Abstract

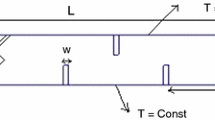

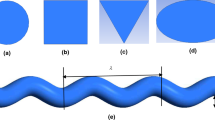

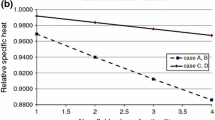

This paper presents the results of a numerical study on the thermal–hydraulic and entropy generation analysis for a nanofluid flow inside a plate-fin triangular duct. Vortex generators are placed in the duct to improve the heat transfer rate and fluid mixing. Reynolds number (Re), volume fraction of nanoparticles (α) and vortex generators’ angle of attack (θ) are selected as the pertinent parameters. All simulations are performed for the following range of parameters: 200 < Re < 1000; 0<α < 0.05 and 0 < θ< 50. The results are presented for the dimensionless pressure drop, Nusselt number and entropy generations (friction and thermal entropy generations). Results indicate that for θ < 40°, the thermal entropy generation reduces by increasing θ, while for θ > 40°, increasing θ leads to an increase in the thermal entropy generation. Moreover, the friction entropy generation was found to increase by 8% when the angle of attack is increased from 0 to 40°.

Similar content being viewed by others

Abbreviations

- Be :

-

Bejan number (−)

- \( C_{p} \) :

-

Specific heat at constant pressure (J kg−1 K−1)

- D h :

-

Hydraulic diameter (m)

- d :

-

Half of distance between the leading tips of VGs (m)

- f :

-

Friction factor (−)

- H :

-

Height of channel (m)

- h :

-

Height of VGs (m)

- \( h_{x} \) :

-

Local heat transfer coefficient (W m−2 K−1)

- \( k \) :

-

Thermal conductivity (W m−1 K−1)

- L :

-

Length of channel (m)

- l :

-

Length of VGs (m)

- Nu :

-

Nusselt number (−)

- N :

-

Non-dimensional entropy generation (−)

- \( p \) :

-

Pressure (Pa)

- Pe :

-

Peclet number (−)

- \( q^{{{\prime \prime }}} \) :

-

Heat flux (W/m2)

- Re :

-

Reynolds number (−)

- \( S_{g}^{{{\prime \prime \prime }}} \) :

-

Entropy generation rate (W m−3 K−1)

- s :

-

Distance from the leading edge of duct and VG (m)

- \( T \) :

-

Temperature (K)

- t :

-

Thickness of VGs (m)

- \( u,\;v,_{{}} w \) :

-

Velocity component in x and y directions, respectively (ms−1)

- W :

-

Channel width (m)

- x,y, z :

-

Rectangular coordinates components (m)

- θ :

-

VG’s angle of attack (degree)

- α :

-

Volume fraction of nanoparticles (-)

- \( \mu \) :

-

Dynamic viscosity (kg m−1 s−1)

- \( \rho \) :

-

Density of the fluid (kg m−3)

- \( \forall \) :

-

Volume of the domain (m3)

- ave:

-

Average

- ref:

-

Reference

- eff:

-

Effective

- in:

-

Inlet

- out:

-

Outlet

- x:

-

Local

- VG:

-

Vortex generator

- w:

-

Wall

References

Habibzadeh S, Kazemi-Beydokhti A, Khodadadi AA, Mortazavi Y, Omanovic S, Shariat-Niassar M. Stability and thermal conductivity of nanofluids of tin dioxide synthesized via microwave-induced combustion route. Chem Eng J. 2010;156:471–8.

Wang W, Wu Z, Li B, Sundén B. A review on molten-salt-based and ionic-liquid-based nanofluids for medium-to-high temperature heat transfer. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7765-y.

Sharma S. Fabricating an experimental setup to investigate the performance of an automobile car radiator by using aluminum/water nanofluid. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7224-9.

Abadeh A, Mohammadi M, Passandideh-Fard M. Experimental investigation on heat transfer enhancement for a ferrofluid in a helically coiled pipe under constant magnetic field. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7478-2.

Bovand M, Rashidi S, Ahmadi G, Esfahani JA. Effects of trap and reflect particle boundary conditions on particle transport and convective heat transfer for duct flow—A two-way coupling of Eulerian-Lagrangian model. Appl Therm Eng. 2016;108:368–77.

Togun H, Ahmadi G, Abdulrazzaq T, Shkarah AJ, Kazi SN, Badarudin A, Safaei MR. Thermal performance of nanofluid in ducts with double forward-facing steps. J Taiwan Inst Chem Eng. 2015;47:28–42.

