Abstract

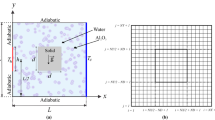

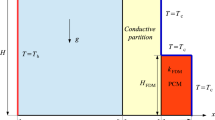

Numerical study of natural convection and melting in a corrugated square cavity filled with CNT-water nanofluid under the influence of inclined magnetic field was performed. The left and right walls of the cavity are kept at constant temperatures while the horizontal wall is adiabatic. Galerkin weighted residual finite element was used. The effects of Hartmann number (between 0 and 40), magnetic inclination angle (between 0° and 90°), nanoparticle volume fraction (between 0 and 4%), number (between 1 and 20) and height (between 0.002 H and 0.16 H) of the corrugation on the convective heat transfer features and melting in the square cavity were examined. Magnetic field was found to dampen the fluid motion, and less movement of the melt front in the upper part of the cavity is observed. By using the CNT nanoparticles in the base fluid, significant enhancement in the heat transfer and faster propagation of the melt front is observed in the absence and presence of magnetic field. Average heat transfer enhancements are around 118% and 95% when nanofluid at the highest particle volume fraction is compared with water in the absence and presence of magnetic field. The heat transfer is reduced and melt front curve characteristics are affected when the number and height of corrugation waves are increased.

Similar content being viewed by others

References

Hasan A, McCormack S, Huang M, Norton B. Evaluation of phase change materials for thermal regulation enhancement of building integrated photovoltaics. Sol Energy. 2010;84:1601–12.

Park J, Kim T, Leigh S-B. Application of a phase-change material to improve the electrical performance of vertical-building-added photovoltaics considering the annual weather conditions. Sol Energy. 2014;105:561–74.

Huang M, Eames P, Norton B. Thermal regulation of building-integrated photovoltaics using phase change materials. Int J Heat Mass Transf. 2003;47:2715–33.

Lin W, Ma Z, Sohel MI, Cooper P. Development and evaluation of a ceiling ventilation system enhanced by solar photovoltaic thermal collectors and phase change materials. Energy Convers Manag. 2014;88:218–30.

Smith CJ, Forster PM, Crook R. Global analysis of photovoltaic energy output enhanced by phase change material cooling. Appl Energy. 2014;126:21–8.

Ho C, Tanuwijava A, Lai C-M. Thermal and electrical performance of a bipv integrated with a microencapsulated phase change material layer. Energy Build. 2012;50:331–8.

Brano VL, Ciulla G, Piacentino A, Cardona F. Finite difference thermal model of a latent heat storage system coupled with a photovoltaic device: description and experimental validation. Renew Energy. 2014;68:181–93.

Pahamli Y, Hosseini MJ, Ranjbar AA, Bahrampoury R. Analysis of the effect of eccentricity and operational parameters in pcm-filled single-pass shell and tube heat exchangers. Renew Energy. 2016;97:344–57.

Jin X, Medina MA, Zhang X. Numerical analysis for the optimal location of a thin PCM layer in frame walls. Appl Therm Eng. 2016;103:1057–63.

Ismail KAR, de Jesus AB. Modeling and solution of the solidification problem of pcm around a cold cylinder. Numer Heat Transf Part A Appl. 1999;36:95–114.

Srivatsa PVSS, Baby R, Balaji C. Numerical investigation of pcm based heat sinks with embedded metal foam/crossed plate fins. Numer Heat Transf Part A Appl. 2014;66:1131–53.

Yilbas BS, Shuja SZ, Shaukat MM. Thermal characteristics of latent heat thermal storage: comparison of aluminum foam and mesh configurations. Numer Heat Transf Part A Appl. 2015;68:99–116.

Gharebaghi M, Sezai I. Enhancement of heat transfer in latent heat storage modules with internal fins. Numer Heat Transf Part A Appl. 2007;53:749–65.

Jmal I, Baccar M. Numerical study of pcm solidification in a finned tube thermal storage including natural convection. Appl Therm Eng. 2015;84:320–30.

Sheikholeslami M. Numerical simulation for solidification in a lhtess by means of nano-enhanced pcm. J Taiwan Inst Chem Eng. 2018;86:25–41.

Mumtaz M, Khan A, Ibrahim NI, Mahbubul IM, Ali HM, Al-Sulaiman FA. Evaluation of solar collector designs with integrated latent heat thermal energy storage: a review. Sol Energy. 2018;166:334–50.

