Abstract

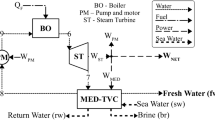

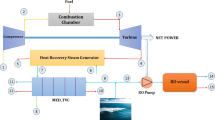

This research consists of a brief overview of some methods used to produce freshwater and how they work, the obvious points of performance, and the advantages and disadvantages of each of these methods. The effects of change in operation parameters on the performance as well as thermal energy consumption of sample MED–TVC (MED with thermal vapor compression) are investigated. This article represents the result of experimental and actual changes provided by process engineering department in Kavian Petrochemical Company (11th Olefin) to find best operating conditions for system stability. The most significant reason to opt these MED units is the internal steam source (5 * 140 ton h−1 boilers) which is located inside the complex’s battery limit making the control of operational variables more accessible. Also, the performance of the system and thermodynamic and thermo-hydraulic equations have been studied carefully. By writing a solving algorithm for the governing equations and implementing it in the MATLAB software, a conceptual design of the system has been considered. By using the written program, the effect of change in parameters such as inlet steam pressure, seawater temperature, feed water temperature, inlet seawater flow, the performance ratio on the steam consumption has been reviewed. Although most of the above-mentioned changes cannot be implemented after the system designing, changes in the steam consumption that is generated inside the complex have been investigated and the results have been communicated to the operation department through the process engineering department to modify the system.

Similar content being viewed by others

Abbreviations

- A :

-

Inner cross section of the pipe (m2)

- \(C_{\text{p}}\) :

-

Heat capacity \(\left( {{\text{kJ}}\,{\text{Kg}}^{ - 1} \,{\text{k}}} \right)\)

- h :

-

Enthalpy \(\left( {{\text{MMBtu}}\,{\text{h}}^{ - 1} } \right)\)

- m :

-

Mass flow \(\left( {{\text{lb}}\,{\text{h}}^{ - 1} } \right)\)

- n :

-

Molar flow \(\left( {{\text{lbmol}}\,{\text{h}}^{ - 1} } \right)\)

- Q :

-

Heat flux \(\left( {{\text{MMBtu}}\,{\text{h}}^{ - 1} } \right)\)

- S :

-

Entropy \(\left( {{\text{MMBtu}}\,{\text{h}}^{ - 1} \,{\text{k}}} \right)\)

- T :

-

Temperature \(\left( {\text{K}} \right)\)

- \(T_{\text{r}}\) :

-

Resource temperature \(\left( {\text{k}} \right)\)

- CR:

-

Concentration

- d :

-

Pipe diameter (m)

- ER:

-

Entrainment ratio

- GOR:

-

Gain output ratio

- h :

-

Convectional heat coefficient \(\left( {{\text{kW}}\,{\text{m}}^{ - 2} \,{\text{k}}^{1} } \right)\)

- H :

-

Tube bundle height (m)

- L :

-

Tube bundle length (m)

- P :

-

Pressure (kPa)

- R :

-

Thermal resistance \(\left( {{\text{m}}^{2} \,{\text{K}}\,{\text{kw}}^{ - 1} } \right)\)

- Re :

-

Reynolds

- TTD:

-

Temperature difference in cells (°C)

- U :

-

Overall heat coefficient \(\left( {{\text{kW}}\,{\text{m}}^{ - 2} \,{\text{k}}^{1} } \right)\)

- Γ :

-

Falling film mass flux on pipe length \(\left( {{\text{kg}}\,{\text{m}}^{ - 1} \,{\text{s}}^{ - 1} } \right)\)

- δ :

-

Falling film thickness (m)

- Δ:

-

Length segment (m)

- Δρ :

-

Phase density difference \(\left( {{\text{kg}}\,{\text{m}}^{ - 3} } \right)\)

- µ :

-

Dynamic viscosity \(\left( {{\text{N}}\,{\text{s}}\,{\text{m}}^{ - 2} } \right)\)

References

Darwish MA, Alsairafi A. Technical comparison between TVC/MEB and MSF. Desalination. 2004;170:223–39.

Al-Shammiri M, Safar M. Multi-effect distillation plants: state of the art. Desalination. 1999;126(1):45–59.

Hajbi F, Hammi H, Solimando R, M’nif A. Evaporation of a reverse osmosis discharge studied by Pitzer model and solubility phase diagrams. Fluid Phase Equilib. 2011;307(2):126–34.

Giron D. Applications of thermal analysis and coupled techniques in pharmaceutical industry. J Therm Anal Calorim. 2002;68:335.

Buros OK. The ABC’s of desalting. Topsfield: International Desalination Association; 1990.

Saleh S, Pirouzfar V, Alihosseini A. Performance analysis and development of a refrigeration cycle through various environmentally friendly refrigerants. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7809-3.

Barza A, Mehri B, Pirouzfar V. Mathematical modeling of ethane cracking furnace of olefin plant with coke formation approach. Int J Chem Reactor Eng. 2018;16(9):20170243.

Zolfaghari Mohabbat, Pirouzfar Vahid, Sakhaeinia Hossein. Technical characterization and economic evaluation of recovery of flare gas in various gas-processing plants. Energy. 2017;124:481–91.

