Abstract

Thermal degradation and combustion of pesticides lead to the emission of chemicals that are harmful and dangerous for humans and the environment. The aim of the work was to study thermal decomposition of triadimenol and analyze organic compounds, in particular dioxins precursors released during that process. The thermogravimetry and differential scanning calorimetry method was used to examine the physical and chemical processes occurring under high temperatures in air atmosphere. The application of a simultaneous thermal analyzer combined with an infrared spectrometer allowed to identify substances generated during the experiments. To generate the fire effluents contained in thermal degradation products, the steady-state tube furnace was also used. The gas samples were taken using solid-phase microextraction method. Meanwhile for the detection and identification of released chemicals, the gas chromatograph with mass spectrometer was adopted. The obtained results showed that tested pesticides undergo both thermal decomposition and oxidation during thermal degradation in air. In the gases emitted during thermal decomposition, carbon oxides, hydrogen cyanide and many aliphatic and aromatic compounds were found. However, the main toxic substances identified under all tested conditions were: hydrogen cyanide, 4-chlorophenol and many substituted benzenes and polycyclic hydrocarbons.

Similar content being viewed by others

Introduction

Triadimenol is a triazole-type fungicide that is identified as weak estrogen receptor agonist [1]. The structure of that compound from the triazoles group is presented in Fig. 1. Triadimenol is the mixture of two diastereomers, isomer A (erythro-configuration, SS- and RR-form) and isomer B (threo-configuration, RS- and SR-form). Isomer A has a higher level of biological activity than isomer B. Each isomer is in itself the racemic mixture of two optical isomer forms. The ratio of the two isomers in the currently manufactured material is ≈ 80% isomer A: ≈ 20% isomer B (hereafter referred to as the 80:20 material) [2, 3]. Triadimenol is widely used in chemicals that kill or inhibit the growth of fungi in agricultural applications, on wood, plastics, or other materials, in swimming pools, etc. [4,5,6].

Production, storage and wide use of pesticides can cause accidental fires in storage facilities, while contaminated plant matter subjected to wildfire provides thermal decomposition and additional pathways for generating toxic products [7,8,9,10,11]. The available literature on thermal decomposition and combustion of pesticides [8, 12,13,14,15,16,17] reports different burning behavior and patterns of thermal decomposition. Specifically, pesticides with complex aromatic structure exhibit below 300 °C melt, evaporate and experience the first pyrolysis process with formation of heavy substances. Further pyrolysis and oxidation determine fragmentation of these products [7, 15]. In gases released during thermal decomposition of endosulfan, a polychlorinated pesticide, Dharmarathne et al. [11] identified chlorinated styrenes and chlorinated benzenes, major precursors of toxic polychlorinated dibenzodioxins and dibenzofurans (PCDD/F). Moreover, during oxidative studies on that pesticide, they observed large concentrations of PCDD/F [18]. Thermal decomposition of permethrin can also be a potential source of PCDD/PCDF [12]. On the other hand, Sánchez-Soto et al. [19] studied thermal decomposition of 3-amino-l,2,4-triazole. At 600 °C, there occurred total decomposition of the pesticide. In evolved gases, ammonia and very dangerous hydrogen cyanide were released. In our previous study [20], we used thermogravimetry and differential scanning calorimetry to determine thermal characteristics of pyrethroids. Moreover, we identified the main products released during their thermal decomposition. The obtained results led to the conclusion that in the gaseous products the organic compounds, polycyclic aromatic hydrocarbons and halogenated aromatic hydrocarbons were present. Different techniques could be employed to determine thermal decomposition of pesticides and identify released toxic products [8]. Recently, thermal decomposition of the pesticide was also studied using density functional methods [21]. Authors tested chlorpyrifos and 3,5,6-trichloro-2-pyridinol and identified 2,3,7,8-tetrachloro-[1,4]dioxinodipyridine—dioxin analog as decomposed product. The conducted tests confirm that fire effluents released during thermal decomposition and combustion of pesticide, especially those containing chlorine atoms, can contain many carcinogenic and other chronic toxicants (for example, persistent organic pollutants and polycyclic aromatic hydrocarbons) [22].

