Abstract

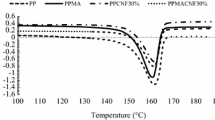

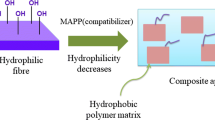

Polypropylene block copolymer (PPco) is easier to process in extrusion-based additive manufacturing compared to isotactic PP homopolymer because it shrinks and warps less during printing. This study investigated the thermal properties of PPco and spray-dried CNF (SDCNF)-PPco composite pellet formulations. Thermogravimetric analysis data showed that the addition of SDCNF lowered the thermal degradation onset temperature and increased the residual mass content (at 450 °C) of PPco pellets. The peak degradation temperatures of SDCNF and PPco remained the same. The peak crystallization temperature and relative crystallinity of PPco were increased by the addition of SDCNF and MAPP. The peak melting temperature of PPco was not significantly changed. Printed specimens showed three melting peaks (β, β′ and α crystals) while injection molded PPco only showed one (α crystal) melting peak. Dynamic mechanical analysis results showed that the heat deflection temperatures of printed SDCNF-PPco composites were higher than injection molded PPco. SEM micrographs showed that the addition of SDCNF increased the number of voids inside the printed parts.

Similar content being viewed by others

References

Wendel B, Rietzel D, Kühnlein F, Feulner R, Hülder G, Schmachtenberg E. Additive processing of polymers. Macromol Mater Eng. 2008;293:799–809.

Wang L, Gardner DJ, Bousfield DW. Cellulose nanofibril-reinforced polypropylene composites for material extrusion: rheological properties. Polym Eng Sci. 2017. https://doi.org/10.1002/pen.24615.

Wang L, Gardner DJ. Effect of fused layer modeling (FLM) processing parameters on impact strength of cellular polypropylene. Polymer. 2017;24:74–80.

Nandi S, Ghosh AK. Crystallization kinetics of impact modified polypropylene. J Polym Res. 2007;14:387–96.

Moon RJ, Martini A, Nairn J, Simonsen J, Youngblood J. Cellulose nanomaterials review: structure, properties and nanocomposites. Chem Soc Rev. 2011;40:3941–94.

Wang L, Sanders JE, Gardner DJ, Han Y. In-situ modification of cellulose nanofibrils by organosilanes during spray drying. Ind Crops Prod. 2016;93:129–35.

Gardner DJ, Han Y, Wang L. Wood–plastic composite technology. Curr For Rep. 2015;1(3):139–50. https://doi.org/10.1007/s40725-015-0016-6.

Wang L, Roach AW, Gardner DJ, Han Y. Mechanisms contributing to mechanical property changes in composites of polypropylene reinforced with spray-dried cellulose nanofibrils. Cellulose. 2018;25(1):439–48. https://doi.org/10.1007/s10570-017-1556-7.

Sun L, Wu Q, Xie Y, Song K, Lee S, Wang Q. Thermal decomposition of fire-retarded wood flour/polypropylene composites. J Therm Anal Calorim. 2016;123(1):309–18.

Tajvidi M, Takemura A. Thermal degradation of natural fiber-reinforced polypropylene composites. J Thermoplast Compos Mater. 2010;23:281–98.

Zhao P, Guo C, Li L. Flame retardancy and thermal degradation properties of polypropylene/wood flour composite modified with aluminum hypophosphite/melamine cyanurate. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7544-9.

Tajvidi M, Sharma AM, Simon LC. Thermal transitions and temperature dependent mechanical behavior of wheat straw/talc isotactic/impact modified polypropylene composites. J Reinf Plast Compos. 2013;32:1430–43.

Guo B, Zhang T, Zhang W, Dou Y. Influence of surface flame-retardant layer containing ammonium polyphosphate and expandable graphite on the performance of jute/polypropylene composites. J Therm Anal Calorim. 2018. https://doi.org/10.1007/s10973-018-7406-5.

Ljungberg N, Cavaillé JY, Heux L. Nanocomposites of isotactic polypropylene reinforced with rod-like cellulose whiskers. Polymer. 2006;47:6285–92.

Panaitescu DM, Donescu D, Bercu C, Vuluga DM, Iorga M, Ghiurea M. Polymer composites with cellulose microfibrils. Polym Eng Sci. 2007;47:1228–34.

Nagalakshmaiah M, El Kissi N, Dufresne A. Ionic compatibilization of cellulose nanocrystals with quaternary ammonium salt and their melt extrusion with polypropylene. ACS Appl Mater Interfaces. 2016;8:8755–64.

Bahar E, Ucar N, Onen A, Wang Y, Oksüz M, Ayaz O, Ucar M, Demir A. Thermal and mechanical properties of polypropylene nanocomposite materials reinforced with cellulose nano whiskers. J Appl Polym Sci. 2012;125:2882–9.

