Abstract

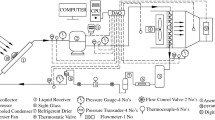

The thermodynamic analysis of direct expansion solar-assisted heat pump system working with R290 as a drop-in substitute for R22 was carried out under the metrological conditions of Calicut, India. A prototype of a DXSAHP system consists of a compressor, an air-cooled condenser with evaporator–collector and thermostatic expansion valve. The experiments were carried during the winter months of 2016. The artificial intelligence technique artificial neural network integrated with genetic algorithm model was presented to predict energy and exergy performance of a system. The energy performance ratio of a system was found to be 5.75% higher and reduced heating capacity of about 6.8% when compared to R22. Similarly, the second law analysis (exergy analysis) of a total system working with R290 was found to be better when compared to baseline refrigerant. The selected alternative working fluid is a hydrocarbon and has zero ozone depletion and negligible global warming potential. Hence, R290 can be used as a drop-in substitute for R22 in DXSAHP systems.

Similar content being viewed by others

References

Sporn P, Ambrose ER. The heat pump and solar energy. In: Proceedings of the world symposium on applied solar energy, Phoenix: 1955

Ito S, Miura N, Wang K. Performance of a heat pump using direct expansion type solar collectors. Solar Energy. 1999;65(1):189–96.

Daghigh R, Ruslan MH, Sulaiman MY, Sopian K. Review of solar assisted heat pump drying systems for agricultural and marine products. Renew Sustain Energy Rev. 2010;14(1):2564–79.

Fadhel MI, Sopian MI, Daud WRW, Alghoul MA. Review on advanced of solar assisted chemical heat pump dryer for agriculture produce. Renew Sustain Energy Rev. 2011;15(1):115268.

Kalogirou SA. Seawater desalination using renewable energy sources. Prog Energy Combust Sci. 2005;31(1):242–81.

Hepbasli A, Kalinci Y. A review of heat pump water heating systems. Renew Sustain Energy Rev. 2009;13:121129.

Mohanraj M, Jayaraj S, Muraleedharan C. Environment friendly alternatives to halogenated refrigerants A review. Int J Green House Gas Emiss Control. 2009;1:3108–19.

Mohanraj M, Belyayev Y, Jayaraj S, Kaltayev SA. Research and developments on solar assisted compression heat pump systems A comprehensive review (Part A: modeling and modifications). Renew Sustain Energy Rev. 2018;83(1):90–123.

Mohanraj M, Belyayev Y, Jayaraj S, Kaltayev SA. Research and developments on solar assisted compression heat pump systems A comprehensive review (Part-B: applications). Renew Sustain Energy Rev. 2018;83(1):124–55.

Purkayastha B, Bansal P. An experimental study on HC290 and a commercial liquefied petroleum gas (LPG) mix as suitable replacements for HCFC22. Int J Refrig. 1998;21(1):213–7.

Chang Y, Kim M, Ro S. Performance and heat transfer characteristics of hydrocarbon refrigerants in a heat pump system. Int J Refrig. 2000;23(1):232–42.

Park KJ, Shim YB, Jung D. Performance of heat pumps charged with R170/R290 mixture. Appl Therm Eng. 2009;83(1):2598–600.

Park KJ, Shim YB, Jung D. Performance of R433A for replacing HCFC22 used in residential air-conditioners and heat pumps. Appl Therm Eng. 2008;85(1):896–900.

Park KJ, Shim YB, Jung D. Experimental performance of R432A to replace R22 in residential air-conditioners and heat pumps. Appl Therm Eng. 2009;23:597–600.

Chaichana C, Lu A, Charters WWS. Natural working fluids for solar boosted heat pumps. Int J Refrig. 2003;26:637–43.

Kara O, Ulgen K, Hepbasli A. Exergitic assessment of a direct expansion solar assisted heat pump systems: review and modeling. Renew Sustain Energy Rev. 2008;12(1):1383–401.

Mohanraj M, Jayaraj S, Muraleedharan C. A comparison of the performance of a direct expansion solar assisted heat pump working with R22 and a mixture of R407Cliquefied petroleum gas. Proc Inst Mech Eng Part A J Power Energy. 2009;223(1):821–33.

Mohanraj M, Jayaraj S, Muraleedharan C. Exergy assessment of a direct expansion solar-assisted heat pump working with R22 and R407C/LPG mixture. Int J Green Energy. 2010;7(1):6583.

