Abstract

The objective of this study was to investigate effects of morphology and precipitation on thermal properties of Al-9.8%Si-0.4%Mg-0.7%Cu (in mass%) alloys using a laser flash apparatus, differential scanning calorimetry, and a thermomechanical analyser. Results revealed that mean particle size and shape of Si depended on mould temperature. Specimens with higher mould temperature had long and needle-like eutectic Si. As-cast specimens were solid solution treated at 535 °C for 6 h and then quenched in warm water of 80 °C. As-solution specimens were then aged at 180 or 190 °C for 1, 5, and 10 h. After artificial ageing treatment, the long needle-like eutectic silicon phase was split into smaller particles. It then gradually became spherical. When the shape of Si phase became similar after artificial ageing treatment, thermal diffusivity and thermal conductivity had similar values. It was found that shape change of Si particles greatly influenced thermal diffusivity and thermal conductivity.

Similar content being viewed by others

References

Sepehrband P, Mahmudi R. Effect of Zr addition on the aging behavior of A319 aluminum cast alloy. Scr Mater. 2005;52:253–7.

Ammar HR, Samuel AM, Samuel FH, Simielli E, Sigworth GK, Lin JC. Influence of aging parameters on the tensile properties and quality index of Al-9 Pct Si-1.8 Pct Cu-0.5 Pct Mg 354-type casting alloys. Metall Mater Trans A. 2012;43:61–73.

El Sebaie O, Samuel AM, Samuel FH, Doty HW. The effects of mischmetal, cooling rate and heat treatment on the hardness of A319.1, A356.2 and A413.1 Al–Si casting alloys. Mater Sci Eng A. 2008;486:241–52.

Samuel FH, Ouellet P, Samuel AM, Doty HW. Effect of Mg and Sr additions on the formation of intermetallics in AI-6 Wt Pet Si-3.5 Wt Pet Cu-(0.45) to (0.8) Wt Pet Fe 319-Type Alloys. Metall Mater Trans A Phys Metall Mater Sci. 1998;29:2871–84.

Mohamed AMA, Samuel FH, Kahtani S. Materials science & engineering a microstructure, tensile properties and fracture behavior of high temperature Al–Si–Mg–Cu cast alloys. Mater Sci Eng A. 2013;577:64–72. https://doi.org/10.1016/j.msea.2013.03.084.

Chakrabarti DJ, Peng Y, Laughlin DE. Precipitation in Al–Mg–Si alloys with Cu additions and the role of the Q’ and related phases. Mater Sci Forum. 2002;396–402:857–62.

Buha J, Lumley RN, Crosky AG, Hono K. Secondary precipitation in an Al–Mg–Si–Cu alloy. Acta Mater. 2007;55:3015–24.

Li RX, Li RD, Zhao YH, He LZ, Li CX, Guan HR, et al. Age-hardening behavior of cast Al–Si base alloy. Mater Lett. 2004;58:2096–101.

Mattos JJI, Uehara AY, Sato M, Ferreira I. Fatigue properties and micromechanism of fracture of an AlSiMg0. 6 cast alloy used in diesel engine cylinder head. Procedia Eng. 2010;2:759–65. https://doi.org/10.1016/j.proeng.2010.03.082.

Dong L, Chu S, Hu B, Zeng X, Chen B. Atomic-scale investigation into precipitated phase thickening in Al–Si–Mg–Cu alloy. J Alloys Compd. 2018;766:973–8.

Tonn B, Zak H, Asadi M. Cast aluminum alloy, and use thereof. PCT patent. WO 2009010264 A3. 2009.

Mohamed AMA, Samuel AM, Samuel FH, Doty HW. Influence of additives on the microstructure and tensile properties of near-eutectic Al–10.8% Si cast alloy. Mater Des. 2009;30:3943–57. https://doi.org/10.1016/j.matdes.2009.05.042.

