Abstract

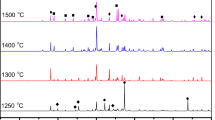

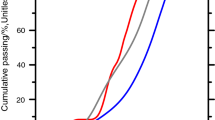

Crystalline admixtures (CAs), categorized as permeability-reducing admixtures, are commercial products employed in low contents in cement-based materials either to improve concrete durability or to stimulate autogenous healing of cracks. This study investigated the effects on crystal formation promoted by CA presence in cementitious pastes by thermal analysis. X-ray diffraction was used as a complementary technique to identify the formed phases. The results indicated that the increment in CA content increased calcium hydroxide (CH) and monocarboaluminate contents. However, it did not change the total combined water and calcium carbonate (CaCO3) contents. In fact, the increment in CA content prolonged the retarding of hydration reactions and decreased the dehydroxylation temperature of CH, suggesting the decrease in crystallinity and purity degree. The primary action mechanisms of CA confirmed were the long-term ability for further hydration to occur, the CH recrystallization, and the conversion of lower to higher thermal stability phases. Chemical and physical mechanisms of CAs are related to their surface area increase and their chemical nature, mainly composed of limestone. These characteristics confer with CA, the ability to act as a nucleation and precipitation stimulator to form new products.

Similar content being viewed by others

Abbreviations

- C:

-

CaO

- S:

-

SiO2

- A:

-

Al2O3

- F:

-

Fe2O3

- \({\bar{\text{S}}}\) :

-

SO3

- \({\bar{\text{C}}}\) :

-

CO2

- H:

-

H2O

- ACH:

-

Aluminate calcium hydrate

- AFm:

-

Monosulfoaluminate (C4A\({\bar{\text{S}}}\)H12)

- AFt:

-

Ettringite (C6A\({\bar{\text{S}}}\)3H22)

- CaCO3 :

-

Calcium carbonate

- C–A–S–H:

-

Calcium–aluminosilicate–hydrate

- CH:

-

Portlandite or calcium hydroxide

- C–S–H:

-

Calcium–silicate–hydrate

- Hca:

-

Hemicarboaluminate (C4A\({\bar{\text{C}}}\)0.5H12)

- Mca:

-

Monocarboaluminate (C4A\({\bar{\text{C}}}\)H11)

References

De Belie N, Gruyaert E, Al-Tabbaa A, Antonaci P, Baera C, Bajare D, et al. A review of self-healing concrete for damage management of structures. Adv Mater Interfaces. 2018;1800074:1–28. https://doi.org/10.1002/admi.201800074.

Pazderka J. Concrete with crystalline admixture for ventilated tunnel against moisture. Key Eng Mater. 2016;677:108–13.

Reiterman P, Pazderka J. Crystalline coating and its influence on the water transport in concrete. Adv Civ Eng. 2016;2016:1–8.

Pazderka J, Hájková E. Crystalline admixtures and their effect on selected properties of concrete. Acta Polytech. 2016;56:291.

Mailvaganam NP. Admixtures for repair and restoration of concrete. In: Ramachandram VS, editor. Concrete admixtures handbook: properties, science, and technology. 2nd ed. Ottawa: Elsevier; 1995. p. 843–65.

Mailvaganam NP. Miscellaneous admixtures. In: Ramachandram VS, editor. Concrete admixtures handbook: properties, science, and technology. 2nd ed. Ottawa: Elsevier; 1995. p. 986–94.

Zizkova N, Nevrivova L, Ledl M, Keprdova S. Mortars with crystalline additive in aggressive environments. IOP Conf Ser Mater Sci Eng. 2018;385:6.

Cappellesso VG, dos Santos Petry N, Dal Molin DCC, Masuero AB. Use of crystalline waterproofing to reduce capillary porosity in concrete. J Build Pathol Rehabil. 2016;1:9. https://doi.org/10.1007/s41024-016-0012-7.

Ferrara L, Krelani V, Moretti F. On the use of crystalline admixtures in cement based construction materials: from porosity reducers to promoters of self healing. Smart Mater Struct. 2016;25:1–17.

Ferrara L, Krelani V, Carsana M. A “fracture testing” based approach to assess crack healing of concrete with and without crystalline admixtures. Constr Build Mater. 2014;68:535–51. https://doi.org/10.1016/j.conbuildmat.2014.07.008.

ACI 212.3R. Report on Chemical Admixtures for Concrete. Farmington Hills: ACI Committee 212; 2016.