While burning behavior is dependent on physical aspects of fire scenario, such as shape and orientation of the fuel, effluent toxicity is most dependent on material composition temperature and oxygen concentration. The generalized development of the fire has been recognized and used to classify fire growth into stages, from smoldering combustion and early well-ventilated flaming to fully developed under-ventilated flaming [23].

To enable the realistic assessment of the toxicity and environmental impact of compounds, it is clearly important to understand the range and concentrations of chemical species likely to be produced in fires. Therefore, it is important to reach better understanding of the mechanism of thermal decomposition of triadimenol and formation of toxic products, volatile and semi-volatile organic compounds, especially dioxins precursors: chlorinated benzenes, chlorinated phenols, chlorinated diphenyl ethers and chlorinated biphenyls. To explore the thermal hazard of pesticide, the simultaneous thermal analyzer (STA) was applied. Differential scanning calorimetry and thermogravimetry were used to analyze the thermal stability parameters and mass loss conditions under high temperatures. Decomposed products were identified by the infrared spectrometer with Fourier analysis (FT-IR) combined online with STA. Moreover, to understand thermal degradation and combustion phenomena, the steady-state tube furnace [24, 25] was used. This instrument enabled to generate toxic products from real fires under different conditions. The released species were sampled using solid-phase microextraction technique (SPME) and identified using gas chromatography with mass selective detector (GC–MS). SPME technique was successfully applied to sampling directly from the fire effluents in order to analyze thermal degradation and combustion products in our previous investigation [17]. SPME is a helpful tool for sampling and analysis that could be employed for monitoring thermal degradation and combustion processes avoiding sample collection and sample pretreatment, thus reducing laboratory working time.

Materials and methods

Materials

Triadimenol (CAS 55219-65-3) ≥ 96% was purchased from Santa Cruz Biotechnology, Inc. (Germany).

The collection of analytes from tube furnace was performed using a solid-phase microextraction manual holder supplied with polydimethylsiloxane (PDMS) 100-μm fiber, polyacrylate (PA) 85-µm fiber, carboxen/polydimethylsiloxane (CAR/PDMS) 75-µm fiber, and polydimethylsiloxane/divinylbenzene (PDMS/DVB) 65-µm fiber, acquired from Supelco (USA).

Methods

Thermal analysis: evolved gas analysis

Thermal degradation of triadimenol was studied in air atmosphere using the simultaneous thermal analyzer (STA 449F3 Jupiter, Netzsch, Germany). The 10 mg samples were placed in aluminum oxide crucibles and heated at the rate of 10 °C min−1 from room temperature (25 °C) to 900 °C. The flow rate of the air was 30 mL min−1, and the nitrogen was 20 mL min−1. To ensure good reproducibility of the process, the experiments were performed at least three times. The simultaneous thermal analyzer was coupled with the Fourier transform infrared spectroscopy (Bruker Tensor 27 FTIR, Germany). The STA–FT-IR was also used to study the formation of volatiles produced in the thermal degradation process of selected material. The FT-IR instrument was linked to the STA instrument through polytetrafluoroethylene pipe and flow cell, which were heated to 200 °C to prevent condensing of the released gases. After the evolved gases of samples from STA went through the flow cell, absorbance information was obtained at different wave numbers as a function of temperature. The scanning range was from 4000 to 600 cm−1 with a resolution of 4 cm−1.

Analysis of fire effluent

A tube furnace method was used for the generation of fire effluent emitted during thermal degradation and combustion of triadimenol. This method can be used to model a wide range of fire conditions by using different combinations of temperature, non-flaming and flaming degradation conditions and fuel/oxygen ratios in the tube furnace. These include different types of fires, as detailed in ISO/TS 19700:2007 [24, 25].

Material samples (triadimenol, m = 5 g) were combusted under steady-state conditions in one of four environments whose temperature and air flow are representative of four types of fire: oxidative pyrolysis, well-ventilated flaming developing fires, small flaming vitiated fires and post-flashover vitiated fires (Table 1).

