Abstract

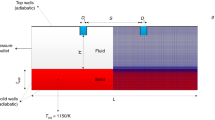

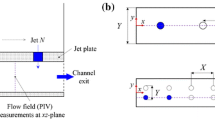

In this paper, a numerical simulation of jet impingement quenching is provided. The VOF method in the basic solver of the OpenFOAM CFD package is developed to simulate boiling and condensation phenomena. In simulations, surface tension and mass transfer between two phases were modeled with continuous surface force (CSF) model and Lee mass transfer model, respectively, and energy equation was solved in the solid region. Numerical simulation of jet impingement quenching process is validated by experimental data and a good agreement is observed. The effects of pulsating jet velocity and step jet velocity on quenching process are studied, and parameters such as temporal and spatial variation of solid part temperature and standard temperature uniformity index (STUI) are investigated. The effects of frequency and amplitude of sinusoidal single jet and also the period of two jets with step pulse are investigated. The results revealed that using two jets with step velocity profile leads to the best performance or least uniformity index (best temperature distribution) among the considered cases. Studying the maximum temperature difference inside the solid region indicated that for pulse flows this parameter is considerably lower than the continuous flows. Also, at a constant flow rate, 43% reduction in STUI is achieved by sinusoidal pulsating jet compared to the single continuous jet, while 66% STUI reduction was reached for two-jet cases. These substantial reductions in uniformity index present these methods as promising approaches for the quenching process in various industrial applications.

Similar content being viewed by others

Abbreviations

- A :

-

Jet inlet area (m2)

- A oc :

-

Oscillating amplitude

- \(C_{\alpha }\) :

-

Compression factor

- C p :

-

Specific heat (J kg−1K−1)

- f :

-

Frequency (Hz)

- g :

-

Gravity acceleration (m s−2)

- H LG :

-

Latent heat of evaporation (J kg−1)

- K :

-

Thermal conductivity (W m−2K−1)

- \(\Delta m\) :

-

Mass difference (kg)

- \(\dot{m}^{\prime\prime\prime}\) :

-

Condensate or evaporate mass flow rate per unit volume (kg m−3s−1)

- n st :

-

Step counter

- p :

-

Pressure (Pa)

- r e :

-

Evaporation mass transfer time relaxation parameter (s−1)

- r c :

-

Condensation mass transfer time relaxation parameter (s−1)

- STUI:

-

Standard temperature uniformity index

- T :

-

Temperature (K)

- T w :

-

Wall temperature (K)

- T oc :

-

Oscillation period (s)

- T st :

-

Step period (s)

- \(\Delta T\) :

-

Temperature difference (K)

- \(\Delta t\) :

-

Time difference (s)

- \(\vec{U}_{\text{r}}\) :

-

Vapor and liquid relative velocity (m s−1)

- \(\vec{U}_{\text{ref}}\) :

-

Reference velocity (m s−1)

- \(\Delta u\) :

-

Velocity difference (m s−1)

- \(\vec{U}\) :

-

Velocity vector (m s−1)

- V :

-

Cell volume (m3)

- W :

-

Width (m)

- \(\alpha\) :

-

Volume fraction factor

- \(\alpha_{\text{t}}\) :

-

Thermal diffusivity (m2 s−1)

- \(\kappa\) :

-

Interface curvature (m−1)

- \(\mu\) :

-

Dynamic viscosity (Pa s)

- \(\rho\) :

-

Density (kg m−3)

- \(\sigma\) :

-

Surface tension (N m−1)

- ave:

-

Average

- f:

-

Fluid

- fa:

-

Cell face

- G:

-

Gas

- i:

-

Number of sub-cycles

- L:

-

Liquid

- n:

-

Normal to surface

- s:

-

Solid

- sat:

-

Saturation

- sc:

-

Sub-cycle

References

Mujumdar AS. 15 Impingement Drying. In: Handbook of Industrial Drying. 2014:371.

Banooni S, Hosseinalipour SM, Mujumdar AS, Taherkhani P, Bahiraei M. Baking of flat bread in an impingement oven: modeling and optimization. Drying Technol. 2009;27(1):103–12. https://doi.org/10.1080/07373930802565954.