Rixom R, Mailvaganam N. Chemical admixtures for concrete. Third. Rixom R, Mailvaganam N (eds). Taylor Fr. Gr. London: E. & F.N. Spon; 1999.

Hassani EM, Vessalas K, Sirivivatnanon V, Baweja D. Influence of permeability-reducing admixtures on water penetration in concrete. ACI Mater J. 2017;114:1–12.

Silva EF, Moreira M, Manzano MA, Blanco R. Case study of permeability-reducing admixture use in anti-flotation slabs: building in Brasilia, Brazil. J Build Pathol Rehabil. 2017;2:1–9. https://doi.org/10.1007/s41024-016-0014-5.

Roig-Flores M, Pirritano F, Serna P, Ferrara L. Effect of crystalline admixtures on the self-healing capability of early-age concrete studied by means of permeability and crack closing tests. Constr Build Mater. 2016;114:447–57. https://doi.org/10.1016/j.conbuildmat.2016.03.196.

Sisomphon K, Copuroglu O, Koenders E. Effect of exposure conditions on self healing behavior of strain hardening cementitious composites incorporating various cementitious materials. Constr Build Mater. 2013;42:217–24. https://doi.org/10.1016/j.conbuildmat.2013.01.012.

Cuenca E, Tejedor A, Ferrara L. A methodology to assess crack-sealing effectiveness of crystalline admixtures under repeated cracking-healing cycles. Constr Build Mater. 2018;179:619–32.

Oliveira A, Toledo Filho R, Fairbairn E, Gomes O. Self-Healing of cement slurry for oil wells containing crystalline admixture: early results. In: SynerCrete’18—international conference on interdisciplinary approaches for cement-based materials and structural concrete, 2018, Funchal—Madeira Island. vol. 2. Paris - France: RILEM Publications S.A.R.L., 2018. p. 1109–14.

Cheung J, Jeknavorian A, Roberts L, Silva D. Impact of admixtures on the hydration kinetics of Portland cement. Cem Concr Res. 2011;41:1289–309. https://doi.org/10.1016/j.cemconres.2011.03.005.

Biparva A, Yuers K. Integral Crystalline Waterproofing Technology. Integr. Cryst. Waterproofing Technol. 2010 [cited 2019 Jan 19]. p. 65. https://www.slideshare.net/KrytonIntl/integral-crystalline-waterproofing-technology.

Jiang Z, Li W, Yuan Z. Influence of mineral additives and environmental conditions on the self-healing capabilities of cementitious materials. Cem Concr Compos. 2015;57:116–27.

Rahhal V, Bonavetti V, Trusilewicz L, Pedrajas C, Talero R. Role of the filler on Portland cement hydration at early ages. Constr Build Mater. 2012;27:82–90. https://doi.org/10.1016/j.conbuildmat.2011.07.021.

De Nardi C, Bullo S, Ferrara L, Ronchin L, Vavasori A. Effectiveness of crystalline admixtures and lime/cement coated granules in engineered self-healing capacity of lime mortars. Mater Struct. 2017;50:191. https://doi.org/10.1617/s11527-017-1053-3.

Lucas SS, Von Tapavicza M, Schmidt AM, Bertling J, Nellesen A. Study of quantification methods in self-healing ceramics, polymers and concrete: a route towards standardization. J Intell Mater Syst Struct. 2016;27:2577–98.

Termkhajornkit P, Nawa T, Yamashiro Y, Saito T. Self-healing ability of fly ash–cement systems. Cem Concr Compos. 2009;31:195–203. https://doi.org/10.1016/j.cemconcomp.2008.12.009.

Ahn T-H, Kishi T. Crack self-healing behavior of cementitious composites incorporating various mineral admixtures. J Adv Concr Technol. 2010;8:171–86.

Van Tittelboom K, Gruyaert E, Rahier H, De Belie N. Influence of mix composition on the extent of autogenous crack healing by continued hydration or calcium carbonate formation. Constr Build Mater. 2012;37:349–59. https://doi.org/10.1016/j.conbuildmat.2012.07.026.

Dao VTN, Dux PF, Morris PH, Carse AH. Performance of permeability-reducing admixtures in marine concrete structures. ACI Mater J. 2010;107:291–6.

Ferrara L, Albertini I, Gettu R, Krelani V, Moscato S, Pirritano F, et al. Self healing of cement based materials engineered through crystalline admixtures: experimental results from a multinational university network. Am Concr Institute, ACI Spec Publ. 2015; 2015–Janua:13.1–13.10. https://www.scopus.com/inward/record.uri?eid=2-s2.0-84988220919&partnerID=40&md5=64b4d7b99599cfee11a3a3eaf36f64a8.