The samples of fire effluents were taken from the mixing chamber of tube furnace by introducing the SPME device with the fiber to the sampling port after 1 min from placing the sample of pesticide in the furnace heating zone. After introducing the SPME syringe to the mixing chamber, the products of thermal degradation were extracted on the SPME fiber coating. After 5 min sorption, the fiber was withdrawn from the chamber and desorbed immediately in the gas chromatograph injector for analysis. The desorption time was 30 min. The fibers were conditioned in the injection port before use, according to the manufacturer’s instructions.

The chromatographic separation was achieved with an HP-5 MS fused silica capillary column (30 m × 250 μm × 0.25 μm film thickness) from Agilent Technologies (USA). The oven temperature was initially maintained at 40 °C for 10 min and then increased to 250 °C at a heating rate of 10 °C min−1. Helium at a constant flow rate of 1 mL min−1 was used as the carrier gas and the split ratio was 10:1. The separated compounds were then analyzed by the mass spectrometer, which was operated in electron ionization (EI) mode at the ionization energy of 70 eV. The mass spectra were obtained from m/z 35 to 350. Chromatographic peaks were identified through comparing the mass ions of each peak with NIST MS Library. On the basis of the NIST library, the highest possibility of product identification was chosen. Because the chromatographic peak area of a specific compound is correlated linearly with its quantity, its concentration can be reflected by the peak area ratio. The summed identified peak areas were normalized to 100%, and the relative abundance of specific compound can be reflected by its peak area ratio.

Results and discussion

Thermal analysis: evolved gas analysis

The results of thermal degradation of triadimenol performed under air atmosphere are shown in Fig. 2. The course of differential thermogravimetric analysis (DTG) and differential scanning calorimetry (DSC) curves suggests that thermal degradation of triadimenol is a multistage process. The pesticide melts at low temperature (~ 119 °C) during the endothermic process. This is confirmed by the literature data according to which the melting point is approx. 118–130 °C [26]. Then triadimenol begins to degrade. The first or main stage of this process is observed between 180 and 300 °C, with the maximum decomposition temperature at 289 °C. This process is accompanied by endothermic effect. Next, pesticide degrades with lower thermal degradation rate to 580 °C, when the process is completed. The obtained results suggest that the samples exposed to heat in air undergo both thermal degradation and oxidation. Moreover, the mass loss is related to the emission of gaseous molecules, because there are no solid residues.

The 3D FT-IR spectra and extracted FT-IR spectra of gaseous products evolved during thermal decomposition of triadimenol under air atmosphere are presented in Fig. 3. During thermal decomposition at temperatures ranging from 25 to 290 °C, no gaseous products were emitted. When the temperature achieved 290 °C, the beginning of the emission of gaseous products was indicated. Analysis of the IR spectrum recorded at 495 °C allowed to state that the –C≡N groups were present in the structures of the emitted products. The bands at 2281 cm−1 probably correspond to the stretching vibration in the CH3–C≡N molecule. The presence of aromatic compounds with the nitrile group, Ar–C ≡ N, in released products is also not excluded. The presence of aromatic compounds in evolved gases can be also evidenced by bands > 3000 cm−1 (with a maximum at 3085 cm−1). They can be attributed to the Ar–H stretching vibrations. Confirming the presence of aromatic compounds are bands around 1500 cm−1 resulting from the stretching vibrations of the ring and the oscillation of the protons at the ring and the band < 900 cm−1 (888 and 826 cm−1) that may be associated with non-planar Ar and Ar–H deformation vibrations.

