Abstract

In this study, we investigated the change of the heat transfer coefficient on the surface with the TLC method on a blade model with three-pass channel. It is seen that the Reynolds number effects, speed distribution in the channel and heat transfer coefficient distribution differ as a result of the geometry of the parts’ transition. In the experimental studies, comparison of circular- and square-holed transition parts of 20 m3 h−1 and 30 m3 h−1 flow experiments shows that although the channel with three passes has been found to have a more homogenous heat relay, the square hole used for the part of the transition with three-pass channels has access to the higher heat occurring compared to the circular-holed transition piece. In the 40 m3 h−1 and 50 m3 h−1 value experiments, the circular-holed transition piece used had the higher heat transfer coefficient in the channel and a more homogeneous distribution of the heat transfer was observed.

Similar content being viewed by others

Abbreviations

- h :

-

Local heat transfer coefficient (W m−2 K−1)

- k :

-

Thermal conductivity (W m−1 K−1)

- α :

-

Thermal diffusivity of acrylic material (Plexiglas) (m2 s−1)

- D h :

-

Jet hydraulic diameter (mm)

- D jet :

-

Jet diameter (m)

- D hi :

-

Inlet hydraulic diameter (m)

- D ho :

-

Outlet hydraulic diameter (m)

- Nu :

-

Nusselt number, hDh/k

- V jet :

-

The value of velocity in jet (m s−1)

- TLC:

-

Thermal liquid crystal

- T i :

-

Temperature of the solid (°C)

- T r :

-

Temperature of the convective flow (°C)

- T w :

-

Temperature at which the liquid crystal color changes from red to green (°C)

- t :

-

Time of the liquid crystal color change (s)

- Q :

-

Flow rate (m3 s−1)

- Q jet :

-

The value of jet flow rate (m3 s−1)

- Re :

-

Reynolds number, V. Dh/ν

- μ :

-

Fluid dynamic viscosity (m2 s−1)

- ν :

-

Kinematic viscosity (m2 s−1)

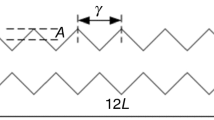

- Y :

-

Channel width (mm)

References

Han JC, Dutta S, Ekkad SV. Gas turbine heat transfer and cooling technology. New York: CCR Press Taylor & Francis, Inc.; 2013.

Ameno R, Sunda B. Impingement jet cooling in gas turbine. Southampton: WIT Press; 2014.

Chyu MK, Siw S. Recent advances of internal cooling techniques for gas turbine airfoils. ASME J Therm Sci Eng Appl. 2013;5(2):021008. https://doi.org/10.1115/1.4023829.

Albeirutty MH, et al. Heat transfer analysis for a multistage gas turbine using different blade-cooling schemes. Appl Therm Eng. 2004;24(4):563–77. https://doi.org/10.1016/j.applthermaleng.2003.10.007.

Osama MA. Heat transfer distributions on the walls of a narrow channel with jet impingement and cross flow. University of Pittsburgh, PhD. 2003.

Chyu MK. Determination of local heat transfer coefficient based on bulk mean temperature using transient liquid crystal technique. Exp Therm Fluid Sci. 1998;18:142–9.

Uysal U, Li PW, Chyu MK, Cunha FJ. Heat transfer on internal surfaces of a duct subjected to impingement of a jet array with varying jet hole-size and spacing. J Turbomach. 2006;128:158–65. https://doi.org/10.1115/1.2101859.

Han JC, et al. Augmented heat transfer in square channels with parallel, crossed, and V-shaped angled ribs. ASME Trans J Heat Transf. 1991;113:590–6. https://doi.org/10.1115/1.2910606.

Uysal U. Effect of jet diameter on heat transfer in a two-pass channel. J Enhanc Heat Transf. 2013;20:277–87.

Wang L, Sunden B. Experimental investigation of local heat transfer in a square duct with continuous and truncated ribs. Exp Heat Transf. 2005;18:179–97. https://doi.org/10.1080/08916150590953397.

Cavallero D, Tanda G. An experimental investigation of forced convection heat transfer in channels with rib turbulators by means of liquid crystal thermography. Exp Therm Fluid Sci. 2002;26(2–4):115–21. https://doi.org/10.1016/S0894-1777(02)00117-6.

Ekkad SV. Detailed heat transfer distributions in two-pass square channels with rib turbulators and bleed holes. Int J Heat Mass Transf. 1998;41(23):3781–91. https://doi.org/10.1016/S0017-9310(98)00099-4.

Han JC, Park JS. Developing heat transfer in rectangular channels with rib turbulators. Int J Heat Mass Transf. 1988;31(1):183–95. https://doi.org/10.1016/0017-9310(88)90235-9.

Han JC. Heat transfer and friction on channels with two opposite rib-roughened walls. ASME J Heat Transf. 1984;106:774–81.