Banooni S, Hosseinalipour SM, Mujumdar AS, Taheran E, Bahiraei M, Taherkhani P. Baking of flat bread in an impingement oven: an experimental study of heat transfer and quality aspects. Drying Technol. 2008;26(7):902–9. https://doi.org/10.1080/07373930802142614.

Karwa N, Stephan P, editors. Jet impingement quenching: effect of coolant accumulation. Journal of Physics: Conference Series; 2012: IOP Publishing.

Chen C, Lin T, Yan W-M, Amani M. Time periodic evaporation heat transfer of R-134a in a narrow annular duct due to mass flow rate oscillation. Int J Heat Mass Transf. 2018;118:154–64.

Chen C, Lin T, Yan W-M. Experimental study on time periodic evaporation heat transfer of R-134a in annular ducts due to wall heat flux oscillation. Int J Heat Mass Transf. 2017;106:1232–41.

Chen C, Lin T, Yan W-M. Time periodic saturated flow boiling heat transfer of R-134a in a narrow annular duct due to heat flux oscillation. Int J Heat Mass Transf. 2017;106:35–46.

Wang Y-H, Wang S-Y, Lu G, Wang X-D. Effects of wettability on explosive boiling of nanoscale liquid films: whether the classical nucleation theory fails or not? Int J Heat Mass Transf. 2019;132:1277–83.

Wang Y-H, Wang S-Y, Lu G, Wang X-D. Explosive boiling of nano-liquid argon films on high temperature platinum walls: effects of surface wettability and film thickness. Int J Therm Sci. 2018;132:610–7.

Qiu L, Dubey S, Choo FH, Duan F. Recent developments of jet impingement nucleate boiling. Int J Heat Mass Transf. 2015;89:42–58.

Gradeck M, Kouachi A, Lebouché M, Volle F, Maillet D, Borean J-L. Boiling curves in relation to quenching of a high temperature moving surface with liquid jet impingement. Int J Heat Mass Transf. 2009;52(5–6):1094–104.

Karwa N, Gambaryan-Roisman T, Stephan P, Tropea C. Experimental investigation of circular free-surface jet impingement quenching: transient hydrodynamics and heat transfer. Exp Therm Fluid Sci. 2011;35(7):1435–43.

Agrawal C, Kumar R, Gupta A, Chatterjee B. Effect of jet diameter on the rewetting of hot horizontal surfaces during quenching. Exp Therm Fluid Sci. 2012;42:25–37.

Agrawal C, Kumar R, Gupta A, Chatterjee B. Determination of rewetting velocity during jet impingement cooling of a hot surface. J Therm Sci Eng Appl. 2013;5(1):011007.

Narumanchi S, Troshko A, Bharathan D, Hassani V. Numerical simulations of nucleate boiling in impinging jets: applications in power electronics cooling. Int J Heat Mass Transf. 2008;51(1):1–12.

Waldeck S, Woche H, Specht E, Fritsching U. Evaluation of heat transfer in quenching processes with impinging liquid jets. Int J Therm Sci. 2018;134:160–7.

Vakili S, Gadala MS. Boiling heat transfer of multiple impinging jets on a hot moving plate. Heat Transf Eng. 2013;34(7):580–95.

Lee J, Son G, Yoon HY. Numerical simulation of the quenching process in liquid jet impingement. Int Commun Heat Mass Transf. 2015;61:146–52.

Ghasemian M, Ramiar A, Ranjbar AA. Numerical investigation of boiling heat transfer in a quenching process of jet impingement considering solid temperature distribution. J Therm Anal Calorim. 2019;136(6):2409–20.

El-Nasar A. Heat transfer characteristics of horizontal cylinder cooling under single impinging water jet. Int J Appl Sci Eng Res 2012.

Toghraie D. Numerical thermal analysis of water’s boiling heat transfer based on a turbulent jet impingement on heated surface. Physica E. 2016;84:454–65.

