Abstract

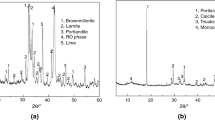

The hydration properties of quick cooled copper slag (QCS) and slow cooled copper slag (SCS) activated with 4% and 8% (by Na2O mass) sodium hydroxide (NA) and water glass (NS) were investigated by hydration heat. Meanwhile, the hydration degrees and hydration products of alkali-activated copper slags were determined by X-ray diffraction, Fourier transform infrared, scanning electron microscope, energy-dispersive X-ray and backscattered electron tests. In addition, the compressive strengths of alkali-activated copper slag mortars were tested. Results show that alkali-activated QCS has significantly higher activities than alkali-activated SCS. At the concentration of 4%, the QCS activated with NA has a higher hydration heat than the QCS activated with NS, and the cumulative hydration heat of QCS activated with NS increases with the silica modulus at early ages. But this regularity generally reverses when the activator concentration is 8%. Meanwhile, elevated activator concentration could increase the cumulative hydration heat of QCS. In addition, with the increase in silica modulus, the second exothermic peak value decreases, the time of the second exothermic peak delays and the peak width increases. The hydration degree of QCS and the polymerization of amorphous hydration products increase with the silica modulus of activator. What’s more, the compressive strengths of alkali-activated QCS mortars and SCS mortars increase with the silica modulus of activator. When the silica modulus is more than 1, the compressive strength of the QCS mortar activated with NS could be qualified for common constructions.

Similar content being viewed by others

Reference s

Aprianti E, Shafigh P, Bahri S, Farahani JN. Supplementary cementitious materials origin from agricultural wastes-A review. Constr Build Mater. 2015;74:176–87.

Wang Q, Wang D, Zhuang S. The soundness of steel slag with different free CaO and MgO contents. Constr Build Mater. 2017;151:138–46.

Mehta PK. Concrete Technology for Sustainable Development. Concr Int. 1999;21:47–53.

Wang Q, Yang J, Chen H. Long-term properties of concrete containing limestone powder. Mater Struct. 2017;50:168.

Wang Q, Wang D, Chen H. The role of fly ash microsphere in the microstructure and macroscopic properties of high-strength concrete. Cem Concr Compos. 2017;83:125–37.

Feng J, Liu S, Wang Z. Effects of ultrafine fly ash on the properties of high-strength concrete. J Therm Anal Calorim. 2015;121:1213–23.

Zhang T, Yu Q, Wei J, Gao P, Zhang P. Study on optimization of hydration process of blended cement. J Therm Anal Calorim. 2012;107:489–98.

Han F, Zhang Z. Hydration, mechanical properties and durability of high-strength concrete under different curing conditions. J Therm Anal Calorim. 2018;132:823–34.

Tänzer R, Jin Y, Stephan D. Alkali activated slag binder: effect of cations from silicate activators. Mater Struct. 2017;50:91.

Thomas RJ, Gebregziabiher BS, Giffin A, Peethamparan S. Micromechanical properties of alkali-activated slag cement binders. Cem Concr Compos. 2018;90:241–56.

Haha MB, Saout GL, Winnefeld F, Lothenbach B. Influence of activator type on hydration kinetics, hydrate assemblage and microstructural development of alkali activated blast-furnace slags. Cem Concr Res. 2011;41(3):301–10.

Pan Z, Tao Z, Cao YF, Wuhrer R, Murphy T. Compressive strength and microstructure of alkali-activated fly ash/slag binders at high temperature. Cem Concr Compos. 2018;86:9–18.

Mehdizadeh H, Kani EN, Sanchez AP, Fernandez-Jimenez A. Rheology of activated phosphorus slag with lime and alkaline salts. Cem Concr Res. 2018;113:121–9.

Wang D, Wang Q, Zhuang S, Yang J. Evaluation of alkali-activated blast furnace ferronickel slag as a cementitious material: Reaction mechanism, engineering properties and leaching behaviors. Constr Build Mater. 2018;188:860–73.

Liu Z, Zhang D, Li L, Wang J, Shao N, Wang D. Microstructure and phase evolution of alkali-activated steel slag during early age. Constr Build Mater. 2019;204:158–65.

Nath SK, Kumar S. Reaction kinetics, microstructure and strength behavior of alkali activated silico-manganese (SiMn) slag-Fly ash blends. Constr Build Mater. 2017;147:371–9.

Wang D, Wang Q, Fang Z. Influence of alkali activators on the early hydration of cement-based binders under steam curing condition. J Therm Anal Calorim. 2017;130:1801–16.

Gebregziabiher BS, Thomas R, Peethamparan S. Very early-age reaction kinetics and microstructural development in alkali-activated slag. Cem Concr Compos. 2015;55:91–102.

Liu S, Li Q, Han W. Effect of various alkalis on hydration properties of alkali-activated slag cements. J Therm Anal Calorim. 2018;131:3093–104.

Sun J, Chen Z. Effect of silicate modulus of water glass on the hydration of alkali-activated converter steel slag. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-019-08146-3.

Sun J, Wang Z, Chen Z. Hydration mechanism of composite binders containing blast furnace ferronickel slag at different curing temperatures. J Therm Anal Calorim. 2018;131:2291–301.

Han F, Zhang Z, Liu J, Yan P. Effect of water-to-binder ratio on the hydration kinetics of composite binder containing slag or fly ash. J Therm Anal Calorim. 2017;128:855–65.

Deir E, Gebregziabiher BS, Peethamparan S. Influence of starting material on the early age hydration kinetics, microstructure and composition of binding gel in alkali activated binder systems. Cem Concr Compos. 2014;48:108–17.

