Abstract

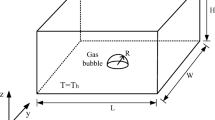

In this paper, the problem of steady forced convection heat transfer and fluid flow characteristics of a hybrid nanofluid flowing through an isothermally heated horizontal tube considering various nanoparticle shapes has been investigated numerically. The three dimensionless cylindrical coordinate equations are discretized using the finite volume method and solved via a FORTRAN program. A numerical parametric investigation is carried out for a tube filled with regular water, (TiO2/water) nanofluid and (Ag–TiO2/water) hybrid nanofluid. Four different types of nanoparticle shapes are considered in this study, spherical, cylindrical, platelets and blades, with different volume fractions ranging from 0 to 8% using water as a base liquid. The influence of nanoparticle shape, nanoparticle concentration and Reynolds number on the local Nusselt number and the friction factor is essentially examined. The results showed that the friction factor of both nanofluid and hybrid nanofluid flow was increased as the nanoparticle volume fraction increased for all kinds of nanoparticle shapes, whereas it decreased as the Reynolds number increased. Nusselt number increased with increase in the nanoparticle concentration and Reynolds number. The highest heat transfer rate was acquired for the maximum nanoparticle volume concentration by using blade nanoparticle shape followed by platelet shape, cylindrical shape and lastly the sphere shape. It was found that the maximum values of the friction factor were registered for platelet-shape nanoparticles.

Similar content being viewed by others

Abbreviations

- Cp:

-

Heat capacity (J kg−1 K−1)

- D :

-

Diameter of tube (m)

- f :

-

Friction factor (–)

- g :

-

Gravitational acceleration (m s−2)

- h :

-

Convective heat transfer coefficient (W m−2 K−1)

- Gr :

-

Grashof number \(( = g\beta_{\text{f}} q^{\prime \prime } D^{4} /k_{\text{f}} \nu_{\text{f}}^{2} )\)

- k :

-

Thermal conductivity (W m−1 K−1)

- L :

-

Length (m)

- Nu :

-

Nusselt number (= hD/k)

- Pr :

-

Prandtl number \(( = {\text{Cp}}_{\text{f}} \cdot \mu_{\text{f}} /k_{\text{f}} )\)

- P :

-

Pressure (Pa)

- P * :

-

Dimensionless pressure \(( = P/\rho_{\text{hnf}} v_{0}^{2} )\)

- \(q^{\prime \prime }\) :

-

Uniform heat flux (W m−2)

- Re :

-

Reynolds number \(( = \rho_{\text{f}} v_{0} D/\mu_{\text{f}} )\)

- r :

-

Radial direction (m)

- \(r^{*}\) :

-

Dimensionless radius (= r/D)

- T :

-

Temperature (K)

- \(T^{*}\) :

-

Dimensionless temperature \(( = (T - T_{0} )/(q_{\text{w}} D/k_{\text{nf}} )\)

- t :

-

Time (s)

- \(t^{*}\) :

-

Dimensionless time \(( = v_{0} t/D)\)

- u :

-

Radial velocity component (m s−1)

- \(u^{*}\) :

-

Dimensionless radial velocity (= u/v0)

- v :

-

Axial velocity component (m s−1)

- \(v^{*}\) :

-

Dimensionless axial velocity (= v/v0)

- w:

-

Tangential velocity (m s−1)

- \(w^{*}\) :

-

Dimensionless tangential velocity \(( = w/v_{0} )\)

- z:

-

Axial direction (m)

- \(z^{*}\) :

-

Dimensionless axial direction (= z/D)

- \(\beta\) :

-

Volumetric expansion coefficient (K−1)

- θ :

-

Angular coordinate

- \(\phi\) :

-

Volume fraction

- µ :

-

Dynamic viscosity (kg m−1 s−1)

- υ :

-

Kinematic viscosity (m2 s−1)

- b:

-

Bulk

- hnf:

-

Hybrid nanofluid

- nf:

-

Nanofluid

- f:

-

Base fluid

- 0:

-

Inlet condition

- *:

-

Dimensionless parameters

References

Choi SUS. Enhancing thermal conductivity of fluids with nanoparticles. ASME Publ Fed. 1995;231:99–106.

