Abstract

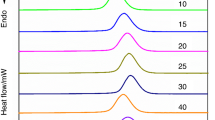

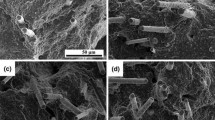

We investigated the crystalline properties of injection-molded polyamide 6 matrix composites containing carbon nanotubes and microfibers (basalt and carbon). We showed with differential scanning calorimetry tests that microfibers affect crystalline properties differently. Basalt fibers do not have a nucleating effect, while carbon fibers do, to a small extent. Carbon nanotubes acted as nucleating agents themselves, but in composites reinforced with microfibers they increased the crystallinity even more. Due to the nucleating effect of the nanotubes, crystallization started at a higher temperature in each composite. We observed synergistic effects concerning nucleation in hybrid composites. We decomposed the crystalline melting curves to determine the characteristics of the crystallite types and proved that the presence of nanotubes facilitated the formation of α-type crystallites. We showed that nanotubes have a double effect: They have a nucleating effect regarding crystallinity, and they inhibit the movement of polyamide molecules relative to each other, which decreases the tendency to crystallize. Therefore, nanotube content has an optimum concerning crystallization. This is in accordance with tensile mechanic properties.

Similar content being viewed by others

References

Gumede TP, Luyt AS, Muller AJ. Review on PCL, PBS, and PCL/PBS blends containing carbon nanotubes. Express Polym Lett. 2018;12:505–29. https://doi.org/10.3144/expresspolymlett.2018.43.

Wang FX, Liang WY, Wang ZQ, Yang B, He L, Zhang K. Preparation and property investigation of multi-walled carbon nanotube (MWCNT)/epoxy composite films as high-performance electric heating (resistive heating) element. Express Polym Lett. 2018;12:285–95. https://doi.org/10.3144/expresspolymlett.2018.26.

Tahouneh V. An elasticity solution for vibration analysis of laminated plates with functionally graded core reinforced by multi-walled carbon nanotubes. Period Polytech Mech. 2017;61(4):309–19. https://doi.org/10.3311/PPme.11254.

Jalalvand M, Czél G, Wisnom MR. Damage analysis of pseudo-ductile thin-ply UD hybrid composites—a new analytical method. Compos A Appl Sci. 2015;69:83–93. https://doi.org/10.1016/j.compositesa.2014.11.006.

Rafiq R, Cai D, Jin J, Song M. Increasing the toughness of nylon 12 by the incorporation of functionalized graphene. Carbon. 2010;48(15):4309–14. https://doi.org/10.1016/j.carbon.2010.07.043.

Chen G-X, Kim H-S, Park BH, Yoon J-S. Multi-walled carbon nanotubes reinforced nylon 6 composites. Polymer. 2006;47(13):4760–7. https://doi.org/10.1016/j.polymer.2006.04.020.

Friedrich K, Fakirov S, Zhang Z. Polymer composites: from nano-to-macro-scale. Berlin: Springer; 2005.

Lee C, Wei X, Kysar JW, Hone J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science. 2008;321(5887):385–8. https://doi.org/10.1126/science.1157996.

Yu M-F, Lourie O, Dyer MJ, Moloni K, Kelly TF, Ruoff RS. Strength and breaking mechanism of multiwalled carbon nanotubes under tensile load. Science. 2000;287(5453):637–40. https://doi.org/10.1126/science.287.5453.637.

Ruoff RS, Qian D, Liu WK. Mechanical properties of carbon nanotubes: theoretical predictions and experimental measurements. Comptes Rendus Physique. 2003;4(9):993–1008. https://doi.org/10.1016/j.crhy.2003.08.001.

Ma P-C, Siddiqui NA, Marom G, Kim J-K. Dispersion and functionalization of carbon nanotubes for polymer-based nanocomposites: a review. Compos A Appl Sci. 2010;41(10):1345–67. https://doi.org/10.1016/j.compositesa.2010.07.003.

Rahmat M, Hubert P. Carbon nanotube–polymer interactions in nanocomposites: a review. Compos Sci Technol. 2011;72(1):72–84. https://doi.org/10.1016/j.compscitech.2011.10.002.

