Abstract

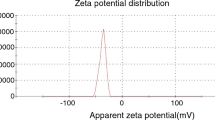

In order to decrease the energy consumptions in energy conversion devices, boiling heat transfer augmentation is one of the important research activities for the scientific community. In present study, the pool boiling heat transfer characteristics of Cu–TiO2 composite coating on copper surfaces are reported. A two-step electrodeposition technique is employed to develop the nanocomposite coatings on copper surfaces, where higher current densities are applied for a short period and then the deposition is continued with lower current density for longer period in the second step of electrochemical deposition. The layer deposited during the first step is fragile, which is stabilized during the second step of electrodeposition at lower current density for longer duration. The surface morphology properties like porosity, wettability, coating layer thickness are easily controlled by managing the electrodeposition parameters like electrolyte composition, deposition time and current density. The pool boiling experiments are performed on bare and composite-coated surfaces at atmospheric pressure with saturated DI water. The boiling performance of coated surfaces is compared with the bare (uncoated) surface. The maximum boiling heat transfer coefficient and critical heat flux on coated surfaces are achieved to be 151 kW m−2 K−1 and 1988 kW m−2, which are 185% and 86% higher than the bare copper surface, respectively. The enhancement in boiling performance is associated with several parameters like increase in porosity, presence of high-density nucleation sites, and improvement in surface wettability.

Similar content being viewed by others

References

Kandlikar SG, Shoji M, Dhir VK. Handbook of phase change. Philadelphia: Taylor and Francis; 1999.

Teodori E, Moita AS, Moreira ALN. Characterization of pool boiling mechanisms over micro-patterned surfaces using PIV. Int J Heat Mass Transf. 2013;66:261–70.

Moita AS, Teodori E, Moreira ALN. Influence of surface topography in the boiling mechanisms. Int J Heat Fluid Flow. 2015;52:50–63.

Birce D, Edidiong E, Marc C. Pool boiling enhancement with environmentally friendly surfactant additives. J Therm Anal Calorim. 2014;116:1387–94.

Hashemi M, Noie SH. Study of flow boiling heat transfer characteristics of critical heat flux using carbon nanotubes and water nanofluid. J Therm Anal Calorim. 2017;130:2199–209.

Patil CM, Kandlikar SG. Review of the manufacturing techniques for porous surfaces used in enhanced pool boiling. Heat Transfer Eng. 2013;35:887–902.

Machlouf AS, Tiginyanu I. Nanocoatings and ultra-thin films. Technologies and applications., A volume in Woodhead Publishing Series in metals and surface engineeringCambridge: Woodhead Publishing; 2011. ISBN 978-1-84569-812-6.

Shin HC, Dong J, Liu M. Nanoporous structures prepared by an electrochemical deposition process. Adv Mater. 2003;15:1610–4.

Gupta SK, Misra RD. An experimental investigation on flow boiling heat transfer enhancement using Cu–TiO2 nanocomposite coating on copper substrate. Exp Therm Fluid Sci. 2018;98:406–19.

Anderson TM, Mudawar I. Microelectronic cooling by enhanced pool boiling of a dielectric fluorocarbon liquid. Trans ASME. 1989;111:752–9.

You SM, Simon TW, Bar-Cohen A. A technique for enhancing boiling heat transfer with application to cooling of electronic equipment. IEEE Trans Compon Hybrids Manuf Technol. 1992;15(5):823–31.

Memory SB, Sugiyama DC, Marto PJ. Nucleate pool boiling of R-114 and R-114-oil mixtures from smooth and enhanced surfaces—I. Single tubes. Int J Heat Mass Transf. 1995;38(8):1347–61.

Golobic I, Ferjančič K. The role of enhanced coated surface in pool boiling CHF in FC-72. Heat Mass Transf. 2000;36(6):525–31.

Chang JY, You SM. Enhanced boiling heat transfer from microporous surfaces: effects of a coating composition and method. Int J Heat Mass Transf. 1997;40(18):4449–60.

Albertson CE. Boiling heat transfer surface and method. US Patent. 1977; 572:376.

Kim JH. Enhancement of pool boiling heat transfer using thermally conductive microporous coating techniques. Ph.D. thesis, University of Texas at Arlington, TX, USA (2006).

El-Genk MS, Ali AF. Enhanced nucleate boiling on copper micro-porous surfaces. Int J Multiphase Flow. 2010;36(10):780–92.