Han JC, et al. Augmented heat transfer in rectangular channels of narrow aspect ratios with rib turbulators. Int J Heat Mass Transf. 1989;32(9):1619–30. https://doi.org/10.1016/0017-9310(89)90044-6.

Metzger DE, Bunker RS. Local heat transfer in internally cooled turbine airfoil leading edge regions: part I—impingement cooling without film coolant extraction. J Turbomach. 1990;112(3):451–8.

Bunker RS, Metzger DE. Local heat transfer in internally cooled turbine airfoil leading edge regions: part II—impingement cooling with film coolant extraction. J Turbomach. 1990;112(3):459–66.

Chang H, Zhang D, Huang T. Impingement heat transfer from rib roughened surface within arrays of circular jet: the effect of the relative position of the jet hole to the ribs. 1997. p. 97-GT-331.

Chyu MK. Regional heat transfer in two-pass and three-pass passages with 180° sharp turns. ASME J Heat Transf. 1991;113:63–70.

Astarita T, Cardone G, Carlomagno GM. Average heat transfer measurements near a sharp 180° turn channel for different aspect ratios. In: Proceedings of IMECHE conference transactions. Mechanical Engineering Publications. 1998. p. 137–146.

Mochizuki S, et al. Detailed measurements of local heat transfer coefficients in turbulent flow through smooth and rib-roughened serpentine passages with a 180° sharp bend. Int J Heat Mass Transf. 1999;42(11):1925–34. https://doi.org/10.1016/S0017-9310(98)00308-1.

Astarita T, Cardone G, Carlomagno GM. Convective heat transfer in ribbed channels with a 180° turn. Exp Fluids. 2002;33:90–100.

Algawair W, Iacovides H, Kounadis D, Xu Z. Experimental assessment of the effects of Prandtl Number and of a guide vane on the thermal development in a ribbed square-ended U-bend. Exp Therm Fluid Sci. 2007;32:670–81.

Salameh T, Sunden B. An experimental study of heat transfer and pressure drop on the bend surface of a U-duct, ASME GT2010-22139. In: Proceedings of ASME Turbo Expo (2010). Power for Land, Sea and Air GT (2010). Glasgow, UK. 2010.

Farina DJ. Making Surface temperature measurements using liquid crystal thermography. Electron Cool. 1995;1(2):10–5.

Siddique W, Khan WA, Haq I. Analysis of numerical results for two-pass trapezoidal channel with different cooling configurations of trailing edge: the effect of dimples. J Enhanc Heat Transf. 2013;20(5):379–88.

Wu PS, et al. Numerical flow and experimental heat transfer of S-shaped two-pass square channel with cooling applications to gas turbine blade. Int J Heat Mass Transf. 2017;108(Part A):362–73.

Fan X, et al. Local heat transfer of vortex cooling with multiple tangential nozzles in a gas turbine blade leading edge cooling passage. Int J Heat Mass Transf. 2018;126(Part B):377–89. https://doi.org/10.1016/j.ijheatmasstransfer.2018.06.018.

Hu KY, Chi X, et al. Steady RANS Of flow and heat transfer in a smooth and pin-finned U-duct with a trapezoidal cross section. In: ASME Turbo Expo 2018: Power for Land, Sea, and Air, Volume 5A: Heat Transfer: V05AT11A004. https://doi.org/10.1115/GT2018-75530.

Ashforh-Frost S. The use of liquid crystals in temperature visualization. In: Proceedings of Biomechanics’94, Technical University of Wroclaw, Poland, Oct. 20–23; 1994. p. 342–351.

Ashforh-Frost S, Jambunathan K. Flow visualization using liquid crystals. In: Proceedings of’93 SPIE International conference on optical diagnostics in fluid and thermal flow, San Diego, USA, July, 14–16; 1993. p. 237–245.

Kelker H, Hatz R. Technical applications of liquid crystals. Chem Ing Tech Ger. 1973;45(16):1005–13.

Brown GH. Structure properties and some applications of liquid crystals. J Opt Soc Am. 1973;63(12):1505–14.

Cooper TE, Field RJ, Meyer JF. Liquid crystal thermography and its application to the study of convective heat transfer. ASME J Heat Transf. 1975;97(3):442–50. https://doi.org/10.1115/1.3450396.

Goldstein RJ, Timmers JF. Visualization of heat transfer from arrays of impinging jets. Int J Heat Mass Transf. 1982;25(2):1857–68.

Richards CD, Richards RF. Transient temperature measurements in a convectively cooled droplet. Exp Fluids. 1999;25(5/6):392–400.

Ekkad SV. Gas turbine film cooling and heat transfer measurement using transient liquid crystal technique. Texas University, PhD. 1995.

Kline SJ, McClintock FA. Describing uncertainty in single-sample experiments. Mech Eng. 1953;75:3–8.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Uysal, U., Taymaz, I. Experimental investigation of heat transfer on trapezoidal channel with three passes. J Therm Anal Calorim 140, 953–964 (2020). https://doi.org/10.1007/s10973-019-08237-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08237-1