Abstract

SiC nanowires were prepared by sol–gel sintering at high temperature, then shaped and encapsulated Na2SO4·10H2O-based composite phase change energy storage materials. The properties of these materials, named PCMs-1, PCMs-3, and PCMs-5, were then investigated. The best-shaped phase change energy storage material was prepared when the content of SiC nanowires added reached 3 mass%. By scanning electron microscopy, PCMs-3 showed that SiC nanowires and Na2SO4·10H2O-based phase change materials have good compatibility with the network layer structure formed by SiC nanowires tightly wrapping the Na2SO4·10H2O-based phase change energy storage materials. The layered phenomenon of Na2SO4·10H2O-based phase change energy storage materials can be effectively reduced in this way, with increased additions of SiC nanowires reducing the degree of undercooling from 2.8 to 1, 0.5 and 0.9 °C with 1, 3 and 5 mass% SiC nanowires, respectively. The thermal conductivity of the phase change materials also improved, with conductivities of PCMs, PCMs-1, 3, 5 being 0.7812, 0.9941, 1.001 and 1.016 W m−1 K−1, respectively. By comparing the latent heat values of PCMs, PCMs-1, 3, 5 phase change energy storage materials thermally cycled 500 times, it was determined that PCMs-3 had the lowest phase change latent heat loss, effectively improving the cycle life of the phase change energy storage materials.

Similar content being viewed by others

Abbreviations

- R c :

-

The critical radius of heterogeneous nucleation

- γ sl :

-

The specific surface free energy of the interface between crystal and fluid

- Ωs :

-

The volume of single atom

- Δg :

-

The change of free energy caused by the transition of single atom and fluid phases to crystal phase

- ΔG :

-

The critical nucleation work

- ΔGv :

-

The volume free energy of crystallization

- ΔGs :

-

The interface free energy of crystallization

- θ :

-

The angle between liquid surface tension and solid–liquid interfacial tension

- σ LB :

-

The surface free energy between fluid

- σ SB :

-

The surface free energy between the crystal nucleus

- σ LS :

-

The surface free energy between the crystal nucleus and fluid

- ΔT :

-

Degree of undercooling (°C)

- T om :

-

Initial dissolution temperature (°C)

- T em :

-

Termination dissolution temperature (°C)

- T oc :

-

Initial solidification temperature (°C)

- T ec :

-

Termination solidification temperature (°C)

- ΔHm :

-

Melting latent heat (J g−1)

- ΔHc :

-

Solidification latent heat (J g−1)

- λ :

-

Thermal conductivity at 20 °C (W m−1 K−1)

- PCMs:

-

Na2SO4·10H2O-based composite phase change energy storage materials

- PCMs-1:

-

SiC nanowires of 1 mass% were added in PCMs

- PCMs-3:

-

SiC nanowires of 3 mass% were added in PCMs

- PCMs-5:

-

SiC nanowires of 5 mass% were added in PCMs

References

Guarino F, Athienitis A, Cellura M, Bastien D. PCM thermal storage design in buildings: experimental studies and applications to solaria in cold climates. Appl Energy. 2017;185:95–106. https://doi.org/10.1016/j.apenergy.2016.10.046.

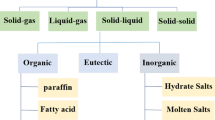

Mohamed SA, Al-Sulaiman FA, Ibrahim NI, Zahir MH, Al-Ahmed A, Saidur R, et al. A review on current status and challenges of inorganic phase change materials for thermal energy storage systems. Renew Sustain Energy Rev. 2017;70:1072–89. https://doi.org/10.1016/j.rser.2016.12.012.

Ibrahim NI, Al-Sulaiman FA, Rahman S, Yilbas BS, Sahin AZ. Heat transfer enhancement of phase change materials for thermal energy storage applications: a critical review. Renew Sustain Energy Rev. 2017;74:26–50. https://doi.org/10.1016/j.rser.2017.01.169.

Wang W, Wu Z, Li B, Sundén B. A review on molten-salt-based and ionic-liquid-based nanofluids for medium-to-high temperature heat transfer. J Therm Anal Calorim. 2018;136(3):1037–51. https://doi.org/10.1007/s10973-018-7765-y.

Ricklefs A, Thiele AM, Falzone G, Sant G, Pilon L. Thermal conductivity of cementitious composites containing microencapsulated phase change materials. Int J Heat Mass Transf. 2017;104:71–82. https://doi.org/10.1016/j.ijheatmasstransfer.2016.08.013.

Jiang ZP, Tie SN. Preparation and properties of Glauber’s salt-based composite phase change materials by physical method. J Synth Cryst. 2015;12(44):3639–45. https://doi.org/10.16553/j.cnki.issn1000-985x.2015.12.050.