Hepbasli A. A key review on exergetic analysis and assessment of renewable energy resources for a sustainable future. Renew Sustain Energy Rev. 2008;12(1):593–661.

Torres RE, Picon NP, Cervantes GJ. Exergy analysis and optimization of a solar-assisted heat pump. Energy. 1998;23(1):337–44.

Cervantes GJ, Torres R E. Experiments on a solar-assisted heat pump and an exergy analysis of the system. Appl Therm Eng. 2002;22(1):1289–97.

Viorel B. First and second law analysis of a solar assisted heat pump based heating system. Energy Convers Manag. 2002;43(1):2539–52.

Mohanraj M, Jayaraj S, Muraleedharan C. Applications of artificial neural networks for refrigeration, air-conditioning and heat pump systems A review. Renew Sustain Energy Rev. 2012;16(1):1340–58.

Mohanraj M, Jayaraj S, Muraleedharan C. Performance prediction of a direct expansion solar assisted heat pump using artificial neural networks. Appl Energy. 2009;86(1):1442–9.

Mohanraj M, Jayaraj S, Muraleedharan C. Exergy analysis of direct expansion solar-assisted heat pumps using artificial neural networks. Int J Energy Res. 2009;33(1):1005–20.

Bs EN, 378, Refrigerating systems and heat pumps safety and environmental requirements, 2000.

Kim M, Kim MS, Kim Y. Experimental study on the performance of a heat pump system with refrigerant mixtures composition change. Energy. 2004;29(7):1053–68.

Lokesh P, Srinivas M, Jayaraj S. Parametric studies of a simple direct expansion solar assisted heat pump operating in a hot and humid environment. Energy Procedia. 2016;90(1):635–44.

Kalogirou SA. Applications of artificial neural-networks for energy systems. Appl Energy. 2000;67(1–2):17–35.

Author information

Authors and Affiliations

Corresponding author

Appendices

Appendix A

The following typical values are considered for uncertainty calculation.

\(\hbox {T}_{1}\) = 10.51\(\,\pm \,\)0.01\(^\circ\)C \(\hbox {T}_{2}\) = 81.62\(\,\pm \,\)0.01\(^\circ\)C \(\hbox {T}_{3}\) = 48.12\(\,\pm \,\)0.01\(^\circ\)C \(\hbox {T}_{4}\) = 8.68\(\,\pm \,\)0.01\(^\circ\)C

\(\hbox {T}_{\mathrm{ciat}}\) = 34.46\(\,\pm \,\)0.01\(^\circ\)C \(\hbox {T}_{\mathrm{coat}}\) = 47.32\(\, \pm \,\)0.01\(^\circ\)C \(\hbox {T}_{\mathrm{o}}\) = 34.46\(\,\pm \,\)0.01\(^\circ\)C

\(\hbox {P}_{1}\) = 4.80\(\,\pm \,\)0.05 bar \(\hbox {P}_{2}\) = 1.68\(\,\pm \,\)0.02 bar \(\hbox {P}_{3}\) = 1.62\(\,\pm \,\)0.05 bar \(\hbox {P}_{4}\) = 4.15\(\,\pm \,\)0.05 bar

\(\hbox {Q}_{\mathrm{c}}\) = 3468 W \(\hbox {V}_{\mathrm{air}}\) = 3.5\(\,\pm \,\)0.1 m/s \(\hbox {m}_{\mathrm{r}}\) = 0.03\(\,\pm \,\)0.0001 kg/s I = 860 \(\,\pm \,\) 5 W/m\(^2\)

\(\hbox {m}_{\mathrm{air}}\) = 0.228\(\,\pm \,\)0.01 kg/s PC = 1268\(\,\pm \,\)1 W

The uncertainty associated in the performance parameters is computed using the following relations:

I. Energy performance parameters

-

1.

Power consumption

Power consumption = f (T\(_{1}\), P\(_{1}\), m\(_{\mathrm{r}}\) )

$$\begin{aligned} \frac{\delta {\mathrm{PC}}_{\mathrm{comp}}}{{\mathrm{PC}}_{\mathrm{comp}}}= \left[ \left( \frac{\delta T_1}{T_1} \right) ^2+ \left( \frac{\delta P_1}{P_1} \right) ^2+\left( \frac{\delta m_\mathrm{r}}{m_\mathrm{r}} \right) ^2\right] ^{1/2} \end{aligned}$$Substituting the values

$$\begin{aligned} \frac{\delta {\mathrm{PC}}_{\mathrm{comp}}}{{\mathrm{PC}}_{\mathrm{comp}}} =2.09\% \end{aligned}$$ -

2.

