Abstract

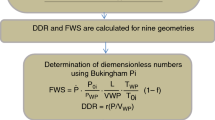

During rapid expansion in supersonic nozzles and turbine blades, under special conditions, steam may become supercooled vapor, and the heat release rate (\(\dot{Q}\)) due to phase change is substantial. Droplet radius (r) and wetness fraction (WF) are important parameters in designing wet steam equipment. Until now, cost-intensive and complicated methods are applied for designing wet steam equipment. In this paper, an innovative method based on Buckingham Pi dimensional analysis is proposed for predicting r and WF using dry vapor data. A dimensionless droplet radius (DDR) is obtained from the influential parameters at the Wilson point (named DWP). First, DWP, DDR, and WF are obtained from the results of the analytical modeling, and then, two regression equations are proposed for calculating DDR and WF with DWP. Finally, results of the proposed regression relationships are compared for seven analytical cases; the average percent errors associated with the presented equations for the droplet radius or DDR and WF percentage (\(\dot{Q}\)) are found to be less than 30% and 12%, respectively.

Similar content being viewed by others

Abbreviations

- A :

-

Area (m2)

- B :

-

Virial coefficients

- C :

-

Sonic velocity (m s−1)

- C L :

-

Specific heat capacity of liquid (J/kg K)

- d :

-

Number of main dimensions

- D :

-

Diffusion coefficient

- D e :

-

Hydraulic diameter

- DDR:

-

Dimensionless droplet radius

- DWP:

-

Droplet–wetness parameters

- E :

-

Total energy

- f :

-

Friction coefficient

- G :

-

Gibbs free energy change

- h :

-

Enthalpy (J kg−1)

- h fg :

-

Latent heat (J kg−1)

- j :

-

Number of repeated variables

- J :

-

Nucleation rate (#/m3 s)

- Kn :

-

Knudsen number

- L :

-

Divergent section length (m)

- Ma :

-

Mach number

- \(\dot{m}\) :

-

Mass flow rate (kg s−1)

- m L :

-

Droplet mass (kg)

- M L :

-

Liquid mass flow rate (kg s−1)

- M T :

-

Total mass flow rate (kg s−1)

- n :

-

Total number of dimensional (physical) variables

- N :

-

Number of molecules per unit mass

- P :

-

Pressure (kPa)

- P r :

-

Pressure ratio

- \(\dot{P}\) :

-

Dry expansion rate

- q c :

-

Condensation coefficient

- \(\dot{Q}\) :

-

Heat release rate due to phase change (W)

- r :

-

Droplet radius (μm)

- R :

-

Gas constant for steam (= 461.4 J/kg K)

- Sc :

-

Schmidt number \(\left( {\mu_{\text{G}} /\rho_{\text{G}} D} \right)\)

- T :

-

Temperature (K)

- U :

-

X-component velocity (m s−1)

- V :

-

Velocity (m s−1)

- WF:

-

Wetness fraction (ML/MT)

- x :

-

Cartesian direction (m)

- α r :

-

Droplet convectional heat transfer coefficient (W/m2 K)

- t :

-

Time (s)

- δ :

-

Tolman coefficient

- ΔT :

-

Degree of supercooling (K)

- λ :

-

Thermal conductivity of vapor (W/m K)

- μ :

-

Viscosity (m2 s−1)

- ρ :

-

Density (kg m−3)

- π :

-

Dimensionless group

- τ :

-

Viscous stress tensor (N m−2)

- θ :

-

Thermal (K)

- σ :

-

Liquid surface tension (N m)

- Γ:

-

Density of interfacial region

- 0:

-

Stagnation

- i:

-

Inlet

- K:

-

Kalva’s surface tension correction

- L:

-

Liquid

- s:

-

Saturation

- T:

-

Total

- G:

-

Gas (vapor)

- WP:

-

Wilson point

- ∞:

-

Flat surface tension

- *:

-

Critical condition

References

Keshavar OM, Jafarian A, Shekafti MS. Dynamic simulation of a heat recovery steam generator dedicated to a brine concentration plant. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-018-7448-8.