Additionally, the recorded IR spectrums show bands below < 3000 cm−1, which testify to the presence of aliphatic groups. In turn, the deformation vibrations of aliphatic groups are reflected in the bands at 1421 and 1397 cm−1. In the spectrum recorded at 495 °C, bands > 3600 cm−1 and about 1650 cm−1 can also be observed, which indicates the presence of water vapor, but can also be attributed to the tensile vibrations of –OH groups in the phenol molecule. The C–O stretching vibrations bands characteristic for the phenol structure are visible at 1256 cm−1 and 1570 cm−1. During the thermal decomposition of triadimenol, significant amounts of carbon dioxide (2361 cm−1—asymmetric stretching vibrations, branch R) and carbon monoxide (2115 cm−1—stretching vibrations, branch R) were also formed. In addition, the increase in the temperature at which the thermal decomposition process took place resulted in an increase in the amount of carbon oxides emitted, because the intensities of individual bands increased. On the other hand, there are no bands at 2285 cm−1 on the spectrum of products emitted at 775 °C. Based on this information, it can be concluded that above this temperature the products that were produced no longer contained molecules with nitrile groups. From the temperature of 775 °C, the bands that confirm the presence of phenols have been strengthened. In addition, peaks visible at around 1100 cm−1 (1099 and 1097 cm−1) suggest the presence of aromatic products containing a chlorine substituent (Ar–Cl stretching vibrations) as well as chlorinated aliphatic compounds (bands < 850 cm−1).

Moreover, the strong absorption peak at 714 cm−1 observed when the thermal decomposition occurred between 395 and 610 °C indicates that HCN molecules were also present in the emitted gases. It is worth to notice that HCN is very dangerous, because it is approximately 25 times more toxic than CO.

Analysis of fire effluent

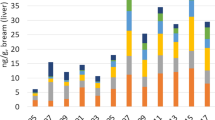

Based on the obtained results, it was found that the quantity and type of products detected in the fire effluents emitted during thermal degradation and combustion of triadimenol strongly depended on experiment conditions (temperature and air flow), Fig. 4. The largest amount of species was detected in the samples emitted in conditions representative of a well-ventilated flaming developing fire (temperature = 650 °C, primary air flow = 10 l min−1), while the least products were created during oxidative pyrolysis (temperature = 350 °C, primary air flow = 2 l min−1). The amount and type of detected compounds also depended on the type of SPME fiber coating used for the extraction of analytes from the mixing chamber of the tube furnace. The least extraction efficient showed the polydimethylsiloxane coatings, which also had the shortest lifetime. Moreover, the individual SPME fiber coatings differed in the type of detected substances. The PA fiber was more effective in the sorption of polar compounds such as phenols. During its use, in the samples of gases and fumes emitted during decomposition of triadimenol, the 4-chloro-2-methylphenol and p-cresol were detected. These chemicals were not identified when another SPME fiber coating were used. Therefore, to evaluate the wide range of different decomposition products, it is best to use different types of SPME fibers with different sorption properties. The best extraction efficiency of the analyzed chemicals was reached with CAR/PDMS and DVB/PDMS fibers. Figure 5 shows the chromatograms obtained during the analysis of fire effluent samples emitted during the measurements under selected conditions when the CAR/PDMS fiber was used for extraction of analytes. Unfortunately, not all detected compounds have been identified. The main identified substances present in gases and fumes emitted during the degradation of triadimenol are shown in Tables 2–5.

When the degradation occurred under oxidative pyrolysis conditions in fire effluents, 10 compounds were identified, Table 2. The main detected product was 4-chlorophenol, which may be due to impurities introduced during the synthesis of the pesticide and also be derived from molecular decomposition of triadimenol. In these conditions, the vapor of undecomposed pesticide was present. The other identified compounds were derived from decomposition and oxidation of fragments of pesticide molecule.

Table 3 presents the results obtained when degradation occurred under conditions representative of a small flaming vitiated fire. In the mixture of emitted products, the vapor of undecomposed pesticide was not present, but the main detected product was still 4-chlorophenol. Other phenolic compounds were present in smaller amounts, such as phenol and 4-chloro-2-methyl-phenol. Compounds such as 5-chlorobenzofuran, 5-chloro-2-methyl-benzofuran and 4-chlorobenzaldehyde were also obtained in significant amounts. Moreover, in samples of fire effluents the polycyclic aromatic hydrocarbons (PAHs) were detected. The largest amount and the number of substances was determined when the extraction took place on carboxen/polidimethylosiloxane SPME fiber coating.