Oppenheim T, Tewfic S, Scheck T, Klee V, Lomeli S, Dahir W, et al. On the correlation of mechanical and physical properties of 6061-T6 and 7249-T76 aluminum alloys. Eng Fail Anal. 2007;14:218–25.

Chen JK, Hung HY, Wang CF, Tang NK. Effects of casting and heat treatment processes on the thermal conductivity of an Al–Si–Cu–Fe–Zn alloy. Int J Heat Mass Transf. 2017;105:189–95. https://doi.org/10.1016/j.ijheatmasstransfer.2016.09.090.

Zhang C, Du Y, Liu S, Liu Y, Sundman B. Thermal conductivity of Al–Cu–Mg–Si alloys: Experimental measurement and CALPHAD modeling. Thermochim Acta. 2016;635:8–16.

Shivkumar S, Ricci S, Keller C, Apelian D. Effect of solution treatment parameters on tensile properties of cast aluminum alloys. J Heat Treat. 1990;8:63–70.

Wang QG, Apelian D, Lados DA. Fatigue behavior of A356/357 aluminum cast alloys. Part II ± Effect of microstructural constituents. J Light Met. 2001;1:85–97.

Tritt TM. editor. Thermal conductivity: Theory, properties, and applications. New York: Kluwer Academic/Plenum; 2004. p. 21–4.

Stadler F, Antrekowitsch H, Fragner W, Kaufmann H, Pinatel ER, Uggowitzer PJ. The effect of main alloying elements on the physical properties of Al–Si foundry alloys. Mater Sci Eng A. 2013;560:481–91. https://doi.org/10.1016/j.msea.2012.09.093.

Lumley RN, Polmear IJ, Groot H, Ferrier J. Thermal characteristics of heat-treated aluminum. Scr Mater. 2008;58:1006–9.

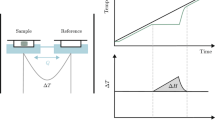

Choi S, Kim Y-M, Kim Y-C. Influence of precipitation on thermal diffusivity of Al-6Si-0.4Mg-0.9Cu-(Ti) alloys. J Alloys Compd. 2019;775:132–7.

Tritt TM. editor. Thermal conductivity: Theory, properties, and applications. New York: Kluwer Academic/Plenum; 2004. p. 46–73.

Smallman RE, Bishop RJ. Modern physical metallurgy and materials engineering. 6th ed. Oxford: Butterworth-Heinemann; 1999.

Kaschnitz E, Funk W, Pabel T. Electrical resistivity measured by millisecond pulse-heating in comparison to thermal conductivity of the aluminium alloy Al-7Si-0.3 Mg at elevated temperature. High Temp Press. 2014;43:175–91.

Mukhopadhyay AK, Yang QB, Singh SR. The influence of zirconium on the early stages of aging of a ternary Al–Zn–Mg alloy. Acta Metall Mater. 1994;42:3083–91.

Biswas A, Siegel DJ, Seidman DN. Compositional evolution of Q-phase precipitates in an aluminum alloy. Acta Mater. 2014;75:322–36. https://doi.org/10.1016/j.actamat.2014.05.001.

Lasagni F, Mingler B, Dumont M, Degischer HP. Precipitation kinetics of Si in aluminium alloys. Mater Sci Eng, A. 2008;480:383–91.

Kim Y, Kang D, Hong S, Kim Y, Choi S, Kang C. Influence of variation in the silicon content on the silicon precipitation in the Al–Si binary system. J Therm Anal Calorim. 2017;128:107–13.

Acknowledgements

We gratefully acknowledge the support provided by the Ministry of Trade, Industry and Energy (MTIE) of the Republic of Korea for funding our research programme on the development of convergent manufacturing technology for IE4-class electric motors. The present research is a part of the programme mentioned above.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Choi, SW., Kim, YM., Kim, YC. et al. Effect of morphology and precipitation of Si phase on thermal properties of Al–Si–Mg–Cu foundry alloy. J Therm Anal Calorim 142, 29–35 (2020). https://doi.org/10.1007/s10973-019-09196-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-09196-3