Acar MS, Arslan O. Energy and energy analysis of solar energy-integrated, geothermal energy-powered organic rankine cycle. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-018-7977-1.

Sun W, Chen D, Wang L, Peng W. A control-oriented modeling approach for two-phase flow plate heat exchanger. J Therm Anal Calorim. 2018;131(2):1735–46.

Sadeghi S, Maghsoudi P, Shabani B, Gorgani HH, Shabani N. Performance analysis and multi-objective optimization of an organic rankine cycle with binary zeotropic working fluid employing modified artificial bee colony algorithm. J Therm Anal Calorim. 2019. https://doi.org/10.1007/s10973-018-7801-y.

Sun W, Chen D, Wang L, Peng W. A control-oriented modeling approach for two-phase flow plate heat exchanger. J Therm Anal Calorim. 2018;131(2):1735–46.

Binnie AM, Woods MW. The pressure distribution in a convergent–divergent steam nozzle. Proc Inst Mech Eng. 1938;138(1):229–66.

Binnie AM, Green JR. An electrical detector of condensation in high-velocity steam. Proc R Soc Lond Ser A Math Phys Sci. 1942;181(985):134–54.

Deych MY, Kurshakov AV, Saltanov GA, Yatcheni IA. A study of the structure of two-phase flow behind a condensation shock in supersonic nozzles. Heat Transf Sov Res. 1969;1:95–105.

Stein GD. Angular and wavelength dependence of the light scattered from a cloud of particles formed by homogeneous nucleation. J Chem Phys. 1969;51(3):938–42.

Gyarmathy G, Lesch F. Paper 12: fog droplet observations in Laval nozzles and in an experimental turbine. In: Proceedings of the institution of mechanical engineers, conference proceedings; 184, No. 7); 1969. London: Sage. p. 29–36.

Krol T. Results of optical measurement of diameters of drops formed due to condensation of steam in a Laval nozzle. Trans Inst Fluid Flow Mach Pol. 1971;57:19–30.

Petr V. Measurement of an average size and number of droplets during spontaneous condensation of supersaturated steam. Proc Inst Mech Eng. 1970;23(184):22–8.

Barschdorff D, Dunning WJ, Wegener PP, Wu BJ. Homogeneous nucleation in steam nozzle condensation. Nat Phys Sci. 1972;240(103):166.

Moore MJ, Walters PT, Crane RI, Davidson BJ. Predicting the Fog Drop Size in Wet Steam Turbines, Wet Steam 4th Conference, Institute of Mechanical Engineers, UK, 1973, p. 101–9.

Moses CA, Stein GD. On the growth of steam droplets formed in a Laval nozzle using both static pressure and light scattering measurements. J Fluids Eng. 1978;100(3):311–22.

Young JB. Nucleation in high pressure steam and flow in turbines, vol. 16. Doctoral dissertation, University of Birmingham; 1973.

Bakhtar F, Ebrahimi M, Webb RA. On the performance of a cascade of turbine rotor tip section blading in nucleating steam: part 1: surface pressure distributions. Proc Inst Mech Eng C J Mech Eng Sci. 1995;209(2):115–24.

Dykas S, Majkut M, Strozik M, Smołka K. Experimental study of condensing steam flow in nozzles and linear blade cascade. Int J Heat Mass Transf. 2015;1(80):50–7.

Bakhtar F, Young JB. A comparison between theoretical calculations and experimental measurements of droplet sizes in nucleating steam flows. Trans Inst Fluid Flow Mach. 1976;16(70):259–71.

Somesaraee MT, Rad EA, Mahpeykar MR. Analytical investigation of simultaneous effects of convergent section heating of Laval nozzle, steam inlet condition, and nozzle geometry on condensation shock. J Therm Anal Calorim. 2018;133(2):1023–39.