Sharma A. A comprehensive study of solar power in India and World. Renew Sustain Energy Rev. 2011;15:1767–76.

Thirugnanasambandam M, Iniyan S, Goic R. A review of solar thermal technologies☆. Renew Sustain Energy Rev. 2010;14:312–22.

Raja Sekhar Y, Sharma KV, Thundil Karupparaj R, Chiranjeevi C. Heat transfer enhancement with Al2O3 nanofluids and twisted tapes in a pipe for solar thermal applications. Procedia Eng. 2013;64:1474–84.

Krajnik P, Pusavec F, Rashid A. Nanofluids: properties, applications and sustainability aspects in materials processing technologies. 2011. p. 107–13.

Salata O. Applications of nanoparticles in biology and medicine. J Nanobiotechnol. 2004;2:1–6.

Duangthongsuk W, Wongwises S. Heat transfer enhancement and pressure drop characteristics of TiO2–water nanofluid in a double-tube counter flow heat exchanger. Int J Heat Mass Transf. 2009;52:2059–67.

Saidur R, Leong KY, Mohammad HA. A review on applications and challenges of nanofluids. Renew Sustain Energy Rev. 2011;15:1646–68.

Jajja SA, Ali W, Ali HM. Multiwalled carbon nanotube nanofluid for thermal management of high heat generating computer processor. Heat Transf Asian Res. 2014;43:653–66.

Ali HM, Arshad W. Thermal performance investigation of staggered and inline pin fin heat sinks using water based rutile and anatase TiO2 nanofluids. Energy Convers Manag. 2015;106:793–803.

Ali HM, Ali H, Liaquat H, Maqsood HTB, Nadir MA. Experimental investigation of convective heat transfer augmentation for car radiator using ZnO/water nanofluid. Energy. 2015;84:317–24.

Ali HM, Arshad W. Effect of channel angle of pin–fin heat sink on heat transfer performance using water based graphene nanoplatelets nanofluids. Int J Heat Mass Transf. 2017;106:465–72.

Arshad W, Ali HM. Graphene nanoplatelets nanofluids thermal and hydrodynamic performance on integral fin heat sink. Int J Heat Mass Transf. 2017;107:995–1001.

Arshad W, Ali HM. Experimental investigation of heat transfer and pressure drop in a straight minichannel heat sink using TiO2 nanofluid. Int J Heat Mass Transf. 2017;110:248–56.

Jafaryar M, Sheikholeslami M, Li Z, Moradi R. Nanofluid turbulent flow in a pipe under the effect of twisted tape with alternate axis. J Therm Anal Calorim. 2018;135:305–23.

Sheikholeslami M, Jafaryar M, Shafee A, Li Z. Nanofluid heat transfer and entropy generation through a heat exchanger considering a new turbulator and CuO nanoparticles. J Therm Anal Calorim. 2018;134:2295–303.

Sheikholeslami M, Arabkoohsar A, Khan I, Shafee A, Li Z. Impact of Lorentz forces on Fe3O4–water ferrofluid entropy and exergy treatment within a permeable semi annulus. J Clean Prod. 2019;221:885–98.

Sheikholeslami M. Numerical approach for MHD Al2O3–water nanofluid transportation inside a permeable medium using innovative computer method. Comput Methods Appl Mech Eng. 2019;344:306–18.

Sheikholeslami M. New computational approach for exergy and entropy analysis of nanofluid under the impact of Lorentz force through a porous media. Comput Methods Appl Mech Eng. 2019;344:319–33.

Sheikholeslami M, Mahian O. Enhancement of PCM solidification using inorganic nanoparticles and an external magnetic field with application in energy storage systems. J Clean Prod. 2019;215:963–77.

Sheikholeslami M, Haq R-U, Shafee A, Li Z. Heat transfer behavior of nanoparticle enhanced PCM solidification through an enclosure with V shaped fins. Int J Heat Mass Transf. 2019;130:1322–42.