Kousksou T, Bruel P, Jamil A, Rhafiki TE, Zeraouli Y. Solar energy materials and solar cells. Sol Energy Mater Sol Cells. 2014;120:59–80.

Kabeel AE, El-Samadony YAF, El-Maghlany WM. Comparative study on the solar still performance utilizing different pcm. Desalination. 2018;432:89–96.

Nkurikiyimfura I, Wang Y, Pan Z. Heat transfer enhancement by magnetic nanofluids–a review. Renew Sustain Energy Rev. 2013;21:548–61.

Ghasemi B, Aminossadati S, Raisi A. Magnetic field effect on natural convection in a nanofluid-filled square enclosure. Int J Therm Sci. 2011;50:1748–56.

Hamad M, Ismail IPA. Magnetic field effects on free convection flow of a nanofluid past a vertical semi-infinite flat plate. Nonlinear Anal Real World Appl. 2010;12:1338–46.

Sarkar S, Ganguly S, Biswas G. Buoyancy driven convection of nanofluids in an infinitely long channel under the effect of a magnetic field. Int J Heat Mass Transf. 2014;71:328–40.

Hatami M, Sheikholeslami M, Hosseini M, Ganji DD. Analytical investigation of mhd nanofluid flow in non-parallel walls. J Mol Liq. 2014;194:251–9.

Sheikholeslami M, Bandpy MG, Ellahi R, Zeeshan A. Simulation of mhd cuo-water nanofluid flow and convective heat transfer considering lorentz forces. J Magn Magn Mater. 2014;369:69–80.

Kefayati G. Effect of a magnetic field on natural convection in an open cavity subjugated to water/alumina nanofluid using lattice boltzmann method. Int Commun Heat Mass Transf. 2013;40:67–77.

Selimefendigil F, Oztop HF. Numerical study of mhd mixed convection in a nanofluid filled lid driven square enclosure with a rotating cylinder. Int J Heat Mass Transf. 2014;78:741–54.

Pekmen B, Sezgin MT. Mhd flow and heat transfer in a lid-driven porous enclosure. Comput Fluids. 2014;89:191–9.

Oztop HF, Al-Salem K, Pop I. Mhd mixed convection in a lid-driven cavity with corner heater. Int J Heat Mass Transf. 2011;54:494–3504.

Selimefendigil F, Oztop HF. Modeling and optimization of mhd mixed convection in a lid-driven trapezoidal cavity filled with alumina-water nanofluid: effects of electrical conductivity models. Int J Mech Sci. 2018;136:264–78.

Piratheepan M, Anderson T. An experimental investigation of turbulent forced convection heat transfer by a multi-walled carbon-nanotube nanofluid. Int Commun Heat Mass Transf. 2014;57:286–90.

Kamali R, Binesh A. Numerical investigation of heat transfer enhancement using carbon nanotube-based non-newtonian nanofluids. Int Commun Heat Mass Transf. 2010;37:1153–7.

Rahman M, Mojumder S, Saha S, Mekhilef S, Saidur R. Effect of solid volume fraction and tilt angle in a quarter circular solar thermal collectors filled with cnt-water nanofluid. Int Commun Heat Mass Transf. 2014;57:79–90.

Murshed S, de Castro CAN. Superior thermal features of carbon nanotubes-based nano uids–a review. Renew Sustain Energy Rev. 2014;37:155–67.

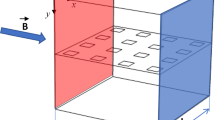

Al-Rashed A, Kolsi L, Oztop HF, Aydi A, Malekshah E Hasani, Abu-Hamdeh N, Borjini MN. 3D magnetoconvective heat transfer in cnt-nanofluid filled cavity under partially active magnetic field. Physica E Low Dimens Syst Nanostruct. 2018;99:294–303.

Al-Sayegh R. Influence of external magnetic field inclination on three-dimensional buoyancy-driven convection in an open trapezoidal cavity filled with cnt-water nanofluid. Int J Mech Sci. 2018;148:756–65.

Feng Y, Li H, Li L, Zhan F. Investigation of the effect of magnetic field on melting of solid gallium in a bottom-heated rectangular cavity using the lattice boltzmann method. Numer Heat Transf Part A Appl. 2016;69:1263–79.