Akbarzadeh M, Rashidi S, Bovand M, Ellahi R. A sensitivity analysis on thermal and pumping power for the flow of nanofluid inside a wavy channel. Mol Liq. 2016;220:1–13.

Keshmiri A, Gotts J. Thermalhydraulic analysis of four geometrical design parameters in rib-roughened channels. Numer Heat Transf Part A: Appl. 2011;60:305–27.

Keshmiri A, Osman K, Benhamadouche S, Shokri N. Assessment of advanced RANS models against large eddy simulation and experimental data in the investigation of ribbed passages with passive heat transfer. Numer Heat Transf Part B: Fundam. 2016;69:96–110.

Keshmiri A. Numerical sensitivity analysis of 3- and 2-dimensional rib-roughened channels. Heat Mass Transf. 2012;48:1257–71.

Promvonge P, Suwannapan S, Pimsarn M, Thianpong C. Experimental study on heat transfer in square duct with combined twisted-tape and winglet vortex generators. Int Commun Heat Mass Transfer. 2014;59:158–65.

Ahmed HE, Ahmed MI, Yusoff MZ. Heat transfer enhancement in a triangular duct using compound nanofluids and turbulators. Appl Therm Eng. 2015;91:191–201.

Hsiao KY, Wu CY, Huang YT. Fluid mixing in a microchannel with longitudinal vortex generators. Chem Eng J. 2014;235:27–36.

Ali S, Menanteau S, Habchi C, Lemenand T, Harion JL. Heat transfer and mixing enhancement by using multiple freely oscillating flexible vortex generators. Appl Therm Eng. 2016;105:276–89.

Ko TH. Effects of corrugation angle on developing laminar forced convection and entropy generation in a wavy channel. Heat Mass Transfer. 2007;44:261–71.

Ebrahimi A, Rikhtegar F, Sabaghan A, Roohi E. Heat transfer and entropy generation in a microchannel with longitudinal vortex generators using nanofluids. Energy. 2016;101:190–201.

Amirahmadi S, Rashidi S, Esfahani JA. Minimization of exergy losses in a trapezoidal duct with turbulator, roughness and beveled corners. Appl Therm Eng. 2016;107:533–43.

Mokrani A, Castelain C, Peerhossaini H. Experimental study of the influence of the rows of vortex generators on turbulence structure in a tube. Chem Eng Process. 2009;48:659–71.

Guyer EC. Handbook of applied thermal design. Castleton: Hamilton Printing Co.; 1999.

Torabi M, Zhang K, Yang G, Wang J, Wu P. Heat transfer and entropy generation analyses in a channel partially filled with porous media using local thermal non-equilibrium model. Energy. 2015;82:922–38.

Bejan A. A study of entropy generation in fundamental convective heat transfer. J Heat Transf. 1979;101(4):718–25.

Abdollahi A, Shams M. Optimization of heat transfer enhancement of nanofluid in a channel with winglet vortex generator. Appl Therm Eng. 2015;91:1116–26.

Albojamal A, Vafai K. Analysis of single phase, discrete and mixture models, in predicting nanofluid transport. Int J Heat and Mass Transf. 2017;114:225–37.

Bejan A. ‘Entropy generation through heat and fluid flow’. New York: Wiley; 1982.

Patankar SV. Numerical heat transfer and fluid flow. New York: Hemisphere; 1980.

Bovand M, Rashidi S, Esfahani JA. Enhancement of heat transfer by nanofluids and orientations of the equilateral triangular obstacle. Energy Convers Manag. 2015;97:212–23.

Wang C, Lo J, Lin Y, Liu M. Flow visualization of wave-type vortex generators having inline fin-tube arrangement. Int J Heat Mass Transf. 2002;45:1933–44.

Wu JM, Tao WQ. Numerical study on laminar convection heat transfer in a channel with longitudinal vortex generator: part A: Verification of field synergy principle. Int J Heat Mass Transf. 2008;51:1179–91.

Abdollahi A, Shams M. Optimization of shape and angle of attack of winglet vortex generator in a rectangular channel for heat transfer enhancement. Appl Therm Eng. 2015;81:376–87.

Ahmed HE, Mohammed HA, Yusoff MZ. An overview on heat transfer augmentation using vortex generators and nanofluids: approaches and applications. Renew Sustain Energy Rev. 2012;16:5951–93.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Darbari, B., Rashidi, S. & Keshmiri, A. Nanofluid heat transfer and entropy generation inside a triangular duct equipped with delta winglet vortex generators. J Therm Anal Calorim 140, 1045–1055 (2020). https://doi.org/10.1007/s10973-019-08382-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08382-7