Xin Liu, Shengnian Tie, Jian Tie. Energy storage properties of mans nitro phase transition materials of muli-walled carbon nano-tubes of greenhouse. Trans Chin Soc Agric Eng. 2016;32(6):226–31. https://doi.org/10.11975/j.issn.1002-6819.2016.06.031.

Jiang G, Chen W, Xia W. Environmental-sensitive hyperbranched polymers as drug carriers. Des Monomers Polym. 2008;11(2):105–22. https://doi.org/10.1163/156855508x298017.

Chen C, Wang L, Huang Y. Crosslinking of the electrospun polyethylene glycol/cellulose acetate composite fibers as shape-stabilized phase change materials. Mater Lett. 2009;63(5):569–71. https://doi.org/10.1016/j.matlet.2008.11.033.

Sarı A, Bicer A, Al-Sulaiman FA, Karaipekli A, Tyagi VV. Diatomite/CNTs/PEG composite PCMs with shape-stabilized and improved thermal conductivity: preparation and thermal energy storage properties. Energy Build. 2018;164:166–75. https://doi.org/10.1016/j.enbuild.2018.01.009.

Zhu F-R, Zhang L, Zeng J-L, Zhu L, Zhu Z, Zhu X-Y, et al. Preparation and thermal properties of palmitic acid/polyaniline/copper nanowires form-stable phase change materials. J Therm Anal Calorim. 2014;115(2):1133–41. https://doi.org/10.1007/s10973-013-3508-2.

Milián YE, Gutiérrez A, Grágeda M, Ushak S. A review on encapsulation techniques for inorganic phase change materials and the influence on their thermophysical properties. Renew Sustain Energy Rev. 2017;73:983–99. https://doi.org/10.1016/j.rser.2017.01.159.

Lv P, Liu C, Rao Z. Review on clay mineral-based form-stable phase change materials: preparation, characterization and applications. Renew Sustain Energy Rev. 2017;68:707–26. https://doi.org/10.1016/j.rser.2016.10.014.

Ferri JM, Garcia-Garcia D, Carbonell-Verdu A, Fenollar O, Balart R. Poly(lactic acid) formulations with improved toughness by physical blending with thermoplastic starch. J Appl Polym Sci. 2017. https://doi.org/10.1002/app.45751.

Liu C, Rao Z, Li Y. Composites enhance heat transfer in paraffin/melamine resin microencapsulated phase change materials. Energy Technol. 2016;4(4):496–501. https://doi.org/10.1002/ente.201500309.

Onder E, Sarier N, Ukuser G, Ozturk M, Arat R. Ultrasound assisted solvent free intercalation of montmorillonite with PEG1000: a new type of organoclay with improved thermal properties. Thermochim Acta. 2013;566:24–35. https://doi.org/10.1016/j.tca.2013.05.021.

Li WQ, Qu ZG, He YL, Tao WQ. Experimental and numerical studies on melting phase change heat transfer in open-cell metallic foams filled with paraffin. Appl Therm Eng. 2012;37:1–9. https://doi.org/10.1016/j.applthermaleng.2011.11.001.

Liu X, Tie J, Tie SN. Corrosion on metal packaging materials by sodium sulfate decahydrate composite phase change material. J Synth Cryst. 2016;45(4):986–94. https://doi.org/10.16553/j.cnki.issn1000-985x.2016.04.024.

Zhang X, Liu H, Huang Z, Yin Z, Wen R, Min X, et al. Preparation and characterization of the properties of polyethylene glycol @ Si3N4 nanowires as phase-change materials. Chem Eng J. 2016;301:229–37. https://doi.org/10.1016/j.cej.2016.05.024.

Chen C, Wang L, Huang Y. A novel shape-stabilized PCM: electrospun ultrafine fibers based on lauric acid/polyethylene terephthalate composite. Mater Lett. 2008;62(20):3515–7. https://doi.org/10.1016/j.matlet.2008.03.034.

Chen C, Wang L, Huang Y. Electrospinning of thermo-regulating ultrafine fibers based on polyethylene glycol/cellulose acetate composite. Polymer. 2007;48(18):5202–52077. https://doi.org/10.1016/j.polymer.2007.06.069.

Funding

Funding was provided by Scientific and technological support Project of Haixi Prefecture, Qinghai Province (Grant No. 174610137100713).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tie, J., Liu, X., Tie, S. et al. Packing and properties of composite phase change energy storage materials based on SiC nanowires and Na2SO4·10H2O. J Therm Anal Calorim 139, 855–862 (2020). https://doi.org/10.1007/s10973-019-08473-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08473-5