Heating capacity

Heating capacity = f (T\(_{\mathrm{ciat}}\), T\(_{\mathrm{coat}}\), T\(_{3}\), m\(_{\mathrm{air}}\))

$$\begin{aligned} \frac{\delta Q_\mathrm{c}}{Q_\mathrm{c}}=\left[ \left( \frac{\delta T_{\mathrm{ciat}}}{T_{\mathrm{ciat}}}\right) ^2+ \left( \frac{\delta T_{\mathrm{coat}}}{T_{\mathrm{coat}}}\right) ^2+\left( \frac{\delta T_{3}}{T_{3}} \right) ^2 +\left( \frac{\delta m_{\mathrm{air}}}{m_{\mathrm{air}}} \right) ^2 \right] ^{1/2} \end{aligned}$$Substituting the values

$$\begin{aligned} \frac{\delta Q_\mathrm{c}}{Q_\mathrm{c}} =3.38\% \end{aligned}$$ -

3.

Energy performance ratio

Heating capacity = f (Q\(_{\mathrm{c}}\), PC\(_{\mathrm{comp}}\))

$$\begin{aligned} \frac{\delta \mathrm{EPR}}{\mathrm{EPR}}=\left[ \left( \frac{\delta \mathrm{PC}_{\mathrm{comp}}}{\mathrm{PC}_{\mathrm{comp}}} \right) ^2 + \left( \frac{\delta Q_\mathrm{c}}{Q_\mathrm{c}}\right) ^2\right] ^{1/2} \end{aligned}$$Substituting the values

$$\begin{aligned} \frac{\delta \mathrm{EPR}}{\mathrm{EPR}}=3.47\% \end{aligned}$$

II. Exergy-efficiency assessment parameters

-

Compressor

-

Exergy efficiency of compressor = f (T\(_{1}\), P\(_{1}\),T\(_{2}\), P\(_{2}\), PC, T\(_{\mathrm{o}}\), m\(_{\mathrm{r}}\))

$$\begin{aligned} \frac{\delta \varepsilon _{\mathrm{comp}}}{\varepsilon _{\mathrm{comp}}}= \left[ \left( \frac{\delta T_1}{T_1} \right) ^2+ \left( \frac{\delta P_1}{P_1} \right) ^2+\left( \frac{\delta T_2}{T_2} \right) ^2+\left( \frac{\delta P_2}{P_2} \right) ^2+\left( \frac{\delta T_\mathrm{0}}{T_0} \right) ^2+\left( \frac{\delta m_{\mathrm{r}}}{m_{\mathrm{r}}} \right) ^2\right] ^{1/2} \end{aligned}$$ -

Substituting the values

$$\begin{aligned} \frac{\delta \varepsilon _{\mathrm{comp}}}{\varepsilon _{\mathrm{comp}}} =4.58\% \end{aligned}$$ -

Condenser

-

Exergy efficiency of compressor = f (T\(_{2}\), P\(_{2}\),T\(_{3}\), P\(_{3}\), PC, T\(_{\mathrm{o}}\), T\(_{\mathrm{ciat}}\), T\(_{\mathrm{coat}},\) m\(_{\mathrm{r}}\), m\(_{\mathrm{air}}\))

$$\begin{aligned} \frac{\delta \varepsilon _{\mathrm{cond}}}{\varepsilon _{\mathrm{cond}}} &= \left[ \left( \frac{\delta T_2}{T_2} \right) ^2+\left( \frac{\delta P_2}{P_2} \right) ^2 +\left( \frac{\delta T_3}{T_3} \right) ^2+\left( \frac{\delta P_3}{P_3} \right) ^2+\left( \frac{\delta m_{\mathrm{air}}}{m_{\mathrm{air}}} \right) ^2+\left( \frac{\delta m_{\mathrm{r}}}{m_{\mathrm{r}}} \right) ^2\right. \\&\left. +\left( \frac{\delta T_{\mathrm{ciat}}}{T_{\mathrm{ciat}}} \right) ^2+\left( \frac{\delta T_{\mathrm{coat}}}{T_{\mathrm{coat}}} \right) ^2+\left( \frac{\delta T_\mathrm{0}}{T_\mathrm{0}} \right) ^2\right] ^{1/2} \end{aligned}$$ -