Dobbertean MM, Rahman MM. Numerical analysis of steady state heat transfer for jet impingement on patterned surfaces. Appl Therm Eng. 2016;103:481–90.

Sen S, Aksakal B, Ozel A. Transient and residual thermal stresses in quenched cylindrical bodies. Int J Mech Sci. 2000;42(10):2013–29.

Ghasemian M, Ranjbar AA, Ramiar A. Heat transfer and uniformity enhancement in quenching process of multiple impinging jets with Newtonian and non-Newtonian quenchants. Int J Therm Sci. 2019;142:220–32.

Rusche H. Computational fluid dynamics of dispersed two-phase flows at high phase fraction-Ph. D. thesis, Imperial College of Science, Technology and Medicine, London, 2002.

Klostermann J, Schaake K, Schwarze R. Numerical simulation of a single rising bubble by VOF with surface compression. Int J Numer Methods Fluids. 2013;71(8):960–82.

Samkhaniani N, Ansari M. Numerical simulation of bubble condensation using CF-VOF. Prog Nucl Energy. 2016;89:120–31.

Bahreini M, Ramiar A, Ranjbar AA. Numerical simulation of bubble behavior in subcooled flow boiling under velocity and temperature gradient. Nucl Eng Des. 2015;293:238–48.

Brackbill JU, Kothe DB, Zemach C. A continuum method for modeling surface tension. J Comput Phys. 1992;100(2):335–54.

Lee W. A pressure iteration scheme for two-phase flow modeling (Technical Paper No. LA-UR-79-975). Los Alamos, New Mexico, USA: Los Alamos National Laboratory. 1979.

De Schepper SC, Heynderickx GJ, Marin GB. CFD modeling of all gas–liquid and vapor–liquid flow regimes predicted by the Baker chart. Chem Eng J. 2008;138(1–3):349–57.

Alizadehdakhel A, Rahimi M, Alsairafi AA. CFD modeling of flow and heat transfer in a thermosyphon. Int Commun Heat Mass Transf. 2010;37(3):312–8.

Yang Z, Peng X, Ye P. Numerical and experimental investigation of two phase flow during boiling in a coiled tube. Int J Heat Mass Transf. 2008;51(5–6):1003–16.

Bahreini M, Ramiar A, Ranjbar A. Numerical simulation of subcooled flow boiling under conjugate heat transfer and microgravity condition in a vertical mini channel. Appl Therm Eng. 2017;113:170–85.

Hirt CW, Nichols BD. Volume of fluid (VOF) method for the dynamics of free boundaries. J Comput Phys. 1981;39(1):201–25.

Shu B, Dammel F, Stephan P, editors. Phase change model for two-phase fluid flow based on the volume of fluid method. ICHMT Digital Library Online; 2008: Begel House Inc.

Welch SW, Wilson J. A volume of fluid based method for fluid flows with phase change. J Comput Phys. 2000;160(2):662–82.

Ramezanzadeh H, Ramiar A, Yousefifard M. Numerical investigation into coolant liquid velocity effect on forced convection quenching process. Appl Therm Eng. 2017;122:253–67.

Bahreini M, Ramiar A, Ranjbar AA. Development of a phase change model for volume-of-fluid method in OpenFOAM. J Heat Mass Transf Res. 2016;3(2):131–43.

Karwa N, Stephan P. Experimental investigation of free-surface jet impingement quenching process. Int J Heat Mass Transf. 2013;64:1118–26.

Rahimi M, Owen I, Mistry J. Thermal stresses in boiler tubes arising from high-speed cleaning jets. Int J Mech Sci. 2003;45(6–7):995–1009.

Huang Z, Zhu H, Yan R, Wang S. Simulation and prediction of radio frequency heating in dry soybeans. Biosyst Eng. 2015;129:34–47.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ramezanzadeh, H., Ramiar, A., Yousefifard, M. et al. Numerical analysis of sinusoidal and step pulse velocity effects on an impinging jet quenching process. J Therm Anal Calorim 140, 331–349 (2020). https://doi.org/10.1007/s10973-019-08828-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08828-y