Abstract

Hot-rolled strips are cooled on the run-out table to achieve the customer-required mechanical properties. Cooling reduces the oxidation, which can assist the coiling operation. The ability to obtain a range of mechanical properties from a single steel grade reduces the use of alloying elements (elements added to a metal or an alloy which are incorporated in the metallic structure and change in the properties of the basic alloy) and the size of the slab inventories. So in this paper, the high-temperature steel strip cooling pattern with the temperature of 870 °C and reaching the temperature of 630 °C using water and air is studied. Moreover, the numerical simulation of the high-temperature strip cooling and its cooling method is carried out. The results are compared with the similar sampler ones. The changes of three key parameters such as change in strip speed and its effect on cooling rate, change in pattern and arrangement of water showers and its effects and change in the cooling water temperature are investigated. It was found that the uniformity of the heat distribution inside the strip was increased, but the temperature of the strip was lower than the required temperature. The middle and up surface temperatures of the strip were performed at a speed of 3.48 (m s−1), which showed a very good match with the actual tested sample.

Similar content being viewed by others

Abbreviations

- c p :

-

Specific heat (J kg−1 K−1)

- h :

-

Convection heat transfer coefficient (W m−2 C−1)

- Nu:

-

Nusselt number unitless

- P :

-

Pressure (Pa)

- Pr:

-

Prandtl number unitless

- Re:

-

Reynolds number unitless

- T :

-

Temperature (K)

- rc:

-

Critical radius (m)

- V s = V p :

-

Strip speed (m s−1)

- k :

-

Conduction heat transfer coefficient (W m−1 K−1)

- t :

-

Time (s)

- T a :

-

Ambient temperature (°C)

- T w :

-

Water temperature (°C)

- T s :

-

Strip surface temperature (K)

- H imp :

-

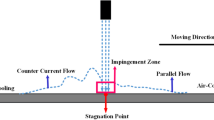

Convection heat transfer coefficient at impingement point (W m−2 C−1)

- H paralel :

-

Convection heat transfer coefficient between header and strip surface (W m−2 C−1)

- H a :

-

Air convection heat transfer coefficient (W m−2 C−1)

- H spray :

-

Convection heat transfer coefficient of spray water (W m−2 C−1)

- m s :

-

Mass water velocity at impingement point (kg s−1)

- \(\Delta T_{{{\text{sat}} .}}\) :

-

Superheat surface temperature (K)

- X :

-

Distance between strip and the last finishing stand (m)

- ρ :

-

Density (kg m−3)

- \(\dot{q}\) :

-

Heat generation per unit volume

References

Mei RB, Li CS, Liu XH, Bin HAN. Analysis of strip temperature in hot rolling process by finite element method. J Iron Steel Res Int. 2010;17(2):17–21.

Edalatpour S, Saboonchi A, Hassanpour S. Effect of phase transformation latent heat on prediction accuracy of strip laminar cooling. J Mater Process Technol. 2011;211(11):1776–82.

Sun CG, Han HN, Lee JK, Jin YS. A finite element model for the prediction of thermal and metallurgical behavior of strip on run-out-table in hot rolling. ISIJ Int. 2002;42(4):392–400.

Chen SX, Zou J, Fu X. Coupled models of heat transfer and phase transformation for the run-out table in hot rolling. J Zhejiang Univ Sci A. 2008;9(7):932–9.

Chen SJ, Tseng AA. Spray and jet cooling in steel rolling. Int J Heat Fluid Flow. 1992;13(4):358–69.

Siegfried Distl J, Kaspar R, Zeislmair U. Effect of the finish rolling and cooling conditions on the properties of microalloyed plate steels. Steel Res. 1987;58(11):514–22.

Otomo A, Yasunaga S, Ishida R. Cooling characteristics of steel sheet by water film in hot strip mill. Tetsu-to-Hagané. 1987;73(8):996–1003.

Ellerbrock DF, Tsuei YG, Behbahani AI. Characterization of wide-angle spray nozzles for use in accelerated cooling of hot steel bodies. In: Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy, Pergamon. 1988. p. 147–157.

