Abstract

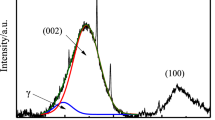

In this study, a combustion study of tire pyrolytic carbon black (CBp), gas coal (GC), and their blends was carried out by thermogravimetric analysis with four heating rates under air atmosphere. And the structure characteristics of CBp and GC were studied using particle size distribution, scanning electron microscope, X-ray diffraction, Raman spectra followed by peak deconvolution and data analysis. The results demonstrated that the structural differences between CBp and GC directly affected their thermal behavior trends. GC with low graphitization degree had more combustibility reactivity than that of CBp, while the mean reaction rate and maximum reaction rate of CBp were larger than GC due to its bigger specific surface area and higher porosity. For blends, the combustibility reactivity could be improved by blending with GC, and there was obviously synergetic effect for the co-combustion of CBp and GC. The combustion reaction mechanisms and kinetic parameters were carried out using three non-isothermal kinetic models: random nucleation nuclei growth model (RNGM), volume reaction model, and unreacted core model. The kinetic analysis demonstrated that the RNGM model had a better performance than other models for describing the thermal behavior of the selected samples. In addition, the synergetic effect between CBp and GC was observed from the kinetics data calculated by RNGM. The activation energies of CBp and GC calculated by RNGM model were 119.6 kJ mol−1 and 126.4 kJ mol−1, respectively, whereas the lowest activation energy for their blends was 104.3 kJ mol−1 when CBp ratio was 40%.

Similar content being viewed by others

References

Wu B, Zhou MH. Recycling of waste tyre rubber into oil absorbent. Waste Manag. 2009;29:355–9.

Ramarad S, Khalid M, Ratnam CT. Waste tire rubber in polymer blends: a review on the evolution, properties and future. Progress Mater Sci. 2015;72:100–8.

Aranda A, Murillo R, Garcia T. Steam activation of tyre pyrolytic carbon black: kinetic study in a thermobalance. Chem Eng J. 2007;126:79–85.

Fukumori K, Matsushita M, Okamoto H, Sato N, Takeuchi K. Recycling technology of tire rubber. JSAE Rev. 2002;23:259–64.

Karger J, Mészáros L, Bárány T. Ground tyre rubber (GTR) in thermoplastics, thermosets, and rubbers. J Mater Sci. 2013;48:1–38.

Zhu BZ, Cheng G, Wang Y. Review of Recycling Utilization for Waste Tire in China. Guangzhou Chem Ind. 2014;42:11–2.

Li L, Liu S, Zhu T. Application of activated carbon derived from scrap tires for adsorption of Rhodamine B. J Environ Sci. 2010;22:1273–80.

Aylón E, Fernández-Colino A, Murillo R. Valorisation of waste tyre by pyrolysis in a moving bed reactor. Waste Manag. 2010;30:1220–4.

Frigo S, Seggiani M, Puccini M. Liquid fuel production from waste tyre pyrolysis and its utilisation in a diesel engine. Fuel. 2014;116:399–408.

Li S, Wan C, Wang S. Separation of core-shell structured carbon black nanoparticles from waste tires by light pyrolysis. Comp Sci Technol. 2016;135:13–20.

Li S, Wan C, Wu X. Core-shell structured carbon nanoparticles derived from light pyrolysis of waste tires. Polym Degrad Stab. 2016;129:192–8.

Ware PS. Pyrolysis of waste tyres and future. Chem Biol. 2015;1:1–9.

Sawada Y. Iron and steel production and technology in Japan during 2004. ISIJ. 2005;45:771–90.

Allen JL, Gatz JL, Eklund PC. Applications for activated carbons from used tires: butane working capacity. Carbon. 1999;37:1485–9.

Wang G, Zhang J, Chang W. Structural features and gasification reactivity of biomass chars pyrolyzed in different atmospheres at high temperature. Energy. 2018;147:25–35.

Wang G, Zhang J, Zhang G. Experimental and kinetic studies on co-gasification of petroleum coke and biomass char blends. Energy. 2017;131:27–40.

Wang G, Zhang J, Shao J. Experimental and modeling studies on CO2 gasification of biomass chars. Energy. 2016;114:143–54.

Wang G, Zhang J, Shao J. Thermal behavior and kinetic analysis of co-combustion of waste biomass/low rank coal blends. Energy Convers Manag. 2016;124:414–26.

Çepelioğullar Ö, Pütün AE. Thermal and kinetic behaviors of biomass and plastic wastes in co-pyrolysis. Energy Convers Manag. 2013;75:263–70.

Zhou L, Wang Y, Huang Q. Thermogravimetric characteristics and kinetic of plastic and biomass blends co-pyrolysis. Fuel Process Technol. 2006;87:963–9.