Azarsa P, Gupta R, Biparva A. Assessment of self-healing and durability parameters of concretes incorporating crystalline admixtures and Portland Limestone Cement. Cem Concr Compos. 2019;99:17–31. https://doi.org/10.1016/j.cemconcomp.2019.02.017.

Roig-Flores M, Moscato S, Serna P, Ferrara L. Self-healing capability of concrete with crystalline admixtures in different environments. Constr Build Mater. 2015;86:1–11.

Roig-Flores M, Moscato S, Serna P, Ferrara L. Self-healing capability of concrete containing crystalline admixtures in different exposure conditions. In: Concrete—innovation and design, fib symposium, Copenhagen. 2015;2013–7.

Cuenca E, Ferrara L. Self-healing capacity of fiber reinforced cementitious composites. State of the art and perspectives. KSCE J Civ Eng. 2017;21:2777–89.

Li W, Dong B, Yang Z, Xu J, Chen Q, Li H, et al. Recent advances in intrinsic self-healing cementitious materials. Adv Mater. 2018;30:9. https://doi.org/10.1002/adma.201705679.

Joa BW, Ali Sikandar M, Baloch Z, Asad Khan RM. Effect of incorporation of self healing admixture (SHA) on physical and mechanical properties of mortars. J Ceram Process Res. 2015;16:s138–43.

Sisomphon K, Copuroglu O, Koenders E. Self-healing of surface cracks in mortars with expansive additive and crystalline additive. Cem Concr Compos. 2012;34:566–74. https://doi.org/10.1016/j.cemconcomp.2012.01.005.

Yodmalai D, Sahamitmongkol R, Tangtermsirikul S, Lawtrakul L. Carbonation resistance of concrete with crystalline material coating. Mag Concr Res. 2011;63:573–82.

Huang H, Ye G, Qian C, Schlangen E. Self-healing in cementitious materials: materials, methods and service conditions. Mater Des. 2016;92:499–511. https://doi.org/10.1016/j.matdes.2015.12.091.

Huang H, Ye G, Damidot D. Characterization and quantification of self-healing behaviors of microcracks due to further hydration in cement paste. Cem Concr Res. 2013;52:71–81. https://doi.org/10.1016/j.cemconres.2013.05.003.

Dweck J, Cherem Da Cunha AL, Pinto CA, Pereira Gonçalves J, Büchler PM. Thermogravimetry on calcined mass basis—hydrated cement phases and pozzolanic activity quantitative analysis. J Therm Anal Calorim. 2009;97:85–9.

Dweck J, Buchler PM, Coelho ACV, Cartledge FK. Hydration of a Portland cement blended with calcium carbonate. Thermochim Acta. 2000;346:105–13.

Dweck J, Melchert MBM, Viana MM, Cartledge FK, Büchler PM. Importance of quantitative thermogravimetry on initial cement mass basis to evaluate the hydration of cement pastes and mortars. J Therm Anal Calorim. 2013;113:1481–90.

Cheary RW, Coelho A. Fundamental parameters approach to X-ray line-profile fitting. J Appl Crystallogr. 1992;25:109–21.

Taylor HFW. Cement chemistry. In: Taylor HFW, editor. Library (London). 1st ed. London: Academic Press; 1990.

Hewlett P, Bensted J, Blezard RG, Brown B, Capmas A, Edmeades RM, et al. LEA’s chemistry of cement and concrete, 4th edn. In: Hewlett PC, editor. Elsevier Sci. Technol. Books. Oxford: Elsevier Science & Technology Books; 2004. http://www.dbpia.co.kr/view/ar_view.asp?arid=1536305.

Scrivener K, Snellings R, Lothenbach B. A practical guide to microstructural analysis of cementitious materials, 1st edn. In: Scrivener K, Snellings R, Lothenbach B, editors. New York: CRC Press Taylor & Francis Group; 2016.

Ramachandran VS, Paroli RM, Beaudoin JJ, Delgado AH. Handbook of thermal analysis of construction materials, 1st edn. In: Ramachandran VS, editor. Noyes Publ. New York: Noyes Publications; 2002.

Chaipanich A, Nochaiya T. Thermal analysis and microstructure of Portland cement–fly ash–silica fume pastes. J Therm Anal Calorim. 2010;99:487–93.