Kreitzer P, Kuhlman J. Spray cooling droplet impingement model. In: 10th AIAA/ASME joint thermophysics and heat transfer conference. 2010. p. 4500.

Bathe KJ, Saunders H. Finite element procedures in engineering analysis. 1984. p. 421–422.

Xu F. Finite element simulation of water cooling process of steel strips on runout table. Doctoral dissertation, University of British Columbia. 2006.

Suebsomran A, Butdee S. Cooling process on a run-out table by the simulation method. Case Stud Therm Eng. 2013;1(1):51–6.

Hall DE, Incropera FP, Viskanta R. Jet impingement boiling from a circular free-surface jet during quenching: part 1—single-phase jet. J Heat Transf. 2001;123(5):901–10.

Hatta N, Kokado JI, Hanasaki K. Numerical analysis of cooling characteristics for water bar. Trans Iron Steel Inst Jpn. 1983;23(7):555–64.

Wendelstorf J, Spitzer KH, Wendelstorf R. Spray water cooling heat transfer at high temperatures and liquid mass fluxes. Int J Heat Mass Transf. 2008;51(19–20):4902–10.

Sarafraz MM, Nikkhah V, Madani SA, Jafarian M, Hormozi F. Low-frequency vibration for fouling mitigation and intensification of thermal performance of a plate heat exchanger working with CuO/water nanofluid. Appl Therm Eng. 2017;121:388–99.

Esfe MH. Designing a neural network for predicting the heat transfer and pressure drop characteristics of Ag/water nanofluids in a heat exchanger. Appl Therm Eng. 2017;126:559–65.

Esfe MH, Hajmohammad H, Toghraie D, Rostamian H, Mahian O, Wongwises S. Multi-objective optimization of nanofluid flow in double tube heat exchangers for applications in energy systems. Energy. 2017;137:160–71.

Nakhjavani M, Nikkhah V, Sarafraz MM, Shoja S, Sarafraz M. Green synthesis of silver nanoparticles using green tea leaves: experimental study on the morphological, rheological and antibacterial behaviour. Heat Mass Transf. 2017;53(10):3201–9.

Sarafraz MM. Experimental investigation on pool boiling heat transfer to formic acid, propanol and 2-butanol pure liquids under the atmospheric pressure. J Appl Fluid Mech. 2013;6(1):73–9.

Nikkhah V, Sarafraz MM, Hormozi F. Application of spherical copper oxide (II) water nano-fluid as a potential coolant in a boiling annular heat exchanger. Chem Biochem Eng Q. 2015;29(3):405–15.

Esfe MH, Rostamian H, Shabani-samghabadi A, Arani AAA. Application of three-level general factorial design approach for thermal conductivity of MgO/water nanofluids. Appl Therm Eng. 2017;127:1194–9.

Arya A, Sarafraz MM, Shahmiri S, Madani SAH, Nikkhah V, Nakhjavani SM. Thermal performance analysis of a flat heat pipe working with carbon nanotube-water nanofluid for cooling of a high heat flux heater. Heat Mass Transf. 2018;54(4):985–97.

Salari E, Peyghambarzadeh M, Sarafraz MM, Hormozi F. Boiling heat transfer of alumina nano-fluids: role of nanoparticle deposition on the boiling heat transfer coefficient. Period Polytech Chem Eng. 2016;60(4):252–8.

Esfe MH, Firouzi M, Rostamian H, Afrand M. Prediction and optimization of thermophysical properties of stabilized Al2O3/antifreeze nanofluids using response surface methodology. J Mol Liquids. 2018;261:14–20.

Salari E, Peyghambarzadeh SM, Sarafraz MM, Hormozi F, Nikkhah V. Thermal behavior of aqueous iron oxide nano-fluid as a coolant on a flat disc heater under the pool boiling condition. Heat Mass Transf. 2017;53(1):265–75.