Hassan ML, Mathew AP, Hassan EA, Fadel SM, Oksman K. Improving cellulose/polypropylene nanocomposites properties with chemical modified bagasse nanofibers and maleated polypropylene. J Reinf Plast Compos. 2014;33:26–36.

Yang HS, Kiziltas A, Gardner DJ. Thermal analysis and crystallinity study of cellulose nanofibril-filled polypropylene composites. J Therm Anal Calorim. 2013;113:673–82.

Khoshkava V, Kamal MR. Effect of cellulose nanocrystals (CNC) particle morphology on dispersion and rheological and mechanical properties of polypropylene/CNC nanocomposites. ACS Appl Mater Interfaces. 2014;6:8146–57.

González-González VA, Neira-Velázquez G, Angulo-Sánchez JL. Polypropylene chain scissions and molecular weight changes in multiple extrusion. Polym Degrad Stab. 1998;60:33–42.

Hermanová S, Tocháček J, Jančář J, Kalfus J. Effect of multiple extrusion on molecular structure of polypropylene impact copolymer. Polym Degrad Stab. 2009;94:1722–7.

Turner BN, Strong R, Gold SA. A review of melt extrusion additive manufacturing processes: I. Process design and modeling. Rapid Prototyp J. 2014;20:192–204.

Seo Y, Kim J, Kim KU, Kim YC. Study of the crystallization behaviors of polypropylene and maleic anhydride grafted polypropylene. Polymer. 2000;41:2639–46.

Wang L, Gramlich WM, Gardner DJ, Han Y, Tajvidi M. Spray-dried cellulose nanofibril-reinforced polypropylene composites for extrusion-based additive manufacturing: nonisothermal crystallization kinetics and thermal expansion. J Compos Sci. 2018;2(1):7. https://doi.org/10.3390/jcs2010007.

Wang L, Gramlich WM, Gardner DJ. Improving the impact strength of poly (lactic acid)(PLA) in fused layer modeling (FLM). Polymer. 2017;114:242–8.

Tordjeman P, Robert C, Marin G, Gerard P. The effect of α, β crystalline structure on the mechanical properties of polypropylene. Eur Phys J E Soft Matter. 2001;4:459–65.

Papageorgiou DG, Chrissafis K, Bikiaris DN. β-nucleated polypropylene: processing, properties and nanocomposites. Polym Rev. 2015;55:596–629.

Fujiwara Y. Das doppelschmelzverhalten derb-Phase des isotaktischen polypropylenes. Colloid Polym Sci. 1975;253:273–82.

Li JX, Cheung WL, Jia D. A study on the heat of fusion of β-polypropylene. Polymer. 1999;40:1219–11222.

Wang L, Sanders JE, Gardner DJ, Han Y. Effect of fused deposition modeling process parameters on the mechanical properties of a filled polypropylene. Prog Addit Manuf. 2018. https://doi.org/10.1007/s40964-018-0053-3.

Varga J. β-modification of isotactic polypropylene: preparation, structure, processing, properties, and application. J Macromol Sci B. 2002;41(4–6):1121–71.

Landel RF, Nielsen LE. Mechanical properties of polymers and composites. Amsterdam: CRC Press; 1993.

Chattopadhyay SK, Khandal RK, Uppaluri R, Ghoshal AK. Mechanical, thermal, and morphological properties of maleic anhydride-g-polypropylene compatibilized and chemically modified banana fiber-reinforced polypropylene composites. J Appl Polym Sci. 2010;117:1731–40.

Chattopadhyay SK, Khandal RK, Uppaluri R, Ghoshal AK. Bamboo fiber reinforced polypropylene composites and their mechanical, thermal, and morphological properties. J Appl Polym Sci. 2011;119:1619–26.

Ning F, Cong W, Qiu J, Wei J, Wang S. Additive manufacturing of carbon fiber reinforced thermoplastic composites using fused deposition modeling. Compos Part B Eng. 2015;80:369–78.

Zafar MT, Zarrinbakhsh N, Mohanty AK, Misra M, Maiti SN, Ghosh AK. Biocomposites based on poly (lactic acid)/willow-fiber and their injection moulded microcellular foams. Expr Polym Lett. 2016;10:176–86.

Acknowledgements

Funding was provided in part by the National Science Foundation REU Project No. 1461116, the Maine Agricultural and Forest Experiment Station (MAFES) project ME0-M-8-00527-13 and the USDA ARS Forest Products Research Agreement 58-0202-4-003. The authors thank J. Elliott Sanders at the University of Maine for preparing the pellets and composites for analysis.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, L., Palmer, J., Tajvidi, M. et al. Thermal properties of spray-dried cellulose nanofibril-reinforced polypropylene composites from extrusion-based additive manufacturing. J Therm Anal Calorim 136, 1069–1077 (2019). https://doi.org/10.1007/s10973-018-7759-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7759-9