Substituting the values

$$\begin{aligned} \frac{\delta \varepsilon _{\mathrm{cond}}}{\varepsilon _{\mathrm{cond}}} =6.22\% \end{aligned}$$ -

Expansion valve

-

Exergy efficiency of compressor = f (T\(_{3}\), P\(_{3}\),T\(_{4}\), P\(_{4}\) T\(_{o}\), m\(_{\mathrm{r}}\))

$$\begin{aligned} \frac{\delta \varepsilon _{txv}}{\varepsilon _{txv}}= \left[ \left( \frac{\delta T_3}{T_3} \right) ^2+\left( \frac{\delta P_3}{P_3} \right) ^2+\left( \frac{\delta T_4}{T_4} \right) ^2+\left( \frac{\delta P_4}{P_4} \right) ^2+\left( \frac{\delta T_\mathrm{0}}{T_\mathrm{0}} \right) ^2+\left( \frac{\delta m_\mathrm{r}}{m_\mathrm{r}} \right) ^2\right] ^{1/2} \end{aligned}$$ -

Substituting the values

$$\begin{aligned} \frac{\delta \varepsilon _{\mathrm{txv}}}{\varepsilon _{\mathrm{txv}}}=3.33\% \end{aligned}$$ -

Collector–evaporator

-

Exergy efficiency of compressor = f (T\(_{4}\), P\(_{4}\),T\(_{1}\), P\(_{1}\) T\(_{\mathrm{o}}\), I)

$$\begin{aligned} \frac{\delta \varepsilon _{\mathrm{sol.col}}}{\varepsilon _{\mathrm{sol.col}}}= \left[ \left( \frac{\delta T_4}{T_4} \right) ^2+ \left( \frac{\delta P_4}{P_4} \right) ^2+\left( \frac{\delta T_1}{T_1} \right) ^2+\left( \frac{\delta T_1}{T_1} \right) ^2+\left( \frac{\delta T_{\mathrm{ciat}}}{T_{\mathrm{ciat}}} \right) ^2+\left( \frac{\delta I}{I} \right) ^2\right] ^{1/2} \end{aligned}$$ -

Substituting the values

$$\begin{aligned} \frac{\delta \varepsilon _{\mathrm{sol.col}}}{\varepsilon _{\mathrm{sol.col}}} =1.36\% \end{aligned}$$ -

Total system

$$\begin{aligned}&\hbox {Exergy efficiency of compressor=f} \left( \left( \frac{\delta \varepsilon _{\mathrm{comp}}}{\varepsilon _{\mathrm{comp}}}\right) , \left( \frac{\delta \varepsilon _{\mathrm{cond}}}{\varepsilon _{\mathrm{cond}}}\right) , \left( \frac{\delta \varepsilon _{\mathrm{txv}}}{\varepsilon _{\mathrm{txv}}}\right) ,\left( \frac{\delta \varepsilon _{\mathrm{sol.col}}}{\varepsilon _{\mathrm{sol.col}}}\right) \right) \\&\frac{\delta \varepsilon _{\mathrm{total.sys}}}{\varepsilon _{\mathrm{total.sys}}}= \left[ \left( \frac{\delta \varepsilon _{\mathrm{comp}}}{\varepsilon _{\mathrm{comp}}}\right) ^2+ \left( \frac{\delta \varepsilon _{\mathrm{cond}}}{\varepsilon _{\mathrm{cond}}}\right) ^2+\left( \frac{\delta \varepsilon _{\mathrm{txv}}}{\varepsilon _{\mathrm{txv}}}\right) ^2+\left( \frac{\delta \varepsilon _{\mathrm{sol.col}}}{\varepsilon _{\mathrm{sol.col}}}\right) ^2\right] ^{1/2} \end{aligned}$$ -

Substituting the values

$$\begin{aligned} \frac{\delta \varepsilon _{\mathrm{total.sys}}}{\varepsilon _{\mathrm{total.sys}}} =6.58\% \end{aligned}$$

Rights and permissions

About this article

Cite this article

Paradeshi, L., Srinivas, M. & Jayaraj, S. Thermodynamic analysis of a direct expansion solar-assisted heat pump system working with R290 as a drop-in substitute for R22. J Therm Anal Calorim 136, 63–78 (2019). https://doi.org/10.1007/s10973-018-7928-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7928-x