Mahpeykar MR, Lakzian E, Amirirad E. Reduction of thermodynamic losses in a supersonic nucleating steam nozzle by spraying water droplets. 2009;253–262.

Lakzian E, Masjedi A. Slip effects on the exergy loss due to irreversible heat transfer in a condensing flow. Int J Exergy. 2014;14(1):22–37.

Lakzian E, Shaabani S. Analytical investigation of coalescence effects on the exergy loss in a spontaneously condensing wet-steam flow. Int J Exergy. 2015;16(4):383–403.

Bakhtar F, Tochai MM. An investigation of two-dimensional flows of nucleating and wet steam by the time-marching method. Int J Heat Fluid Flow. 1980;2(1):5–18.

Bakhtar F, Mahpeykar MR, Abbas K. An investigation of nucleating flows of steam in a cascade of turbine blading-theoretical treatment. J Fluids Eng. 1995;117(1):138–44.

Gerber AG, Mousavi A. Application of quadrature method of moments to the polydispersed droplet spectrum in transonic steam flows with primary and secondary nucleation. Appl Math Model. 2007;31(8):1518–33.

Abadi SN, Kouhikamali R. CFD-aided mathematical modeling of thermal vapor compressors in multiple effects distillation units. Appl Math Model. 2016;40(15–16):6850–68.

Xinggang Y, Danmei X, Cong W, Chun W, Chu N. Numerical investigation of condensing flow in the last stage of low-pressure nuclear steam turbine. Nucl Eng Des. 2014;1(275):197–204.

Halama J, Hric V, Pátý M. Numerical solution of transonic flow of steam with non-equilibrium phase change using typical and simplified method. Appl Math Comput. 2018;15(319):499–509.

Bakhtar F, Webb RA. Tabular method of estimating nucleating steam flows. Int J Heat Fluid Flow. 1983;4(4):217–27.

Mahpeykar MR, Mohammadi AR. Effect of important thermophysical properties on condensation shock in a steam flow. J Thermophys Heat Transf. 2013;27(2):286–97.

Amiri Rad E, Mahpeykar MR, Teymourtash AR. Analytic investigation of the effects of condensation shock on turbulent boundary layer parameters of nucleating flow in a supersonic convergent–divergent nozzle. Sci Iran. 2014;12:21.

Yousefi Rad E, Mahpeykar MR. A novel hybrid approach for numerical modeling of the nucleating flow in Laval nozzle and transonic steam turbine blades. Energies. 2017;10(9):1285.

Rai P, Gautam N, Chandra H. An experimental approach of generation of micro/nano scale liquid droplets by electrohydrodynamic atomization (EHDA) process. Mater Today Proc. 2017;4(2):611–20.

Li CJ, Su CC. Characteristics of a series-connected two-evaporator refrigerating system. Appl Therm Eng. 2005;25(4):519–32.

Ma J, Zhou P, Cheng W, Song Y, Shi P. Dimensional analysis and experimental study of gas penetration depth model for submerged side-blown equipment. Exp Therm Fluid Sci. 2016;1(75):220–7.

Lin JH, Huang CY, Su CC. Dimensional analysis for the heat transfer characteristics in the corrugated channels of plate heat exchangers. Int Commun Heat Mass Transf. 2007;34(3):304–12.

Nazaruddin AT, Mohamed Z, Mohd Azizul L, Hafez MA. Prediction of axial limit capacity of stone columns using dimensional analysis. In: 2nd International conference on applied physics and engineering (ICAPE 2016). American Institute of Physics Inc; 2017; p. 8.

Zohuri B. Dimensional analysis beyond the Pi theorem. Berlin: Springer; 2017.

Asadov SM, Mustafaeva SN, Mammadov AN. Thermodynamic assessment of phase diagram and concentration–temperature dependences of properties of solid solutions of the GaS–GaSe system. J Therm Anal Calorim. 2018;133(2):1135–41. https://doi.org/10.1007/s10973-018-6967-7.