Wang Q, Zhang J, Wang G. Thermal and kinetic analysis of a coal with different waste plastic (PVC) in co-combustion. Energy Fuels. 2018;32:2145–55.

Ma S, Lu J, Gao J. Study of the low temperature pyrolysis of PVC. Energy Fuels. 2002;16:338–42.

Zhao D, Zhang J, Wang G. Structure characteristics and combustibility of carbonaceous materials from blast furnace flue dust. Appl Therm Eng. 2016;108:1168–77.

Bhatia SK, Perlmutter DD. A random pore model for fluid-solid reactions: I isothermal, kinetic control. AIChE J. 1980;26:379–86.

Bhatia SK, Perlmutter DD. A random pore model for fluid-solid reactions: II diffusion and transport effects. AIChE J. 1981;27:247–54.

Ochoa J, Cassanello MC, Bonelli PR. CO2 gasification of argentinean coal chars: a kinetic characterization. Fuel Process Technol. 2001;74:161–76.

Kasaoka S, Sakata Y, Kayano S. Kinetic evaluation of reactivity of various coal chars for gasification with carbon dioxide in comparison with stream. Int Chem Eng. 1984;25:160–75.

Yuh SJ, Wolf EE. Kinetic and FTIR studies of the sodium catalyzed steam gasification of coal char. Fuel. 1984;63:1604–9.

Xu YG, Zhang C, Xia J. Experimental study on the comprehensive behavior of combustion for blended coals. Asia-Pacific J Chem Eng. 2010;5:435–40.

Essenhigh RH, Misra MK, Shaw SW. Ignition of coal particles: a review. Combust Flame. 1989;77:3–30.

Hu SC, Ma XQ, Lin YS, Yu ZS, Fang SW. Thermogravimetric analysis of the cocombustion of paper sludge and municipal solid waste. Energy Convers Manag. 2015;99:112–8.

Aranda A, Murillo R, García T. Steam activation of tyre pyrolytic carbon black: kinetic study in a thermobalance. Chem Eng J. 2007;126:79–85.

Li X, Hayashi J, Li CZ. FT-Raman spectroscopic study of the evolution of char structure during the pyrolysis of a Victorian brown coal. Fuel. 2006;85:1700–7.

Dun W, Guijian L. Investigation of structural characteristics of thermally metamorphosed coal by FTIR spectroscopy and X-ray diffraction. Energy Fuels. 2013;27:5823–30.

Li K, Khanna R, Zhang J. Comprehensive investigation of various structural features of bituminous coals using advanced analytical techniques. Energy Fuels. 2015;29:7178–89.

Xu RS, Zhang JL, Wang GW. Devolatilization characteristics and kinetic analysis of lump coal from China COREX3000 under high temperature. Metall Mater Trans B. 2016;47:2535–48.

Jiang JP, Luo GY, Kang JW. Study on XRD and dynamometamorphism of fault coal. J China Coal Soc. 2001;1:31–4.

Wen JL, Sun SL, Yuan TQ, Xu F. Understanding the chemical and structural transformation of lignin macromolecule during torrefaction. Appl Energy. 2014;121:1–9.

Takagi H, Maruyama K, Yoshizawa N, Yamada Y, Sato Y. XRD analysis of carbon stacking structure in coal during heat treatment. Fuel. 2004;83:2427–33.

Wu S, Gu J, Zhang X. Variation of carbon crystalline structures and CO2 gasification reactivity of Shenfu coal chars at elevated temperatures. Energy Fuel. 2007;22:199–206.

Li RP, Zhang JL, Wang GW. Study on CO2 gasification reactivHity of biomass char derived from high-temperature rapid pyrolysis. Appl Therm Eng. 2017;121:1022–31.

Wang G, Zhang J, Hou X. Study on CO2 gasification properties and kinetics of biomass chars and anthracite char. Bioresour Technol. 2015;177:66–73.

Shen BX, Liu DC, Chen HP. The kinetic parameters of petroleum coke pyrolysis and their compensating effect. J Huazhong Univ Sci Technol. 1999;27:36–7.

Yu RG, Chen Y, Lin C, Zhang JY. Catalytic gasification kinetics and compensation effect of high metamorphosed anthracite. Combust Sci Technol. 2012;18:85–9.

Acknowledgements

This work was supported by the Yong Elite Scientists Sponsorship Program by CAST (2017QNRC001). The authors are grateful to the Natural Science Foundation for Young Scientists of China (No. 51704019) for the financial support.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, Q., Wang, G., Zhang, J. et al. Thermal and kinetic behaviors of pyrolytic carbon black and gas coal in co-combustion. J Therm Anal Calorim 137, 193–204 (2019). https://doi.org/10.1007/s10973-018-7938-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7938-8