Sheikholeslami M, Jafaryar M, Hedayat M, Shafee A, Li Z, Nguyen TK, Bakouri M. Heat transfer and turbulent simulation of nanomaterial due to compound turbulator including irreversibility analysis. Int J Heat Mass Transf. 2019;137:1290–300.

Sheikholeslami M, Gerdroodbary MB, Moradi R, Shafee A, Li Z. Application of neural network for estimation of heat transfer treatment of Al2O3–H2O nanofluid through a channel. Comput Methods Appl Mech Eng. 2019;344:1–12.

Benkhedda M, Boufendi T. Computational study of the mixed convection heat transfer of Ag–water nanofluid in an annular duct. In: IRSEC2016, IEEE, Marrakech, Morocco; 2016.

Timofeeva EV, Routbort JL, Singh D. Particle shape effects on thermophysical properties of alumina nanofluids. J Appl Phys. 2009;106:014304.

Sheikholeslami M, Sajjadi H, Amiri Delouei A, Atashafrooz M, Li Z. Magnetic force and radiation influences on nanofluid transportation through a permeable media considering Al2O3 nanoparticles. J Therm Anal Calorim. 2018;136:2477–85.

Jeong J, Li C, Kwon Y, Lee J, Kim SH, Yun R. Particle shape effect on the viscosity and thermal conductivity of ZnO nanofluids. Int J Refrig. 2013;36:2233–41.

Murshed S, Leong K, Yang C. Enhanced thermal conductivity of TiO2/water based nanofluids. Int J Therm Sci. 2005;44:367–73.

Vanaki SM, Mohammed HA, Abdollahi A, Wahid MA. Effect of nanoparticle shapes on the heat transfer enhancement in a wavy channel with different phase shifts. J Mol Liq. 2014;196:32–42.

Akbar NS, Tripathi D, Bég OA. Modeling nanoparticle geometry effects on peristaltic pumping of medical magnetohydrodynamic nanofluids with heat transfer. J Mech Med Biol. 2016;16:1650088.

Hatami M, Jafaryar M, Zhou J, Jing D. Investigation of engines radiator heat recovery using different shapes of nanoparticles in H2O/(CH2OH)2 based nanofluids. Int J Hydrog Energy. 2017;42:10891–900.

Ellahi R, Hassan M, Zeeshan A. Shape effects of nanosize particles in Cu–H2O nanofluid on entropy generation. Int J Heat Mass Transf. 2015;81:449–56.

Elias MM, Miqdad M, Mahbubul IM, Saidur R, Kamalisarvestani M, Sohel MR, Hepbasli A, Rahim NA, Amalina MA. Effect of nanoparticle shape on the heat transfer and thermodynamic performance of a shell and tube heat exchanger. Int Commun Heat Mass Transf. 2013;44:93–9.

Tayebi T, Chamkha AJ. Buoyancy-driven heat transfer enhancement in a sinusoidally heated enclosure utilizing hybrid nanofluid. Comput Therm Sci Int J. 2017;9:405–21.

Tayebi T, Chamkha AJ. Natural convection enhancement in an eccentric horizontal cylindrical annulus using hybrid nanofluids. Numer Heat Transf Part A Appl. 2017;71:1159–73.

Tayebi T, Chamkha AJ. Entropy generation analysis due to MHD natural convection flow in a cavity occupied with hybrid nanofluid and equipped with a conducting hollow cylinder. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08651-5.

Ali HM, Babar H, Shah TR, Sajid MU, Qasim MA, Javed S. Preparation techniques of TiO2 nanofluids and challenges: a review. Appl Sci. 2018;8:587.

Sajid MU, Ali HM. Thermal conductivity of hybrid nanofluids: a critical review. Int J Heat Mass Transf. 2018;126:211–34.

Babar H, Ali HM. Viscosity of hybrid nanofluids: a critical review, Therm Sci. 2019;15.