Sarafraz MM, Peyghambarzadeh SM, Alavi FS. Experimental studies on nucleate pool boiling heat transfer to ethanol/MEG/DEG ternary mixture as a new coolant. Chem Ind Chem Eng Q/CICEQ. 2012;18(4–1):577–86.

Sarafraz MM, Hormozi F. Application of thermodynamic models to estimating the convective flow boiling heat transfer coefficient of mixtures. Exp Therm Fluid Sci. 2014;53:70–85.

Pordanjani AH, Aghakhani S, Karimipour A, Afrand M, Goodarzi M. Investigation of free convection heat transfer and entropy generation of nanofluid flow inside a cavity affected by magnetic field and thermal radiation. J Therm Anal Calorim. 2019;1–23.

Arasteh H, Mashayekhi R, Toghraie D, Karimipour A, Bahiraei M, Rahbari A. Optimal arrangements of a heat sink partially filled with multilayered porous media employing hybrid nanofluid. J Therm Anal Calorim. 2019;1–14.

Mozaffari M, Karimipour A, D’Orazio A. Increase lattice Boltzmann method ability to simulate slip flow regimes with dispersed CNTs nanoadditives inside. J Therm Anal Calorim. 2019;1–15.

Dehghani Y, Abdollahi A, Karimipour A. Experimental investigation toward obtaining a new correlation for viscosity of WO3 and Al2O3 nanoparticles-loaded nanofluid within aqueous and non-aqueous basefluids. J Therm Anal Calorim. 2019;135(1):713–28.

Hassani M, Karimipour A. Discrete ordinates simulation of radiative participating nanofluid natural convection in an enclosure. J Therm Anal Calorim. 2018;134(3):2183–95.

Arabpour A, Karimipour A, Toghraie D, Akbari OA. Investigation into the effects of slip boundary condition on nanofluid flow in a double-layer microchannel. J Therm Anal Calorim. 2018;131(3):2975–91.

Arabpour A, Karimipour A, Toghraie D. The study of heat transfer and laminar flow of kerosene/multi-walled carbon nanotubes (MWCNTs) nanofluid in the microchannel heat sink with slip boundary condition. J Therm Anal Calorim. 2018;131(2):1553–66.

Zadkhast M, Toghraie D, Karimipour A. Developing a new correlation to estimate the thermal conductivity of MWCNT-CuO/water hybrid nanofluid via an experimental investigation. J Therm Anal Calorim. 2017;129(2):859–67.

Moradi A, Toghraie D, Isfahani AHM, Hosseinian A. An experimental study on MWCNT–water nanofluids flow and heat transfer in double-pipe heat exchanger using porous media. J Therm Anal Calorim. 2019;1–11.

Shahsavar A, Godini A, Sardari PT, Toghraie D, Salehipour H. Impact of variable fluid properties on forced convection of Fe3O4/CNT/water hybrid nanofluid in a double-pipe mini-channel heat exchanger. J Therm Anal Calorim. 2019;1–13.

Goodarzi M, Toghraie D, Reiszadeh M, Afrand M. Experimental evaluation of dynamic viscosity of ZnO–MWCNTs/engine oil hybrid nanolubricant based on changes in temperature and concentration. J Therm Anal Calorim. 2019;136(2):513–25.

Pourdel H, Afrouzi HH, Akbari OA, Miansari M, Toghraie D, Marzban A, Koveiti A. Numerical investigation of turbulent flow and heat transfer in flat tube. J Therm Anal Calorim. 2019;135(6):3471–83.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Corresponding author at Department for Management of Science and Technology Development, Ton Duc Thang University, Ho Chi Minh City, Vietnam

Rights and permissions

About this article

Cite this article

Karimi Kerdabadi, J., Haghanimanesh, M., Karimipour, A. et al. The experimental/numerical investigation of variations in strip speed, water shower pattern and water temperature on high-temperature strip cooling rate in hot strip mill. J Therm Anal Calorim 143, 293–308 (2021). https://doi.org/10.1007/s10973-019-09052-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-09052-4