Im Y, Dietz C, Lee SS, Joshi Y. Flower-like CuO nanostructures for enhanced boiling. Nanoscale Microscale Thermophys Eng. 2012;16(3):145–53.

Ahn HS, Sathyamurthi V, Banerjee D. Pool boiling experiments on a nanostructured surface. IEEE Trans Compon Packag Technol. 2009;32:156–62.

Patil CM, Santhanam KSV, Kandlikar SG. Development of a two-step electrodeposition process for enhancing pool boiling. Int J Heat Mass Transf. 2014;79:989–1001.

Holman JP. Experimental methods for engineers. 7th ed. London: Tata McGraw Hill Education Private Limited; 2007.

Nikolic ND. Fundamental aspects of copper electrodeposition in the hydrogen co-deposition range. Zastita Mater. 2010;51:1970203.

Rohsenow WM. A method of correlating heat transfer data for surface boiling of liquids. ASME. 1952;74:969–76.

Das S, Kumar DS, Bhaumik S. Experimental study of nucleate pool boiling heat transfer of water on silicon oxide nanoparticle coated copper heating surface. Appl Therm Eng. 2016;96:555–67.

Webb R. The evolution of enhanced surface geometries for nucleate boiling. Heat Transf Eng. 1981;2:46–69.

Betz AR, Xu J, Qiu H, Attinger D. Do surfaces with mixed hydrophilic and hydrophobic areas enhance pool boiling? Appl Phys Lett. 2010;97:141909.

Liu Y, Yao W, Wang Y, Moita A, Han Z, Ren L. Reversibly switchable wettability on aluminium substrate corresponding to different pH droplet and its corrosion resistance. Chem Eng J. 2016;303:565–74.

Morshed AKMM, Paul TC, Khan J. Effect of Cu–Al2O3 nanocomposite coating on flow boiling performance of a microchannel. Appl Therm Eng. 2013;51:1135–43.

Dai X, Yang F, Fang R, Yemame T, Khan JA, Li C. Enhanced single- and two phase transport phenomena using flow separation in a micro gap with copper woven mesh coatings. Appl Therm Eng. 2013;54:281–8.

Yang F, Dai X, Peles Y, Cheng P, Khan J, Li C. Flow boiling phenomena in a single annular flow regime in microchannels (I): characterization of flow boiling heat transfer. Int J Heat Mass Transf. 2014;68:703–15.

Cooper MG, Lloyd AJ. The microlayer in nucleate pool boiling. Int J Heat Mass Transf. 1969;12:895–913.

Chu KH, Enright R, Wang EN. Structured surfaces for enhanced pool boiling heat transfer. Appl Phys Lett. 2012;100(24):241603.

Kwark SM, Kumar R, Moreno G, Yoo J, You SM. Pool boiling characteristics of low concentration nanofluids. Int J Heat Mass Transf. 2010;53:972–81.

Bo S, Yi-Biao W, Kai C. Pool boiling heat transfer enhancement with copper nanowire arrays. Appl Therm Eng. 2015;75:115–21.

Das S, Saha B, Bhaumik S. Experimental study of nucleate pool boiling heat transfer of water by surface functionalization with crystalline TiO2 nanostructure. Appl Therm Eng. 2017;113:1345–57.

Gupta SK, Misra RD. Experimental study of pool boiling heat transfer on copper surfaces with Cu–Al2O3 nanocomposite coatings. Int Commun Heat Mass Transf. 2018;97:47–55.

Gupta SK, Misra RD. An experimental investigation on pool boiling heat transfer enhancement using Cu–Al2O3 nano-composite coating. Exper Heat Transf. 2018;1:1–26. https://doi.org/10.1080/08916152.2018.1485785.

Li G, Thomas B, Stubbins J. Modeling creep and fatigue of copper alloys. Metall Mater Trans A. 2000;31(10):2491–502.

Acknowledgements

The authors acknowledge the Sophisticated Analytical Instrument Facility, Indian Institute of Technology Mumbai, India, for providing FEG-SEM facility.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gupta, S.K., Misra, R.D. Effect of two-step electrodeposited Cu–TiO2 nanocomposite coating on pool boiling heat transfer performance. J Therm Anal Calorim 136, 1781–1793 (2019). https://doi.org/10.1007/s10973-018-7805-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7805-7