Suresh S, Venkitaraj KP, Selvakumar P, Chandrasekar M. Synthesis of Al2O3–Cu/water hybrid nanofluids using two step method and its thermo physical properties. Colloids Surf A. 2011;388:41–8.

Nine MdJ, Munkhbayar B, Rahman MS, Chung H, Jeong H. Highly productive synthesis process of well dispersed Cu2O and Cu/Cu2O nanoparticles and its thermal characterization. Mater Chem Phys. 2013;141:636–42.

Batmunkh M, Tanshen MdR, Nine MdJ, Myekhlai M, Choi H, Chung H, Jeong H. Thermal conductivity of TiO2 nanoparticles based aqueous nanofluids with an addition of a modified silver particle. Ind Eng Chem Res. 2014;53:8445–51.

Hemmat Esfe M, Wongwises S, Naderi A, Asadi A, Safaei MR, Rostamian H, Dahari M, Karimipour A. Thermal conductivity of Cu/TiO2–water/EG hybrid nanofluid: experimental data and modeling using artificial neural network and correlation. Int Commun Heat Mass Transf. 2015;66:100–4.

Toghraie D, Chaharsoghi VA, Afrand M. Measurement of thermal conductivity of ZnO–TiO2/EG hybrid nanofluid. J Therm Anal Calorim. 2016;125:527–35.

Baby TT, Sundara R. Synthesis and transport properties of metal oxide decorated graphene dispersed nanofluids. J Phys Chem C. 2011;115(17):8527–33.

Takabi B, Gheitaghy AM, Tazraei P. Hybrid water-based suspension of Al2O3 and Cu nanoparticles on laminar convection effectiveness. J Thermophys Heat Transf. 2016;30:523–32.

Rahman MRA, Leong KY, Idris AC, Saad MR, Anwar M. Numerical analysis of the forced convective heat transfer on Al2O3–Cu/water hybrid nanofluid. Heat Mass Transf. 2016;53:1835–42.

Balla HH, Abdullah S, Faizal WM, Zulkifli R, Sopian K. Numerical study of the enhancement of heat transfer for hybrid CuO–Cu nanofluids flowing in a circular pipe. J Oleo Sci. 2013;62(7):533–9.

Labib MN, Nine MJ, Afrianto H, Chung H, Jeong H. Numerical investigation on effect of base fluids and hybrid nanofluid in forced convective heat transfer. Int J Therm Sci. 2013;71:163–71.

Tayebi T, Chamkha AJ. Free convection enhancement in an annulus between horizontal confocal elliptical cylinders using hybrid nanofluids. Numer Heat Transf Part A Appl. 2016;70:1141–56.

Benkhedda M, Boufendi T, Touahri S. Laminar mixed convective heat transfer enhancement by using Ag–TiO2–water hybrid nanofluid in a heated horizontal annulus. Heat Mass Transf. 2018;54:2799–814.

Brinkman HC. The viscosity of concentrated suspensions and solutions. J Chem Phys. 1952;20:571.

Maxwell JC. A treatise on electricity and magnetism. Oxford: Clarendon Press; 1881.

Patankar SV. Numerical heat transfer and fluid flow. New York: McGraw-Hill; 1980.

Shah RK, London AL. Laminar flow forced convection heat transfer and flow friction in straight and curved ducts—a summary of analytical solutions. New York: Academic Press; 1971.

Shah RK, Bhatti MS. Laminar convective heat transfer in ducts, chapter 3. In: Kakac S, editor. New York: Wiley; 1987.

Acknowledgements

The authors would like to acknowledge the Energy Physics Laboratory (LPE) of Brothers Mentouri University of Constantine (Algeria) and the Algerian Ministry of High Education and Scientific Research (MESRS) for the financial support through FNR Grant.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Benkhedda, M., Boufendi, T., Tayebi, T. et al. Convective heat transfer performance of hybrid nanofluid in a horizontal pipe considering nanoparticles shapes effect. J Therm Anal Calorim 140, 411–425 (2020). https://doi.org/10.1007/s10973-019-08836-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08836-y