The biggest number of products was detected in fire effluents when degradation occurred under conditions representative of a well-ventilated fire. In gaseous mixture phenolic compounds (phenol, p-cersol, 2,6-dichlorophenol, 4-chlorophenol and 4-chloro-2-methylphenol), oxidation product of phenol-p-benzoquinone, substituted benzenes and benzofurans were identified. Moreover, in these conditions many substances from the group of polycyclic aromatic hydrocarbons were present in fire effluents (naphthalene, acenaphthylene, fluorene and anthracene). In addition, significant amounts of chlorinated naphthalenes, biphenyl and dibenzofuran were also detected. It should be noted that under these conditions fire effluents may also feature polychlorinated derivatives of dibenzofuran, which are compounds with a structure and properties similar to dioxins. It can be noted that the presence of oxygen probably enhances the formation of radicals, which contributes to a more reactive situation. This could explain why some aromatics and aliphatic hydrocarbons appeared at well-ventilated fire experiments, whereas they were not detected in fire effluents under conditions of a small ventilated fire.

In gases emitted during the post-flashover fire experiment, 15 products were identified, Table 5. The main detected thermal degradation product of triadimenol in these conditions was still 4-chlorophenol. In fire effluents, phenolic compounds, benzofurans and polycyclic aromatic hydrocarbons were also present. Numerous studies confirm that compounds from PAHs are not present singly but always in mixture. Therefore, although not all of the polycyclic aromatic hydrocarbons were identified in fire effluents, it is very probable that they were present in these samples.

Toxicity profile of products generated during thermal decomposition and combustion of triadimenol

On the basis of the obtained results, it can be stated that during the combustion and thermal degradation of triadimenol, significant quantities of hazardous substances can be released. Meanwhile, in the United States the Emergency Management Issues Special Interest Group (EMI SIG) states that “Protective Action Criteria (PACs) are essential components for planning and responding to uncontrolled releases of hazardous chemicals. These criteria, combined with estimates of exposure, provide the information necessary to evaluate chemical release events for the purpose of taking appropriate protective actions. During an emergency response, these criteria may be used to evaluate the severity of the event, to identify potential outcomes, and to decide what protective actions should be taken” [27]. PAC values are based on the following exposure limit values: Acute Exposure Guideline Levels (AEGL) values published by the U.S. Environmental Protection Agency (EPA); Emergency Response Planning Guideline (ERPG) values produced by the American Industrial Hygiene Association (AIHA); and Temporary Emergency Exposure Limit (TEEL) values developed by SCAPA. There are the three levels of PAC value (1–3) where each successive value is associated with an increasingly severe effect from a higher level of exposure. Each level is defined as follows: PAC-1: Mild, transient health effects; PAC-2: Irreversible or other serious health effects that could impair the ability to take protective action and PAC-3: Life-threatening health effects [28].

Table 6 presents the value of PAC for the main organic substances that were detected and identified in mixtures of gases and fumes emitted during thermal decomposition and combustion of triadimenol. Unfortunately, the values of these parameters are not available for all detected chemicals, because clinical effects are still an active area of research.

One of the products released during thermal decomposition is hydrogen cyanide, which is approximately 25 times more toxic than carbon monoxide through the formation of the cyanide ion formed by hydrolysis in the blood. This product causes rapid incapacitation, preventing escape and then, with carbon monoxide, contributes to death from asphyxiation [29]. The main product of thermal degradation and combustion of triadimenol was 4-chlorophenol. This chemical was present in fire effluents released during all the tested conditions. 4-Chlorophenol is toxic by all routes (ingestion, inhalation, dermal absorption). Effects from exposure can include burns to the skin and eyes, weakness, headache, dizziness, shock, and death from cardiac or pulmonary failure. Moreover, during decomposition it emits toxic fumes of hydrogen chloride [30]. In gases and fumes released during thermal decomposition of triadimenol many organic compounds: chlorobenzene and chlorinated phenols were present, which are suspected to be dioxins precursors. The polycyclic hydrocarbons were also detected in fire effluents. Most of these substances are carcinogenic, mutagenic, with biological accumulation. What is more important, due to the health risks to humans and ecosystems, some of those pollutants were listed as priority pollutants by the United States Environmental Protection Agency.