Lothenbach B, Winnefeld F, Alder C, Wieland E, Lunk P. Effect of temperature on the pore solution, microstructure and hydration products of Portland cement pastes. Cem Concr Res. 2007;37:483–91.

Gabrovšek R, Vuk T, Kaučič V. Evaluation of the hydration of Portland cement containing various carbonates by means of thermal analysis. Acta Chim Slov. 2006;53:159–65.

Munn R, Kao G, Chang Z. Performance and compatability of permeability reducing and other chemical admixtures in Australian concretes. ACI-CANMET_Berlin. 2003.

Gabrovšek R, Vuk T, Kaucic V. The preparation and thermal behavior of calcium monocarboaluminate. Acta Chim Slov. 2008;55:942–50.

Wieskawa N-W. The tricalcium silicate hydration—calcium_hydroxide determination. Thermochim Acta. 1985;93:565–8.

Esteves LP. On the hydration of water-entrained cement-silica systems: combined SEM, XRD and thermal analysis in cement pastes. Thermochim Acta. 2011;518:27–35.

Morandeau A, Thiéry M, Dangla P. Investigation of the carbonation mechanism of CH and C–S–H in terms of kinetics, microstructure changes and moisture properties. Cem Concr Res. 2014;56:153–70. https://doi.org/10.1016/j.cemconres.2013.11.015.

Shen Q, Pan G, Bao B. Influence of CSH carbonation on the porosity of cement paste. Mag Concr Res. 2016;68:504–14.

Stepkowska ET, Aviles MA, Blanes JM. Gradual transformation of Ca(OH)2 into CaCO3 on cement hydration. J Therm Anal Calorim. 2007;87:189–98.

Villain G, Thiery M, Platret G. Measurement methods of carbonation profiles in concrete: thermogravimetry, chemical analysis and gammadensimetry. Cem Concr Res. 2007;37:1182–92.

Bukowski JM, Berger RL. Reactivity and strength development of CO2 activated non-hydraulic calcium silicates. Cem Concr Res. 1979;9:57–68.

Sauman Z. Carbonization of porous concrete and its main binding components. Cem Concr Res. 1971;I:645–62.

Goto S, Suenaga K, Kado T, Fukuhara M. Calcium silicate carbonation products. J Am Ceram Soc. 1995;78:2867–72.

Lothenbach B, Le Saout G, Gallucci E, Scrivener K. Influence of limestone on the hydration of Portland cements. Cem Concr Compos. 2008;38:848–60.

Ipavec A. Vpliv dodatka finih delcev apnenca na hidratacijo Portland cementa. [Ljubljana]: Univerza v Ljubljani; 2009. Available from: Andrej Ipavec. (2009). Vpliv dodatka finih delcev apnenca na hidratacijo Portland cementa.

Lothenbach B, Winnefeld F. Thermodynamic modelling of the hydration of Portland cement. Cem Concr Res. 2006;36:209–26.

Ipavec A, Gabrovšek R, Vuk T, Kaucic V, Macek J, Meden A. Carboaluminate phases formation during the hydration of calcite-containing Portland cement. J Am Ceram Soc. 2011;94:1238–42.

Gutteridge AW, Dalziel JA. Filler cement: the effect of the secondary component on the hydration of Portland cement—part I: a fine non-hydraulic filler. Cem Concr Res. 1990;20:778–82.

Feldman R, Ramachandran VS, Sereda PJ. Influence of CaCO3 on the hydration of 3CaOAl2O3. J Am Ceram Soc. 1965;48:25–30.

Acknowledgements

This study was financed in part by the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior—Brasil (CAPES)—Finance Code 001. The support of Brazilian funding agencies CNPq—Conselho Nacional de Desenvolvimento Cientifico e Tecnológico, FAPERJ—Fundação Carlos Chagas Filho de Amparo à Pesquisa do Estado do Rio de Janeiro, and FINEP—Empresa Brasileira de Inovação e Pesquisa is also gratefully acknowledged. The authors would also like to thank Dr. Reiner Neumann (CETEM and National Museum/UFRJ, Brazil) for the quantitative XRD analyses and the anonymous reviewers for their careful review of the paper.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

de Souza Oliveira, A., Dweck, J., de Moraes Rego Fairbairn, E. et al. Crystalline admixture effects on crystal formation phenomena during cement pastes’ hydration. J Therm Anal Calorim 139, 3361–3375 (2020). https://doi.org/10.1007/s10973-019-08745-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08745-0