El-Sayed YM, Silver RS. Chapter 2 – fundamentals of distillation. In: Spiegler KS, Laird ADK, editors. Princ. Desalin., Academic Press; 1980, p. 55–109. https://doi.org/10.1016/B978-0-12-656701-4.50008-5.

Janajreh I, Hasania A, Fath H. Numerical simulation of vapor flow and pressure drop across the demister of MSF desalination plant. Energy Convers Manag. 2013;65:793–800.

Husain A, Hassan A, Al-Gobaisi DM, Al-Radif A, Woldai A, Sommariva C. Modeling, simulation, optimization and control of multistage flashing (MSF) desalination plants part I: modeling and simulation. Desalination. 1993;92:21–41.

Narmine HA, EL-Fiqi AK. Thermal performance of seawater desalination systems. Desalination. 2003;158:127–42.

Steven CH. Assessment of desalination treatment processes for future water supplies. M.Sc. thesis, Massachusetts Institute of Technology; 2003.

Miller JE. Review of water resources and desalination technologies. SAND; 2003. p. 2003–0800.

Zivi SM. Estimation of steady-state steam void-fraction by means of the principle of minimum entropy production. J Heat Transf. 1964;86(2):247–51.

El-Dessouky HT, Alatiqi IM, Ettouney HT, Al-Deffeeri NS. Performance of wire mesh mist eliminator. Chem Eng Process. 2000;39(2):129–39.

Jaster H, Kosky PG. Condensation heat transfer in a mixed flow regime. Int J Heat Mass Transf. 1976;19(1):95–9.

Kocamustafaoğulları G, Chen IY. Horizontal tube evaporators: part I. Theoretically-based correlations. Int Commun Heat Mass Transf. 1989;16(4):487–99.

Fan Niroo®. Operation and maintenance manual, Doc no. K443-44-CN-090; 2011.

Han J, Leroy SF. Falling film evaporation and boiling in circumferential and axial grooves on horizontal tubes. Ind Eng Chem Process Des Dev. 1985;24(3):570–5.

Chato JC. Laminar condensation inside horizontal and inclined Tubes. ASHRAE J. 1962;4:52–60.

Hou H, Qincheng B, Hong M, Gang W. Distribution characteristics of falling film thickness around a horizontal tube. Desalination. 2012;285:393–8.

Shah MM. A general correlation for heat transfer during film condensation inside pipes. Int J Heat Mass Transf. 1979;22(4):547–56.

El-Dessouky HT, Ettouney HM. Multiple-effect evaporation desalination systems. thermal analysis. Desalination. 1999;125(1):259–76.

El-Dessouky HT, Ettouney HT, Mandani F. Performance of parallel feed multiple effect evaporation system for seawater desalination. Appl Therm Eng. 2000;20:1673–706.

Ashour MM. Steady state analysis of the tripoli west LT-HT-MED plant. Desalination. 2002;152:191–4.

Bin Amer AO. Development and optimization of ME-TVC desalination system. Desalination. 2009;249(3):1315–31.

Rahbar M. Improvement of the design and operation of desalination plants by computer modeling and simulation. Desalination. 1993;92(1):253–69.

Shivayyanamath S, Tewari PK. Simulation of start-up characteristics of multi-stage flash desalination plants. Desalination. 2003;155:277–86.

El-Dessouky Hisham, Ettouney Hisham, Al-Fulaij Hala, Mandani Faisal. Multistage flash desalination combined with thermal vapor compression. Chem Eng Process. 2000;39:343–56.

Incropera FP. Introduction to heat transfer. New York: Wiley; 2011.

Palen JW, Breber G, Taborek J. Prediction of flow regimes in horizontal tube-side condensation. Heat transf Eng. 1979;1(2):47–57.

Ould Didi MB, Kattan N, Thome JR. Prediction of two-phase pressure gradients of refrigerants in horizontal tubes. Int J Refrig. 2002;25(7):935–47.

El-Dessouky HT, Ettouney HT, Alatiqi IM, Al-Nuwaibit G. Evaluation of steam jet ejectors. Chem Eng Process. 2002;41:551–61.

Thome JR. Wolverine engineering data book III. Lausanne: Wolverine Tube Inc; 2009.

Cengel YA, Boles MA. Thermodynamics: an engineering approach. 5th ed. New York: McGraw Hill; 2006.

Lide DR, editor. Handbook of chemistry and physics. 73rd ed. Boca Raton: CRC Press; 1992.

Power BR. Steamjet ejectors for process industries. New York: McGraw-Hill; 1994.

Michels T. Recent achievements of low temperature multiple effect desalination in the western areas of Abu Dhabi, UAE. Desalination. 1993;93:111–8.

Lienhard IV JH, Lienhard VA. Heat transfer textbook. Cambridge: Phlogiston Press; 2008.

Bejan A. Convective heat transfer. 3rd ed. New York: Wiley; 2004 (Chapter 10).

El-Dessouky HT, Ettouney HM. Fundamentals of salt water desalination. New York: Elsevier; 2002.

Cipollina A. Experimental study and dynamic modelling of multi stage flash desalination units. Ph.d. thesis, University of Palermo, Italy; 2004–2005.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Barza, A., Shourije, S.R. & Pirouzfar, V. Industrial optimization of multi-effect desalination equipment for olefin complex. J Therm Anal Calorim 139, 237–249 (2020). https://doi.org/10.1007/s10973-019-08279-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08279-5