Conclusions

The obtained results suggest that thermal decomposition of triadimenol is a multistage process. The pesticide exposed to heat in air atmosphere undergoes both thermal degradation and oxidation. In the gases involved during that process, carbon oxides, hydrogen cyanide and many organic compounds were present. To identify these volatile and semi-volatile organic compounds, fire effluents were generated in different conditions using the steady-state tube furnace. The solid-phase microextraction method was adopted for sampling and concentration of the detected chemicals. Different SPME fiber coatings were used to identify a wide range of emitted products. The best extraction efficiency was found with CAR/PDMS and DVB/PDMS fibers.

The largest amount of species was detected in the samples emitted during a well-ventilated flaming developing fire, while the least products were created during oxidative pyrolysis. The main organic product of thermal degradation of triadimenol was toxic 4-chlorophenol. In gases and fumes released during thermal degradation and combustion of tested pesticide, chlorobenzene, chlorinated phenols, polycyclic aromatic hydrocarbons and chlorinated polycyclic aromatic hydrocarbons were also present.

References

Vinggaard AM, Breinholt V, Larsen JC. Screening of selected pesticides for estrogen receptor activation in vitro. Food Addit Contam. 1999;16:533–42.

Burger A, van den Boom C. Physicochemical properties of plant protection substances: I. Polymorphism and binary systems of triadimenol. Mikrochim Acta. 2000;135:63–9.

CLH report, Proposal for Harmonised Classification and Labelling Based on Regulation (EC) No 1272/2008 (CLP Regulation), Part 2, TRIADIMENOL, 2011, https://echa.europa.eu/documents/10162/13626/clh_triadimenol_en.pdf. Accessed 15 May 2019.

http://www.ebi.ac.uk/chebi/searchId.do?chebiId=CHEBI:24127. Accessed 15 May 2019.

Siegel MR. Sterol inhibiting fungicides: effects on sterol biosynthesis and sites of action. Plant Dis. 1981;65:986–9.

Zhao L, Liu F, Wu L, Xue X, Hou F. Fate of triadimefon and its metabolite triadimenol in jujube samples during jujube wine and vinegar processing. Food Control. 2017;73:468–73.

Senneca O, Scherillo F, Nunziata A. Thermal degradation of pesticides under oxidative conditions. J Anal Appl Pyrol. 2007;80:61–76.

Chen K, Mackie JC, Kennedy EM, Dlugogorski BZ. Determination of toxic products released in combustion of pesticides. Prog Energy Combust. 2012;38:400–18.

Gupta N, Yadav KK, Kumar V, Kumar S, Chadd RP, Kumar A. Trace elements in soil-vegetables interface: Translocation, bioaccumulation, toxicity and amelioration—a review. Sci Total Environ. 2019;651:2927–42.

Taiwo AM. A review of environmental and health effects of organochlorine pesticide residues in Africa. Chemosphere. 2019;220:1126–40. https://doi.org/10.1016/j.chemosphere.2019.01.001.

Dharmarathne NK, Mackie JC, Lucas J, Kennedy EM, Stockenhuber M. Mechanisms of thermal decomposition of cyclodiene pesticides, identification and possible mitigation of their toxic products. Proc Combust Inst. 2019;37:1143–50.

Altarawneh M, Carrizo D, Ziolkowski A, Kennedy EM, Dlugogorski BZ, Mackie JC. Pyrolysis of permethrin and formation of precursors of polychlorinated dibenzo-p-dioxins and dibenzofurans (PCDD/F) under nonoxidative conditions. Chemosphere. 2009;74:1435–43.

Kaisersberger E, Post E. Applications for skimmer coupling systems, combining simultaneous thermal analysers with mass spectrometers. Thermochim Acta. 1998;324:197–201.