Ahmed M, Shuaib N, Yusoff M, Al-Falahi A. Numerical investigations of flow and heat transfer enhancement in a corrugated channel using nanofluid. Int Commun Heat Mass Transf. 2011;38:1368–75.

Nasrin R, Alim M, Chamkha AJ. Combined convection flow in triangular wavy chamber filled with water-cuo nanofluid: effect of viscosity models. Int Commun Heat Mass Transf. 2012;39:1226–36.

Hussain SH, Hussein AK, Mohammed RN. Studying the effects of a longitudinal magnetic field and discrete isoflux heat source size on natural convection inside a tilted sinusoidal corrugated enclosure. Comput Math Appl. 2012;64:476–88.

Mohammed KA, Talib ARA, Nuraini AA, Ahmed KA. Review of forced convection nanofluids through corrugated facing step. Renew Sustain Energy Rev. 2017;75:234–41.

Kareem ZS, Jaafar MNM, Lazim TM, Abdullah S, Abdulwahid AF. Passive heat transfer enhancement review in corrugation. Exp Therm Fluid Sci. 2015;68:22–38.

Selimefendigil F, Oztop HF. Corrugated conductive partition effects on mhd free convection of cnt-water nanofluid in a cavity. Int J Heat Mass Transf. 2019;129:265–77.

Biwole P, Eclache P, Kuznik F. Phase-change materials to improve solar panels performance. Energy Build. 2013;62:59–67.

Kant K, Shukla A, Sharma A. Heat transfer studies of building brick containing phase change materials. Sol Energy. 2017;155:1233–42.

Voller V, Prakash C. A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems. Int J Heat Mass Transf. 1987;30:1709–19.

Brent A, Voller V, Reid K. Enthalpy-porosity technique for modeling convection-diffusion phase change: application to the melting of a pure metal. Numer Heat Transf A Appl. 1988;13:297–318.

Bondareva NS, Buonomo B, Manca O, Sheremet MA. Heat transfer inside cooling system based on phase change material with alumina nanoparticles. Appl Therm Eng. 2018;144:972–81.

Bondareva NS, Buonomo B, Manca O, Sheremet MA. Heat transfer performance of the finned nano-enhanced phase change material system under the inclination influence. Int J Heat Mass Transf. 2019;135:1063–72.

Brinkman H. The viscosity of concentrated suspensions and solutions. J Chem Phys. 1952;20:571–81.

Xue Q. Model for thermal conductivity of carbon nanotube-based composites. Physica B. 2005;368:302–7.

Zienkiewicz O, Taylor R, Nithiarasu P. The finite element method for fluid dynamics. 6th ed. Amsterdam: Elsevier; 2005.

Reddy J. An introduction to the finite element method. New York: McGraw-Hill; 1993.

Ghalambaz M, Chamkha AJ, Wen D. Natural convective flow and heat transfer of nano-encapsulated phase change materials (nepcms) in a cavity. Int J Heat Mass Transf. 2019;138:738–49.

Chamkha AJ, Doostanidezfuli A, Izadpanahi E, Ghalambaz M. Phase-change heat transfer of single/hybrid nanoparticles-enhanced phase-change materials over a heated horizontal cylinder confined in a square cavity. Adv Powder Technol. 2017;28(2):385–97.

Pirmohammadi M, Ghassemi M. Effect of magnetic field on convection heat transfer inside a tilted square enclosure. Int Commun Heat Mass Transf. 2009;36:776–80.

Sarris I, Zikos G, Grecos A, Vlachos N. On the limits of validity of the low magnetic reynolds number approximation in mhd natural-convection heat transfer. Numer Heat Transf Part B. 2006;50:158–80.

Rudraiah N, Barron R, Venkatachalappa M, Subbaraya C. Effect of a magnetic field on free convection in a rectangular enclosure. Int J Eng Sci. 1995;33:1075–84.

Sheikholeslami M, Shamlooei M. Convective flow of nanofluid inside a lid driven porous cavity using cvfem. Physica B. 2017;521:239–50.

Oztop H, Abu-Nada E. Numerical study of natural convection in partially heated rectangular enclosures filled with nanofluids. Int J Heat Fluid Flow. 2008;29:1326–36.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Selimefendigil, F., Öztop, H.F. Natural convection and melting of NEPCM in a corrugated cavity under the effect of magnetic field. J Therm Anal Calorim 140, 1427–1442 (2020). https://doi.org/10.1007/s10973-019-08667-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08667-x