Abstract

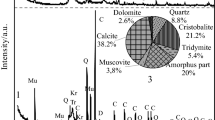

In this work, the peculiarities of the formation of α-C2SH using natural raw materials (calcined limestone and carbonated opoka) as well as the impact of thermal activation parameters to the formation of hydraulically active C2S polymorphs, their mineral composition, and hydraulic activity are presented. Hydrothermal syntheses were carried out at the temperatures of 180 and 200 °C for 2, 4, 8, 12, 24, and 72 h from mixtures with molar ratio CaO/SiO2 = 2.0. XRD, DTA, and DSC analyses showed that opoka, calcined at 775 °C, is a suitable material for the synthesis of α-C2SH. After tribochemical activation (950 rpm, 5 min), α-C2SH and its mixture with quartz (1:1 by mass) were treated thermally at the temperatures ranging between 450 and 1000 °C. At dehydration temperature (450 °C), α-C2SH forms the most active phase—x-C2S. By increasing the temperature, the other active phases such as β-C2S (600 °C) and α′L-C2S (800 °C) are formed. Unfortunately, they coexist with inactive γ-C2S. Thus, it is possible to avoid the last phase formation by grinding α-C2SH with quartz sand. Thermally activated α-C2SH mixture with quartz sand at the temperature of 450–500 °C is suitable for binder material manufacture: during the main hydration reaction, heat flow reached 0.0017–0.0018 W g−1, and total heat release after 72 h of hydration was 61.30–67.52 J g−1.

Similar content being viewed by others

References

Cement Technology Roadmap 2009: Carbon Emissions Reductions up to 2050. IEA Publications; 2009.

Stemmermann P, Schweike U, Garbev K, Beuchle G. Celitement—a sustainable prospect for the cement industry. Cem Int. 2010;8:52–66.

Van Oss HG. Mineral commodity summaries. U.S. Geological Survey. 2015:1–196.

Mazouzi W, Kacimi L, Cyr M, Clastres P. Properties of low temperature belite cements made from aluminosilicate wastes by hydrothermal method. Cem Concr Compos. 2014;53:170–7.

Science and Technology of Concrete Admixtures. Edited by: Aïtcin PC and Flatt RJ. 1st ed. Woodhead Publishing; 2015.

Gartner E, Hirao H. A review of alternative approaches to the reduction of CO2 emissions associated with the manufacture of the binder phase in concrete. Cem Concr Res (Keynote papers from 14th International Congress on the Chemistry of Cement (ICCC 2015)). 2015;78(Part A):126–42.

Maheswaran S, Kalaiselvam S, Karthikeyan Saravana SKS, Kokila C, Palani GS. β-Belite cements (β-dicalcium silicate) obtained from calcined lime sludge and silica fume. Cem Concr Compos. 2016;66:57–65.

Naber C, Goetz-Neunhoeffer F, Göbbels M, Rößler C, Neubauer J. Synthesis of monocrystalline Ca3SiO5 using the optical floating zone method. Cem Concr Res. 2016;85:156–62.

Ludwig HM, Zhang W. Research review of cement clinker chemistry. Cem Concr Res (Keynote papers from 14th International Congress on the Chemistry of Cement (ICCC 2015)). 2015;78(Part A):24–37.

Link T, Bellmann F, Ludwig HM, Ben Haha M. Reactivity and phase composition of Ca2SiO4 binders made by annealing of alpha-dicalcium silicate hydrate. Cem Concr Res. 2015;67:131–7.

Wang Q, Febg L, Shen X, Shi W, Li X, Guo Y, Xiong S, Zhu Q. Relation between reactivity and electronic structure for άL-, β- and γ-dicalcium silicate: a first-principles study. Cem Concr Res. 2014;57:28–32.

Iacobescu RI, Pontikes Y, Koumpouri D, Angelopoulos GN. Synthesis, characterization and properties of calcium ferroaluminate belite cements produced with electric arc furnace steel slag as raw material. Cem Concr Compos. 2013;44:1–8.

Cuesta A, Lossila ER, Aranda MAG, Sanz J, De La Torre AG. Reactive belite stabilization mechanisms by boron-bearing dopants. Cem Concr Res. 2012;42:598–606.

Dent Glasser LS, Funk H, Hilmer W, Taylor HFW. The identity of some dicalcium silicate hydrates. J Appl Chem. 1961;11:186–90.

Jernejcic J, Vene N, Zajc A. Thermal decomposition of α-dicalcium silicate hydrate. Thermochim Acta. 1977;20:237–47.

Gross S. The mineralogy of the hatrurim formation, Israel. Geol Surv Israel Bull. 1977;70:1–80.

Ishida H, Yamazaki S, Sasaki K, Okada Y, Mitsuda T. α-Dicalcium silicate hydrate: preparation decomposed phase and its hydration. J Am Ceram Soc. 1993;76(7):1707–12.

Miyazaki M, Yamazaki S, Sasaki K, Ishida H, Toraya H. Crystallographic data of a new phase of a dicalcium silicate. J Am Ceram Soc. 1998;81(5):1339–43.

Toraya H, Yamazaki S. Simulated annealing structure changes from α-dicalcium silicate hydrate to αL-dicalcium silicate via the new phase. Acta Crystallogr. 2002;58:613–21.

Garbev K, Gasharova B, Beuchle G, Kreisz S, Stemmermann P. First observation of α-Ca2[SiO3(OH)](OH)–Ca6[Si2O7][SiO4](OH)2 phase transformation upon thermal treatment in air. J Am Ceram Soc. 2008;91:263–71.

Siauciunas R, Mikaliunaite J, Urbonas L, Baltakys K. Tribochemical and thermal activation of α-C2S hydrate as precursor for cementitious binders // J Therm Anal Calorim. 2014;118:817–23.

Šiaučiūnas R, Gendvilas R, Mikaliūnaitė J, Urbonas L. Heat flow and strength properties of perspective hydraulic binder material. J Thermal Anal Calorim. 2015;121:57–65.

Acknowledgements

This research was funded by a Grant (No. S-LB-17-6) from the Research Council of Lithuania and performed in cooperation with the Belarusian State Technological University.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Stankeviciute, M., Siauciunas, R. & Miachai, A. Impact of α-C2SH calcination temperature on the mineral composition and heat flow of the products. J Therm Anal Calorim 134, 101–110 (2018). https://doi.org/10.1007/s10973-018-7548-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10973-018-7548-5