Lubkowski J, Janiak T, Czerminski J, Blazejowski J. Thermoanalytical investigations of some chloro-organic pesticides and related compounds. Thermochim Acta. 1998;155:7–28.

Nageswara R, Khalid S, Rajani T, Husain S. Gas chromatographic-mass spectrometric separation and identification of combustion products of organo-phosphorus and chlorine pesticides and evaluation of their impact on the environment. J Chromatogr. 2002;954:227–34.

Summoogum SL, Mackie JC, Kennedy EM, Dlugogorski BZ. Formation of toxic species and precursors of PCDD/F in thermal decomposition of alpha-cypermethrin. Chemosphere. 2011;85:143–50.

Sankowska M, Gajek A, Celiński M, Sałasińska K. Determination of gaseous products of thermal degradation of thiram. J Therm Anal Calorim. 2017;128:1639–47.

Dharmarathne NK, Mackie JC, Kennedy EM, Stockenhuber M. Gas phase thermal oxidation of endosulfan and formation of polychlorinated dibenzo-p-dioxins and dibenzofurans. Environ Sci Technol. 2016;50:10106–13.

Sánchez-Soto PJ, Morillo E, Pérez-Rodríguez JL, Real C. Thermoanalytical study of the pesticide 3-amino-1,2,4-triazole. J Therm Anal Calorim. 1995;45:1189–97.

Sankowska M, Gajek A. Determination of toxic products released during combustion of selected pyrethroids. Chem Eng Trans. 2016;48:409–14.

Kennedy EM, Mackie JC. Mechanism of the thermal decomposition of chlorpyrifos and formation of the dioxin analog, 2,3,7,8-tetrachloro-1,4-dioxino-dipyridine (TCDDpy). Environ Sci Technol. 2018;52:7327–33.

Fardell R, Guillaume E. Sampling and measurement of toxic fire effluent. In: Stec AA, Hull TR, editors. Fire toxicity. Sawston: Woodhead Publishing Limited; 2010. p. 385–422.

Stec AA, Hull TR, Purser DA, Purser JA. Fire toxicity assessment: comparison of asphyxiant yields from laboratory and large scale flaming fires. Fire Saf Sci. 2014;11:404–18.

ISO/TS 19700:2007. Controlled equivalence ratio method for the determination of hazardous components of fire effluents. International Organization for Standardization. Geneva, Switzerland.

Stec AA, Hull TR, Lebek K. Characterization of the steady state tube furnace (ISO TS 19700) for fire toxicityassessment. Polym Degrad Stabil. 2008;93:2058–65.

Verschueren K. Handbook of environmental data on organic chemicals. 4th ed. New York: Wiley; 2001.

Protective Action Criteria for Chemicals—Including AEGLs, ERPGs, and TEELs. Emergency Preparedness. The Emergency Management Issues Special Interest Group (EMI SIG), Retrieved 3 February 2012.

U.S. Department of Energy, https://sp.eota.energy.gov/pac/Search. Accessed 15 May 2019.

Hull TR, Stec AA. Introducion to fire toxicity. In: Stec AA, Hull TR, editors. Fire toxicity. Woodhead Publishing Limited: Sawston; 2010. p. 3–47.

HSDB, 4-CHLOROPHENOL, https://toxnet.nlm.nih.gov/cgi-bin/sis/search/r?dbs+hsdb:@term+@rn+@rel+106-48-9. Accessed 15 May 2019.

Acknowledgements

This paper has been based on the results of a research task carried out within the scope of the fourth stage of the National Programme—Improvement of safety and working conditions partly supported in 2017–2019—within the scope of research and development—by the Ministry of Science and Higher Education/National Centre for Research and Development. The Central Institute for Labour Protection—National Research Institute is the Programme’s main coordinator.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Borucka, M., Celiński, M., Sałasińska, K. et al. Identification of volatile and semi-volatile organic compounds emitted during thermal degradation and combustion of triadimenol. J Therm Anal Calorim 139, 1493–1506 (2020). https://doi.org/10.1007/s10973-019-08531-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08531-y