FernándezJiménez A, Palomo A, Sobrados I, Sanz J. The role played by the reactive alumina content in the alkaline activation of fly ashes. Microporous Mesoporous Mater. 2006;91:111–9.

Alonso S, Palomo A. Calorimetric study of alkaline activation of calcium hydroxide-metakaolin solid mixtures. Cem Concr Res. 2001;31:25–30.

Wang SD, Scrivener KL. Hydration products of alkali activated slag cement. Cem Concr Res. 1995;25:561–71.

Krstulović R, Dabić P. A conceptual model of the cement hydration process. Cem Concr Res. 2000;30:693–8.

Gorai B, Jana RK. Characteristics and utilisation of copper slag-a review. Resour, Conserv Recycl. 2003;39:299–313.

Zuo Z, Yu Q, Liu S, Xie H, Duan W, Liu J, Qin Q, Yang S. Thermodynamic analysis of thermal energy recovery and direct reduction (TER-DR) system for molten copper slag. J Therm Anal Calorim. 2018;131:1691–8.

Wu W, Zhang W, Ma G. Optimum content of copper slag as a fine aggregate in high strength concrete. Mater Design. 2010;31:2878–83.

Zuo Z, Yu Q, Xie H, Duan W, Liu S, Qin Q. Thermogravimetric analysis of the biomass pyrolysis with copper slag as heat carrier. J Therm Anal Calorim. 2017;129:1233–41.

Takebe H, Tomita S, Saitoh A, Kawahara M, Sueoka Y, Sakakibara M. Effect of crystallization on microstructure and elution properties in copper slag. J Sustain Metall. 2017;3:543–50.

Wang Z, Zhang T, Zhou L. Investigation on electromagnetic and microwave absorption properties of copper slag-filled cement mortar. Cem Concr Compos. 2016;74:174–81.

Edwin RS, Schepper MD, Gruyaert E, Belie ND. Effect of secondary copper slag as cementitious material in ultra-high performance mortar. Constr Build Mater. 2016;119:31–44.

Chun T, Ning C, Long H, Li J, Yang J. Mineralogical characterization of copper slag from tongling nonferrous metals group China. JOM. 2016;68:2332–400.

Zhou S, Wei Y, Li B, Wang H. Cleaner recycling of iron from waste copper slag by using walnut shell char as green reductant. J Clean Prod. 2019;217:423–31.

Zuo Z, Yu Q, Xie H, Yang F, Qin Q. Thermodynamic analysis of reduction in copper slag by biomass molding compound based on phase equilibrium calculating model. J Therm Anal Calorim. 2018;132(2):1277–89.

Zuo Z, Yu Q, Wei M, Xie H, Duan W, Wang K, Qin Q. Thermogravimetric study of the reduction of copper slag by biomass. J Therm Anal Calorim. 2016;126(2):481–91.

Raposeiras AC, Vargas-Cerón A, Movilla-Quesada D, Castro-Fresno D. Effect of copper slag addition on mechanical behavior of asphalt mixes containing reclaimed asphalt pavement. Constr Build Mater. 2016;119:268–76.

Behnood A, Gharehveran MM, Asl FG, Ameri M. Effects of copper slag and recycled concrete aggregate on the properties of CIR mixes with bitumen emulsion, rice husk ash, Portland cement and fly ash. Constr Build Mater. 2015;96:172–180.

Mavroulidou M. Mechanical properties and durability of concrete with water cooled copper slag aggregate. Waste Biomass Valor. 2017;8:1841–54.

Madheswaran CK, Ambily PS, Dattatreya JK, Rajamane NP. Studies on use of copper slag as replacement material for river sand in building constructions. J Inst Eng India Ser A. 2014;95:169–77.

Liu J, Guo R, Shi P, Huang L. Hydration mechanisms of composite binders containing copper slag at different temperatures. J Therm Anal Calorim. 2019;137:1919–28.

Murari K, Siddique R, Jain KK. Use of waste copper slag, a sustainable material. J Mater Cycles Waste Manage. 2015;17:13–26.

Zhou H, Wu X, Xu Z, Tang M. Kinetic study on hydration of alkali-activated slag. Cem Concr Res. 1993;23:1253–8.

Fernández-Jiménez A, Palomo A, Criado M. Microstructure development of alkali-activated fly ash cement: a descriptive model. Cem Concr Res. 2005;35:1204–9.

Brough AR. Sodium silicate-based alkali-activated slag mortars. Cem Concr Res. 2002;32:865–79.

Krizan D, Zivanovic B. Effects of Dosage and Modulus of Water Glass on Early Hydration of Alkali-Slag Cements. Cem Concr Res. 2002;32:1181–8.

Pacheco-Torgal F, Castro-Gomes J, Jalali S. Alkali-activated binders: A review: Part 1. Historical background, terminology, reaction mechanisms and hydration products. Constr Build Mater. 2008;22:1305–14.

Lodeiro IG, Macphee DE, Palomo A, Fernandez-Jimenez A. Effect of alkalis on fresh C-S-H gels. FTIR analysis Cem Concr Res. 2009;39:147–53.

Lodeiro IG, Fernández-Jimenez A, Palomo A, Macphee DE. Effect on fresh C-S-H gels of the simultaneous addition of alkali and aluminium. Cem Concr Res. 2010;40:27–322.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, J., Guo, R. Hydration properties of alkali-activated quick cooled copper slag and slow cooled copper slag. J Therm Anal Calorim 139, 3383–3394 (2020). https://doi.org/10.1007/s10973-019-08708-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08708-5