. 2019;207:248–60.

Ornaghi FG, Bianchi O, Ornaghi HL Jr, Jacobi MAM. Fluoroelastomers reinforced with carbon nanofibers: a survey on rheological, swelling, mechanical, morphological, and prediction of the thermal degradation kinetic behavior. Polym Eng Sci. 2019;59:1223–32.

Benini KCCC, Voorwald HJC, Cioffi MOH, Milanese AC, Ornaghi HL Jr. Characterization of a new lignocellulosic fiber from Brazil: imperata brasiliensis (Brazilian Satintail) as an alternative source for nanocellulose extraction. J Nat Fibers. 2016;14:112–25.

Segal L, Creely J, Martin AE Jr, Conrad CM. An empirical method for estimating the degree of crystallinity of native cellulose using the X-ray diffractometer. Text Res J. 1959;29:786–94.

French AD. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose. 2014;21:885–96.

Wada M, Okano T. Localization of Iα and Iβ phases in algal cellulose revealed by acid treatments. Cellulose. 2001;8:183–8.

Scheller HV, Ulvskov P. Hemicelluloses. Annu Rev Plant Biol. 2010;61:263–89.

Aziz SH, Ansell MP. The effect of alkalization and fibre alignment on the mechanical and thermal properties of kenaf and hemp bast fibre composites: part 1—polyester resin matrix. Compos Sci Technol. 2004;64:1219–30.

Defoirdt N, Biswas S, Vriese L, Tran LQN, Acker J, Ahsan Q, Gorbatikh L, Vuure AV, Verpoest I. Assessment of the tensile properties of coir, bamboo and jute fibre. Compos Part A Appl Sci Manuf. 2010;41:588–95.

Kargarzadeh H, Ahmad I, Abdullah I, Dufresne A, Zainudin SY, Sheltami RM. Effect of hydrolysis conditions on the morphology, crystallinity, and thermal stability of cellulose nanocrystals extracted from kenaf bast fibers. Cellulose. 2012;19:855–66.

Jonoobi M, Harun J, Mathew AP, Oksman K. Mechanical properties of cellulose nanofiber (CNF) reinforced polyactic acid (PLA) prepared by twin screw extrusion. Compos Sci Tech. 2010;70:1742–7.

Azubuike CP, Odulaja O, Okhamafe AO. Physicotechnical, spectroscopy and thermogravimetry properties of powdered cellulose and microcrystalline cellulose derived from groundnut shells. J Excip Food Chem. 2016;3:106–15.

Ornaghi HL Jr, Moraes AF, Poletto M, Zattera AJ, Amico SC. Chemical composition, tensile properties and structural characterization of buriti fiber. Cell Chem Technol. 2016;50:15–22.

Satyaranayana GK, Flores-Sahagun THS, Santos LP, Santos J, Mazzaro I, Mikowski A. Characterization of blue agave bagasse fibers of Mexico. Compos Part A Appl Sci. 2013;45:153–61.

Orfão JJM, Antunes FJA, Figueiredo JL. Pyrolysis kinetics of ignocellulosic materials—three independent reactions model. Fuel. 1999;78:349–58.

Yao F, Wu Q, Lei Y, Guo W, Xu Y. Thermal decomposition kinetics of natural fibers: activation energy with dynamic thermogravimetric analysis. Polym Degrad Stab. 2008;93:90–8.

Azwa ZN, Yousif BF. Characteristics of kenaf fibre/epoxy composites subjected to thermal degradation. Polym Degrad Stab. 2013;98:2752–9.

Acknowledgements

Funding: this work was supported by FAPESP (2011/14153-8 and 2015/10386-9), Capes and CNPq (Project Number (15335/2018-1).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Carvalho Benini, K.C.C., Ornaghi, H.L., Pereira, P.H.F. et al. Survey on chemical, physical, and thermal prediction behaviors for sequential chemical treatments used to obtain cellulose from Imperata Brasiliensis. J Therm Anal Calorim 143, 73–85 (2021). https://doi.org/10.1007/s10973-019-09221-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-09221-5