Abstract

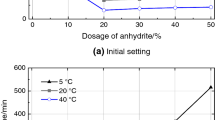

In order to find out the rules of the effect of temperature on performances and hydration process of sulphoaluminate cement-based dual liquid grouting material, the performances of the grouting material were studied by determining its setting time, compressive strength and setting temperature. Its hydration process, hydration products and microstructure were analyzed by using XRD, TG–DTA and SEM–DES. The results show that water temperature has a significant effect on the setting time and setting temperature. The higher the water temperature, the shorter the setting time and the higher the setting temperature. In addition, as the water temperature and curing temperature increase, the hydration rate grows faster and the early strength becomes higher. However, the later strength of samples which are with lower temperature is higher. The results of TG–DTA, XRD and SEM–DES show that ettringite (AFt) is the main hydration product. Higher water temperature and curing temperature accelerate the formation of AFt, but also restrict the later hydration rate. The type of hydration product does not change as the temperature changes, but the microstructure of hydration product does.

Similar content being viewed by others

References

Zhang YL, Sun Q, Geng JS. Olivine thermal diffusivity influencing factors. J Therm Anal Calorim. 2018;132:7–16.

Xu LL, et al. Formation of ettringite in Portland cement/calcium aluminate cement/calcium sulfate ternary system hydrates at lower temperatures. Constr Build Mater. 2012;31(6):347–52.

Borinaga-Trevi OR, et al. Freeze–thaw durability of cement-based geothermal grouting materials. Constr Build Mater. 2014;55:390–7.

Miao SQ, Zhou YS. Temperature dependence of thermal diffusivity and conductivity for sandstone and carbonate rocks. J Therm Anal Calorim. 2018;131:1647–52.

Feng X, et al. Estimation of the degree of hydration of blended cement paste by a scanning electron microscope point-counting procedure. Cem Concr Res. 2004;34(10):1787–93.

Chang J, et al. A reaction range for hydration of calcium sulphoaluminate with calcium sulfate and calcium hydroxide: theory and experimental validation. Cem Concr Res. 2016;28:664–74.

Myers RJ, et al. Effect of temperature and aluminium on calcium (alumino) silicate hydrate chemistry under equilibrium conditions. Cem Concr Res. 2015;68:83–93.

Zhang JW, et al. Performance and hydration study of ultra-fine CSA cement-based double liquid grouting material. Constr Build Mater. 2017;132:262–70.

Kaljuvee T, Štubňa I, Hulan T, Kuusik R. Heating rate effect on the thermal behavior of some clays and their blends with oil shale ash additives. J Therm Anal Calorim. 2017;127:33–45.

Wang PM, et al. Hydration evolution and compressive strength of calcium sulphoaluminate cement constantly cured over the temperature range of 0 to 80 °C. Cem Concr Res. 2017;100:203–13.

Han S, et al. Mechanical energy dissipation using carbon fiber polymer-matrix structural composites with filler incorporation. J Mater Sci. 2012;47:2434–53.

Song F, et al. Microstructure of amorphous aluminum hydroxide in belite-calcium sulfoaluminate cement. Cem Concr Res. 2015;71:1–6.

Zhang Y, et al. Effects of lithium carbonate on performances of sulphoaluminate cement-based dual liquid high water material and its mechanisms. Constr Build Mater. 2018;161:374–80.

Ma SH, et al. Study on the hydration and microstructure of portland cement containing diethanol-isopropanolamine. Cem Concr Res. 2015;67:122–30.

Zhang W, Sun Q, Zhu Y, et al. Experimental study on response characteristics of micro–macroscopic performance of red sandstone after high-temperature treatment. J Therm Anal Calorim. 2019;136:1935–45.

Han T, et al. Multiscale carbon nanosphere–carbon fiber reinforcement for cement-based composites with enhanced high-temperature resistance. J Mater Sci. 2015;50:2038–48.

Wang PM, et al. Hydration characteristics and strength development of sulphoaluminate cement cured at low temperature. J Chin Ceram Soc. 2017;45:242–8.

Niu L. Effect of high ambient temperature on the cement hydration heat performance. Const Technol. 2017;46:91–3.

Liao Y, et al. Effect of temperature on electrical resistivity and chemical shrinkage of calcium sulphoaluminate cement. J Build Mater. 2018;21:476–83.

Wang Z, et al. Effect of moisture content on freeze–thaw behavior of cement paste by electrical resistance measurements. J Mater Sci. 2014;49:4305–14.

Jewell RB, et al. Interfacial bond between reinforcing fibers and calcium CSA cements: fiber pullout characteristics. ACI Mater J. 2015;112:39–48.

Chang J, et al. A reaction range for hydration of calcium sulphoaluminate with calcium sulfate and calcium hydroxide: theory and experimental validation. Cem Concr Res. 2016;28:664–74.

Olson RA, et al. Interpretation of the impedance spectroscopy of cement paste via computer modelling Part III: microstructural analysis of frozen cement paste. J Mater Sci. 1995;30:5078–86.

Hargis CW, et al. Calcium sulphoaluminate (Ye’elimite) hydration in the presence of gypsum, calcite, and vaterite. Cem Concr Res. 2014;65:15–20.

Xu LL, et al. Temperature effect on early hydration of calcium aluminate cement based ternary blends. J Chin Ceram Soc. 2016;11:1552–7.

Kaufmann J, et al. Stability of ettringite in CSA cement at elevated temperatures. Adv Cem Res. 2016;4(2):1–11.

Zhang P, Zhang S, Wang S. Effect of BaO on mineral structure and hydration behavior of phosphoaluminate cement. J Therm Anal Calorim. 2019;136:2319–26.

Maciel MH, Soares GS, Cesar R, Romano RC de O. Monitoring of Portland cement chemical reaction and quantification of the hydrated products by XRD and TG in function of the stoppage hydration technique. J Therm Anal Calorim. 2019;136:1269–84.

Wang YL, He H, He FX. Effect of slaked lime and aluminum sulfate on the properties of dry-mixed masonry mortar. Constr Build Mater. 2018;180:117–23.

Acknowledgements

The authors gratefully acknowledge the financial support for this research from the Universities support program of technological innovation team and innovative talents in Henan Province (17HSTIT032); Innovative technology team of development and application of grouting and filling materials in Henan Province; The National Natural Science Foundation of China (Grant Number: 41572291).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared that they have no conflicts of interest to this work. We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Li, T., Feng, W. et al. Effects of temperature on performances and hydration process of sulphoaluminate cement-based dual liquid grouting material and its mechanisms. J Therm Anal Calorim 139, 47–56 (2020). https://doi.org/10.1007/s10973-019-08426-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08426-y