Abstract

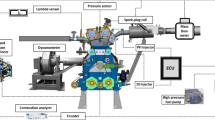

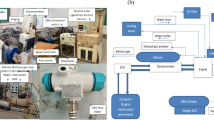

This paper investigates the effect of some biofuels on thermal balance and performance characteristics of a single-cylinder, four-stroke SI internal combustion engine. In this study, total and instantaneous energy balance of an air-cooled, small-scale engine using various biofuels is investigated. An experimental study is carried out on gasoline engine to validate the numerical calculations. Bio-alternative fuels which include methanol, ethanol and 2-ethanol–gasoline-blended fuels consisting of E85, E15 are examined numerically. Results indicate that methanol is the most effective fuel in aspect of power generation. Ethanol, E85, E15 and gasoline are placed in next positions, respectively. Break specific fuel consumption shows totally reversed trend. It is evaluated that by increasing engine speed, heat transfer to brake power ratio decreases and lower percentage of energy in form of heat transfer is lost. The least heat transfer to brake power ratio among studied fuel is related to methanol which approves it as the most efficient biofuel. Based on instantaneous in-cylinder energy balance analysis, at the end of combustion and during expansion stroke, instantaneous brake work of fuels outpaces each other at around 40° crank angle aTDC.

Similar content being viewed by others

Abbreviations

- \(P\) :

-

Cylinder pressure (kPa)

- \(\theta\) :

-

Crank angle (°)

- \(\gamma\) :

-

Specific heat ratio

- \(x_{\text{b}}\) :

-

Mass fraction burned

- \(q_{\text{w}}\) :

-

Engine’s wall heat loss (J)

- \(V\) :

-

In-cylinder volume (m3)

- \(V_{\text{C}}\) :

-

Cylinder clearance volume (m3)

- \(B\) :

-

Cylinder bore (m)

- \(l\) :

-

Connecting rod’s length (m)

- \(a\) :

-

Crank radius (m)

- \(s\) :

-

Distance between piston pin axis and crank axis (m)

- \(a\) :

-

Adjustable parameter

- \(m\) :

-

Adjustable parameter

- \(\theta_{0}\) :

-

Start of combustion (°)

- \(h\) :

-

Heat transfer coefficient (W m−2 K−1)

- \(T\) :

-

Temperature (K)

- \(\omega\) :

-

Average cylinder gas velocity (m s−1)

- \(A_{\text{w}}\) :

-

Wall area (m2)

- \(T_{\text{w}}\) :

-

Wall temperature (K)

- \(T_{\text{g}}\) :

-

In-cylinder gas temperature (K)

- \(C_{1}\) :

-

Constant parameter

- \(\bar{S}_{\text{P}}\) :

-

Mean piston speed (m s−1)

- \(C_{2}\) :

-

Constant parameter

- \(T_{\text{r}}\) :

-

Working-fluid temperature (K)

- \(P_{\text{r}}\) :

-

Working-fluid pressure (kPa)

- \(V_{\text{r}}\) :

-

Working-fluid volume (m3)

- \(P_{\hbox{max} }\) :

-

In-cylinder maximum pressure (kPa)

- \(P_{\text{m}}\) :

-

Motored cylinder pressure (kPa)

- \(N\) :

-

Engine speed (rpm)

- \(\dot{E}\) :

-

Rate of energy (kJ)

- \(\dot{Q}_{\text{fuel}}\) :

-

Fuel power (kW)

- \(\dot{W}_{\text{b}}\) :

-

Brake power (kW)

- \(\dot{Q}_{\text{ex}}\) :

-

Dissipated power by exhaust (kW)

- \(\dot{Q}_{\text{ht}}\) :

-

Dissipated power by heat transfer (kW)

- \(Q_{\text{HV}}\) :

-

Fuel heating value (kJ kg−1)

- \(\eta_{\text{c}}\) :

-

Combustion efficiency

- \(\dot{m}_{\text{a}}\) :

-

Mass flow rate of air (kg s−1)

- \(\dot{m}_{\text{f}}\) :

-

Mass flow rate of fuel (kg s−1)

- \(T_{\text{ex}}\) :

-

Exhaust gases temperature (°C)

- \(T_{\text{a}}\) :

-

Ambient temperature (°C)

- \(C_{\text{ex}}\) :

-

Average specific heat of exhaust gases (kJ kg−1 K−1)

- \(V_{\text{d}}\) :

-

Displacement volume (m3)

- \(n\) :

-

Number of cylinders

- \({\text{bmep}}\) :

-

Brake mean effective pressure (bar)

- \({\text{imep}}\) :

-

Indicated mean effective pressure (bar)

- \({\text{fmep}}\) :

-

Friction mean effective pressure (bar)

References

Bae C, Kim J. Alternative fuels for internal combustion engines. Proc Combust Inst. 2017;36(3):3389–413. https://doi.org/10.1016/j.proci.2016.09.009.