Madhurambal G, Mariappan M, Selvarajan G, Mojumdar SC. Investigation on nucleation kinetics of urea–thiourea mixed crystal (UTMC) in methanol and absolute alcohol. J Therm Anal Calorim. 2015;119(2):931–8.

Henderson DW. Experimental analysis of non-isothermal transformations involving nucleation and growth. J Therm Anal. 1979;15(2):325–31.

Hale BN, DiMattio DJ. Scaling of the nucleation rate and a Monte Carlo discrete sum approach to water cluster free energies of formation. J Phys Chem B. 2004;108(51):19780–5.

Girshick SL, Chiu CP. Kinetic nucleation theory: a new expression for the rate of homogeneous nucleation from an ideal supersaturated vapor. J Chem Phys. 1990;93(2):1273–7.

Kalová J, Mareš R. Size dependences of surface tension. Int J Thermophys. 2015;36(10–11):2862–8.

Gerber AG. Two-phase Eulerian/Lagrangian model for nucleating steam flow. J Fluids Eng. 2002;124(2):465–75.

Kermani MJ, Gerber AG. A general formula for the evaluation of thermodynamic and aerodynamic losses in nucleating steam flow. Int J Heat Mass Transf. 2003;46(17):3265–78.

Senoo S, White AJ. Numerical simulations of unsteady wet steam flows with non-equilibrium condensation in the nozzle and the steam turbine. In ASME 2006 2nd joint US-European fluids engineering summer meeting collocated with the 14th international conference on nuclear engineering, vol 1. American Society of Mechanical Engineers; 2006. p. 757–767.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix

Appendix

Nozzle Young A

-

Converging length: L = 81.724 mm

-

Converging radius: R = 127.0 mm

-

Nozzle depth: depth = 12.395 mm = constant

-

Diverging section: W = 24.926 + 0.041358 x2 0 < x < 2.541 mm

-

W = 24.650 + 0.2101x 2.541 < x < 100.0 mm

Nozzle Young B

-

Converging length: L = 83.0 mm

-

Converging radius: R = 150.11 mm

-

Nozzle depth: depth = 12.395 mm = constant

-

Diverging section: W = 24.9869 + 0.007923 x2 + 0.0001637 x3 0 < x < 10 mm

-

W = 23.749 + 0.20757x 10 < x < 117.0 mm

Nozzle Moore

Nozzle Krol

-

Converging length: L = 43.18 mm

-

Nozzle depth: depth = 25 mm

-

Converging section: width = 30.58 mm − 0.02269x

-

Diverging section: W = 29.6 + 0.002578 x2 0 < x < 15.24 mm

-

W = 30.18 + 0.07857x 15.24 < x < 254.0 mm

Nozzle Binnie and Green

-

Converging length: L = 50.39 mm

-

Converging radius: R = 124.87 mm

-

Nozzle depth: depth = 22.20 mm = constant

-

Diverging section: W = 19.075 + 0.02758 x2 0 < x < 1.27 mm

-

W = 19.032 + 0.07005x 1.27 < x < 157.0 mm

Nozzle Binnie and Woods

-

Converging length: L = 49.784 mm

-

Converging radius: R = 156.53 mm

-

Nozzle depth: depth = 9.625 mm = constant

-

Diverging section: W = 35.382 + 0.0002546 x2 + 0.003148 x3 0 < x < 3.81 mm

-

W = 35.030 + 0.13903x 3.81 < x < 158.0 mm

Rights and permissions

About this article

Cite this article

Salmani, F., Mahpeykar, M.R. Dimensional analysis for estimating wetness terms of condensing steam using dry flow data. J Therm Anal Calorim 137, 2121–2134 (2019). https://doi.org/10.1007/s10973-019-08108-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08108-9