Sahoo NG, Cheng HKF, Cai J, Li L, Chan SH, Zhao J, et al. Improvement of mechanical and thermal properties of carbon nanotube composites through nanotube functionalization and processing methods. Mater Chem Phys. 2009;117(1):313–20. https://doi.org/10.1016/j.matchemphys.2009.06.007.

Scaffaro R, Maio A, Tito AC. High performance PA6/CNTs nanohybrid fibers prepared in the melt. Compos Sci Technol. 2012;72(15):1918–23. https://doi.org/10.1016/j.compscitech.2012.08.010.

Wei C, Cho K, eds. Chemical bonding of polymer on carbon nanotube. San Francisco: Mater Res Soc Symp P; 2001.

Karsli GN, Yesil S, Aytac A. Effect of hybrid carbon nanotube/short glass fiber reinforcement on the properties of polypropylene composites. Compos B Eng. 2014;63:154–60. https://doi.org/10.1016/j.compositesb.2014.04.006.

Fiore V, Scalici T, Di Bella G, Valenza A. A review on basalt fibre and its composites. Compos B Eng. 2015;74:74–94. https://doi.org/10.1016/j.compositesb.2014.12.034.

Morgan P. Carbon fibers and their composites. Boca Raton: CRC Press; 2005.

Shen L, Tjiu WC, Liu T. Nanoindentation and morphological studies on injection-molded nylon-6 nanocomposites. Polymer. 2005;46(25):11969–77. https://doi.org/10.1016/j.polymer.2005.10.006.

Fornes TD, Paul DR. Crystallization behavior of nylon 6 nanocomposites. Polymer. 2003;44(14):3945–61. https://doi.org/10.1016/S0032-3861(03)00344-6.

Page IB. Polyamides as engineering thermoplastic materials. Shrewsbury: Rapra Technology Limited; 2000.

Strobl GR. The physics of polymers. Berlin: Springer; 2007.

Piorkowska E, Rutledge GC. Handbook of polymer crystallization. Hoboken: Wiley; 2013.

Bessell TJ, Hull D, Shortall JB. The effect of polymerization conditions and crystallinity on the mechanical properties and fracture of spherulitic nylon 6. J Mater Sci. 1975;10(7):1127–36. https://doi.org/10.1007/BF00541393.

El-Hadi A, Schnabel R, Straube E, Müller G, Henning S. Correlation between degree of crystallinity, morphology, glass temperature, mechanical properties and biodegradation of poly (3-hydroxyalkanoate) PHAs and their blends. Polym Test. 2002;21(6):665–74. https://doi.org/10.1016/S0142-9418(01)00142-8.

Liu W-W, Chai S-P, Mohamed AR, Hashim U. Synthesis and characterization of graphene and carbon nanotubes: a review on the past and recent developments. J Ind Eng Chem. 2014;20(4):1171–85. https://doi.org/10.1016/j.jiec.2013.08.028.

Jancar J, Douglas JF, Starr FW, Kumar SK, Cassagnau P, Lesser AJ, et al. Current issues in research on structure–property relationships in polymer nanocomposites. Polymer. 2010;51(15):3321–43. https://doi.org/10.1016/j.polymer.2010.04.074.

Singh V, Joung D, Zhai L, Das S, Khondaker SI, Seal S. Graphene based materials: past, present and future. Prog Mater Sci. 2011;56(8):1178–271. https://doi.org/10.1016/j.pmatsci.2011.03.003.

Meng H, Sui GX, Xie GY, Yang R. Friction and wear behavior of carbon nanotubes reinforced polyamide 6 composites under dry sliding and water lubricated condition. Compos Sci Technol. 2009;69(5):606–11. https://doi.org/10.1016/j.compscitech.2008.12.004.

Chiu F-C, Huang IN. Phase morphology and enhanced thermal/mechanical properties of polyamide 46/graphene oxide nanocomposites. Polym Test. 2012;31(7):953–62. https://doi.org/10.1016/j.polymertesting.2012.06.014.