Dantas MB, Albuquerque AR, Soledade LEB, Queiroz N, Maia AS, Santos IMG, et al. Biodiesel from soybean oil, castor oil and their blends. J Therm Anal Calorim. 2011;106(2):607–11. https://doi.org/10.1007/s10973-011-1410-3.

Farias AFF, da Conceição MM, Cavalcanti EHS, Melo MAR, dos Santos IMG, de Souza AG. Analysis of soybean biodiesel additive with different formulations of oils and fats. J Therm Anal Calorim. 2016;123(3):2121–7. https://doi.org/10.1007/s10973-015-4772-0.

Vallinayagam R, Vedharaj S, Roberts WL, Dibble RW, Sarathy SM. Performance and emissions of gasoline blended with terpineol as an octane booster. Renew Energy. 2017;101:1087–93. https://doi.org/10.1016/j.renene.2016.09.055.

Othman MF, Adam A, Najafi G, Mamat R. Green fuel as alternative fuel for diesel engine: a review. Renew Sustain Energy Rev. 2017;80:694–709. https://doi.org/10.1016/j.rser.2017.05.140.

Hu T, Wei Y, Liu S, Zhou L. Improvement of spark-ignition (SI) engine combustion and emission during cold start, fueled with methanol/gasoline blends. Energy Fuels. 2007;21(1):171–5. https://doi.org/10.1021/ef0603479.

Reed TB, Lerner R. Methanol: a versatile fuel for immediate use. Science. 1973;182(4119):1299–304. https://doi.org/10.1126/science.182.4119.1299.

Çelik MB, Özdalyan B, Alkan F. The use of pure methanol as fuel at high compression ratio in a single cylinder gasoline engine. Fuel. 2011;90(4):1591–8. https://doi.org/10.1016/j.fuel.2010.10.035.

Kim S, Dale BE. Environmental aspects of ethanol derived from no-tilled corn grain: nonrenewable energy consumption and greenhouse gas emissions. Biomass Bioenergy. 2005;28(5):475–89. https://doi.org/10.1016/j.biombioe.2004.11.005.

Awad OI, Mamat R, Ali OM, Sidik N, Yusaf T, Kadirgama K, et al. Alcohol and ether as alternative fuels in spark ignition engine: a review. Renew Sustain Energy Rev. 2017. https://doi.org/10.1016/j.rser.2017.09.074.

Taymaz I. An experimental study of energy balance in low heat rejection diesel engine. Energy. 2006;31(2):364–71. https://doi.org/10.1016/j.energy.2005.02.004.

Gharehghani A, Koochak M, Mirsalim M, Yusaf T. Experimental investigation of thermal balance of a turbocharged SI engine operating on natural gas. Appl Therm Eng. 2013;60(1):200–7. https://doi.org/10.1016/j.applthermaleng.2013.06.029.

Payri F, Olmeda P, Martín J, Carreño R. Experimental analysis of the global energy balance in a DI diesel engine. Appl Therm Eng. 2015;89:545–57. https://doi.org/10.1016/j.applthermaleng.2015.06.005.

Li T, Caton JA, Jacobs TJ. Energy distributions in a diesel engine using low heat rejection (LHR) concepts. Energy Convers Manag. 2016;130:14–24. https://doi.org/10.1016/j.enconman.2016.10.051.

Qasemian A, Azarikhah P, Jenabi Haqparast S. Derivation of specific heat rejection correlation in an SI engine; experimental and numerical study. Int J Automot Eng. 2018;8(2):2679–91. https://doi.org/10.22068/ijae.8.2.2679.

Shojaeefard MH, Azarikhah P, Qasemian A. Experimental investigation of thermal balance and valve cover heat transfer in a small internal combustion engine. Int J Automot Eng. 2017;7(2):2423–33. https://doi.org/10.22068/ijae.7.2.2423.

Durgun O, Şahin Z. Theoretical investigation of heat balance in direct injection (DI) diesel engines for neat diesel fuel and gasoline fumigation. Energy Convers Manag. 2009;50(1):43–51. https://doi.org/10.1016/j.enconman.2008.09.007.

Wu Y-Y, Chen B-C, Hsieh F-C. Heat transfer model for small-scale air-cooled spark-ignition four-stroke engines. Int J Heat Mass Transf. 2006;49(21–22):3895–905.

Ajav E, Singh B, Bhattacharya T. Thermal balance of a single cylinder diesel engine operating on alternative fuels. Energy Convers Manag. 2000;41(14):1533–41. https://doi.org/10.1016/S0196-8904(99)00175-2.

