Abstract

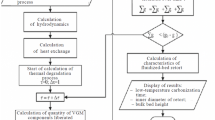

A 2D cylinder transient heat transfer model was developed for single-particle oil shale pyrolysis in the fixed-bed reactor. Variations of physical properties of oil shale were considered in this model. The developed model was solved using ANSYS after determining boundary conditions. And then intraparticle temperature distribution was obtained during oil shale pyrolysis. Moreover, effects of particle size and heating rate on intraparticle temperature distribution were investigated. The radius of 30-mm oil shale and pyrolysis time were divided into ten equal intervals to calculate temperature at any time and any position during the sample pyrolysis. The calculated results reasonably agreed with actually measured temperature.

Similar content being viewed by others

Abbreviations

- \(C_{\text{p}}\) :

-

Heat capacity (J kg−1 K−1)

- \(E_{\text{s}}\) :

-

Internal heat sink (J m−3)

- k :

-

Heat conductivity coefficient of oil shale (W m−1 K−1)

- t :

-

Heating time (s)

- T :

-

Temperature (K)

- \(T_{0}\) :

-

Initial temperature (K)

- \(T_{\text{c}}\) :

-

Central temperature of oil shale (K)

- \(T_{\text{f}}\) :

-

Gaseous temperature (K)

- \(T_{\text{s}}\) :

-

Surface temperature of oil shale (K)

- r :

-

Radius of oil shale particle (m)

- α :

-

Convective heat transfer coefficient (W m−2 K−1)

- β :

-

Heating rate (K min−1)

- \(\rho_{\text{o}}\) :

-

Density of oil shale (kg m−3)

References

Qian J, Yin L. Oil shale-petroleum alternative. Beijing: China Pertochemical Press; 2008. p. 1–2.

Qian J, Wang J, Li S. Oil shale development in China. Oil Shale. 2003;20(3):356–9.

Dyni JR. Geology and resources of some world oil-shale deposits. Oil Shale. 2003;20(3):193–252.

Shih SM, Hong YS. A mathematical model for the retorting of a large block of oil shale: effect of the internal temperature gradient. Fuel. 1978;57(10):622–30.

Maes J, Muggeridge AH, Jackson MD. Scaling heat and mass flow through porous media during pyrolysis. Heat Mass Transf. 2015;51(3):313–34.

Wen CS, Kobylinski TP. Low-temperature oil shale conversion. Fuel. 1983;62(11):1269–73.

Shi J, Ma Y, Li S. Characteristics of Estonian oil shale kerogen and its pyrolysates with thermal bitumen as a pyrolytic intermediate. Energy Fuels. 2017;31(5):4808–16.

Granoff B Jr, Nuttall HE Jr. Pyrolysis kinetics for oil-shale particles. Fuel. 1977;56(3):234–40.

Campbell JH, Koskinas GH. Oil shale retorting. Part I. The effects of particle size and heating rate on oil evolution and intraparticle oil degradation. Situ. 1977;2(1):1–47.

Değirmenci Levent, Durusoy Tülay. Effect of heating rate and particle size on the pyrolysis of Göynük oil shale. Energy Sources. 2005;27(9):787–95.

Khraisha Yahya H. Thermal conductivity of oil shale particles in a packed bed. Energy Sources. 2002;24(7):613–23.

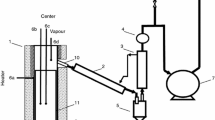

Han X, Liu Q, Jiang X. Heat transfer characteristic of oil shale particle during the retorting. Int J Heat Mass Transf. 2015;84:578–83.

Ma Y, He L, Li S. Heat transfer of oil shale in a small-scale fixed bed. J Therm Anal Calorim. 2016;124(1):461–9.

Fan Z, Parker JC. An efficient modeling approach to simulate heat transfer rate between fracture and matrix regions for oil shale retorting. Transp Porous Media. 2010;84(1):229–40.

Gan J, Zhou Z, Yu A. Particle scale study of heat transfer in packed and fluidized beds of ellipsoidal particles. Chem Eng Sci. 2016;144:201–15.

Wang Q, Feng XU, Bai JR. Study on the basic physicochemical characteristics of the Huadian oil shales. J Jilin Univ. 2006;36(6):1006–11.

Hou J, Li S, Ma Y. Calculation of the heat and material balance for Myanmar oil shale processing by SJ-retort. Energy Fuels. 2016;30(8):6373–80.

Lv LW. Thermal analysis module of ANSYS. Adv Mater Res. 2014;1030–1032:653–6.

Ling G. ANSYS 14.0 Thermodynamics research from entry to proficient. Beijing: Tsinghua University Press; 2013. p. 186–201.

Jing L, Li R, Deng X. Investigation of the heat transfer model in a single wood particle during the pyrolysis process. Renew Energy Resour. 2011;29(6):81–5.

Shi Y, Li S, Ma Y. Pyrolysis of Yaojie oil shale in a sanjiangtype pilot-scale retort. Oil Shale. 2012;29(4):368.

Kreith F, Manglik RM. Principles of heat transfer. Scranton: Intext Educational Publisher; 1965. p. 17–20.

Acknowledgements

This project was funded by national basic research program of china (973 programs) (2014CB744302) and China university of petroleum (Beijing) scientific research fund (2462015YQ0601).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ma, Y., Zhu, Y., Li, S. et al. Internal heat transfer characteristics of large-particle oil shale during pyrolysis. J Therm Anal Calorim 135, 3429–3435 (2019). https://doi.org/10.1007/s10973-018-7622-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7622-z