Brosse A-C, Tencé-Girault S, Piccione PM, Leibler L. Effect of multi-walled carbon nanotubes on the lamellae morphology of polyamide-6. Polymer. 2008;49(21):4680–6. https://doi.org/10.1016/j.polymer.2008.08.003.

Jin J, Rafiq R, Gill YQ, Song M. Preparation and characterization of high performance of graphene/nylon nanocomposites. Eur Polym J. 2013;49(9):2617–26. https://doi.org/10.1016/j.eurpolymj.2013.06.004.

Zhou S, Hrymak AN, Kamal MR. Electrical, morphological and thermal properties of microinjection molded polyamide 6/multi-walled carbon nanotubes nanocomposites. Compos A Appl Sci. 2017;103:84–95. https://doi.org/10.1016/j.compositesa.2017.09.016.

Valentini L, Biagiotti J, López-Manchado MA, Santucci S, Kenny JM. Effects of carbon nanotubes on the crystallization behavior of polypropylene. Polym Eng Sci. 2004;44(2):303–11. https://doi.org/10.1002/pen.20028.

Tan JK, Kitano T, Hatakeyama T. Crystallization of carbon fibre reinforced polypropylene. J Mater Sci. 1990;25(7):3380–4. https://doi.org/10.1007/BF00587701.

Frihi D, Layachi A, Gherib S, Stoclet G, Masenelli-Varlot K, Satha H, et al. Crystallization of glass-fiber-reinforced polyamide 66 composites: Influence of glass-fiber content and cooling rate. Compos Sci Technol. 2016;130:70–7. https://doi.org/10.1016/j.compscitech.2016.05.007.

Schawe JEK. Cooling rate dependence of the crystallinity at nonisothermal crystallization of polymers: a phenomenological model. J Appl Polym Sci. 2016. https://doi.org/10.1002/app.42977.

Dasgupta S, Hammond WB, Goddard WA. Crystal structures and properties of nylon polymers from theory. J Am Chem Soc. 1996;118(49):12291–301. https://doi.org/10.1021/ja944125d.

Szakács J, Mészáros L. Synergistic effects of carbon nanotubes on the mechanical properties of basalt and carbon fiber-reinforced polyamide 6 hybrid composites. J Thermoplast Compos. 2018;31(4):553–71. https://doi.org/10.1177/0892705717713055.

Phang IY, Ma J, Shen L, Liu T, Zhang W-D. Crystallization and melting behavior of multi-walled carbon nanotube-reinforced nylon-6 composites. Polym Int. 2006;55(1):71–9. https://doi.org/10.1002/pi.1920.

Wu B, Gong Y, Yang G. Non-isothermal crystallization of polyamide 6 matrix in all-polyamide composites: crystallization kinetic, melting behavior, and crystal morphology. J Mater Sci. 2011;46(15):5184–91. https://doi.org/10.1007/s10853-011-5452-5.

Liang J, Xu Y, Wei Z, Song P, Chen G, Zhang W. Mechanical properties, crystallization and melting behaviors of carbon fiber-reinforced PA6 composites. J Therm Anal Calorim. 2014;115(1):209–18. https://doi.org/10.1007/s10973-013-3184-2.

Vodovotz Y, Hallberg L, Chinachoti P. Effect of aging and drying on thermomechanical properties of white bread as characterized by dynamic mechanical analysis (DMA) and differential scanning calorimetry (DSC). Cereal Chem. 1996;73(2):264–70.

Höhne GWH, Hemminger W, Flammersheim HJ. Differential scanning calorimetry: an introduction for practitioners. 2nd ed. Berlin: Springer; 2003.

Acknowledgements

This paper was supported by the János Bolyai Research Scholarship of the Hungarian Academy of Sciences and by the Higher Education Excellence Program of the Ministry of Human Capacities in the framework of the Nanotechnology research area of the Budapest University of Technology and Economics (BME FIKP-NANO).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Szakács, J., Petrény, R. & Mészáros, L. Crystalline properties of melt-processed polyamide 6 matrix multiscale hybrid composites. J Therm Anal Calorim 137, 43–53 (2019). https://doi.org/10.1007/s10973-018-7911-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7911-6