Yingjian L, Qi Q, Xiangzhu H, Jiezhi L. Energy balance and efficiency analysis for power generation in internal combustion engine sets using biogas. Sustain Energy Technol Assess. 2014;6:25–33. https://doi.org/10.1016/j.seta.2014.01.003.

Abedin M, Masjuki H, Kalam M, Sanjid A, Rahman SA, Masum B. Energy balance of internal combustion engines using alternative fuels. Renew Sustain Energy Rev. 2013;26:20–33. https://doi.org/10.1016/j.rser.2013.05.049.

Magno A, Mancaruso E, Vaglieco BM. Effects of a biodiesel blend on energy distribution and exhaust emissions of a small CI engine. Energy Convers Manag. 2015;96:72–80. https://doi.org/10.1016/j.enconman.2015.02.066.

Yusri I, Mamat R, Azmi W, Najafi G, Sidik N, Awad OI. Experimental investigation of combustion, emissions and thermal balance of secondary butyl alcohol–gasoline blends in a spark ignition engine. Energy Convers Manag. 2016;123:1–14. https://doi.org/10.1016/j.enconman.2016.05.082.

Doğan B, Erol D, Yaman H, Kodanli E. The effect of ethanol–gasoline blends on performance and exhaust emissions of a spark ignition engine through exergy analysis. Appl Therm Eng. 2017;120(Supplement C):433–43. https://doi.org/10.1016/j.applthermaleng.2017.04.012.

Yusoff M, Zulkifli N, Masjuki H, Harith M, Syahir A, Kalam M, et al. Performance and emission characteristics of a spark ignition engine fuelled with butanol isomer–gasoline blends. Transp Res Part D Transp Environ. 2017;57:23–38. https://doi.org/10.1016/j.trd.2017.09.004.

Singh N, Kumar H, Jha M, Sarma AK. Complete heat balance, performance, and emission evaluation of a CI engine fueled with Mesua ferrea methyl and ethyl ester’s blends with petrodiesel. J Therm Anal Calorim. 2015;122(2):907–16.

Dhinesh B, Annamalai M. A study on performance, combustion and emission behaviour of diesel engine powered by novel nano nerium oleander biofuel. J Clean Prod. 2018;196:74–83.

Dhinesh B, Raj YMA, Kalaiselvan C, KrishnaMoorthy R. A numerical and experimental assessment of a coated diesel engine powered by high-performance nano biofuel. Energy Convers Manag. 2018;171:815–24.

Vigneswaran R, Annamalai K, Dhinesh B, Krishnamoorthy R. Experimental investigation of unmodified diesel engine performance, combustion and emission with multipurpose additive along with water-in-diesel emulsion fuel. Energy Convers Manag. 2018;172:370–80.

Ramalingam K, Kandasamy A, Subramani L, Balasubramanian D, Thadhani JPJ. An assessment of combustion, performance characteristics and emission control strategy by adding anti-oxidant additive in emulsified fuel. Atmos Pollut Res. 2018;9:959–67.

Subramani L, Parthasarathy M, Balasubramanian D, Ramalingam K. Novel Garcinia gummi-gutta methyl ester (GGME) as a potential alternative feedstock for existing unmodified DI diesel engine. Renew Energy. 2018;125:568–77.

Vinukumar K, Azhagurajan A, Vettivel SC, Vedaraman N. Rice husk as nanoadditive in diesel–biodiesel fuel blends used in diesel engine. J Therm Anal Calorim. 2018;131(2):1333–43. https://doi.org/10.1007/s10973-017-6692-7.

Tamilvanan A, Balamurugan K, Vijayakumar M. Effects of nano-copper additive on performance, combustion and emission characteristics of Calophyllum inophyllum biodiesel in CI engine. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7743-4.

Ramajo D, Zanotti A, Nigro N. Assessment of a zero-dimensional model of tumble in four-valve high performance engine. Int J Numer Methods Heat Fluid Flow. 2007;17(8):770–87.

Ferguson CR, Kirkpatrick AT. Internal combustion engines: applied thermosciences. 3rd ed. New York: Wiley; 2016.

Heywood JB. Internal combustion engine fundamentals. New York: McGraw-hill; 1988.

Yeliana, Cooney C, Worm J, Naber J. The calculation of mass fraction burn of ethanol–gasoline blended fuels using single and two-zone models. Pittsburgh: SAE International; 2008.

Yun KT, Cho H, Luck R, Mago PJ. Modeling of reciprocating internal combustion engines for power generation and heat recovery. Appl Energy. 2013;102:327–35. https://doi.org/10.1016/j.apenergy.2012.07.020.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Azarikhah, P., Haghparast, S.J. & Qasemian, A. Investigation on total and instantaneous energy balance of bio-alternative fuels on an SI internal combustion engine. J Therm Anal Calorim 137, 1681–1692 (2019). https://doi.org/10.1007/s10973-019-08063-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-019-08063-5